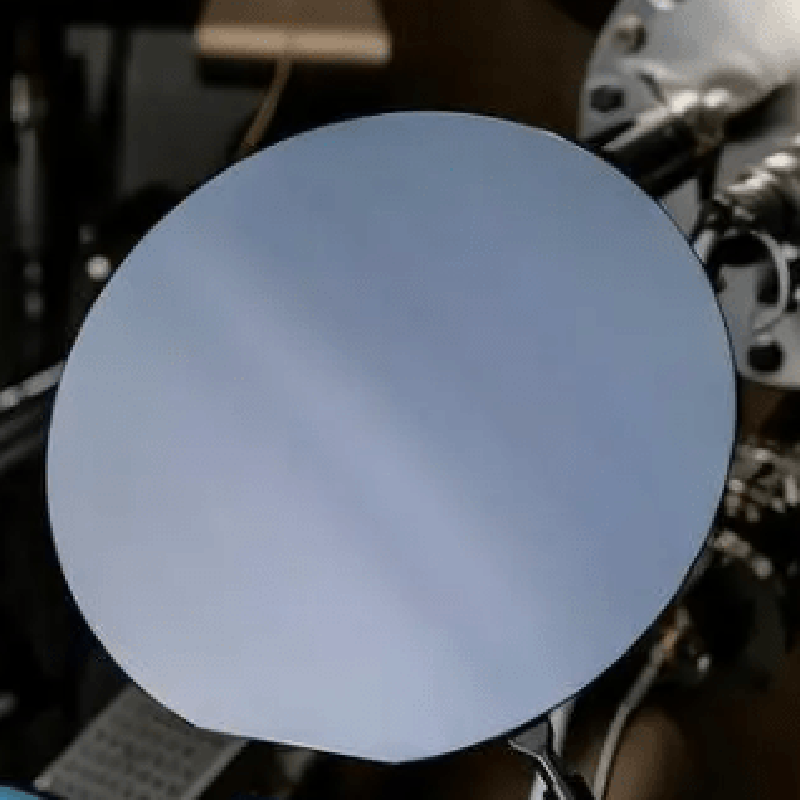

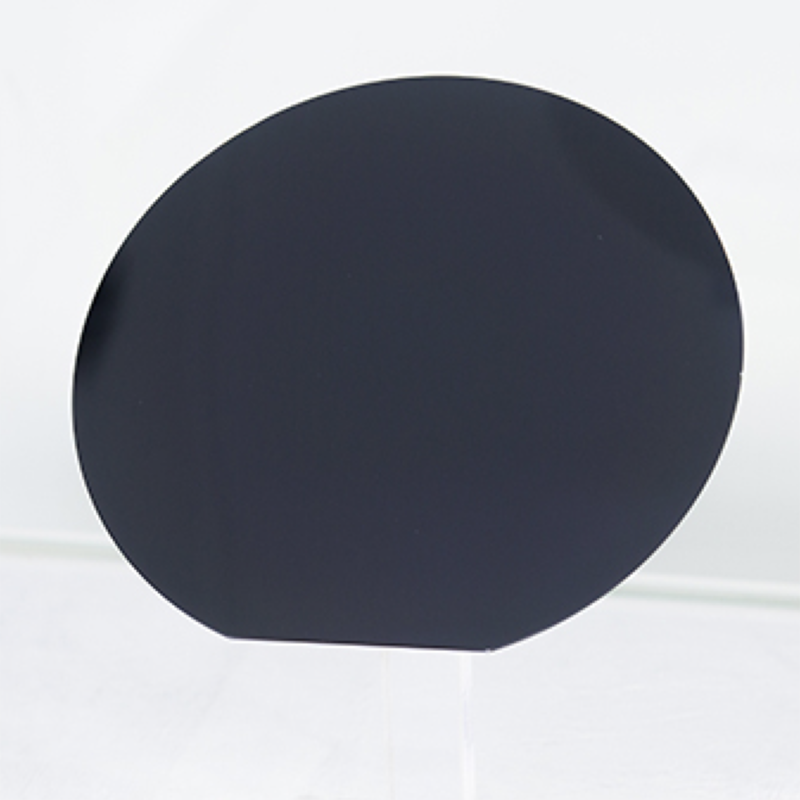

156mm 159mm 6 intshi yeSapphire Wafer yomthuthi weC-Plane DSP TTV

Inkcazo

| Into | I-6-intshi ye-C-plane(0001) iiWafers zeSapphire | |

| Izinto zeCrystal | I-99,999%, i-High Purity, i-Monocrystalline Al2O3 | |

| IBanga | Prime, Epi-Ready | |

| Ukuqhelaniswa nomphezulu | Inqwelomoya (0001) | |

| I-C-plane off-engile ukuya ku-M-axis 0.2 +/- 0.1 ° | ||

| Ububanzi | 100.0 mm +/- 0.1 mm | |

| Ukutyeba | 650 μm +/- 25 μm | |

| Ukuqhelaniswa neFlethi okuPhambili | I-C-plane (00-01) +/- 0.2 ° | |

| Icala Elinye Likhazimlisiwe | Umphezulu ongaphambili | I-Epi-ipolishiwe, i-Ra < 0.2 nm (nge-AFM) |

| (SSP) | Emva koMphezulu | Umhlaba omhle, iRa = 0.8 μm ukuya kwi-1.2 μm |

| Icala eliphindwe kabini lilungisiwe | Umphezulu ongaphambili | I-Epi-ipolishiwe, i-Ra < 0.2 nm (nge-AFM) |

| (DSP) | Emva koMphezulu | I-Epi-ipolishiwe, i-Ra < 0.2 nm (nge-AFM) |

| TTV | < 20 μm | |

| THOBEKA | < 20 μm | |

| WARP | < 20 μm | |

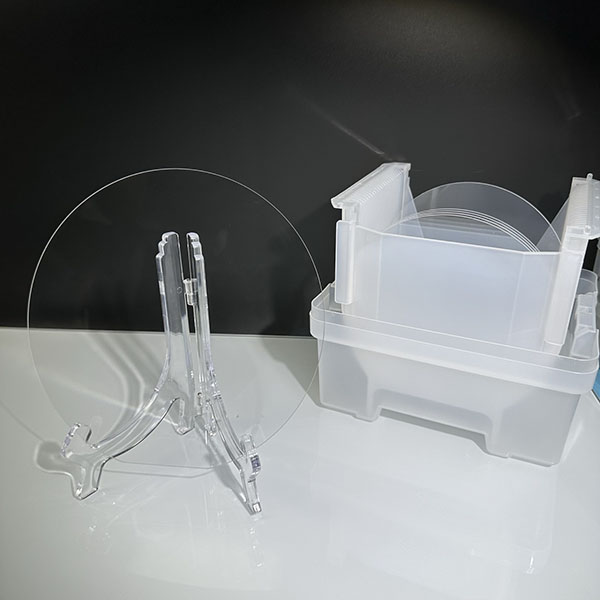

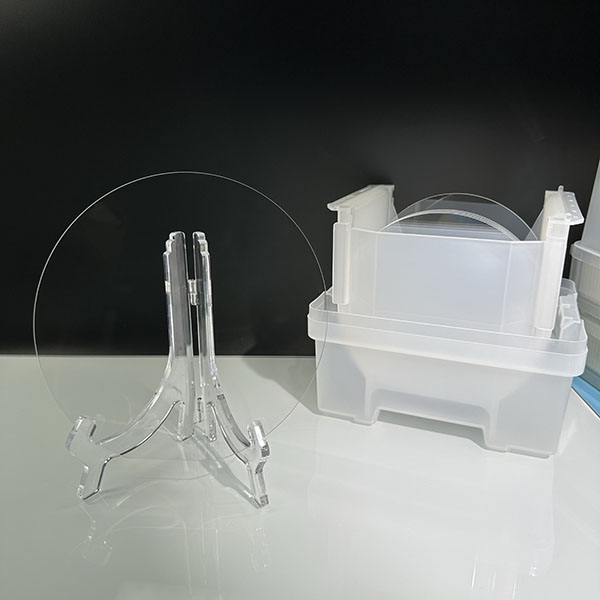

| Ukucoca / ukuPakisha | Ukucoca igumbi le-100 kunye nokupakishwa kwe-vacuum, | |

| Amaqhekeza angama-25 kwikhasethi enye okanye kwipakethe yesiqwenga esinye. | ||

Indlela yeKylopoulos (indlela ye-KY) okwangoku isetyenziswa ziinkampani ezininzi zaseTshayina ukuvelisa iikristale zesafire ukuze zisetyenziswe kwi-electronics and optics industry.

Kule nkqubo, i-high-purity aluminium oxide iyancibilika kwi-crucible kumaqondo okushisa angaphezu kwama-2100 degrees Celsius.Ngokuqhelekileyo i-crucible yenziwe nge-tungsten okanye i-molybdenum.Ikristale yembewu ejongwe ngokuchanekileyo intywiliselwa kwi-alumina etyhidiweyo.Ikristale yembewu itsalwa ngokuthe chu ukuya phezulu kwaye inokujikeleziswa ngaxeshanye.Ngokulawula ngokuchanekileyo i-gradient yeqondo lokushisa, izinga lokutsala kunye nesantya sokupholisa, i-crystal enkulu, enye-crystal, i-ingot ephantse i-cylindrical inokuveliswa kwi-melted.

Emva kokuba i-ingots enye yekristale yesafire ikhulile, yombiwa kwiintonga zecylindrical, ezithi ke zisikwe kubukhulu befestile obufunwayo kwaye ekugqibeleni bukhazimliswe ukuya kumphezulu ofunekayo.

Idayagram eneenkcukacha