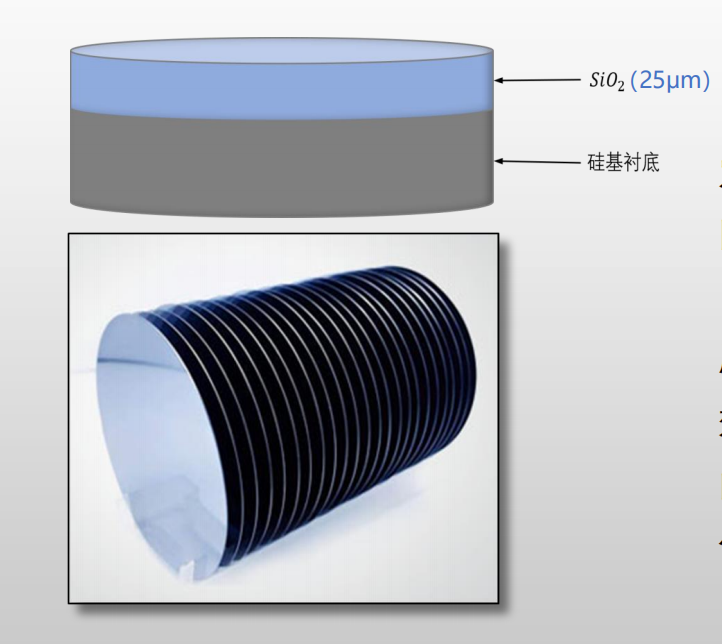

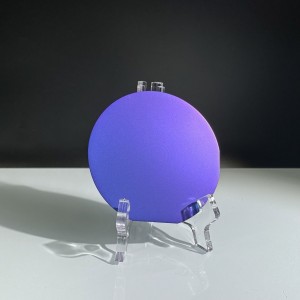

SiO2 Thin Film Thermal Oxide Silicon wafer 4inch 6inch 8inch 12inch

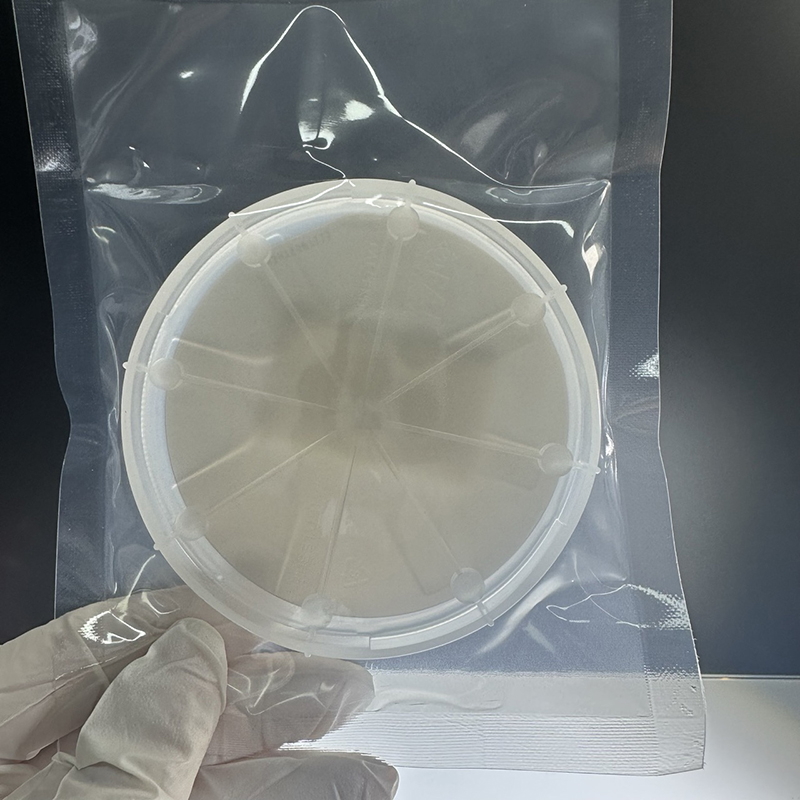

Ukwazisa ngebhokisi ye-wafer

Inkqubo ephambili yokuvelisa ama-wafers e-silicon e-oxid idla ngokubandakanya la manyathelo alandelayo: ukukhula kwe-silicon ye-monocrystalline, ukusika kwii-wafers, ukupholisha, ukucocwa kunye ne-oxidation.

Ukukhula kwe-silicon ye-Monocrystalline: Okokuqala, i-silicon ye-monocrystalline ikhuliswe kumaqondo okushisa aphezulu ngeendlela ezifana nendlela yeCzochralski okanye indlela ye-Float-zone.Le ndlela ivumela ukulungiswa kweekristale ze-silicon ezinobunyulu obuphezulu kunye nentembeko ye-lattice.

Ukudaya: Isilicon ekhuliswe yi-monocrystalline iqhele ukumila kwicylindrical kwaye kufuneka isikwe ibe ngamaqhekeza amancinci ukuze asetyenziswe njenge-wafer substrate.Ukusika ngokuqhelekileyo kwenziwa nge-diamond cutter.

Ukupholisha: Umphezulu wewafer esikiweyo unokungalingani kwaye ufuna ukupolishwa kweekhemikhali ukuze kufumaneke indawo egudileyo.

Ukucoca: Iwafer epholisiweyo iyacocwa ukususa ubumdaka kunye nothuli.

I-Oxidizing: Ekugqibeleni, ii-wafers ze-silicon zifakwa kwiziko lobushushu obuphezulu ukwenzela unyango lwe-oxidizing ukwenza umaleko okhuselayo we-silicon dioxide ukuphucula iimpawu zayo zombane kunye namandla omatshini, kunye nokusebenza njengomaleko okhuselayo kwiisekethe ezidibeneyo.

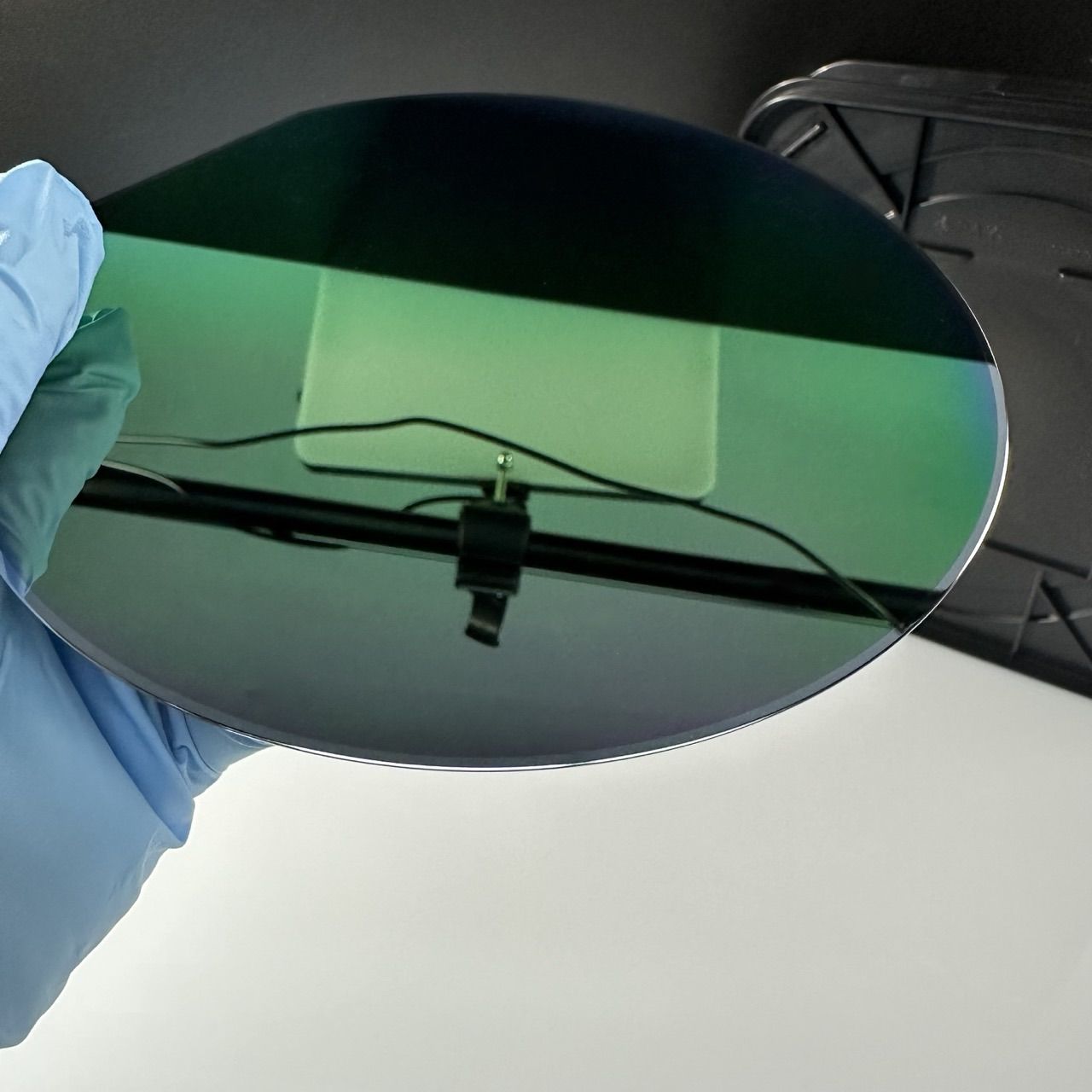

Olona setyenziso luphambili lweziphaluka ze-silicon ezidityanisiweyo ziquka ukwenziwa kweesekethe ezidityanisiweyo, ukwenziwa kweeseli zelanga, kunye nokuveliswa kwezinye izixhobo zombane.Iziqwenga ze-silicon oxide zisetyenziswa ngokubanzi kwintsimi yezixhobo ze-semiconductor ngenxa yeempawu zabo ezigqwesileyo zomatshini, ubukhulu kunye nokuzinza kweekhemikhali, ukukwazi ukusebenza kumaqondo okushisa aphezulu kunye noxinzelelo oluphezulu, kunye neendawo ezintle zokukhusela kunye ne-optical properties.

Iingenelo zayo ziquka ukwakheka kwekristale epheleleyo, ukubunjwa kweekhemikhali ezicocekileyo, imilinganiselo echanekileyo, iipropati ezilungileyo zemishini, njl. Ezi mpawu zenza ii-silicon oxide wafers ngokukodwa zifaneleke ukuveliswa kweesekethe ezidibeneyo ezisebenzayo kunye nezinye izixhobo ze-microelectronic.

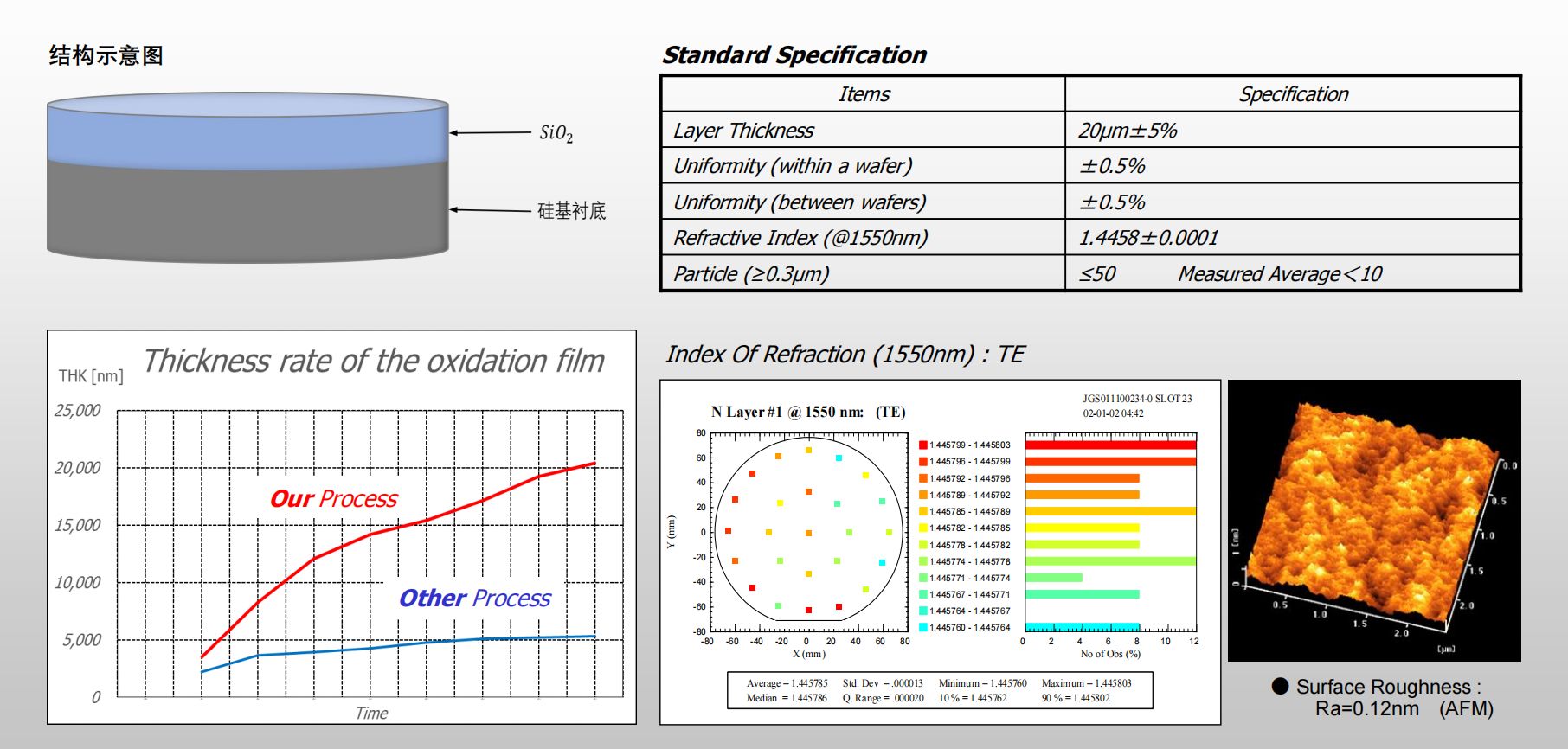

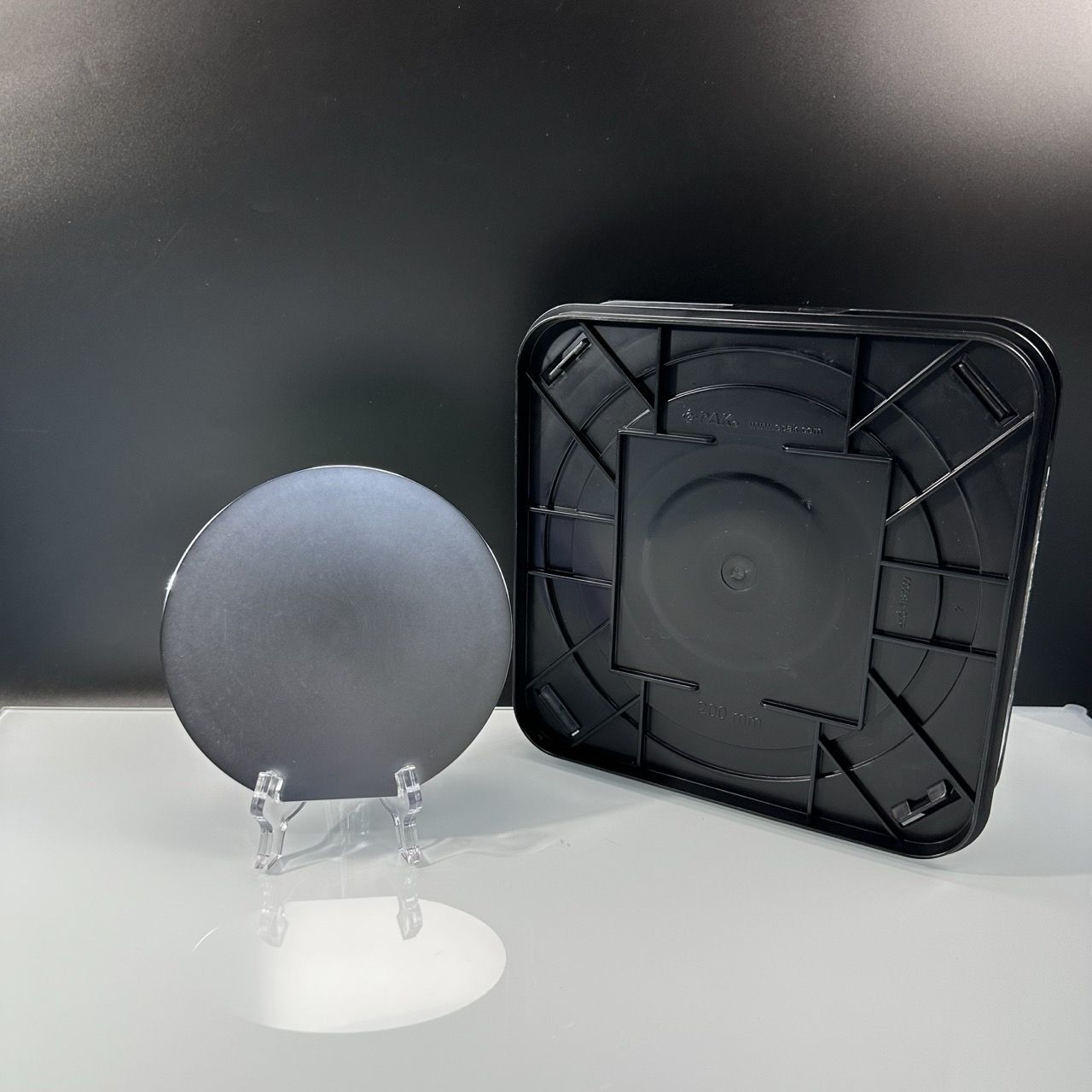

Idayagram eneenkcukacha