INkqubo yeLaser yeMicrojet echanekileyo yeZixhobo eziNqabileyo kunye neziBrittle

Ezona mpawu

1. Dual-Wavelength Nd:YAG Laser Source

Isebenzisa i-diode-pumped solid-state Nd: YAG laser, inkqubo ixhasa zombini uhlaza (532nm) kunye ne-infrared (1064nm) ubude bamaza. Esi sixhobo se-dual-band senza ukuhambelana okuphezulu kunye noluhlu olubanzi lweeprofayili zokufunxa izinto, ukuphucula isantya sokucubungula kunye nomgangatho.

2. UThutho lweLaser yeMicrojet entsha

Ngokudibanisa i-laser kunye ne-microjet yamanzi yoxinzelelo oluphezulu, le nkqubo isebenzisa imbonakalo yangaphakathi epheleleyo kumbane welaser ngokuchanekileyo ecaleni komsinga wamanzi. Le ndlela yonikezelo ikhethekileyo iqinisekisa ugqaliselo lwe-ultra-fine kunye nokusasazwa okuncinci kwaye ihambisa ububanzi belayini ngokucokisekileyo njenge-20μm, inika umgangatho wokusikwa ongenakulinganiswa.

3. Ulawulo lwe-Thermal kwi-Micro Scale

Imodyuli echanekileyo echanekileyo yokupholisa amanzi ilawula ukushisa kwindawo yokucubungula, ukugcina indawo echaphazelekayo ukushisa (HAZ) ngaphakathi kwe-5μm. Olu phawu lubaluleke ngakumbi xa usebenza ngezinto ezingeva lubushushu kunye nezaphukileyo ezifana ne-SiC okanye i-GaN.

4. Ulungelelwaniso lwaMandla eModyuli

Iqonga lixhasa iinketho ezintathu zamandla e-laser-50W, 100W, kunye ne-200W-evumela abathengi ukuba bakhethe ukucwangciswa okuhambelana neemfuno zabo zokuphuma kunye nesisombululo.

5. I-Platform yokuLawula iMotion echanekileyo

Inkqubo ibandakanya inqanaba eliphezulu lokuchaneka kunye ne-± 5μm yokubeka, equkethe i-5-axis motion kunye ne-optional linear or direct-drive motors. Oku kuqinisekisa ukuphindaphindwa okuphezulu kunye nokuguquguquka, nakwijometri ezintsonkothileyo okanye ukusetyenzwa kwebhetshi.

IiNdawo zokuSebenza

ISilicon Carbide Wafer Processing:

Ilungele ukucheba komphetho, ukusika, kunye nokudaywa kwee-wafers ze-SiC kumbane wombane.

IGallium Nitride (GaN) Substrate Machining:

Ixhasa ukuchaneka okuphezulu kokubhala kunye nokusika, okulungiselelwe iRF kunye nezicelo ze-LED.

Ulwakhiwo lweSemiconductor yeBandgap ebanzi:

Iyahambelana nedayimane, i-gallium oxide, kunye nezinye izinto ezivelayo ze-high-frequency, high-voltage applications.

I-Aerospace Composite Cutting:

Ukusikwa ngokuchanekileyo kwe-ceramic matrix composite kunye ne-aerospace-grade substrates ekumgangatho ophezulu.

I-LTCC kunye neMathiriyeli ye-Photovoltaic:

Isetyenziselwa i-micro ngokusebenzisa ukomba, ukugoba, kunye nokubhala kwi-PCB ye-frequency ephezulu kunye nokuveliswa kweeseli zelanga.

I-scintillator kunye ne-Optical Crystal Shaping:

Yenza ukusika okuphantsi kwe-yttrium-aluminiyam garnet, LSO, BGO, kunye nezinye izinto ezichanekileyo.

Inkcazo

| Inkcazo | Ixabiso |

| Uhlobo lweLaser | DPSS Nd:YAG |

| I-Wavelengths exhaswayo | 532nm / 1064nm |

| Iinketho zamandla | 50W / 100W / 200W |

| Ukubeka Ukuchaneka | ±5μm |

| Ubuncinci bobubanzi bomgca | ≤20μm |

| Indawo echatshazelwe bubushushu | ≤5μm |

| Inkqubo eshukumayo | I-Linear / i-Direct-drive motor |

| Ukuxinwa kwamandla aphezulu | Ukuya kuthi ga kwi-10⁷ W/cm² |

Ukuqukumbela

Le nkqubo ye-laser ye-microjet ichaza kwakhona imida ye-laser machining kwizinto ezinzima, ezinqabileyo, kunye nezixhobo ezibuthathaka. Ngokudityaniswa kwayo okukhethekileyo kwe-laser-amanzi, ukuhambelana kwe-wavelength kabini, kunye nenkqubo yentshukumo eguquguqukayo, ibonelela ngesisombululo esilungiselelwe abaphandi, abavelisi, kunye nabahlanganisi benkqubo abasebenza ngezinto zokusika. Nokuba isetyenziswa kwiilaphu ze-semiconductor, iilebhu ze-aerospace, okanye imveliso yephaneli yelanga, eli qonga lizisa ukuthembeka, ukuphindaphinda, kunye nokuchaneka okuxhobisa ukusetyenzwa kwezinto kwisizukulwana esilandelayo.

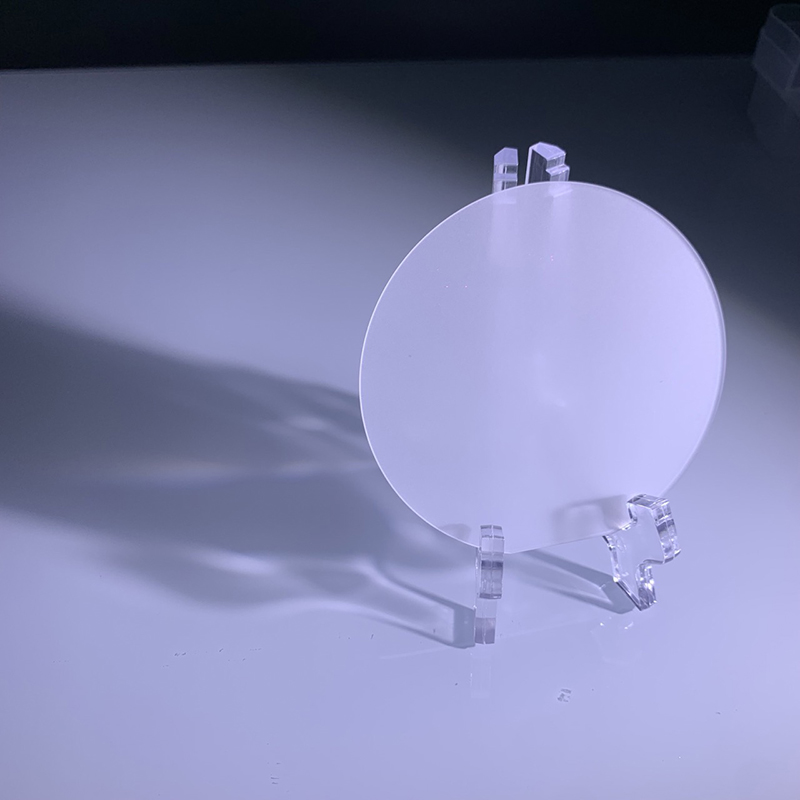

Idayagram eneenkcukacha