I-12inch ngokuPheleleyo ngokuSebenzayo ngokuNgcaciswayo kweSaw yeSixhobo seWafer eZinikezelweyo zokusika iSi/SiC & HBM (Al)

Imilinganiselo yobugcisa

| Ipharamitha | Inkcazo |

| Ubungakanani bokusebenza | Φ8", Φ12" |

| I-spindle | I-Dual-axis 1.2/1.8/2.4/3.0, Max 60000 rpm |

| Ubungakanani beBlade | 2" ~ 3" |

| Umgca we-Y1 / Y2

| Inyathelo elinye lokunyuka: 0.0001 mm |

| Ukumisa ukuchaneka: <0.002 mm | |

| Uluhlu lokusika: 310 mm | |

| X Axis | Uluhlu lwesantya sokutya: 0.1–600 mm/s |

| Umgca we-Z1 / Z2

| Inyathelo elinye lokunyuka: 0.0001 mm |

| Ukumisa ukuchaneka: ≤ 0.001 mm | |

| θ I-axis | Ukuma kokuchaneka: ±15" |

| Isitishi sokucoca

| Isantya sokujikeleza: 100-3000 rpm |

| Indlela yokucoca: Sula ngokuzenzekela kwaye usomise | |

| I-Voltage yokusebenza | I-3-isigaba 380V 50Hz |

| Imilinganiselo (W×D×H) | 1550×1255×1880 mm |

| Ubunzima | 2100 kg |

Umgaqo wokuSebenza

Isixhobo sifezekisa ukusika okuphezulu ngokuchaneka kobu buchwepheshe bulandelayo:

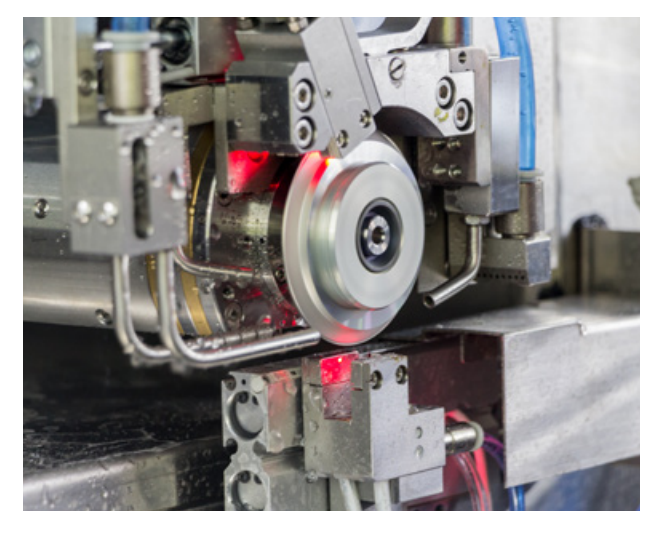

I-1.I-High-Rigidity Spindle System: Isantya sokujikeleza ukuya kwi-60,000 RPM, exhotywe ngamacangci edayimane okanye iintloko zokusika i-laser ukulungelelanisa kwiipropati zezinto ezahlukeneyo.

I-2.Ulawulo lwe-Multi-Axis Motion Control: I-X / Y / Z-i-axis yokuchaneka kokuchaneka kwe-± 1μm, idibaniswe nezikali ezichanekileyo zokugaya ukuqinisekisa ukuphambuka kweendlela zokusika.

3. Ulungelelwaniso olubonakalayo oluBukrelekrele: I-CCD enokulungiswa okuphezulu (iimegapikseli ezi-5) ibona ngokuzenzekelayo izitrato ezisikiweyo kwaye ihlawule ukujija okanye ukungahambi kakuhle.

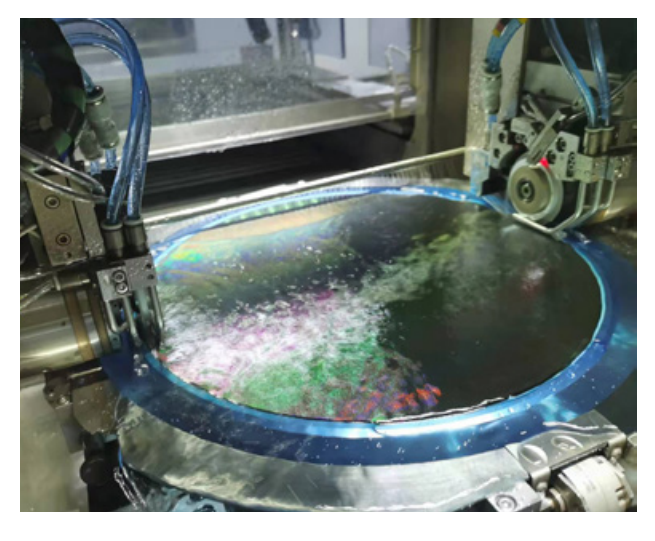

I-4.Ukupholisa kunye nokususwa kothuli: Inkqubo edibeneyo yokupholisa amanzi acocekileyo kunye nokususwa kwe-vacuum suction uthuli ukunciphisa impembelelo ye-thermal kunye nokungcoliswa kwamasuntswana.

Iindlela zokusika

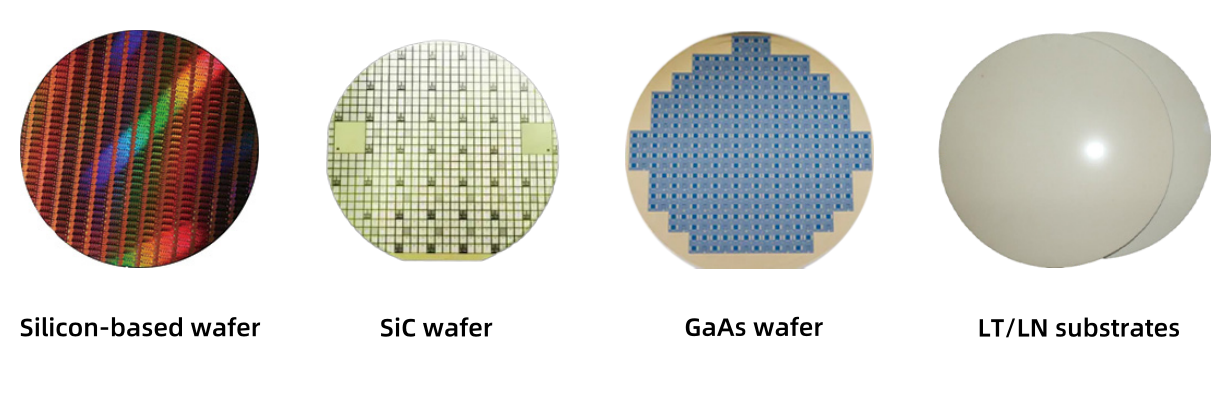

I-1.Blade Dicing: Ifanelekile kwizinto zemveli ze-semiconductor ezifana ne-Si kunye ne-GaAs, kunye nobubanzi be-kerf ye-50-100μm.

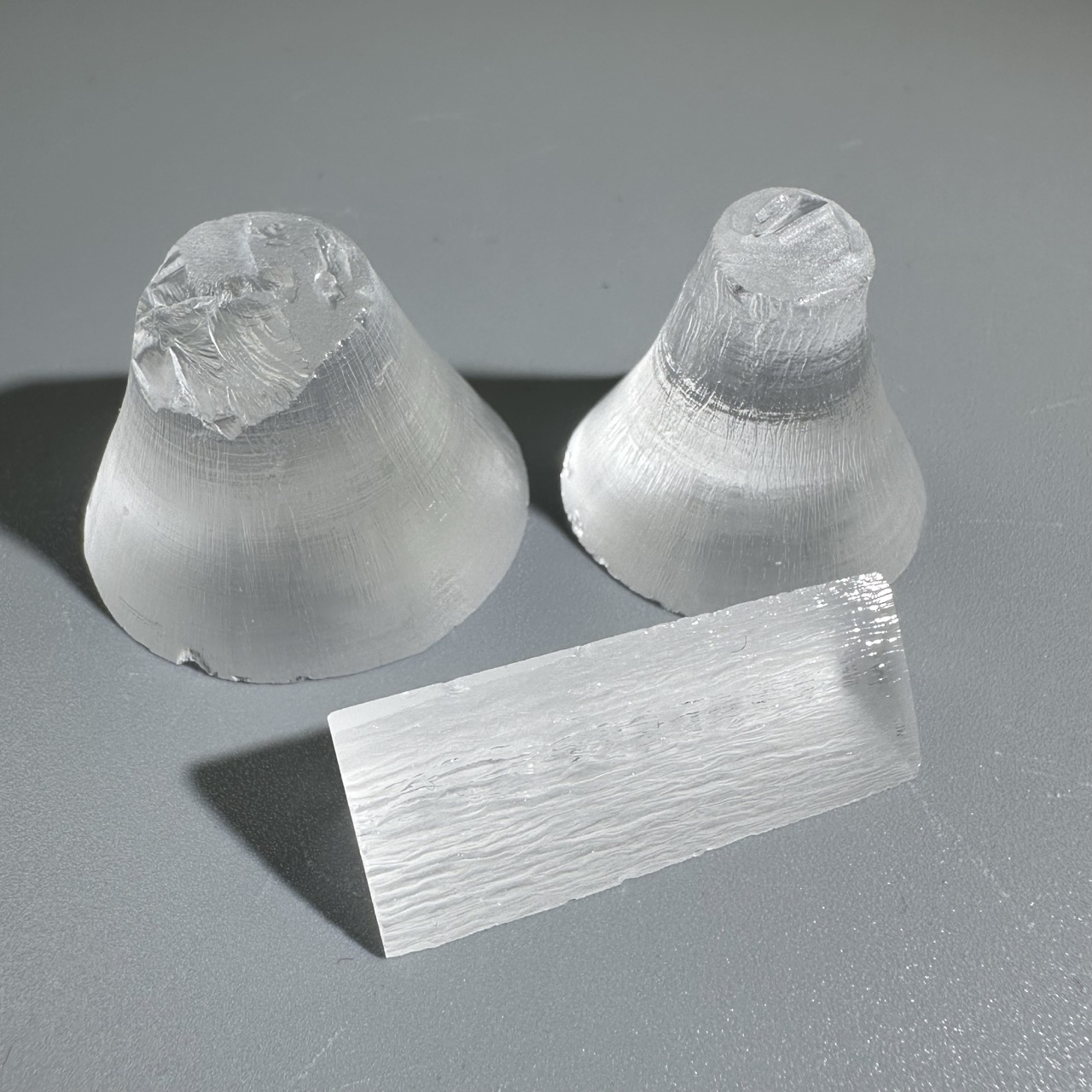

2.I-Stealth Laser Dicing: Isetyenziselwa ii-wafers ezi-ultra-thin (<100μm) okanye izinto ezibuthathaka (umzekelo, i-LT / LN), eyenza ukuhlukana ngaphandle koxinzelelo.

Usetyenziso oluqhelekileyo

| Izinto Ezihambelanayo | Indawo yosetyenziso | IiMfuno zokuSebenza |

| Isilicon (Si) | Ii-ICs, ii-MEMS sensors | Ukusika okuphezulu, ukusika <10μm |

| I-Silicon Carbide (SiC) | Izixhobo zamandla (MOSFET/diodes) | Ukusika umonakalo ophantsi, ukulungiswa kokulawulwa kwe-thermal |

| I-Gallium Arsenide (GaAs) | Izixhobo zeRF, iitshiphusi ze-optoelectronic | Uthintelo lwe-Micro-crack, ulawulo lokucoceka |

| LT/LN Substrates | Izihluzi ze-SAW, iimodyuli zamehlo | Ukusika okungenaxinzelelo, ukugcina iimpawu ze-piezoelectric |

| IiSubstrates zeCeramic | Iimodyuli zamandla, ukupakishwa kwe-LED | Ukulungiswa kwezinto ezinobunzima obuphezulu, ukunyanzeliswa komphetho |

| Izakhelo ze-QFN/DFN | Ukupakishwa okuphezulu | Ukusikwa kwe-Multi-chip ngaxeshanye, ukwenziwa kakuhle |

| WLCSP Wafers | Ukupakishwa kwenqanaba le-wafer | Ukudaywa okungenakonakala kweewafers ezibhityileyo kakhulu (50μm) |

Iingenelo

1. Isantya esiphezulu sokuskena isakhelo sekhasethi yekhasethi kunye neealam zokuthintela ukungqubana, indawo yokudluliselwa ngokukhawuleza, kunye nokukwazi ukulungisa iimpazamo.

2. Imowudi yokusika ephuculwe kabini, iphucula ukusebenza kakuhle malunga ne-80% xa kuthelekiswa neenkqubo zokusonta enye.

3. Izikrufu zebhola ezifakwe ngokuchanekileyo, izikhokelo zomgca, kunye ne-Y-axis grating scale control-loop control-loop control, ukuqinisekisa ukuzinza kwexesha elide lokuchaneka okuphezulu.

4. Ukulayishwa / ukukhulula ngokuzenzekelayo, ukubeka indawo yokudlulisa, ukusika ukulungelelanisa, kunye nokuhlolwa kwe-kerf, ukunciphisa kakhulu umthwalo womsebenzi (OP) womsebenzi.

I-5.I-Gantry-style yokuxhoma i-spindle, kunye ne-spacing encinci ye-dual-blade ye-24mm, eyenza ukulungelelaniswa okubanzi kwiinkqubo zokusika ezimbini.

Iimbonakalo

1.Umlinganiselo wobude obuchanekileyo obuchanekileyo.

2.I-Multi-wafer-dual-blade ukusika kwitreyi enye.

I-3.Ukulinganisa okuzenzekelayo, ukuhlolwa kwe-kerf, kunye neenkqubo zokubona ukuphulwa kwe-blade.

I-4.Ixhasa iinkqubo ezahlukeneyo kunye ne-algorithms yokulungelelanisa okuzenzekelayo.

I-5.I-Fault self-correction functionality kunye nexesha langempela lokubeka iliso kwiindawo ezininzi.

6.Ikhono lokuqala lokuhlola i-post-initial dicing.

I-7.Iimodyuli ezizenzekelayo zefektri ezizenzekelayo kunye neminye imisebenzi ekhethiweyo.

Iinkonzo zeZixhobo

Sinikezela ngenkxaso ebanzi ukusuka ekukhethweni kwezixhobo ukuya kulondolozo lwexesha elide:

(1) Uphuhliso olulungiselelweyo

· Cebisa izisombululo zokusika iiblade/laser ezisekelwe kwiimpawu zemathiriyeli (umzekelo, ubulukhuni beSiC, ubuqhophololo beGaAs).

· Nikeza ngovavanyo lwesampulu yasimahla ukuqinisekisa umgangatho wokusika (kubandakanya ukutshiphuza, ububanzi be-kerf, uburhabaxa bomphezulu, njl. njl.).

(2) Uqeqesho lobuGcisa

· Uqeqesho olusisiseko: Ukusebenza kwezixhobo, ukulungiswa kweparameter, ukugcinwa kwesiqhelo.

· Izifundo ezikwinqanaba eliphezulu: Ukulungiswa kwenkqubo yezinto ezintsonkothileyo (umzekelo, ukusika okungenaxinzelelo lwe-LT substrates).

(3) Emva koThengiso lweNkxaso

· 24/7 Impendulo: Uxilongo olukude okanye uncedo kwisiza.

· Ubonelelo lwaMalungu aSpare: ama-spindles agcweleyo, iibhleyidi, kunye namalungu optical ukuze atshintshwe ngokukhawuleza.

· ULondolozo loThintelo: Ulungelelwaniso lwarhoqo ukugcina ukuchaneka nokwandisa ubomi benkonzo.

Izinto Eziluncedo Zethu

✔ Amava eShishini: Ukukhonza i-300+ ye-semiconductor yehlabathi jikelele kunye nabavelisi bezinto zombane.

✔ Itekhnoloji ye-Cutting-Edge: Izikhokelo ezichanekileyo ezichanekileyo kunye neenkqubo ze-servo ziqinisekisa uzinzo oluhamba phambili kwishishini.

✔ Uthungelwano lweNkonzo yeHlabathi: Ukugubungela e-Asia, eYurophu, naseMntla Melika ngenkxaso yendawo.

Ukuvavanya okanye imibuzo, qhagamshelana nathi!