4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer for MOS okanye SBD

I-SiC Substrate ye-SiC Epi-wafer emfutshane

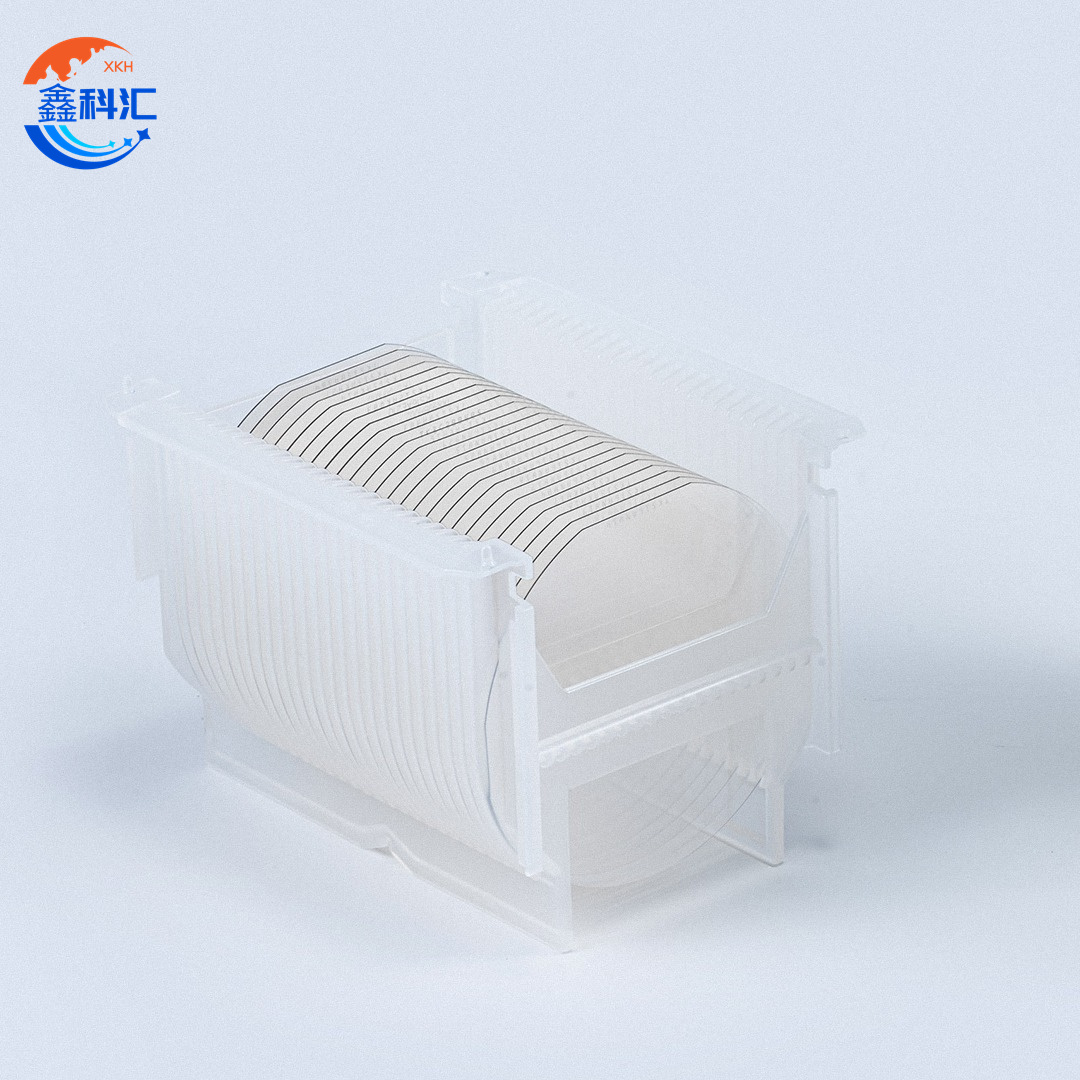

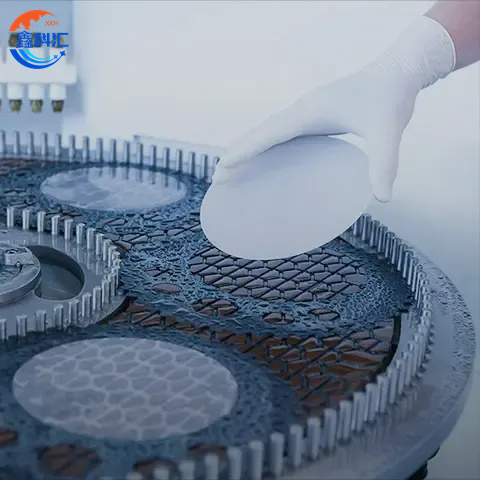

Sinikezela ngeepotfoliyo ezigcweleyo ezikumgangatho ophezulu we-SiC substrates kunye ne-sic wafers kwiipolytypes ezininzi kunye neeprofayili ze-doping-kubandakanya i-4H-N (n-type conductive), 4H-P (p-type conductive), 4H-HPSI (high-purity semi-insulating), kunye ne-6H-P (p-type conductive)-i-4″ yonke, i-6″ yonke, i-8 ukuya kuthi ga kwi-12″. Ngaphaya kwee-substrates ezingenanto, iinkonzo zethu zokukhulisa ixabiso elongeziweyo lwe-epi wafer zizisa iiwafers ze-epitaxial (epi) ezinobungqingqwa obungqongqo (1–20 µm), ugxininiso lwe-doping, kunye nokuxinana kweziphene.

Iwafer ye-sic nganye kunye ne-epi wafer ihlolwa ngokungqongqo emgceni (ubuninzi bemicropipe <0.1 cm⁻², uburhabaxa bomphezulu i-Ra <0.2 nm) kunye neempawu zombane ezigcweleyo (i-CV, imephu yokumelana) ukuqinisekisa ukufana okukhethekileyo kwekristale kunye nokusebenza. Nokuba isetyenziselwa iimodyuli zombane we-elektroniki, ii-amplifiers zeRF eziphezulu, okanye izixhobo ze-optoelectronic (ii-LED, ii-photodetectors), i-substrate yethu ye-SiC kunye nemigca yemveliso ye-epi wafer ihambisa ukuthembeka, ukuzinza kwe-thermal, kunye namandla okuqhekeka afunwa zezona zicelo zinzima namhlanje.

Iipropati zeSiC Substrate 4H-N zodidi kunye nokusetyenziswa

-

4H-N SiC substrate Polytype (Hexagonal) Ulwakhiwo

I-bandgap ebanzi ye-~ 3.26 eV iqinisekisa ukusebenza kombane okuzinzile kunye nokuqina kwe-thermal phantsi kobushushu obuphezulu kunye neemeko eziphezulu zombane.

-

Inxalenye yeSiCN-Uhlobo lweDoping

Idoping yenitrogen elawulwa ngokuchanekileyo ivelisa ugxininiso lomthwali ukusuka kwi-1×10¹⁶ ukuya kwi-1×10¹⁹ cm⁻³ kunye nokushukuma kwe-electron yobushushu begumbi ukuya kuthi ga ku- ~900 cm²/V·s, kuncitshiswe ilahleko yokuqhuba.

-

Inxalenye yeSiCUkuxhathisa okubanzi kunye nokufana

Uluhlu olufumanekayo lokuxhathisa lwe-0.01–10 Ω·cm kunye nobukhulu bewafer obuyi-350–650 µm kunye ne-±5% yokunyamezela kuzo zombini i-doping kunye nobukhulu—ilungele ukwenziwa kwesixhobo sombane ophezulu.

-

Inxalenye yeSiCUbuninzi beSiphene esiPhezulu

Uxinaniso lweMibhobho ye-Micropipe <0.1 cm⁻² kunye noxinano lwe-basal-plane dislocation < 500 cm⁻², ukuhambisa > 99% imveliso yesixhobo kunye nekristale ephezulu imfezeko.

- Inxalenye yeSiCI-Thermal Conductivity ekhethekileyo

I-Thermal conductivity ukuya kuthi ga kwi- ~ 370 W/m·K iququzelela ukususwa kobushushu okusebenzayo, ukonyusa ukuthembeka kwesixhobo kunye nokuxinana kwamandla.

-

Inxalenye yeSiCIzicelo ekujoliswe kuzo

Ii-SiC MOSFETs, ii-Schottky diode, iimodyuli zamandla kunye nezixhobo zeRF zokuqhuba isithuthi sombane, ii-solar inverters, ii-industrial drives, iinkqubo zokutsala, kunye nezinye ezibango iimarike ze-electronics zamandla.

I-6inch 4H-N yohlobo lweSiC wafer's specication | ||

| Ipropati | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| IBanga | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| Ububanzi | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Poly-uhlobo | 4H | 4H |

| Ukutyeba | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Iwafer Orientation | I-off axis: 4.0 ° ukuya <1120> ± 0.5 ° | I-off axis: 4.0 ° ukuya <1120> ± 0.5 ° |

| Ukuxinana kweMibhobho | ≤ 0.2 cm² | ≤ 15cm² |

| Ukuxhathisa | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Ukuqhelaniswa neFlethi okuPhambili | [10-10] ± 50 ° | [10-10] ± 50 ° |

| Ubude beFlethi obuPhambili | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Ukungabandakanywa kuMda | 3 mm | 3 mm |

| LTV / TIV / Isaphetha / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Uburhabaxa | I-Polish Ra ≤ 1 nm | I-Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| I-Edge Cracks ngokuKhanya okuPhakamileyo | Ubude obongezelekayo ≤ 20 mm ubude obunye ≤ 2 mm | Ubude obongezelekayo ≤ 20 mm ubude obunye ≤ 2 mm |

| Iipleyiti zeHex ngokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 0.1% |

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 3% |

| Ukubandakanywa kweCarbon ebonakalayo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 5% |

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Ubude obongezelekayo ≤ I-1 wafer idayamitha | |

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥ 0.2 mm ububanzi nobunzulu | I-7 ivunyelwe, ≤ 1 mm nganye |

| Ukushenxiswa kweScrew somsonto | < 500 cm³ | < 500 cm³ |

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | ||

| Ukupakishwa | Multi-wafer Cassette Okanye Single Wafer Container | Multi-wafer Cassette Okanye Single Wafer Container |

8inch 4H-N uhlobo SiC wafer's iinkcukacha | ||

| Ipropati | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| IBanga | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| Ububanzi | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Poly-uhlobo | 4H | 4H |

| Ukutyeba | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Iwafer Orientation | 4.0 ° ukuya <110> ± 0.5 ° | 4.0 ° ukuya <110> ± 0.5 ° |

| Ukuxinana kweMibhobho | ≤ 0.2 cm² | ≤ 5cm² |

| Ukuxhathisa | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Uqhelaniso oluNoble | ||

| Ukungabandakanywa kuMda | 3 mm | 3 mm |

| LTV / TIV / Isaphetha / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Uburhabaxa | I-Polish Ra ≤ 1 nm | I-Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| I-Edge Cracks ngokuKhanya okuPhakamileyo | Ubude obongezelekayo ≤ 20 mm ubude obunye ≤ 2 mm | Ubude obongezelekayo ≤ 20 mm ubude obunye ≤ 2 mm |

| Iipleyiti zeHex ngokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 0.1% |

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 3% |

| Ukubandakanywa kweCarbon ebonakalayo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 5% |

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Ubude obongezelekayo ≤ I-1 wafer idayamitha | |

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥ 0.2 mm ububanzi nobunzulu | I-7 ivunyelwe, ≤ 1 mm nganye |

| Ukushenxiswa kweScrew somsonto | < 500 cm³ | < 500 cm³ |

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | ||

| Ukupakishwa | Multi-wafer Cassette Okanye Single Wafer Container | Multi-wafer Cassette Okanye Single Wafer Container |

I-4H-SiC yinto ephezulu yokusebenza esetyenziselwa umbane wamandla, izixhobo zeRF, kunye nezicelo zobushushu obuphezulu. I-"4H" ibhekisela kwisakhiwo sekristale, esinehexagonal, kwaye "N" ibonisa uhlobo lwe-doping olusetyenziselwa ukulungelelanisa ukusebenza kwezinto.

II-4H-SiCuhlobo luqhele ukusetyenziselwa:

Umbane woMbane:Isetyenziswa kwizixhobo ezinje ngeediode, ii-MOSFETs, kunye nee-IGBTs kumatshini wombane wesithuthi sombane, oomatshini bemizi-mveliso, kunye neenkqubo zamandla avuselelekayo.

Itekhnoloji ye-5G:Ngemfuno ye-5G ye-high-frequency kunye ne-high-efficiency components, ukukwazi kwe-SiC ukuphatha amandla ombane aphezulu kunye nokusebenza kumaqondo obushushu aphezulu kwenza ukuba ilungele i-amplifiers yamandla esiseko kunye nezixhobo ze-RF.

Iinkqubo zamandla elanga:Iimpawu zokuphatha amandla ezigqwesileyo zeSiC zifanelekile kwi-photovoltaic (amandla elanga) inverters kunye nabaguquli.

Izithuthi zoMbane (EVs):I-SiC isetyenziswa ngokubanzi kwii-EV powertrains ukwenzela uguqulo lwamandla olusebenza ngakumbi, ukuveliswa kobushushu obuphantsi, kunye nokuxinana kwamandla aphezulu.

Iipropati zeSiC Substrate 4H Semi-Insulating kunye nokusetyenziswa kwayo

Iinkcazelo ngeempawu:

-

Iindlela zokulawula uxinaniso ezingenamibhobho: Uqinisekisa ukungabikho kwe-micropipes, ukuphucula umgangatho we-substrate.

-

Iindlela zokulawula i-Monocrystalline: Iqinisekisa ubume bekristale enye yeepropathi zezinto eziphuculweyo.

-

Iindlela zokulawula ukubandakanywa: Ukunciphisa ubukho bokungcola okanye ukufakwa, ukuqinisekisa i-substrate ecocekileyo.

-

Ubuchule bokulawula ukuxhathisa: Ivumela ulawulo oluchanekileyo lokumelana nombane, okubalulekileyo ekusebenzeni kwesixhobo.

-

Ukulawulwa kokungcola kunye neendlela zokulawula: Ukulawula kunye nokunciphisa ukuqaliswa kokungcola ukugcina ingqibelelo ye-substrate.

-

Ubuchule bokulawula ububanzi benyathelo le-Substrate: Ibonelela ngolawulo oluchanekileyo kububanzi benyathelo, iqinisekisa ukuhambelana kwi-substrate

I-6Intshi ye-4H-semi SiC substrate inkcazo | ||

| Ipropati | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| Ububanzi (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Poly-uhlobo | 4H | 4H |

| Ukutyeba (um) | 500 ± 15 | 500 ± 25 |

| Iwafer Orientation | Kwi-axis: ±0.0001 ° | Kwi-axis: ± 0.05 ° |

| Ukuxinana kweMibhobho | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Ukuxhathisa (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Ukuqhelaniswa neFlethi okuPhambili | (0-10) ° ± 5.0 ° | (10-10) ° ± 5.0 ° |

| Ubude beFlethi obuPhambili | Inotshi | Inotshi |

| Ukukhutshwa komda (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Isitya / Warp | ≤ 3µm | ≤ 3µm |

| Uburhabaxa | IsiPolish Ra ≤ 1.5 µm | IsiPolish Ra ≤ 1.5 µm |

| I-Edge Chips NgokuKhanya okuPhakamileyo | ≤ 20µm | ≤ 60µm |

| Iipleyiti zokutshisa ngokuKhanya okuPhakamileyo | Eyongezelekayo ≤ 0.05% | Yongezeleka ≤ 3% |

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Ukubandakanywa kweCarbon ebonakalayo ≤ 0.05% | Yongezeleka ≤ 3% |

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | ≤ 0.05% | Yongezeleka ≤ 4% |

| I-Edge Chips NgokuKhanya okuPhakamileyo (Ubukhulu) | Ayivumelekanga > 02 mm Ububanzi nobunzulu | Ayivumelekanga > 02 mm Ububanzi nobunzulu |

| I-Aiding Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Ukupakishwa | Iikhasethi ezininzi zewafer okanye iSingle Wafer Container | Iikhasethi ezininzi zewafer okanye iSingle Wafer Container |

I-4-Intshi ye-4H-Semi Insulating SiC Substrate Specification

| Ipharamitha | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

|---|---|---|

| Iipropati Zomzimba | ||

| Ububanzi | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Poly-uhlobo | 4H | 4H |

| Ukutyeba | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Iwafer Orientation | Kwi-axis: <600h> 0.5 ° | Kwi-axis: <000h> 0.5 ° |

| Iipropati zoMbane | ||

| Uxinaniso lweMibhobho (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Ukuxhathisa | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Ukunyamezela kweJometri | ||

| Ukuqhelaniswa neFlethi okuPhambili | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Ubude beFlethi obuPhambili | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Ubude beFlethi yesibini | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Ukuqhelaniswa neFlethi yesibini | I-90 ° CW ukusuka kwiflethi yePrime ± 5.0 ° (Si ubuso phezulu) | I-90 ° CW ukusuka kwiflethi yePrime ± 5.0 ° (Si ubuso phezulu) |

| Ukungabandakanywa kuMda | 3 mm | 3 mm |

| LTV / TTV / Isaphetha / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Umgangatho womphezulu | ||

| Uburhabaxa boMphezulu (Polish Ra) | ≤1 nm | ≤1 nm |

| Uburhabaxa boMphezulu (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| IiNceba ze-Edge (UkuKhanya okuPhezulu) | Ayivumelekanga | Ubude obuqokelelweyo ≥10 mm, ukuqhekeka okukodwa ≤2 mm |

| Iziphene zepleyiti eneHexagonal | ≤0.05% indawo eyongezelekayo | ≤0.1% indawo eyongezelekayo |

| IiNdawo zokuBandakanywa kwePolytype | Ayivumelekanga | ≤1% indawo eyongezelekayo |

| Ukubandakanywa kweCarbon ebonakalayo | ≤0.05% indawo eyongezelekayo | ≤1% indawo eyongezelekayo |

| Imikrwelo yoMphezulu weSilicon | Ayivumelekanga | ≤1 i-wafer idayamitha yobude obuqokelelweyo |

| IiChips zoMda | Akukho kuvunyelweyo (≥0.2 mm ububanzi/ubunzulu) | ≤5 iitshiphusi (nganye ≤1 mm) |

| Ungcoliseko lweSilicon Surface | Ayichazwanga ngqo | Ayichazwanga ngqo |

| Ukupakishwa | ||

| Ukupakishwa | Iikhasethi ezininzi zewafer okanye isikhongozeli se-wafer esinye | Multi-wafer cassette okanye |

Isicelo:

II-SiC 4H I-Semi-Insulating substrateszisetyenziswa ikakhulu kumandla aphezulu kunye nezixhobo ze-elektroniki ezisebenza rhoqo, ngakumbi kwiIntsimi yeRF. Ezi substrates zibalulekile kwizicelo ezahlukeneyo kuqukaIinkqubo zonxibelelwano nge-microwave, Irada yoluhlu olunezigaba, kwayeizixhobo zombane ezingenazingcingo. Ukuhanjiswa kwabo okuphezulu kwe-thermal kunye neempawu ezibalaseleyo zombane zibenza balungele izicelo eziyimfuneko kumbane we-elektroniki kunye neenkqubo zonxibelelwano.

SiC epi wafer 4H-N uhlobo lweempawu kunye nesicelo

I-SiC 4H-N Uhlobo lwe-Epi Wafer Properties kunye nezicelo

Iipropati zeSiC 4H-N Uhlobo lwe-Epi Wafer:

Ukuqulunqwa kwezinto:

I-SiC (i-Silicon Carbide): Iyaziwa ngobulukhuni bayo obubalaseleyo, ukuhanjiswa kwe-thermal ephezulu, kunye neempawu ezibalaseleyo zombane, i-SiC ilungele izixhobo zombane ezisebenza kakhulu.

I-4H-SiC Polytype: I-polytype ye-4H-SiC iyaziwa ngokusebenza kwayo okuphezulu kunye nokuzinza kwizicelo ze-elektroniki.

N-uhlobo lweDoping: I-N-type doping (i-doped nge-nitrogen) inika ukuhamba kwe-electron egqwesileyo, okwenza i-SiC ifaneleke kwi-high-frequency kunye nezicelo zamandla aphezulu.

I-High Thermal Conductivity:

Ii-wafers ze-SiC zine-conductivity ephezulu ye-thermal, ngokuqhelekileyo ukusuka120–200 W/m·K, ebavumela ukuba balawule ngokufanelekileyo ukushisa kwizixhobo eziphezulu zamandla ezifana ne-transistors kunye ne-diode.

IBandgap ebanzi:

Nge bandgap ye3.26 eV, I-4H-SiC inokusebenza kwi-voltages ephezulu, i-frequencies, kunye namaqondo okushisa xa kuthelekiswa nezixhobo zendabuko ezisekelwe kwi-silicon, okwenza kube yinto efanelekileyo yokusebenza okuphezulu, izicelo eziphezulu zokusebenza.

Iinkcazelo ngeempawu zoMbane:

Ukuhamba kwe-electron ephezulu ye-SiC kunye nokuhamba kwenza ukuba ilungeleamandla e-elektroniki, enikezela ngesantya sokutshintsha ngokukhawuleza kunye nomthamo ophezulu wangoku kunye nomthamo wombane, okukhokelela kwiinkqubo zolawulo olusebenzayo ngakumbi.

Ukunyangwa koomatshini kunye nemichiza:

I-SiC yenye yezona zinto zinzima, okwesibini kuphela kwidayimani, kwaye ixhathisa kakhulu kwi-oxidation kunye nokubola, iyenza ukuba yomelele kwiindawo ezibuhlungu.

Usetyenziso lweSiC 4H-N Uhlobo lwe-Epi Wafer:

Umbane woMbane:

SiC 4H-N uhlobo epi wafers zisetyenziswa ngokubanzi kwiamandla MOSFETs, Ii-IGBTs, kwayeiidiodengenxaukuguqulwa kwamandlakwiinkqubo ezifanaii-inverters zelanga, izithuthi zombane, kwayeiinkqubo zokugcina amandla, enikezela ukusebenza okuphuculweyo kunye nokusebenza kakuhle kwamandla.

Izithuthi zoMbane (EVs):

In abaqhubi bezithuthi zombane, abalawuli beemoto, kwayeizikhululo zokutshaja, Iziqwenga ze-SiC zinceda ukuphumeza ukusebenza kakuhle kwebhetri, ukutshaja ngokukhawuleza, kunye nokuphuculwa kokusebenza kwamandla ngenxa yokukwazi ukuphatha amandla aphezulu kunye namaqondo obushushu.

IiNkqubo zaMandla aVuselelwayo:

Iziguquli zeSolar: Ii-wafers ze-SiC zisetyenziselwaiinkqubo zamandla elangayokuguqula amandla e-DC ukusuka kwiiphaneli zelanga ukuya kwi-AC, ukwandisa ukusebenza kakuhle kwenkqubo kunye nokusebenza.

Iiinjini zomoya: Itekhnoloji yeSiC iyasebenza kwiiinkqubo zokulawula i-injini yomoya, ukwandisa ukuveliswa kwamandla kunye nempumelelo yokuguqula.

I-Aerospace kunye noKhuseleko:

Ii-wafers ze-SiC zilungele ukusetyenziswai-elektroniki ye-aerospacekwayeizicelo zomkhosi, kuqukaiinkqubo zeradakwayei-elektroniki yesathelayithi, apho ukumelana nemitha ephezulu kunye nokuzinza kwe-thermal kubalulekile.

Ubushushu obuphezulu kunye nosetyenziso oluQhagayo oluPhezulu:

Ii-wafers ze-SiC ziyagqwesai-elektroniki yobushushu obuphezulu, esetyenziswa kwiiinjini zeenqwelomoya, iziphekepheke, kwayeiinkqubo zokufudumeza ishishini, njengoko zigcina ukusebenza kwiimeko ezishushu kakhulu. Ukongeza, i-bandgap yabo ebanzi ivumela ukusetyenziswa ngaphakathiizicelo eziphezulu-frequencynjengayeizixhobo RFkwayeunxibelelwano kwi-microwave.

| I-6-intshi ye-N-uhlobo lwe-epit axial specification | |||

| Ipharamitha | iyunithi | Z-MOS | |

| Uhlobo | Condutivity / Dopant | - | N-uhlobo / Nitrogen |

| Buffer Layer | Buffer Umaleko Ukutyeba | um | 1 |

| Buffer Umaleko wokutyeba ukunyamezelana | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Unyamezelo loMaleko lwe-Buffer | % | ±20% | |

| Uluhlu lwe-Epi yoku-1 | Epi Layer Ukutyeba | um | 11.5 |

| Epi Layer Ukutyeba Uniformity | % | ±4% | |

| Ukunyamezela ukutyeba kweeLayidi ze-Epi((Spec- Ubuninzi , Umzu)/Spec) | % | ±5% | |

| Epi Layer Concentration | cm-3 | 1XE 15~ 1E 18 | |

| Epi Layer Concentration Ukunyamezelana | % | 6% | |

| I-Epi Layer Concentration Uniformity (σ /ithetha) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(ubuninzi-min)/(ubuninzi+min> | % | ≤ 10% | |

| I-Epitaixal Wafer Shape | Ukuqubuda | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Iimpawu eziqhelekileyo | Ubude bemikrwelo | mm | ≤30mm |

| IiChips zoMda | - | AKUKHO | |

| Iziphene ukuchaza | ≥97% (Ilinganiswe nge-2*2, Iziphene zokubulala zibandakanya: Iziphene ziquka Umbhobho/imingxuma emikhulu, Umnqathe, unxantathu | ||

| Ukungcoliswa kwesinyithi | iiathom/cm² | df ndiya ≤5E10 iiathom/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Iphakheji | Ukupakisha iinkcukacha | iipcs/ibhokisi | iikhasethi ezininzi ezisicaba okanye isikhongozeli esinye esisicaba |

| I-8-intshi ye-N-uhlobo lwe-epitaxial specication | |||

| Ipharamitha | iyunithi | Z-MOS | |

| Uhlobo | Condutivity / Dopant | - | N-uhlobo / Nitrogen |

| Umaleko wesithinteli | Buffer Umaleko Ukutyeba | um | 1 |

| Buffer Umaleko wokutyeba ukunyamezelana | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Unyamezelo loMaleko lwe-Buffer | % | ±20% | |

| Uluhlu lwe-Epi yoku-1 | Epi Layers Ukutyeba Average | um | 8 ~ 12 |

| I-Epi Yezingqimba zokutyeba ngokufanayo (σ/intsingiselo) | % | ≤2.0 | |

| Unyamezelo lwe-Epi Ukutyeba ((Spec-Max, Min)/Spec) | % | ±6 | |

| Epi Layers Net Average Doping | cm-3 | 8E+15 ~2E+16 | |

| I-Epi Layers Net Doping Uniformity (σ/mean) | % | ≤5 | |

| I-Epi Layers Net DopingTolerance ((Spec -Max, | % | ± 10.0 | |

| I-Epitaixal Wafer Shape | Mi )/S ) I-Wap | um | ≤50.0 |

| Ukuqubuda | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Ngokubanzi Iimpawu | Imikrwelo | - | Ubude obongezelekayo≤ 1/2Wafer idayamitha |

| IiChips zoMda | - | ≤2 chips, Iradiyasi nganye≤1.5mm | |

| Surface Metals Ungcoliseko | iiathom/cm2 | ≤5E10 iiathom/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Ukuhlolwa kwesiphene | % | ≥ 96.0 (Iziphene ezi-2X2 ziquka iMibhobho/imingxuma emikhulu, Umnqathe, iziphene ezinxantathu, Ukwehla, Linear/IGSF-s, BPD) | |

| Surface Metals Ungcoliseko | iiathom/cm2 | ≤5E10 iiathom/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Iphakheji | Ukupakisha iinkcukacha | - | iikhasethi ezininzi ezisicaba okanye isikhongozeli esinye esisicaba |

I-SiC wafer's Q&A

I-Q1: Zeziphi iingenelo eziphambili zokusebenzisa ii-wafers ze-SiC ngaphezulu kwee-wafers ze-silicon zemveli kumbane wombane?

A1:

Ii-wafers ze-SiC zibonelela ngeengenelo ezininzi ezingundoqo ngaphezulu kwe-silicon yemveli (Si) yafers kumbane wamandla, kubandakanya:

Ukusebenza okuphezulu: I-SiC ine-bandgap ebanzi (3.26 eV) xa kuthelekiswa ne-silicon (1.1 eV), evumela ukuba izixhobo zisebenze kumbane ophezulu, ama-frequencies, kunye namaqondo okushisa. Oku kukhokelela ekulahlekeni kwamandla aphantsi kunye nokusebenza okuphezulu kwiinkqubo zokuguqula amandla.

I-High Thermal Conductivity: I-SiC's conductivity ye-thermal conductivity iphezulu kakhulu kune-silicon, eyenza ukutshatyalaliswa kobushushu obungcono kwizicelo zamandla aphezulu, okuphucula ukuthembeka kunye nobomi bezixhobo zamandla.

Umbane oPhezulu kunye nokuPhathwa kwangoku: Izixhobo ze-SiC zinokuphatha amandla ombane aphezulu kunye namanqanaba angoku, zizenze zilungele ukusetyenziswa kwamandla aphezulu njengezithuthi zombane, iinkqubo zamandla avuselelekayo, kunye neemoto zemizi-mveliso.

Isantya sokutshintsha ngokukhawuleza: Izixhobo ze-SiC zinamandla okutshintsha ngokukhawuleza, okufaka isandla ekunciphiseni ukulahlekelwa kwamandla kunye nobukhulu benkqubo, okwenza kube yinto efanelekileyo kwizicelo eziphezulu ze-frequency.

I-Q2: Zeziphi ezona zicelo ziphambili ze-SiC wafers kushishino lweemoto?

A2:

Kumzi mveliso weemoto, iiwafa zeSiC zisetyenziswa ikakhulu ku:

Izithuthi zoMbane (EV) zoMbane: amacandelo SiC-based ezifanaii-inverterskwayeamandla MOSFETsukuphucula ukusebenza kakuhle kunye nokusebenza kwezitimela zombane zesithuthi ngokuvumela isantya sokutshintsha ngokukhawuleza kunye nokuxinana kwamandla aphezulu. Oku kukhokelela kubomi bebhetri obude kunye nokusebenza ngcono kwesithuthi ngokubanzi.

Iitshaja ezisebhodini: Izixhobo ze-SiC zinceda ekuphuculeni ukusebenza kakuhle kweenkqubo zokutshaja ebhodini ngokuvumela amaxesha okukhawuleza okutshaja kunye nolawulo olungcono lwe-thermal, ebaluleke kakhulu kwii-EVs ukuxhasa izikhululo zokutshaja eziphezulu.

Iinkqubo zolawulo lwebhetri (BMS): Itekhnoloji yeSiC iphucula ukusebenza kakuhle kweiinkqubo zolawulo lwebhetri, ukuvumela ukulawulwa kwamandla ombane angcono, ukuphatha amandla aphezulu, kunye nobomi obude bebhetri.

Iziguquli zeDC-DC: Ii-wafers ze-SiC zisetyenziselwaDC-DC convertersukuguqula amandla e-DC aphezulu kumandla ombane we-DC ngokufanelekileyo, okubalulekileyo kwizithuthi zombane ukulawula amandla ukusuka kwibhetri ukuya kumacandelo ahlukeneyo kwisithuthi.

Ukusebenza okuphezulu kwe-SiC kwi-voltage ephezulu, ubushushu obuphezulu, kunye nezicelo eziphezulu zokusebenza kwenza ukuba kubaluleke kakhulu kwinguqu yoshishino lweemoto ukuya ekuhambeni kombane.

I-6inch 4H-N yohlobo lweSiC wafer's specication | ||

| Ipropati | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| IBanga | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| Ububanzi | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Poly-uhlobo | 4H | 4H |

| Ukutyeba | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Iwafer Orientation | I-off axis: 4.0 ° ukuya <1120> ± 0.5 ° | I-off axis: 4.0 ° ukuya <1120> ± 0.5 ° |

| Ukuxinana kweMibhobho | ≤ 0.2 cm² | ≤ 15cm² |

| Ukuxhathisa | 0.015 - 0.024 Ω · cm | 0.015 - 0.028 Ω · cm |

| Ukuqhelaniswa neFlethi okuPhambili | [10-10] ± 50 ° | [10-10] ± 50 ° |

| Ubude beFlethi obuPhambili | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Ukungabandakanywa kuMda | 3 mm | 3 mm |

| LTV / TIV / Isaphetha / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Uburhabaxa | I-Polish Ra ≤ 1 nm | I-Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| I-Edge Cracks ngokuKhanya okuPhakamileyo | Ubude obongezelekayo ≤ 20 mm ubude obunye ≤ 2 mm | Ubude obongezelekayo ≤ 20 mm ubude obunye ≤ 2 mm |

| Iipleyiti zeHex ngokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 0.1% |

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 3% |

| Ukubandakanywa kweCarbon ebonakalayo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 5% |

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Ubude obongezelekayo ≤ I-1 wafer idayamitha | |

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥ 0.2 mm ububanzi nobunzulu | I-7 ivunyelwe, ≤ 1 mm nganye |

| Ukushenxiswa kweScrew somsonto | < 500 cm³ | < 500 cm³ |

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | ||

| Ukupakishwa | Multi-wafer Cassette Okanye Single Wafer Container | Multi-wafer Cassette Okanye Single Wafer Container |

8inch 4H-N uhlobo SiC wafer's iinkcukacha | ||

| Ipropati | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| IBanga | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| Ububanzi | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Poly-uhlobo | 4H | 4H |

| Ukutyeba | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Iwafer Orientation | 4.0 ° ukuya <110> ± 0.5 ° | 4.0 ° ukuya <110> ± 0.5 ° |

| Ukuxinana kweMibhobho | ≤ 0.2 cm² | ≤ 5cm² |

| Ukuxhathisa | 0.015 - 0.025 Ω · cm | 0.015 - 0.028 Ω · cm |

| Uqhelaniso oluNoble | ||

| Ukungabandakanywa kuMda | 3 mm | 3 mm |

| LTV / TIV / Isaphetha / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Uburhabaxa | I-Polish Ra ≤ 1 nm | I-Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| I-Edge Cracks ngokuKhanya okuPhakamileyo | Ubude obongezelekayo ≤ 20 mm ubude obunye ≤ 2 mm | Ubude obongezelekayo ≤ 20 mm ubude obunye ≤ 2 mm |

| Iipleyiti zeHex ngokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 0.1% |

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 3% |

| Ukubandakanywa kweCarbon ebonakalayo | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 5% |

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Ubude obongezelekayo ≤ I-1 wafer idayamitha | |

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥ 0.2 mm ububanzi nobunzulu | I-7 ivunyelwe, ≤ 1 mm nganye |

| Ukushenxiswa kweScrew somsonto | < 500 cm³ | < 500 cm³ |

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | ||

| Ukupakishwa | Multi-wafer Cassette Okanye Single Wafer Container | Multi-wafer Cassette Okanye Single Wafer Container |

I-6Intshi ye-4H-semi SiC substrate inkcazo | ||

| Ipropati | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

| Ububanzi (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Poly-uhlobo | 4H | 4H |

| Ukutyeba (um) | 500 ± 15 | 500 ± 25 |

| Iwafer Orientation | Kwi-axis: ±0.0001 ° | Kwi-axis: ± 0.05 ° |

| Ukuxinana kweMibhobho | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Ukuxhathisa (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Ukuqhelaniswa neFlethi okuPhambili | (0-10) ° ± 5.0 ° | (10-10) ° ± 5.0 ° |

| Ubude beFlethi obuPhambili | Inotshi | Inotshi |

| Ukukhutshwa komda (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Isitya / Warp | ≤ 3µm | ≤ 3µm |

| Uburhabaxa | IsiPolish Ra ≤ 1.5 µm | IsiPolish Ra ≤ 1.5 µm |

| I-Edge Chips NgokuKhanya okuPhakamileyo | ≤ 20µm | ≤ 60µm |

| Iipleyiti zokutshisa ngokuKhanya okuPhakamileyo | Eyongezelekayo ≤ 0.05% | Yongezeleka ≤ 3% |

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Ukubandakanywa kweCarbon ebonakalayo ≤ 0.05% | Yongezeleka ≤ 3% |

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | ≤ 0.05% | Yongezeleka ≤ 4% |

| I-Edge Chips NgokuKhanya okuPhakamileyo (Ubukhulu) | Ayivumelekanga > 02 mm Ububanzi nobunzulu | Ayivumelekanga > 02 mm Ububanzi nobunzulu |

| I-Aiding Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Ukupakishwa | Iikhasethi ezininzi zewafer okanye iSingle Wafer Container | Iikhasethi ezininzi zewafer okanye iSingle Wafer Container |

I-4-Intshi ye-4H-Semi Insulating SiC Substrate Specification

| Ipharamitha | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leDummy (iBanga D) |

|---|---|---|

| Iipropati Zomzimba | ||

| Ububanzi | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Poly-uhlobo | 4H | 4H |

| Ukutyeba | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Iwafer Orientation | Kwi-axis: <600h> 0.5 ° | Kwi-axis: <000h> 0.5 ° |

| Iipropati zoMbane | ||

| Uxinaniso lweMibhobho (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Ukuxhathisa | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Ukunyamezela kweJometri | ||

| Ukuqhelaniswa neFlethi okuPhambili | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Ubude beFlethi obuPhambili | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Ubude beFlethi yesibini | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Ukuqhelaniswa neFlethi yesibini | I-90 ° CW ukusuka kwiflethi yePrime ± 5.0 ° (Si ubuso phezulu) | I-90 ° CW ukusuka kwiflethi yePrime ± 5.0 ° (Si ubuso phezulu) |

| Ukungabandakanywa kuMda | 3 mm | 3 mm |

| LTV / TTV / Isaphetha / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Umgangatho womphezulu | ||

| Uburhabaxa boMphezulu (Polish Ra) | ≤1 nm | ≤1 nm |

| Uburhabaxa boMphezulu (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| IiNceba ze-Edge (UkuKhanya okuPhezulu) | Ayivumelekanga | Ubude obuqokelelweyo ≥10 mm, ukuqhekeka okukodwa ≤2 mm |

| Iziphene zepleyiti eneHexagonal | ≤0.05% indawo eyongezelekayo | ≤0.1% indawo eyongezelekayo |

| IiNdawo zokuBandakanywa kwePolytype | Ayivumelekanga | ≤1% indawo eyongezelekayo |

| Ukubandakanywa kweCarbon ebonakalayo | ≤0.05% indawo eyongezelekayo | ≤1% indawo eyongezelekayo |

| Imikrwelo yoMphezulu weSilicon | Ayivumelekanga | ≤1 i-wafer idayamitha yobude obuqokelelweyo |

| IiChips zoMda | Akukho kuvunyelweyo (≥0.2 mm ububanzi/ubunzulu) | ≤5 iitshiphusi (nganye ≤1 mm) |

| Ungcoliseko lweSilicon Surface | Ayichazwanga ngqo | Ayichazwanga ngqo |

| Ukupakishwa | ||

| Ukupakishwa | Iikhasethi ezininzi zewafer okanye isikhongozeli se-wafer esinye | Multi-wafer cassette okanye |

| I-6-intshi ye-N-uhlobo lwe-epit axial specification | |||

| Ipharamitha | iyunithi | Z-MOS | |

| Uhlobo | Condutivity / Dopant | - | N-uhlobo / Nitrogen |

| Buffer Layer | Buffer Umaleko Ukutyeba | um | 1 |

| Buffer Umaleko wokutyeba ukunyamezelana | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Unyamezelo loMaleko lwe-Buffer | % | ±20% | |

| Uluhlu lwe-Epi yoku-1 | Epi Layer Ukutyeba | um | 11.5 |

| Epi Layer Ukutyeba Uniformity | % | ±4% | |

| Ukunyamezela ukutyeba kweeLayidi ze-Epi((Spec- Ubuninzi , Umzu)/Spec) | % | ±5% | |

| Epi Layer Concentration | cm-3 | 1XE 15~ 1E 18 | |

| Epi Layer Concentration Ukunyamezelana | % | 6% | |

| I-Epi Layer Concentration Uniformity (σ /ithetha) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(ubuninzi-min)/(ubuninzi+min> | % | ≤ 10% | |

| I-Epitaixal Wafer Shape | Ukuqubuda | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Iimpawu eziqhelekileyo | Ubude bemikrwelo | mm | ≤30mm |

| IiChips zoMda | - | AKUKHO | |

| Iziphene ukuchaza | ≥97% (Ilinganiswe nge-2*2, Iziphene zokubulala zibandakanya: Iziphene ziquka Umbhobho/imingxuma emikhulu, Umnqathe, unxantathu | ||

| Ukungcoliswa kwesinyithi | iiathom/cm² | df ndiya ≤5E10 iiathom/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Iphakheji | Ukupakisha iinkcukacha | iipcs/ibhokisi | iikhasethi ezininzi ezisicaba okanye isikhongozeli esinye esisicaba |

| I-8-intshi ye-N-uhlobo lwe-epitaxial specication | |||

| Ipharamitha | iyunithi | Z-MOS | |

| Uhlobo | Condutivity / Dopant | - | N-uhlobo / Nitrogen |

| Umaleko wesithinteli | Buffer Umaleko Ukutyeba | um | 1 |

| Buffer Umaleko wokutyeba ukunyamezelana | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Unyamezelo loMaleko lwe-Buffer | % | ±20% | |

| Uluhlu lwe-Epi yoku-1 | Epi Layers Ukutyeba Average | um | 8 ~ 12 |

| I-Epi Yezingqimba zokutyeba ngokufanayo (σ/intsingiselo) | % | ≤2.0 | |

| Unyamezelo lwe-Epi Ukutyeba ((Spec-Max, Min)/Spec) | % | ±6 | |

| Epi Layers Net Average Doping | cm-3 | 8E+15 ~2E+16 | |

| I-Epi Layers Net Doping Uniformity (σ/mean) | % | ≤5 | |

| I-Epi Layers Net DopingTolerance ((Spec -Max, | % | ± 10.0 | |

| I-Epitaixal Wafer Shape | Mi )/S ) I-Wap | um | ≤50.0 |

| Ukuqubuda | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Ngokubanzi Iimpawu | Imikrwelo | - | Ubude obongezelekayo≤ 1/2Wafer idayamitha |

| IiChips zoMda | - | ≤2 chips, Iradiyasi nganye≤1.5mm | |

| Surface Metals Ungcoliseko | iiathom/cm2 | ≤5E10 iiathom/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Ukuhlolwa kwesiphene | % | ≥ 96.0 (Iziphene ezi-2X2 ziquka iMibhobho/imingxuma emikhulu, Umnqathe, iziphene ezinxantathu, Ukwehla, Linear/IGSF-s, BPD) | |

| Surface Metals Ungcoliseko | iiathom/cm2 | ≤5E10 iiathom/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Iphakheji | Ukupakisha iinkcukacha | - | iikhasethi ezininzi ezisicaba okanye isikhongozeli esinye esisicaba |

I-Q1: Zeziphi iingenelo eziphambili zokusebenzisa ii-wafers ze-SiC ngaphezulu kwee-wafers ze-silicon zemveli kumbane wombane?

A1:

Ii-wafers ze-SiC zibonelela ngeengenelo ezininzi ezingundoqo ngaphezulu kwe-silicon yemveli (Si) yafers kumbane wamandla, kubandakanya:

Ukusebenza okuphezulu: I-SiC ine-bandgap ebanzi (3.26 eV) xa kuthelekiswa ne-silicon (1.1 eV), evumela ukuba izixhobo zisebenze kumbane ophezulu, ama-frequencies, kunye namaqondo okushisa. Oku kukhokelela ekulahlekeni kwamandla aphantsi kunye nokusebenza okuphezulu kwiinkqubo zokuguqula amandla.

I-High Thermal Conductivity: I-SiC's conductivity ye-thermal conductivity iphezulu kakhulu kune-silicon, eyenza ukutshatyalaliswa kobushushu obungcono kwizicelo zamandla aphezulu, okuphucula ukuthembeka kunye nobomi bezixhobo zamandla.

Umbane oPhezulu kunye nokuPhathwa kwangoku: Izixhobo ze-SiC zinokuphatha amandla ombane aphezulu kunye namanqanaba angoku, zizenze zilungele ukusetyenziswa kwamandla aphezulu njengezithuthi zombane, iinkqubo zamandla avuselelekayo, kunye neemoto zemizi-mveliso.

Isantya sokutshintsha ngokukhawuleza: Izixhobo ze-SiC zinamandla okutshintsha ngokukhawuleza, okufaka isandla ekunciphiseni ukulahlekelwa kwamandla kunye nobukhulu benkqubo, okwenza kube yinto efanelekileyo kwizicelo eziphezulu ze-frequency.

I-Q2: Zeziphi ezona zicelo ziphambili ze-SiC wafers kushishino lweemoto?

A2:

Kumzi mveliso weemoto, iiwafa zeSiC zisetyenziswa ikakhulu ku:

Izithuthi zoMbane (EV) zoMbane: amacandelo SiC-based ezifanaii-inverterskwayeamandla MOSFETsukuphucula ukusebenza kakuhle kunye nokusebenza kwezitimela zombane zesithuthi ngokuvumela isantya sokutshintsha ngokukhawuleza kunye nokuxinana kwamandla aphezulu. Oku kukhokelela kubomi bebhetri obude kunye nokusebenza ngcono kwesithuthi ngokubanzi.

Iitshaja ezisebhodini: Izixhobo ze-SiC zinceda ekuphuculeni ukusebenza kakuhle kweenkqubo zokutshaja ebhodini ngokuvumela amaxesha okukhawuleza okutshaja kunye nolawulo olungcono lwe-thermal, ebaluleke kakhulu kwii-EVs ukuxhasa izikhululo zokutshaja eziphezulu.

Iinkqubo zolawulo lwebhetri (BMS): Itekhnoloji yeSiC iphucula ukusebenza kakuhle kweiinkqubo zolawulo lwebhetri, ukuvumela ukulawulwa kwamandla ombane angcono, ukuphatha amandla aphezulu, kunye nobomi obude bebhetri.

Iziguquli zeDC-DC: Ii-wafers ze-SiC zisetyenziselwaDC-DC convertersukuguqula amandla e-DC aphezulu kumandla ombane we-DC ngokufanelekileyo, okubalulekileyo kwizithuthi zombane ukulawula amandla ukusuka kwibhetri ukuya kumacandelo ahlukeneyo kwisithuthi.

Ukusebenza okuphezulu kwe-SiC kwi-voltage ephezulu, ubushushu obuphezulu, kunye nezicelo eziphezulu zokusebenza kwenza ukuba kubaluleke kakhulu kwinguqu yoshishino lweemoto ukuya ekuhambeni kombane.