I-P-uhlobo lwe-SiC wafer 4H/6H-P 3C-N 6inch ukutyeba 350 μm kunye nokuqhelaniswa neFlethi ePrayimari

Specification4H/6H-P Uhlobo lweSiC Composite Substrates Itheyibhile yeparamitha eqhelekileyo

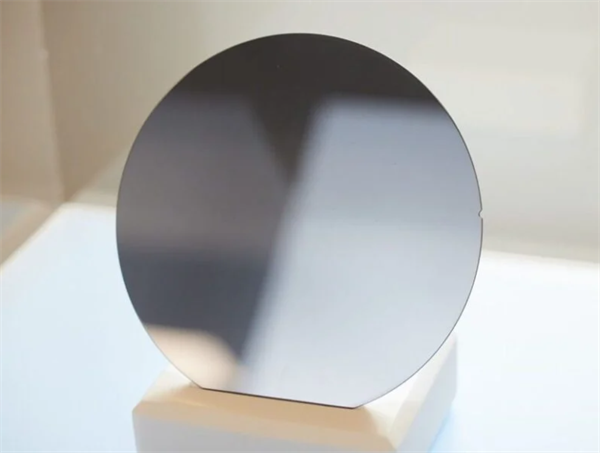

6 intshi ubukhulu Silicon Carbide (SiC) Substrate Inkcazo

| IBanga | Zero MPD ProductionIBanga (Z Ibanga) | Imveliso esemgangathweniIBanga (P Ibanga) | IBanga leDummy (D Ibanga) | ||

| Ububanzi | 145.5 mm~150.0 mm | ||||

| Ukutyeba | 350 μm ± 25 μm | ||||

| I-Wafer Orientation | -Offi-axis: 2.0 ° -4.0 ° ukuya [1120] ± 0.5 ° ye-4H/6H-P, Kwi-axis:〈111〉± 0.5° ye-3C-N | ||||

| Ukuxinana kweMibhobho | 0 cm-2 | ||||

| Ukuxhathisa | p-uhlobo 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| n-uhlobo 3C-N | ≤0.8 mΩꞏcm | ≤1 m Ωꞏcm | |||

| Ukuqhelaniswa neFlethi okuPhambili | 4H/6H-P | -{1010} ± 5.0° | |||

| 3C-N | -{110} ± 5.0° | ||||

| Ubude beFlethi obuPhambili | 32.5 mm ± 2.0 mm | ||||

| Ubude beFlethi yesibini | 18.0 mm ± 2.0 mm | ||||

| Ukuqhelaniswa neFlethi yesibini | Ubuso beSilicon phezulu: 90° CW. ukusuka Prime flat ± 5.0 ° | ||||

| Ukungabandakanywa kuMda | 3 mm | 6 mm | |||

| LTV/TTV/Saphetha/Warp | ≤2.5 μm/≤5 μm/≤15 μm/≤30 μm | ≤10 μm/≤15 μm/≤25 μm/≤40 μm | |||

| Uburhabaxa | IsiPolish Ra≤1 nm | ||||

| I-CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| I-Edge Cracks ngokuKhanya okuPhakamileyo | Akukho nanye | Ubude obongezelekayo ≤ 10 mm, ubude obunye≤2 mm | |||

| Iipleyiti zeHex ngokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤0.05% | Indawo eyongezelekayo ≤0.1% | |||

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Akukho nanye | Indawo eyongezelekayo≤3% | |||

| Ukubandakanywa kweCarbon ebonakalayo | Indawo eyongezelekayo ≤0.05% | Indawo eyongezelekayo ≤3% | |||

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Akukho nanye | Ubude obongezelekayo≤1×i-wafer idayamitha | |||

| I-Edge Chips iPhezulu ngokuKhanya okuKhanya | Akukho kuvunyelweyo ≥0.2mm ububanzi nobunzulu | I-5 ivunyelwe, ≤1 mm nganye | |||

| Ungcoliseko lweSilicon Surface ngoBunzulu obuPhezulu | Akukho nanye | ||||

| Ukupakishwa | Iikhasethi ezininzi zewafer okanye iSingle Wafer Container | ||||

Amanqaku:

※ Imida yeziphene isebenza kuwo wonke umphezulu we-wafer ngaphandle kwendawo esecaleni yomphetho. # Imikrwelo kufuneka ijongwe kuSi face o

I-P-uhlobo lwe-SiC wafer, i-4H / 6H-P 3C-N, kunye nobukhulu bayo obuyi-intshi ezi-6 kunye nobukhulu be-350 μm, idlala indima ebalulekileyo kwimveliso yombane we-electronics ephezulu yokusebenza. Ukuqhuba kakuhle kwe-thermal kunye ne-voltage ephezulu yokuqhekeka kuyenza ilungele izinto zokwenziwa kombane, ii-diode, kunye neetransistors ezisetyenziswa kwindawo ezinobushushu obuphezulu njengezithuthi zombane, iigridi zamandla, kunye neenkqubo zamandla avuselelekayo. Ukukwazi kwe-wafer ukusebenza ngokufanelekileyo kwiimeko ezinzima kuqinisekisa ukusebenza okuthembekileyo kwizicelo zamashishini ezifuna ukuxinana kwamandla aphezulu kunye nokusebenza kakuhle kwamandla. Ukongeza, isiseko sayo sokuqhelaniswa neflethi siluncedo kulungelelwaniso oluchanekileyo ngexesha lokwenziwa kwesixhobo, ukuphucula ukusebenza kakuhle kwemveliso kunye nokungaguquguquki kwemveliso.

Izibonelelo ze-N-uhlobo lwe-SiC composite substrates ziquka

- I-High Thermal Conductivity: Ii-wafers ze-SiC zohlobo lwe-P zibuchitha ngokufanelekileyo ubushushu, zibenze zilungele izicelo zobushushu obuphezulu.

- Ukuqhekeka okuphezulu kweVoltage: Iyakwazi ukumelana nombane ophezulu, ukuqinisekisa ukuthembeka kumbane wamandla kunye nezixhobo eziphezulu zombane.

- Ukuchasana neeNdawo eziBungqwabalala: Ukuqina okugqwesileyo kwiimeko ezigqithisileyo, ezinje ngamaqondo obushushu aphezulu kunye neendawo ezigrulisayo.

- Uguqulo lwamandla olusebenzayo: I-P-type doping iququzelela ukuphathwa kwamandla ngokufanelekileyo, okwenza i-wafer ilungele iinkqubo zokuguqula amandla.

- Ukuqhelaniswa neFlethi okuPhambili: Ukuqinisekisa ulungelelwaniso oluchanekileyo ngexesha lokuvelisa, ukuphucula ukuchaneka kwesixhobo kunye nokuhambelana.

- Ulwakhiwo olubhityileyo (350 μm): Ubukhulu be-wafer buxhasa ukudityaniswa kwezixhobo zombane eziphambili, ezicinezelekileyo.

Ngokubanzi, i-P-type SiC wafer, 4H / 6H-P 3C-N, inikeza uluhlu lweenzuzo ezenza ukuba zifaneleke kakhulu kwi-industrial and electronic applications. I-conductivity yayo ephezulu ye-thermal kunye ne-voltage ye-breakdown yenza umsebenzi othembekileyo kwindawo yokushisa ephezulu kunye ne-high-voltage, ngelixa ukuchasana kwayo kwiimeko ezinzima kuqinisekisa ukuhlala. I-P-type doping ivumela ukuguqulwa kwamandla okusebenzayo, okwenza kube yinto efanelekileyo kumandla ombane kunye neenkqubo zamandla. Ukongeza, i-wafer eyona nto iphambili yokuqhelaniswa neflethi iqinisekisa ulungelelwaniso oluchanekileyo ngexesha lenkqubo yokwenziwa kwemveliso, okomeleza imveliso engaguqukiyo. Ngobukhulu be-350 μm, ifaneleke kakuhle ukudibanisa kwizixhobo eziphambili, ezihlangeneyo.

Idayagram eneenkcukacha