IsiXhobo esiSetyenziswayo ngokuPheleleyo se-wafer-Catting Ubungakanani obuSebenzayo 8inch/12inch Wafer Ring Cutting

Imilinganiselo yobugcisa

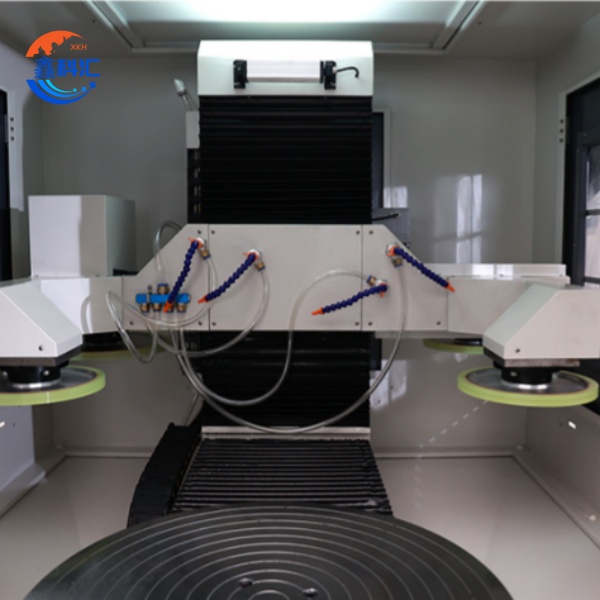

| Ipharamitha | Iyunithi | Inkcazo |

| Ubungakanani obukhulu boMsebenzi | mm | ø12" |

| I-spindle | Uqwalaselo | I-Spindle enye |

| Isantya | 3,000-60,000 rpm | |

| Amandla emveliso | 1.8 kW (2.4 ungazikhethela) ku-30,000 min⁻¹ | |

| UMax Blade Dia. | Ø58 mm | |

| I-X-Axis | Uluhlu lokusika | 310 mm |

| I-Y-Axis | Uluhlu lokusika | 310 mm |

| Inyathelo lokunyuswa | 0.0001 mm | |

| Ukubeka Ukuchaneka | ≤0.003 mm/310 mm, ≤0.002 mm/5 mm (impazamo enye) | |

| Z-Axis | ISigqibo seMovement | 0.00005 mm |

| Ukuphindaphinda | 0.001 mm | |

| θ-Umgca | Ukujikeleziswa okukhulu | 380 deg |

| Uhlobo lweSpindle | I-spindle enye, ixhotyiswe ngencakuba eqinileyo yokusika iringi | |

| Ring-Cutting Ukuchaneka | μm | ±50 |

| IWafer Positioning Ukuchaneka | μm | ±50 |

| I-Single-Wafer Efficiency | umz/isiqwengana | 8 |

| I-Multi-Wafer Efficiency | Ukuya kuthi ga kwii-wafers ezi-4 eziqhutywe ngaxeshanye | |

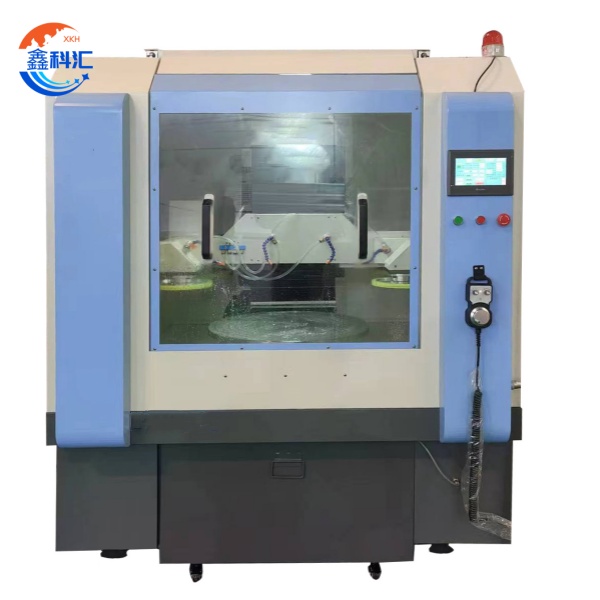

| Ubunzima beZixhobo | kg | ≈3,200 |

| Imilinganiselo yesiXhobo (W×D×H) | mm | 2,730 × 1,550 × 2,070 |

Umgaqo wokuSebenza

Inkqubo ifezekisa ukusebenza okuncomekayo kokulungisa ngezi teknoloji zingundoqo:

1.Inkqubo yoLawulo lweNtshukumo ekrelekrele:

· Ukuchaneka okuphezulu komgca wemoto wokuqhuba (phinda ukuchaneka kokumisa: ±0.5μm)

· I-Six-axis yolawulo oluhambelanayo oluxhasa ucwangciso oluntsonkothileyo lwendlela

· Ii-algorithms zoxinzelelo lwexesha lokwenyani ziqinisekisa uzinzo lokusika

2.Isixokelelwano esiPhambili sokuFumana:

· Inzwa yobude belaser edibeneyo ye-3D (ukuchaneka: 0.1μm)

· Ukubekwa kwembonakalo yeCCD enesoso esiphezulu (5 megapixels)

· Imodyuli yokuhlola umgangatho kwi-Intanethi

3.Inkqubo Ezenzekela Ngokupheleleyo:

· Ukulayisha/ukukhuphela ngokuzenzekelayo (ujongano olusemgangathweni lweFOUP luyahambelana)

· Inkqubo ekrelekrele yokuhlela

· Iyunithi yokucoca iluphu evaliweyo (ucoceko: Udidi lwe-10)

Usetyenziso oluqhelekileyo

Esi sixhobo sinikezela ngexabiso elibalulekileyo kuzo zonke izicelo zokwenziwa kwe-semiconductor:

| Indawo yosetyenziso | Izinto eziphathekayo | Izinto eziluncedo kwezobuGcisa |

| IC Manufacturing | 8/12 "Ii-Silicon Wafers | Ukuphucula ulungelelwaniso lwelithography |

| Izixhobo zamandla | IiWafers zeSiC/GaN | Ikhusela iziphene ezisecaleni |

| Iinzwa zeMEMS | Ii-wafers ze-SOI | Iqinisekisa ukuthembeka kwesixhobo |

| Izixhobo zeRF | GaAs Wafers | Ukuphucula ukusebenza kwe-high-frequency |

| UkuPakisha okuPhezulu | IiWafers ezihlaziyiweyo | Yandisa isivuno sokupakisha |

Iimbonakalo

Uqwalaselo lwesikhululo se-1.

2.Stable TAIKO ring debonding kunye nokususwa;

3.Ukuhambelana okuphezulu kunye nezinto ezisetyenziswayo eziphambili;

I-4.I-Multi-axis yokucutha itekhnoloji yokuvumelanisa iqinisekisa ukusika okuchanekileyo komphetho;

5.Ukuhamba kwenkqubo ezenzekelayo ngokupheleleyo kunciphisa kakhulu iindleko zabasebenzi;

I-6.Uyilo lwe-worktable olulungiselelweyo luvumela ukuqhutyelwa kwezakhiwo ezikhethekileyo;

Imisebenzi

1.Iringi-ithontsi inkqubo yokufumanisa;

2.Ukucoca okuzenzekelayo kwitafile yokusebenza;

3.Intelligent UV inkqubo debonding;

4.Ukurekhoda kwelog yokusebenza;

5.Factory automation imodyuli udibaniso;

Ukuzibophelela ngeNkonzo

I-XKH ibonelela ngeenkonzo ezibanzi, ezipheleleyo zenkxaso yendlela yokuphila eyilelwe ukwandisa ukusebenza kwezixhobo kunye nokusebenza kakuhle kulo lonke uhambo lwakho lokuvelisa.

1. Iinkonzo zokuLungisa

· Ulungelelwaniso lweSixhobo esiQinisekisiweyo: Iqela lethu lobunjineli lisebenzisana ngokusondeleyo nabathengi ukuze kuphuculwe iiparameters zenkqubo (isantya sokusika, ukukhetha i-blade, njl. njl.) ngokusekelwe kwiipropati ezithile zezinto (Si / SiC / GaAs) kunye neemfuno zenkqubo.

· INkxaso yoPhuhliso lweNkqubo: Sinikezela ngokusetyenzwa kwesampulu ngeengxelo zohlalutyo oluneenkcukacha ezibandakanya umlinganiselo woburhabaxa kunye nemephu yesiphene.

· Uphuhliso oluhlangeneyo lwezinto ezisetyenziswayo: Kwimathiriyeli yenoveli (umzekelo, i-Ga₂O₃), sisebenzisana nabenzi bezinto ezityiwayo abakhokelayo ukuphuhlisa iiblades/i-laser optics.

2. Inkxaso yobuGcisa kwezobuGcisa

· INkxaso eMiselweyo kwiNdawo: Yabela iinjineli eziqinisekisiweyo kwizigaba ezibalulekileyo zokunyuka (ngokuqhelekileyo iiveki ezi-2-4), eziquka:

Ulungelelwaniso lwezixhobo & inkqubo yokulungisa kakuhle

Uqeqesho lobuchule bokusebenza

ISO Class 5 isikhokelo sokudityaniswa kwegumbi lokucoca

· Ugcino oluqikelelwayo: Ukuhlolwa kwezempilo ngekota ngohlalutyo lokungcangcazela kunye nokuxilongwa kweemoto ze-servo ukuthintela ixesha lokuphumla elingacwangciswanga.

· Ukujongwa okukude: Ukulandelela ukusebenza kwezixhobo zexesha langempela ngeqonga lethu le-IoT (JCFront Connect®) enezilumkiso ezizenzekelayo ezingaqhelekanga.

3. Iinkonzo ezongeziweyo kwixabiso

· Isiseko soLwazi lweNkqubo: Ukufikelela ku-300+ kwiiresiphi zokusika eziqinisekisiweyo zezixhobo ezahlukeneyo (zihlaziywa ngekota).

· Ulungelelwaniso lweMephu yeTekhnoloji: Ubungqina bexesha elizayo botyalo-mali lwakho ngehardware/isoftware yokuphucula iindlela (umzekelo, imodyuli yokufumanisa isiphene esekwe kwi-AI).

· Iimpendulo eziNgxamisekileyo: Uxilongo oluqinisekisiweyo lweeyure ezi-4 ezikude kunye nongenelelo lweeyure ezingama-48 kwindawo (i-global coverage).

4. Iziseko zoncedo zenkonzo

· Isiqinisekiso sokuSebenza: Ukuzibophelela kwikhontrakthi kwi-≥98% yezixhobo zokusebenza kunye namaxesha okuphendula axhaswa yi-SLA.

Uphuculo oluqhubekayo

Senza uphando lokwaneliseka kwabathengi rhoqo kabini ngonyaka kwaye siphumeza amalinge eKaizen ukomeleza unikezelo lwenkonzo. Iqela lethu le-R&D liguqulela ulwazi kwinkalo yokuphuculwa kwezixhobo - i-30% yokuphuculwa kwe-firmware isuka kwiingxelo zabaxumi.