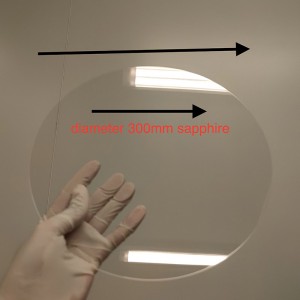

I-Dia300x1.0mmt Ukutyeba kweSapphire Wafer C-Plane SSP/DSP

Ukwazisa ngebhokisi ye-wafer

| Izinto zeCrystal | I-99,999% ye-Al2O3, i-High Purity, i-Monocrystalline, i-Al2O3 | |||

| Umgangatho weCrystal | Ukubandakanywa, amanqaku ebhloko, amawele, Umbala, amaqamza amancinci kunye namaziko okusasazeka azikho | |||

| Ububanzi | 2 intshi | 3intshi | 4intshi | 6intshi ~ 12intshi |

| 50.8± 0.1mm | 76.2±0.2mm | 100±0.3mm | Ngokuhambelana nezibonelelo zemveliso esemgangathweni | |

| Ukutyeba | 430±15µm | 550±15µm | 650±20µm | Inokwenziwa ngokwezifiso ngumthengi |

| Ukuqhelaniswa | I-C- plane (0001) ukuya kwi-M-plane (1-100) okanye i-A-plane (1 1-2 0) 0.2±0.1 ° /0.3±0.1 °, i-R-plane (1-1 0 2), i-A-plane (1 1-2 0), i-M-plane (1-1 0 0), Nayiphi na i-engile | |||

| Ubude beflethi bokuqala | 16.0±1mm | 22.0±1.0mm | 32.5±1.5 mm | Ngokuhambelana nezibonelelo zemveliso esemgangathweni |

| Ukuqhelaniswa neflethi ephambili | I-A-plane (1 1-2 0 ) ± 0.2 ° | |||

| TTV | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| LTV | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| TIR | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| THOBEKA | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| I-Wap | ≤10µm | ≤15µm | ≤20µm | ≤30µm |

| Umphezulu ongaphambili | I-Epi-Polished (Ra< 0.2nm) | |||

*Isaphetha: Ukutenxa kwindawo esembindini yomphezulu we-wafer ekhululekileyo, engabanjwanga ukusuka kwinqwelo-moya yereferensi, apho inqwelo-moya yereferensi ichazwa ziikona ezintathu zonxantathu olinganayo.

*I-Warp: Umahluko phakathi kowona mkhulu kunye nomgama omncinci womphezulu ophakathi we-wafer ekhululekileyo, engabanjwanga kwinqwelo-moya echazwe ngasentla.

Iimveliso ezikumgangatho ophezulu kunye neenkonzo zezixhobo ze-semiconductor zesizukulwana esilandelayo kunye nokukhula kwe-epitaxial:

Iqondo eliphezulu lokuthamba (i-TTV elawulwayo, isaphetha, i-warp njl.njl.)

Ukucocwa komgangatho ophezulu (ungcoliseko lwamasuntswana aphantsi, ukungcoliseka kwentsimbi ephantsi)

I-substrate yokugrumba, i-grooving, ukusika, kunye nokupolisha ngasemva

Ukuqhotyoshelwa kwedatha efana nokucoceka kunye nokumila kwe-substrate (ukhetho)

Ukuba unesidingo sesafire substrates, nceda uzive ukhululekile ukuqhagamshelana:

imeyile:eric@xkh-semitech.com+86 158 0194 2596 /doris@xkh-semitech.com+86 187 0175 6522

Siza kubuyela kuwe ngokukhawuleza!

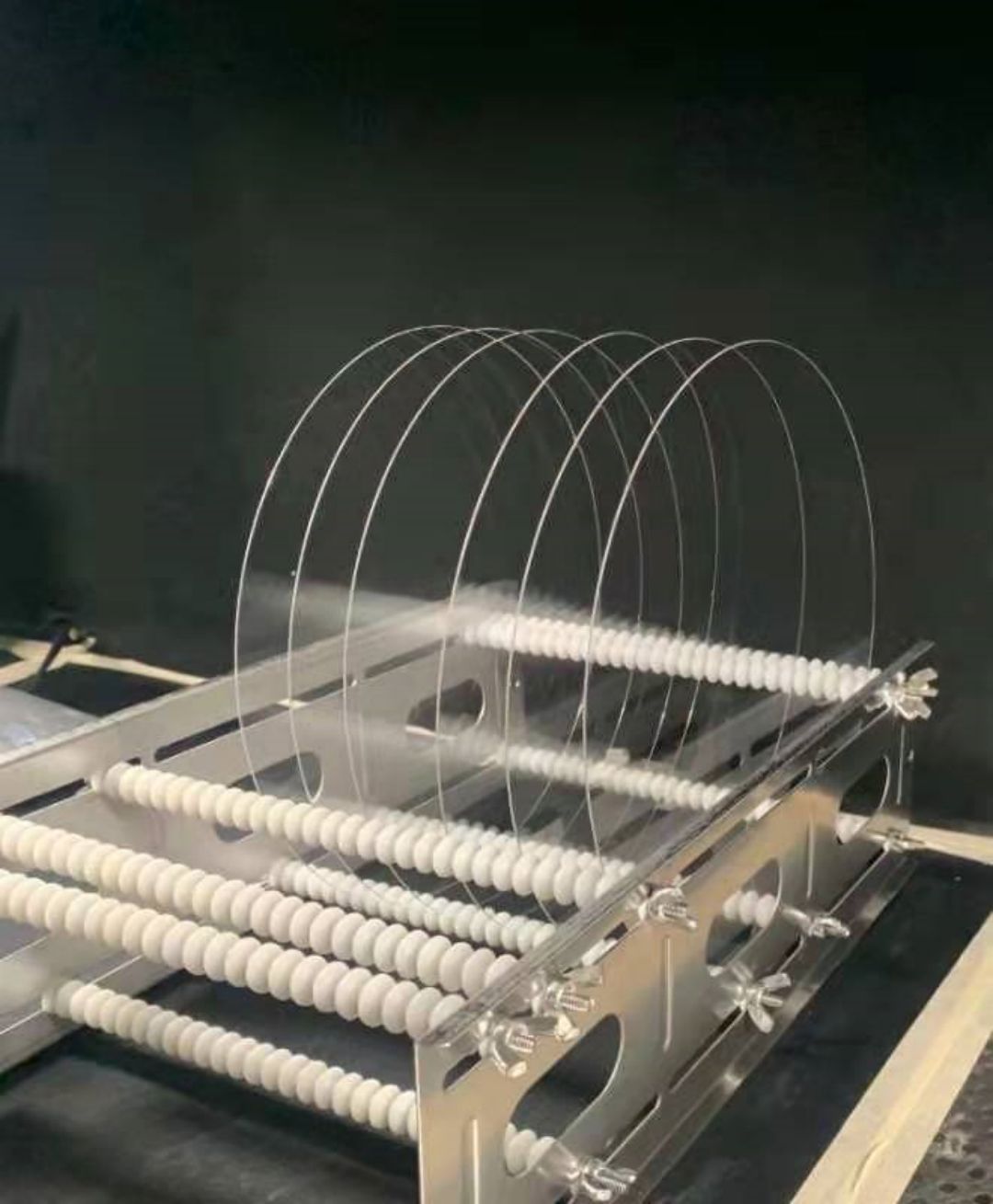

Idayagram eneenkcukacha