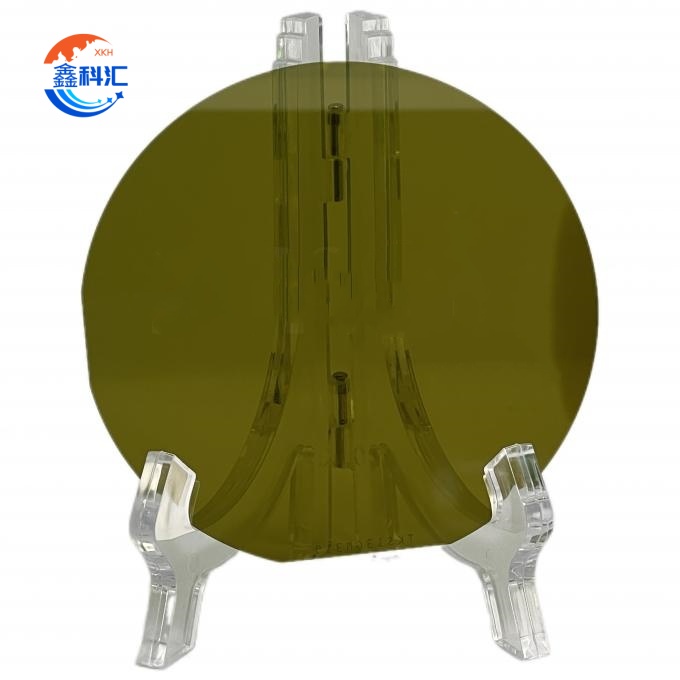

I-8 intshi ye-SiC ye-silicon carbide wafer 4H-N uhlobo lwe-0.5mm ibakala lokuvelisa ibakala lophando lwebakala elikhazimlisiweyo.

Iimpawu eziphambili ze-8-intshi ye-silicon carbide substrate 4H-N uhlobo lubandakanya:

1. Ubuninzi beMicrotubule: ≤ 0.1/cm² okanye ngaphantsi, njengoxinaniso lwe-microtubule luncitshiswe kakhulu ukuya ngaphantsi kwe-0.05/cm² kwezinye iimveliso.

2. I-Crystal form ratio: I-4H-SiC ifom ye-crystal form ratio ifikelela kwi-100%.

3. Ukuxhathisa: 0.014~0.028 Ω·cm, okanye uzinze ngakumbi phakathi kwe-0.015-0.025 Ω·cm.

4. Uburhabaxa bomphezulu: CMP Si Face Ra≤0.12nm.

5. Ukutyeba: Ngokuqhelekileyo 500.0±25μm okanye 350.0±25μm.

6. I-angle ye-Chamfering: 25±5 ° okanye 30±5 ° ye-A1 / A2 ngokuxhomekeke kubukhulu.

7. Uxinaniso olupheleleyo lwe-dislocation: ≤3000/cm².

8. Ungcoliseko lwentsimbi engaphezulu: ≤1E+11 iiathom/cm².

9. Ukugoba kunye ne-warpage: ≤ 20μm kunye ne-≤2μm, ngokulandelanayo.

Ezi mpawu zenza i-8-intshi ye-silicon carbide substrates inexabiso elibalulekileyo lesicelo ekwenzeni ubushushu obuphezulu, i-high-frequency, kunye nezixhobo zombane eziphezulu.

I-8inch ye-silicon carbide wafer inezicelo ezininzi.

1. Izixhobo zamandla: Ii-wafers ze-SiC zisetyenziswa ngokubanzi ekwenzeni izixhobo zombane zamandla ezifana ne-MOSFETs yamandla (i-metal-oxide-semiconductor field-effect transistors), i-Schottky diodes, kunye neemodyuli zokudibanisa amandla. Ngenxa ye-conductivity ephezulu ye-thermal, i-voltage ephezulu yokuphuka, kunye nokuhamba kwe-electron ephezulu ye-SiC, ezi zixhobo zinokufikelela ngokufanelekileyo, ukuguqulwa kwamandla aphezulu kwiqondo lokushisa eliphezulu, i-voltage ephezulu kunye ne-high-frequency environments.

2. Izixhobo ze-Optoelectronic: Ii-wafers ze-SiC zidlala indima ebalulekileyo kwizixhobo ze-optoelectronic, ezisetyenziselwa ukuvelisa i-photodetectors, i-laser diode, imithombo ye-ultraviolet, njl njl. Iimpawu eziphezulu ze-Silicon carbide ze-optical kunye ne-elektroniki zenza ukuba kube yinto ekhethiweyo, ngokukodwa kwizicelo ezifuna ukushisa okuphezulu, i-frequencies ephezulu, kunye namanqanaba aphezulu ombane.

3. Izixhobo zeRadio Frequency (RF): Iitshiphusi zeSiC zikwasetyenziselwa ukuvelisa izixhobo zeRF ezifana nezikhulisi zamandla eRF, iiswitshi ze-high-frequency, ii-sensors zeRF, nokunye. Uzinzo oluphezulu lwe-Thermal ye-SiC, iimpawu ze-frequency ephezulu, kunye nelahleko ephantsi iyenza ilungele usetyenziso lweRF olufana nonxibelelwano olungenazingcingo kunye neenkqubo zerada.

I-4.Ubushushu obuphezulu be-elektroniki: Ngenxa yokuzinza kwabo okuphezulu kwe-thermal kunye ne-elasticity yeqondo lokushisa, ii-wafers ze-SiC zisetyenziselwa ukuvelisa iimveliso zombane ezenzelwe ukusebenza kwiindawo ezinobushushu obuphezulu, kubandakanywa i-electronics yamandla aphezulu, izinzwa kunye nabalawuli.

Iindlela zokusetyenziswa eziphambili ze-8-intshi ye-silicon carbide substrate 4H-N uhlobo lubandakanya ukuveliswa kobushushu obuphezulu, i-high-frequency, kunye nezixhobo zombane zamandla aphezulu, ngokukodwa kwiinkalo ze-automotive electronics, amandla elanga, ukuveliswa kwamandla omoya, iinqwelo zombane, iiseva, izixhobo zasekhaya, kunye neenqwelo zombane. Ukongeza, izixhobo ezinjenge-SiC MOSFETs kunye ne-Schottky diode zibonise ukusebenza kakuhle ekutshintsheni ama-frequencies, ii-experimenti ze-short-circuit, kunye nokusetyenziswa kwe-inverter, ukuqhuba ukusetyenziswa kwazo kumbane wombane.

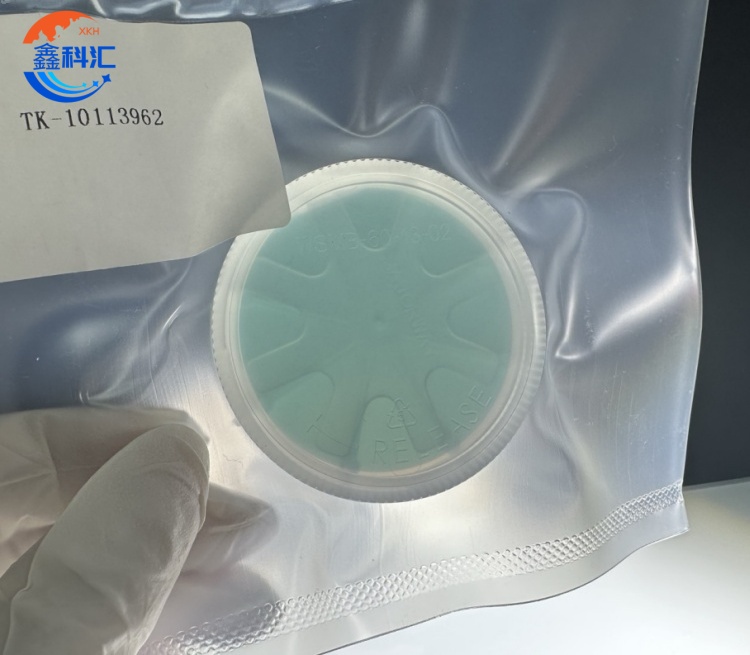

I-XKH inokwenziwa ngokwezifiso ezinobunzima obahlukeneyo ngokweemfuno zabathengi. Uburhabaxa bomphezulu obahlukeneyo kunye nonyango lokugudisa luyafumaneka. Iindidi ezahlukeneyo zedoping (ezifana ne-nitrogen doping) ziyaxhaswa. I-XKH inokubonelela ngenkxaso yobugcisa kunye neenkonzo zokubonisana ukuqinisekisa ukuba abathengi banokucombulula iingxaki kwinkqubo yokusetyenziswa. I-8-intshi ye-silicon carbide substrate ineenzuzo ezibalulekileyo malunga nokunciphisa iindleko kunye nokwanda kwamandla, okunokunciphisa ixabiso leyunithi yeyunithi malunga ne-50% xa kuthelekiswa ne-6-intshi substrate. Ukongeza, ukutyeba okwandisiweyo kwe-substrate ye-intshi ezi-8 kunceda ukunciphisa ukuphambuka kwejometri kunye ne-edge warping ngexesha lomatshini, ngaloo ndlela kuphuculwe isivuno.

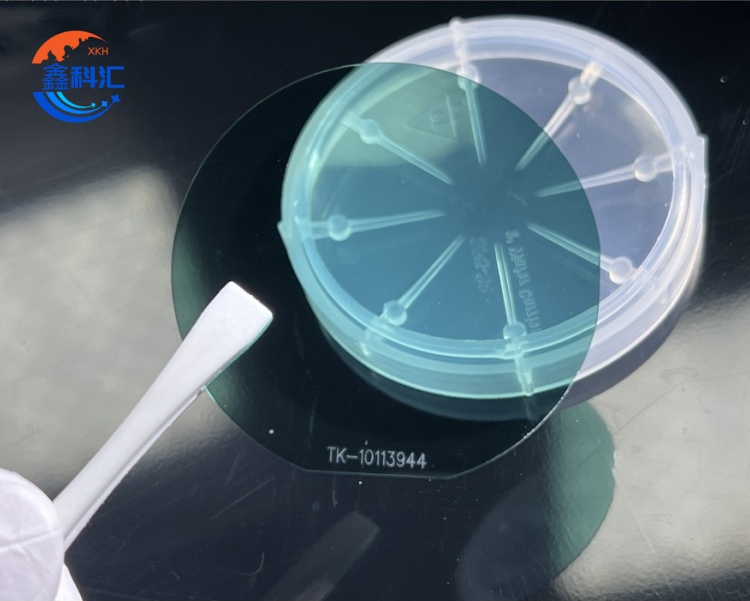

Idayagram eneenkcukacha