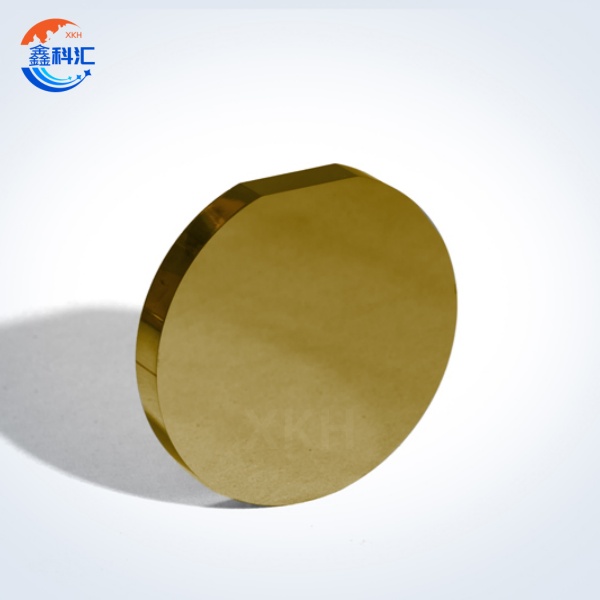

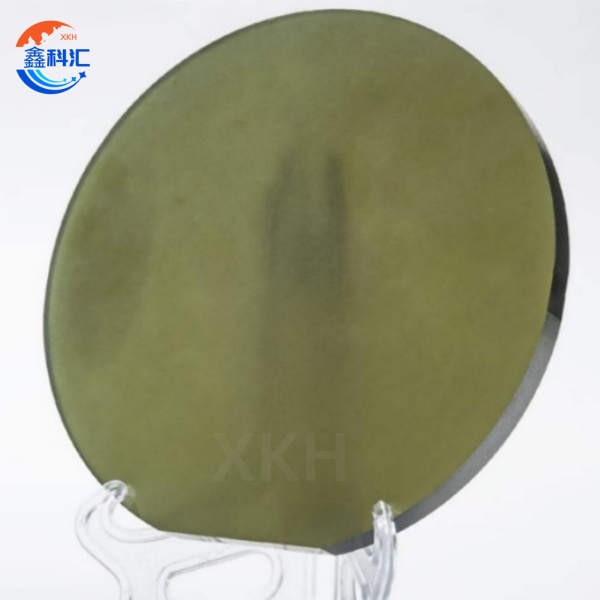

I-12 Intshi ye-SiC substrate Ububanzi 300mm Ukutyeba 750μm 4H-N Uhlobo lunokwenziwa ngokwezifiso

Iiparamitha zobugcisa

| I-12 intshi yeSilicon Carbide (SiC) Inkcazo yeSubstrate | |||||

| IBanga | Imveliso yeZeroMPD IBanga (Z Grade) | Imveliso esemgangathweni IBanga (P Grade) | IBanga leDummy (D Grade) | ||

| Ububanzi | 3 0 0 mm~1305mm | ||||

| Ukutyeba | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| I-Wafer Orientation | I-off axis : 4.0 ° ukuya ku- <1120 > ±0.5 ° ye-4H-N, Kwi-axis : <0001>±0.5 ° ye-4H-SI | ||||

| Ukuxinana kweMibhobho | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ukuxhathisa | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Ukuqhelaniswa neFlethi ePhambili | {10-10} ±5.0° | ||||

| Ubude beFlethi obuPhambili | 4H-N | N / A | |||

| 4H-SI | Inotshi | ||||

| Ukungabandakanywa kuMda | 3 mm | ||||

| LTV/TTV/Saphetha/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Uburhabaxa | IsiPolish Ra≤1 nm | ||||

| I-CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| I-Edge Cracks ngokuKhanya okuPhakamileyo Iipleyiti zeHex ngokuKhanya okuPhakamileyo Iindawo zePolytype ngokuKhanya okuPhakamileyo Ukubandakanywa kweCarbon ebonakalayo I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Akukho nanye Indawo eyongezelekayo ≤0.05% Akukho nanye Indawo eyongezelekayo ≤0.05% Akukho nanye | Ubude obongezelekayo ≤ 20 mm, ubude obunye≤2 mm Indawo eyongezelekayo ≤0.1% Indawo eyongezelekayo≤3% Indawo eyongezelekayo ≤3% Ubude obongezelekayo≤1×i-wafer idayamitha | |||

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥0.2mm ububanzi nobunzulu | I-7 ivunyelwe, ≤1 mm nganye | |||

| (TSD) Ukushenxiswa kwesikrufu somsonto | ≤500 cm-2 | N / A | |||

| (BPD) Isiseko sokuchithwa kwenqwelomoya | ≤1000 cm-2 | N / A | |||

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | Akukho nanye | ||||

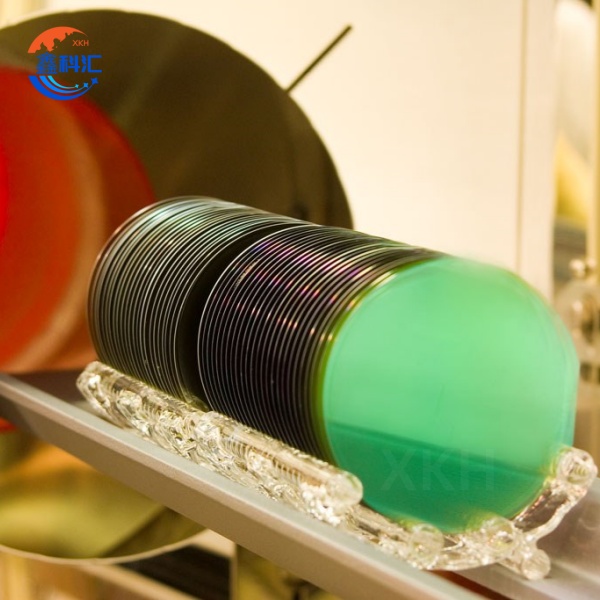

| Ukupakishwa | Multi-wafer Cassette Okanye Single Wafer Container | ||||

| Amanqaku: | |||||

| 1 Imida yeziphene isebenza kuwo wonke umphezulu we-wafer ngaphandle kwendawo yokukhutshwa komphetho. 2Imikrwelo kufuneka ijongwe kuSi face kuphela. 3 Idatha yokususa isuka kwi-KOH etshisiweyo kuphela. | |||||

Ezona mpawu

I-1.Umthamo wemveliso kunye neeNdleko zeNdleko: Ukuveliswa kobuninzi be-12-intshi ye-SiC substrate (i-12-intshi ye-silicon carbide substrate) ibonisa ixesha elitsha kwimveliso ye-semiconductor. Inani leetshiphusi ezifumaneka kwi-wafer enye lifikelela ku-2.25 ngokuphindwe kwi-8-intshi substrates, liqhuba ngokuthe ngqo ukutsiba ekusebenzeni kwemveliso. Ingxelo yoMthengi ibonisa ukuba ukwamkela i-substrates ye-intshi eyi-12 kuye kwanciphisa iindleko zabo zokuvelisa imodyuli yamandla ngama-28%, ukudala inzuzo eqinisekileyo yokukhuphisana kwimarike ekhuphisana ngokukrakra.

I-2.Iimpahla ezigqwesileyo zoMzimba: I-12-intshi ye-SiC substrate izuza zonke iingenelo zezinto ze-silicon carbide - i-conductivity yayo ye-thermal yi-3 yamaxesha e-silicon, ngelixa amandla ayo entsimi yokuphuka afikelela kumaxesha angama-10 e-silicon. Ezi mpawu zivumela izixhobo ezisekelwe kwii-substrates ze-intshi ezili-12 ukuba zisebenze ngokuzinzile kwiindawo eziphakamileyo zokushisa ezingaphezu kwe-200 ° C, okwenza ukuba zifaneleke ngokukodwa kwizicelo ezifunwayo ezifana neenqwelo zombane.

I-3.Ubuchwephesha boNyango lwe-Surface: Siye saqulunqa inkqubo ye-novel chemical mechanical polishing (CMP) ngokukodwa kwi-substrates ye-SiC ye-intshi eyi-12, ukufezekisa i-atomic-level surface flatness (Ra <0.15nm). Le mpumelelo isombulula umceli mngeni wehlabathi jikelele wonyango lomphezulu we-silicon carbide wafer wafer surface, ukususa imiqobo ekukhuleni komgangatho ophezulu we-epitaxial.

I-4.Ukusebenza koLawulo lwe-Thermal: Kwizicelo eziphathekayo, ii-substrates ze-SiC ze-12-intshi zibonisa amandla amangalisayo okutshatyalaliswa kobushushu. Idatha yokuvavanya ibonisa ukuba phantsi koxinzelelo lwamandla afanayo, izixhobo ezisebenzisa i-12-intshi substrates zisebenza kumaqondo okushisa angama-40-50 ° C ngaphantsi kwezixhobo ezisekelwe kwi-silicon, zandisa kakhulu ubomi benkonzo yezixhobo.

Izicelo eziphambili

1.I-Ecosystem yesiThuthi saMandla eNtsha: I-12-intshi ye-SiC substrate (i-12-intshi ye-silicon carbide substrate) iguqula i-architecture yombane wesithuthi sombane. Ukusuka kwiitshaja ze-onboard (OBC) ukuya kwii-inverters eziphambili kunye neenkqubo zokulawula ibhetri, ukuphuculwa kokusebenza okuziswa yi-12-intshi substrates kwandisa uluhlu lwezithuthi nge-5-8%. Iingxelo ezivela kwi-automaker ehamba phambili ibonisa ukuba ukwamkela i-substrates yethu ye-intshi eyi-12 kunciphisa ukulahlekelwa kwamandla kwinkqubo yabo yokutshaja ngokukhawuleza nge-62%.

I-2.Icandelo laMandla aHlaziywayo: Kwizikhululo zamandla e-photovoltaic, ii-inverters ezisekelwe kwi-12-intshi ye-SiC substrates azibonisi nje izinto ezincinci zefom kodwa zifezekisa ukusebenza kakuhle kokuguqulwa okudlula i-99%. Ingakumbi kwimiba esasazwayo yokuvelisa, olu buchule buphezulu buguqulela kugcino lonyaka lwamakhulu amawaka eeyuan kwilahleko yombane kubasebenzi.

I-3.Industrial Automation: Abaguquli bee-frequency abasebenzisa i-12-intshi substrates babonisa ukusebenza kakuhle kwiirobhothi zoshishino, izixhobo zomatshini we-CNC, kunye nezinye izixhobo. Iimpawu zabo zokutshintsha kwe-frequency ephezulu ziphucula isantya sokuphendula i-motor nge-30% ngelixa behlisa ukuphazamiseka kwe-electromagnetic kwisinye kwisithathu sezisombululo eziqhelekileyo.

I-4.I-Consumer Electronics Innovation: Isizukulwana esilandelayo seteknoloji ye-smartphone yokutshaja ngokukhawuleza sele iqalile ukwamkela i-12-intshi ye-SiC substrates. Kuqikelelwa ukuba iimveliso zokutshaja ngokukhawuleza ngaphezulu kwe-65W ziya kutshintshela ngokupheleleyo kwizisombululo ze-silicon carbide, kunye ne-12-intshi ye-substrates evelayo njengolona khetho lufanelekileyo lweendleko.

Iinkonzo eziLungisiweyo ze-XKH ze-12-intshi ye-SiC Substrate

Ukuhlangabezana neemfuno ezithile ze-12-intshi ye-SiC substrates (i-12-intshi ye-silicon carbide substrates), i-XKH inikezela ngenkxaso yenkonzo ebanzi:

1.Ukutyeba ngokwezifiso:

Sibonelela ngee-12-intshi substrates kwiinkcukacha ezahlukeneyo zobunzima kubandakanya i-725μm ukuhlangabezana neemfuno ezahlukeneyo zesicelo.

2. Uxinzelelo lwedoping:

Imveliso yethu isekela iintlobo ezininzi ze-conductivity ezibandakanya i-n-type kunye ne-p-type substrates, kunye nolawulo oluchanekileyo lokumelana noluhlu lwe-0.01-0.02Ω · cm.

3. Iinkonzo zoVavanyo:

Ngezixhobo ezipheleleyo zokuvavanya i-wafer-level, sinikezela ngeengxelo zokuhlola ezipheleleyo.

I-XKH iyaqonda ukuba umthengi ngamnye uneemfuno ezizodwa ze-12-intshi ye-SiC substrates. Ke ngoko sibonelela ngeemodeli zentsebenziswano yeshishini eziguquguqukayo ukubonelela ngezona zisombululo zikhuphisanayo, nokuba:

· Iisampulu zeR&D

· Ukuthengwa komthamo womthamo

Iinkonzo zethu ezilungiselelweyo ziqinisekisa ukuba sinokuhlangabezana neemfuno zakho zobugcisa kunye nemveliso ye-12-intshi ye-SiC substrates.