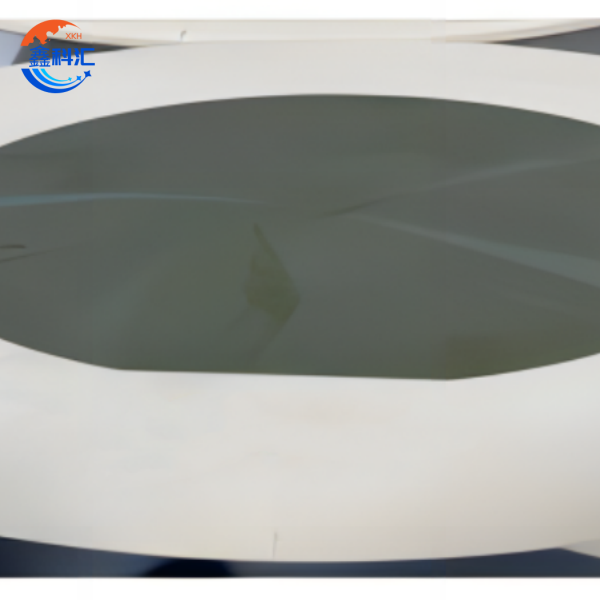

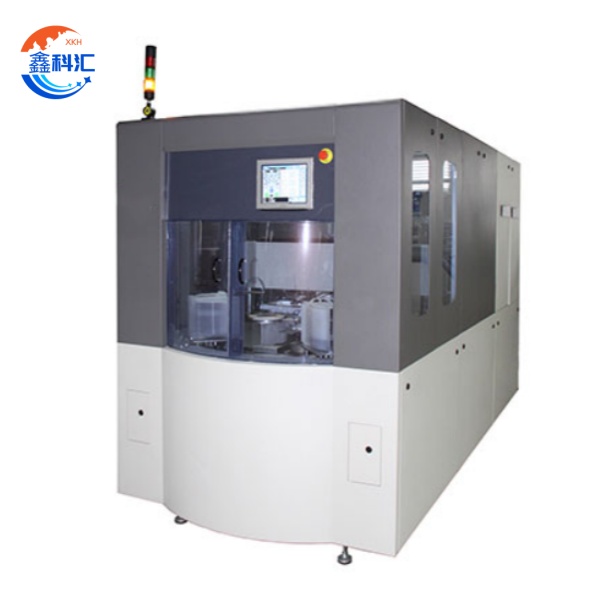

IsiXhobo se-Wafer Thinning se-4 Intshi-12 Intshi yeSapphire/SiC/Si Wafers Processing

UmGaqo wokuSebenza

Inkqubo yokunciphisa i-wafer isebenza ngokwamanqanaba amathathu:

Ukusila ngokurhabaxa: Ivili ledayimane (ubungakanani begrit 200–500 μm) lisusa i-50–150 μm yezinto kwi-3000–5000 rpm ukunciphisa ngokukhawuleza ubukhulu.

Ukugaya kakuhle: Ivili elicolekileyo (ubungakanani begrit 1-50 μm) linciphisa ubukhulu ukuya kwi-20-50 μm kwi-<1 μm / s ukunciphisa umonakalo ongaphantsi komhlaba.

Ukupholisa (CMP): I-chemical-mechanical slurry isusa umonakalo oseleyo, ukuphumeza i-Ra <0.1 nm.

Izinto ezihambelanayo

I-Silicon (Si): Umgangatho wee-wafers ze-CMOS, ezincitshiswe ukuya kwi-25 μm ngokupakishwa kwe-3D.

I-Silicon Carbide (i-SiC): Ifuna amavili edayimani akhethekileyo (i-80% ye-diamond concentration) yokuzinza kwe-thermal.

ISapphire (Al₂O₃): Icutshiwe ukuya kwi-50 μm ye-UV ye-LED yezicelo.

Amacandelo eNkqubo engundoqo

1. Inkqubo yokugaya

I-Dual-Axis Grinder: Idibanisa i-coarse/fine grinder kwiqonga elinye, ukunciphisa ixesha lomjikelo nge-40%.

I-Aerostatic Spindle: 0-6000 rpm uluhlu lwesantya kunye <0.5 μm yokukhutshwa kweradial.

2. Inkqubo yokuphatha iWafer

Vacuum Chuck: >50 N ukubamba amandla kunye ± 0.1 μm ukuchaneka kokuma.

Ingalo yeRobhothi: Ithutha ii-wafers eziyi-4-12-intshi nge-100 mm/s.

3. Inkqubo yokulawula

I-Laser Interferometry: Ukujongwa kobungakanani bexesha lokwenyani (isisombululo 0.01 μm).

I-AI-Driven Feedforward: Iqikelela ukunxitywa kwevili kwaye ihlengahlengise iiparamitha ngokuzenzekelayo.

4. Ukupholisa nokuCoca

Ukucocwa kwe-Ultrasonic: Susa amasuntswana> 0.5 μm ngobuchule obungama-99.9%.

Amanzi aDionized: Ukupholisa iwafer ukuya ku-<5°C ngaphezu kwe-ambient.

Iingenelo ezingundoqo

1. I-Ultra-High Precision: i-TTV (uLwahluko olupheleleyo lokutyeba) <0.5 μm, i-WTW (Ngaphakathi kwe-Wafer Ukutyeba ukwahluka) <1 μm.

2. Ukudityaniswa kweeNkqubo ezininzi: Ukudibanisa ukugaya, i-CMP, kunye ne-plasma etching kumatshini omnye.

3. Ukuhambelana kwezinto:

I-Silicon: Ukunciphisa ukutyeba ukusuka kwi-775 μm ukuya kwi-25 μm.

I-SiC: Iphunyeziwe <2 μm TTV yezicelo zeRF.

IiWafers ezifakwe kwi-Doped: I-Phosphorus-doped InP wafers ene-<5% resistivity drift.

4. I-Smart Automation: Ukudityaniswa kwe-MES kunciphisa impazamo yomntu nge-70%.

5. UkuSebenza koMbane: i-30% yokusetyenziswa kwamandla aphantsi ngokusebenzisa i-regenerative braking.

Usetyenziso oluphambili

1. Ukupakishwa okuPhakamileyo

• I-3D ICs: I-Wafer thinning yenza ukupakishwa okuthe nkqo kwee-logic/memory chips (umzekelo, izitaki ze-HBM), ukufikelela kwi-10× ephezulu ye-bandwidth kunye ne-50% ecuthiweyo ukusetyenziswa kwamandla xa kuthelekiswa nezisombululo ze-2.5D. Izixhobo zixhasa i-hybrid bonding kunye ne-TSV (Nge-Silicon Via) ukuhlanganiswa, okubalulekileyo kwi-AI / ML processors efuna <10 μm interconnect pitch. Ngokomzekelo, ii-wafers ze-intshi ezili-12 ezincitshiswe ukuya kwi-25 μm zivumela ukupakisha iileya ezi-8+ ngelixa zigcina <1.5% iphepha lokulwa, eliyimfuneko kwiinkqubo ze-LiDAR zemoto.

• Ukupakishwa kweFan-Out: Ngokunciphisa ubukhulu bewafer ukuya kuma-30 μm, ubude boqhagamshelwano bufinyezwa nge-50%, kucuthwe ukulibaziseka komqondiso (<0.2 ps/mm) kunye nokwenza i-0.4 mm ultra-thin chiplets kwii-SoCs ezihambayo. Inkqubo inyusa uxinezeleko-imbuyekezo ye-algorithms yokusila ukunqanda i-warpage (>50 μm ulawulo lwe-TTV), iqinisekisa ukuthembeka kwizicelo ze-RF ze-frequency ephezulu.

2. Umbane woMbane

• Iimodyuli ze-IGBT: Ukucutha ukuya kwi-50 μm kunciphisa ukuxhathisa kwe-thermal ku-<0.5 ° C / W, okwenza i-1200V SiC MOSFETs isebenze kwi-200 ° C yokushisa kwe-junction. Izixhobo zethu zisebenzisa amanqanaba amaninzi okusila(coarse: 46 μm grit → fine: 4 μm grit) ukuphelisa umonakalo ongaphantsi komhlaba, ukuphumeza > imijikelo eyi-10,000 yokuthembeka kwebhayisekile eshushu. Oku kubalulekile kwii-inverters ze-EV, apho i-10 μm-engqingqwa ye-SiC wafers iphucula isantya sokutshintsha nge-30%.

• Izixhobo zaMandla ze-GaN-on-SiC: I-Wafer ebhityileyo ukuya kwi-80 μm iphucula ukushukuma kwe-electron (μ > 2000 cm²/V·s) kwi-650V GaN HEMTs, inciphisa ilahleko yokuqhuba nge-18%. Inkqubo isebenzisa i-laser-assisted dicing ukunqanda ukuqhekeka ngexesha lokubhitya, ukufezekisa <5 μm edge chipping kwizikhulisi zamandla eRF.

3. Optoelectronics

• Ii-LED ze-GaN-on-SiC: I-50 μm i-sapphire substrates iphucula ukusebenza kakuhle kokutsalwa kokukhanya (LEE) ukuya kwi-85% (vs. 65% ye-150 μm wafers) ngokunciphisa i-photon trapping. Isixhobo sethu solawulo lwe-TTV esisezantsi kakhulu (<0.3 μm) siqinisekisa ukukhutshwa kwe-LED efanayo kuzo zonke ii-wafers eziyi-intshi ezili-12, zibaluleke kakhulu kwiziboniso ze-Micro-LED ezifuna <100nm ubude obufanayo.

• I-Silicon Photonics: I-25μm-engqingqwa ye-silicon wafers yenza ukuba i-3 dB / cm ilahleko ephantsi yokusabalalisa kwii-waveguides, ibalulekile kwi-1.6 Tbps i-transceivers optical. Inkqubo idibanisa i-CMP smoothing ukunciphisa uburhabaxa bomhlaba kwi-Ra <0.1 nm, ukuphucula ukudibanisa ukusebenza kakuhle nge-40%.

4. IiSensors zeMEMS

• I-Accelerometers: I-25 μm ii-silicon wafers zifikelela kwi-SNR >85 dB (vs. 75 dB for 50 μm wafers) ngokwandisa ubungqina bobunzima bokufuduka. Inkqubo yethu yokugaya i-double-axis ihlawulela ukuthambeka koxinzelelo, iqinisekisa u-<0.5% ubuntununtunu bukhukuliseka ngaphezulu kwe-40°C ukuya kwi-125°C. Usetyenziso lubandakanya ukubhaqwa kokuntlitheka kweemoto kunye nokulandelwa kwentshukumo ye-AR/VR.

• IziBoni zoxinzelelo: Ukucutha ukuya kuma-40 μm kuvumela ukuba u-0–300 woluhlu lomlinganiselo webha kunye ne-<0.1% ye-FS hysteresis. Ukusebenzisa i-bonding okwethutyana (i-glass carriers), inkqubo inqanda ukuphuka kwe-wafer ngexesha lokulinganisa ngasemva, ukufezekisa <1 μm ukunyamezela koxinzelelo kwi-ioT ye-industrial sensors.

• I-Technical Synergy: Isixhobo sethu sokunciphisa i-wafer simanyanisa ukucola koomatshini, i-CMP, kunye ne-plasma etching ukujongana nemiceli mngeni eyahlukeneyo (i-Si, i-SiC, iSapphire). Umzekelo, i-GaN-on-SiC idinga ukucola okuxutyiweyo (amavili edayimane + iplasma) ukulinganisa ubulukhuni kunye nokwandiswa kwe-thermal, ngelixa izinzwa ze-MEMS zifuna uburhabaxa bomphezulu obungaphantsi kwe-5 nm ngokupolisha kweCMP.

• Impembelelo yoShishino: Ngokuvumela ii-wafers ezithambileyo, eziphezulu zokusebenza, obu buchwepheshe buqhuba izinto ezintsha kwii-chips ze-AI, iimodyuli ze-5G mmWave, kunye ne-electronics flexible, kunye nokunyamezela kwe-TTV <0.1 μm yeziboniso ezisongekayo kunye ne-<0.5 μm ye-automotive sensors ye-LiDAR.

Iinkonzo ze-XKH

1. Izisombululo ezenzelwe wena

Ulungelelwaniso olunokukhawuleza: Uyilo lwegumbi le-4-12-intshi kunye nokulayisha okuzenzekelayo / ukukhulula.

Inkxaso ye-Doping: Iiresiphi eziqhelekileyo ze-Er/Yb-doped crystals kunye ne-InP/GaAs wafers.

2. Inkxaso yokuphela ukuya ekupheleni

Uphuhliso Lwenkqubo: Ulingo lwasimahla luqhutywa ngokulungiselela.

UQeqesho lweHlabathi: Iindibano zocweyo zobuchwephesha rhoqo ngonyaka malunga nokugcinwa kunye nokusombulula ingxaki.

3. Ukulungiswa kwezinto ezininzi

I-SiC: I-Wafer iyancipha ukuya kwi-100 μm kunye neRa <0.1 nm.

Isafire: 50μm ubukhulu kwiifestile ze-UV laser (ukudluliselwa>92%@200 nm).

4. Iinkonzo ezongeziweyo kwiXabiso

Ubonelelo oluThengiswayo: Amavili edayimani (2000+ wafers / ubomi) kunye ne-CMP slurries.

Ukuqukumbela

Esi sixhobo sokunciphisa i-wafer sihambisa ukuchaneka okukhokelayo kwishishini, ukuguquguquka kwezinto ezininzi, kunye ne-automation ehlakaniphile, iyenza ibe yimfuneko ekudityanisweni kwe-3D kunye nombane wamandla. Iinkonzo ezibanzi ze-XKH-ukusuka ngokwezifiso ukuya kwi-post-processing-ukuqinisekisa ukuba abathengi bafezekisa iindleko ezifanelekileyo kunye nokugqwesa kokusebenza kwimveliso ye-semiconductor.