Inkqubo yokuJonga iWafer yoMlinganiselo wokuJongene neCrystal

Intshayelelo yeZixhobo

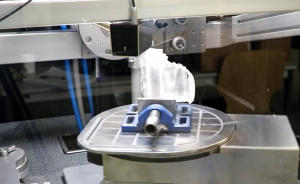

Izixhobo zokuqhelaniswa ne-wafer zizixhobo ezichanekileyo ezisekwe kwimigaqo ye-X-ray diffraction (XRD), esetyenziswa ikakhulu kwimveliso ye-semiconductor, imathiriyeli ebonakalayo, iiseramikhi, kunye namanye amashishini ezinto ezikristale.

Ezi zixhobo zimisela i-crystal lattice orientation kunye nesikhokelo esichanekileyo sokusika okanye iinkqubo zokupolisha. Iimpawu eziphambili ziquka:

- Imilinganiselo yokuchaneka okuphezulu:Iyakwazi ukusombulula iindiza zecrystallographic ezinezisombululo ze-angular ukuya kuthi ga kwi-0.001 °.

- Isampulu ehambelanayo enkulu:Ixhasa ama-wafers ukuya kuthi ga kwi-450 mm ububanzi kunye nobunzima obungama-30 kg, alungele izixhobo ezifana nesilicon carbide (SiC), isafire, kunye nesilicon (Si).

- Uyilo lwemodyuli:Imisebenzi eyongezelelweyo ibandakanya uhlalutyo lwe-rocking curve, imephu ye-3D yesiphene somgangatho, kunye nezixhobo zokupakisha zokusetyenzwa kweesampulu ezininzi.

IiParameters eziphambili zobuGcisa

| Uluhlu lweParameter | Amaxabiso aqhelekileyo/Uqwalaselo |

| Umthombo weX-ray | I-Cu-Kα (indawo ekugxilwe kuyo yi-0.4×1 mm), 30 kV amandla ombane akhawulezayo, 0–5 mA ityhubhu ehlengahlengiswayo ngoku |

| Uluhlu lweAngular | θ: -10 ° ukuya +50 °; 2θ: -10° ukuya +100° |

| Ukuchaneka | Isisombululo se-angle ethambekileyo: 0.001 °, ukubonwa kwesiphene somphezulu: ± 30 arcseconds (ijika elijikajikayo) |

| Isantya sokuskena | Ukuskena kwe-Omega kugqiba ukuqhelaniswa ne-lattice epheleleyo kwimizuzwana emi-5; Ukuskena kweTheta kuthatha ~1 umzuzu |

| Inqanaba leSampuli | I-V-groove, ukufunxa umoya, ukujikeleziswa kwee-angle ezininzi, iyahambelana nee-intshi ezi-2–8 zeewafers |

| Imisebenzi Eyandiswayo | Uhlalutyo oluguquguqukayo lwegophe, imephu ye-3D, isixhobo sokupakisha, ukubonwa kwesiphene samehlo (imikrwelo, ii-GBs) |

Umgaqo wokuSebenza

1. X-ray Diffraction Foundation

- I-X-rays isebenzisana ne-nuclei ye-athomu kunye nee-electron kwi-crystal lattice, ivelisa iipateni zokuphazamiseka. Umthetho kaBragg (nλ = 2d sinθ) ulawula unxulumano phakathi kwee-engile ze-diffraction (θ) kunye nesithuba se-lattice (d).

Ii-detectors zibamba ezi patheni, ezihlalutywayo ukuze kwakhiwe ngokutsha ubume becrystallographic.

2. Itekhnoloji yokuskena ye-Omega

- Ikristale ijikeleza ngokuqhubekayo malunga ne-axis esisigxina ngelixa i-X-reyi iyikhanyisa.

- Abachongi baqokelela imiqondiso ye-diffraction kwiinqwelomoya ezininzi zecrystallographic, zivumela ukuzimisela kokuma kwe-lattice epheleleyo kwimizuzwana emi-5.

3. Uhlalutyo lwe-Rocking Curve

- I-angle ye-crystal elungisiweyo kunye nee-engile ze-X-reyi ezihlukeneyo zokulinganisa ububanzi be-peak (FWHM), ukuvavanya iziphene ze-lattice kunye noxinzelelo.

4. Ulawulo oluzenzekelayo

- I-PLC kunye ne-touchscreen interfaces yenza i-engile yokusika i-preset, impendulo yexesha langempela, kunye nokudibanisa kunye noomatshini bokusika kulawulo oluvaliweyo.

Izinto eziluncedo kunye neempawu

1. Ukuchaneka kunye nokusebenza ngokufanelekileyo

- Ukuchaneka kwe-angular ± 0.001 °, isisombululo sokufumanisa isiphene <30 arcseconds.

- Isantya sokuskena se-Omega si-200 × ngokukhawuleza kuneskeni se-Theta yesintu.

2. I-Modularity kunye ne-Scalability

- Zinokwandiswa kwizicelo ezikhethekileyo (umzekelo, ii-wafers ze-SiC, iiblade zeinjini yomoya).

- Idibanisa neenkqubo ze-MES zokubeka iliso kwimveliso yexesha lokwenyani.

3. Ukuhambelana kunye nokuzinza

- Ithatha iisampulu ezinemilo engaqhelekanga (umzekelo, iingothi zesafire eziqhekekileyo).

- Uyilo olupholileyo lomoya lunciphisa iimfuno zokugcina.

4. Ukusebenza ngobukrelekrele

- Ukucofa-kanye ukulinganisa kunye nokusetyenzwa kwemisebenzi emininzi.

- Ukulinganisa okuzenzekelayo ngeekristale zokubhekisela ukunciphisa impazamo yomntu.

Usetyenziso

1. Ukwenziwa kweSemiconductor

- I-Wafer dicing orientation: Imisela iSi, iSiC, i-GaN wafer orientation for optimized cut performance.

- Imephu eneziphene: Ichonga imikrwelo yomphezulu okanye ukususwa kwindawo yokuphucula isivuno setshiphu.

2. Izinto ezibonwayo

- Iikristale ezingabonakaliyo (umzekelo, i-LBO, i-BBO) yezixhobo ze-laser.

- Isalathiso somphezulu weSapphire sokumakishwa kwe substrates ze-LED.

3. IiCeramics kunye neeComposites

- Ihlalutya i-grain orientation kwi-Si3N4 kunye ne-ZrO2 yezicelo eziphezulu zokushisa.

4. UPhando kunye noLawulo loMgangatho

- Iidyunivesithi/ielebhu zophuhliso lwemathiriyeli yenoveli (umzekelo, iialloyi ezine-entropy ephezulu).

- I-QC yoshishino ukuqinisekisa ukuhambelana kwebhetshi.

Iinkonzo ze-XKH

I-XKH inikezela ngenkxaso yobuchwephesha bomjikelo wobomi kwizixhobo zokuqhelaniswa newafer, kubandakanywa ukufakela, inkqubo yokwenziwa kweparamitha, uhlalutyo lwejiko lokugungqa, kunye nemephu yesiphene somphezulu we-3D. Izisombululo ezilungelelanisiweyo (umzekelo, iteknoloji yokupakishwa kwe-ingot) zibonelelwa ukuphucula i-semiconductor kunye nemveliso yemathiriyeli ebonakalayo ngaphezulu kwe-30%. Iqela elizinikeleyo liqhuba uqeqesho lwendawo, ngelixa i-24/7 inkxaso ekude kunye nokutshintshwa ngokukhawuleza kwe-spare part iqinisekisa ukuthembeka kwezixhobo.