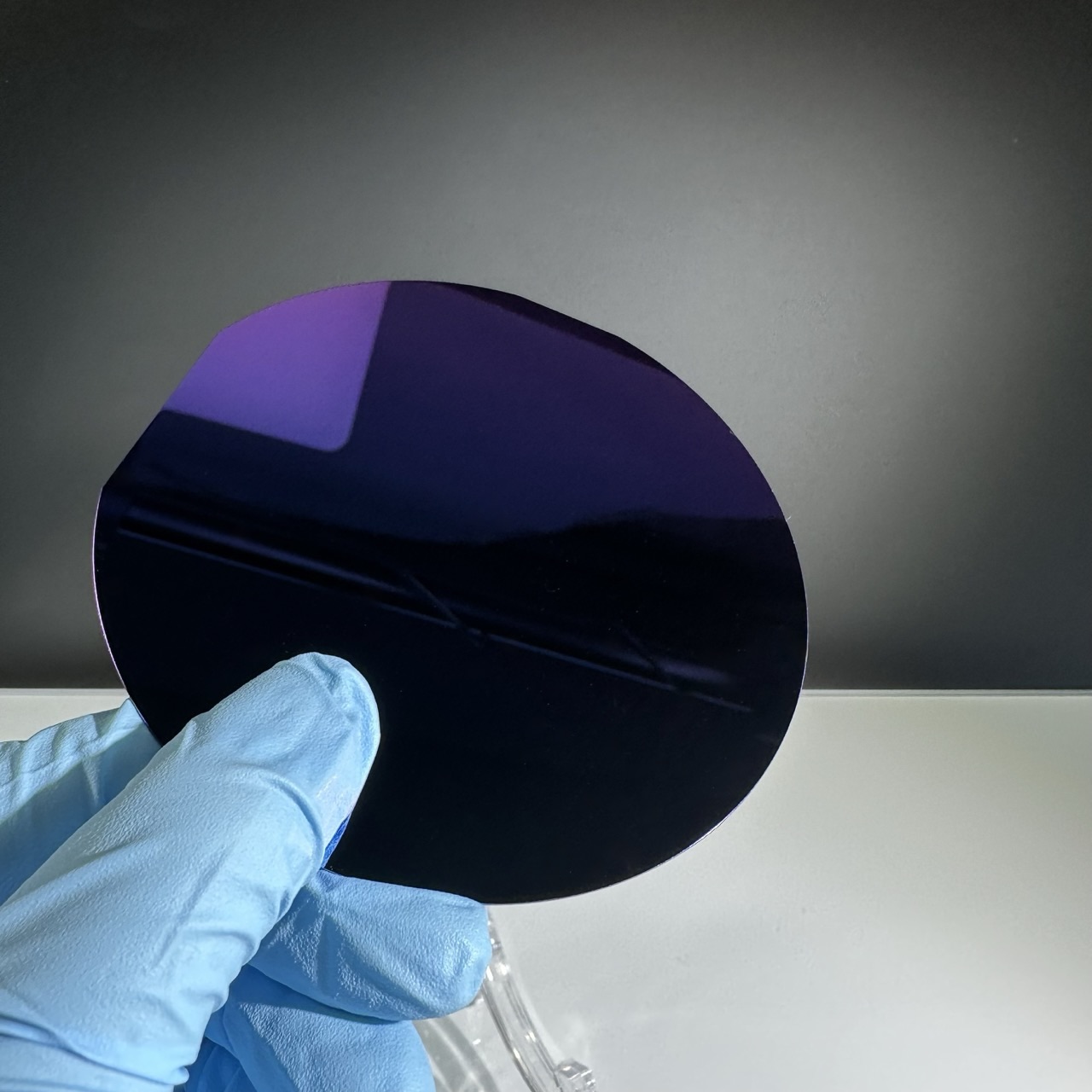

Silicon Dioxide wafer SiO2 wafer etyebileyo egudisiweyo, Prime kunye neBanga loVavanyo

Ukwazisa ngebhokisi ye-wafer

| Imveliso | Iziphaluka ze-Thermal oxide (Si+SiO2). |

| Indlela yokuvelisa | I-LPCVD |

| Ukuguquguquka komphezulu | SSP/DSP |

| Ububanzi | 2inch/3inch/4inch/5inch/6inch |

| Uhlobo | Uhlobo lwe-P / N uhlobo |

| Ukutyeba kweLayer ye-Oxidation | 100nm ~1000nm |

| Ukuqhelaniswa | <100> <111> |

| Ukumelana nombane | 0.001-25000(Ω•cm) |

| Isicelo | Isetyenziselwa i-synchrotron radiation carrier carrier, i-PVD/CVD yokugquma njenge-substrate, isampuli yokukhula ye-magnetron sputtering, i-XRD, i-SEM,Amandla e-atom, i-infrared spectroscopy, i-fluorescence spectroscopy kunye nezinye iisubstrates zokuvavanya uhlalutyo, i-molecular beam epitaxial substrates yokukhula, uhlalutyo lwe-X-ray yee-crystalline semiconductors. |

I-Silicon oxide wafers ziifilimu ze-silicon dioxide ezikhule kumphezulu we-silicon wafers ngokusebenzisa i-oxygen okanye umphunga wamanzi kumaqondo aphezulu (800 ° C ~ 1150 ° C) usebenzisa inkqubo ye-oxidation ye-thermal kunye ne-atmospheric pressure furnace tool. Ubukhulu benkqubo buvela kwi-nanometers ezingama-50 ukuya kwi-microns ezi-2, ubushushu benkqubo bufikelela kwi-1100 degrees Celsius, indlela yokukhula yahlulwe ibe "i-oksijini emanzi" kunye "ne-oksijini eyomileyo" iindidi ezimbini. I-Thermal Oxide ngumaleko weoksidi "okhulileyo", onokulingana okuphezulu, ukuxinana okungcono kunye namandla aphezulu e-dielectric kune-CVD efakwe i-oxide layers, ekhokelela kumgangatho ophezulu.

I-Oxygen Oxidation eyomileyo

I-silicon iphendula kunye ne-oksijini kwaye i-oxide layer iqhubela phambili kwi-substrate layer. I-oxidation eyomileyo kufuneka yenziwe kumaqondo okushisa ukusuka kwi-850 ukuya kwi-1200 ° C, kunye namazinga aphantsi okukhula, kwaye ingasetyenziselwa ukukhula kwesango le-MOS insulated. I-oxidation eyomileyo ikhethwa ngaphezu kwe-oxidation emanzi xa umgangatho ophezulu, i-ultra-thin silicon oxide layer ifuneka. Umthamo we-oxidation owomileyo: 15nm ~ 300nm.

2. I-Oxidation emanzi

Le ndlela isebenzisa umphunga wamanzi ukwenza umaleko we-oxide ngokufaka ityhubhu yesithando somlilo phantsi kweemeko eziphezulu zokushisa. Uxinaniso lwe-oxidation ye-oksijeni emanzi mbi kancinane kune-oxidation ye-oksijeni eyomileyo, kodwa xa kuthelekiswa ne-oxidation ye-oksijini eyomileyo inzuzo yayo kukuba inezinga eliphezulu lokukhula, elifanele ngaphezu kwe-500nm yokukhula kwefilimu. Umthamo we-oxidation omanzi: 500nm ~ 2µm.

I-AEMD ye-atmospheric pressure oxidation furnace tube yi-tube yesithando somlilo saseCzech, ebonakaliswe ngokuzinza okuphezulu kwenkqubo, ukufana okuhle kwefilimu kunye nokulawula i-particle ephezulu. I-silicon oxide furnace ityhubhu inokusebenza ukuya kuthi ga kwi-50 wafers ngetyhubhu nganye, kunye nokufana okugqwesileyo kwe-intra- kunye ne-inter-wafers.

Idayagram eneenkcukacha