I-SICOI (i-Silicon Carbide kwi-Insulator) I-Wafers ye-SiC Film KWI-Silicon

Idayagram eneenkcukacha

Ukwazisa ngeSilicon Carbide kwi-Insulator (SICOI) wafers

I-Silicon Carbide kwi-Insulator (SICOI) iiwafers zesizukulwana esilandelayo semiconductor substrates ezidibanisa iipropathi eziphezulu zomzimba kunye ne-elektroniki ze-silicon carbide (SiC) kunye neempawu ezibalaseleyo zokuhlukaniswa kombane ze-insulating buffer layer, njenge-silicon dioxide (SiO₂) okanye i-silicon nitride (Si₃N₄). I-wafer ye-SICOI eqhelekileyo iquka umaleko obhityileyo we-epitaxial we-SiC, ifilimu ephakathi ekhuselayo, kunye nesiseko esixhasayo, esinokuba yisilicon okanye i-SiC.

Esi sakhiwo sixutywe ngobunjineli benzelwe ukuhlangabezana neemfuno ezingqongqo zamandla aphezulu, amaza omoya aphezulu, kunye nobushushu obuphezulu bezixhobo zombane. Ngokubandakanya i-insulating layer, ii-wafers ze-SICOI zinciphisa i-parasitic capacitance kunye nokucinezela imisinga yokuvuza, ngaloo ndlela iqinisekisa ukuhamba okuphakamileyo kokusebenza, ukusebenza kakuhle, kunye nokuphucula ulawulo lwe-thermal. Ezi zibonelelo zibenza baxabiseke kakhulu kumacandelo afana nezithuthi zombane, iziseko zonxibelelwano ze-5G, iisistim ze-aerospace, ii-elektroniki ze-RF eziphambili, kunye nobuchwepheshe boluvo lwe-MEMS.

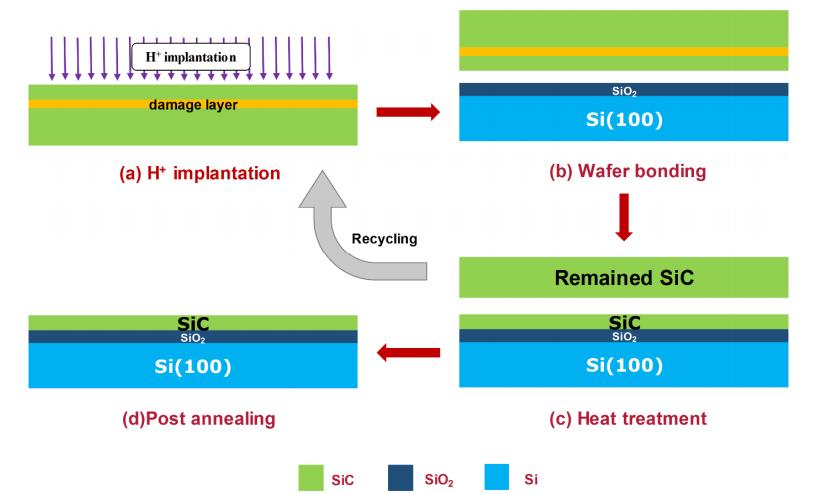

UMgaqo woMveliso we-SICOI Wafers

I-SICOI (i-Silicon Carbide kwi-Insulator) ii-wafers zenziwa ngokuphambilii-wafer bonding kunye nenkqubo yokunciphisa:

-

Ukukhula kweSubstrate yeSiC- I-wafer ye-SiC ye-crystal eyodwa ephezulu ye-crystal (4H / 6H) ilungiselelwe njengento yomnikeli.

-

I-Insulating Layer Deposition- Ifilimu ekhuselayo (i-SiO₂ okanye i-Si₃N₄) yenziwe kwi-carrier carrier (Si okanye i-SiC).

-

I-Wafer Bonding-I-wafer ye-SiC kunye ne-carrier carrier idibene kunye phantsi kobushushu obuphezulu okanye uncedo lwe-plasma.

-

Ukubhitya kunye nokugudiswa-Isiqwenga somnikeli we-SiC sincitshiswe phantsi ukuya kwii-micrometer ezimbalwa kwaye ipolishiwe ukufikelela kwindawo egudileyo ye-atom.

-

Uhlolo lokugqibela– I-wafer ye-SICOI egqityiweyo ivavanyelwa ukufana kobungqimba, uburhabaxa bomphezulu, kunye nokusebenza kokugquma.

Ngale nkqubo, aumaleko obhityileyo we-SiC osebenzayokunye neempawu ezibalaseleyo zombane kunye ne-thermal idibaniswa nefilimu yokukhusela kunye ne-substrate yenkxaso, ukudala iqonga eliphezulu lokusebenza kumandla wesizukulwana esilandelayo kunye nezixhobo zeRF.

Izinto eziluncedo ezingundoqo ze-SICOI Wafers

| Udidi lweFeature | Iimpawu zobuGcisa | IiNzuzo ezingundoqo |

|---|---|---|

| Ulwakhiwo Lwezinto eziphathekayo | 4H/6H-SiC umaleko osebenzayo + ifilimu ekhuselayo (SiO₂/Si₃N₄) + Si okanye iSiC carrier | Ifezekisa ukuhlukaniswa kombane okunamandla, kunciphisa ukuphazamiseka kwe-parasitic |

| Iipropati zoMbane | Amandla okuphuka okuphezulu (> 3 MV / cm), ilahleko ephantsi ye-dielectric | Ilungiselelwe ukusebenza kwe-high-voltage kunye ne-high-frequency operation |

| Iipropati zoThermal | I-Thermal conductivity ukuya kwi-4.9 W/cm·K, izinzile ngaphezu kwe-500°C | Ukutshatyalaliswa kobushushu obusebenzayo, ukusebenza kakuhle phantsi kwemithwalo enzima yokushisa |

| Iipropati zoomatshini | Ubunzima obugqithisileyo (i-Mohs 9.5), i-coefficient ephantsi yokwandiswa kwe-thermal | Yomelele ngokuchasene noxinzelelo, yongeza ixesha elide lesixhobo |

| Umgangatho womphezulu | Umphezulu ogudileyo kakhulu (Ra <0.2 nm) | Ikhuthaza i-epitaxy engenasiphene kunye nokwenziwa kwesixhobo esithembekileyo |

| I-Insulation | Ukuxhathisa >10¹⁴ Ω·cm, ukuvuza okuphantsi kwangoku | Ukusebenza okuthembekileyo kwi-RF kunye nezicelo zokuzihlukanisa eziphezulu ze-voltage |

| Ubungakanani kunye nokwenza ngokwezifiso | Ifumaneka kwiifomathi ze-4, 6, kunye ne-8-intshi; Ubukhulu beSiC yi-1–100 μm; ukugquma 0.1-10 μm | Uyilo oluguquguqukayo lweemfuno ezahlukeneyo zesicelo |

IiNdawo zeSicelo ezingundoqo

| Icandelo leSicelo | Iimeko zokuSebenza eziQhelekileyo | Iinzuzo zokuSebenza |

|---|---|---|

| I-Electronics yamandla | Ii-inverters ze-EV, izikhululo zokutshaja, izixhobo zamandla oshishino | I-voltage ephezulu yokuphuka, ukunciphisa ilahleko yokutshintsha |

| RF & 5G | Izikhulisi zamandla kwisikhululo sesiseko, izixhobo zemilimitha-amaza | I-parasitics ephantsi, ixhasa imisebenzi yoluhlu lwe-GHz |

| Iinzwa zeMEMS | I-Harsh-environment sensors pressure, i-MEMS yebakala lokuhamba | Ukuzinza okuphezulu kwe-thermal, ukumelana nemitha |

| I-Aerospace kunye noKhuseleko | Unxibelelwano lweSatellite, iimodyuli zamandla e-avionics | Ukuthembeka kubushushu obugqithisileyo kunye nokuba sesichengeni ngemitha |

| I-Smart Grid | Iziguquli ze-HVDC, i-slid-state circuit breakers | Ukugquma okuphezulu kunciphisa ilahleko yamandla |

| Optoelectronics | Ii-LED ze-UV, i-laser substrates | Umgangatho ophezulu wekristale uxhasa ukukhutshwa kokukhanya okusebenzayo |

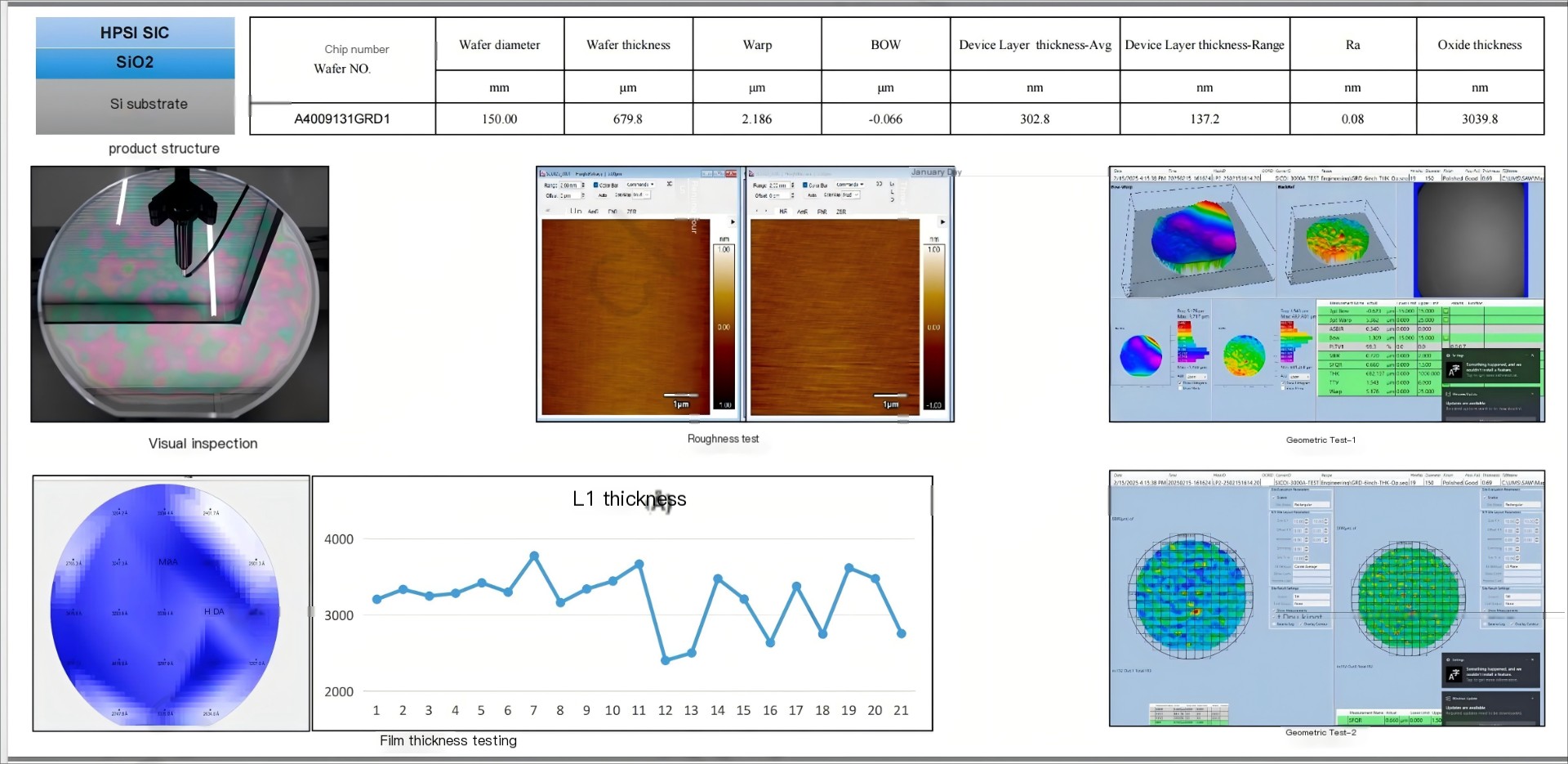

Ukuqulunqwa kwe-4H-SiCOI

Ukuveliswa kwee-wafers ze-4H-SiCOI kufezekiswa ngokusebenzisai-wafer bonding kunye neenkqubo zokunciphisa, eyenza ujongano oluphezulu lwe-insulating kunye neengqimba ezisebenzayo ze-SiC ezingenasiphako.

-

a: I-Schematic ye-4H-SiCOI yokwenziwa kweqonga lezinto eziphathekayo.

-

b: Umfanekiso we-4-intshi ye-4H-SiCOI ye-wafer usebenzisa i-bonding kunye nokunciphisa; iindawo ezineziphene eziphawulweyo.

-

c: Ukutyeba ukufana okufanayo kwe-substrate ye-4H-SiCOI.

-

d: Umfanekiso obonakalayo we-4H-SiCOI yokufa.

-

e: Ukuhamba kwenkqubo yokwenza i-SiC microdisk resonator.

-

f: I-SEM ye-microdisk resonator egqityiweyo.

-

g: I-SEM eyandisiweyo ebonisa udonga olusecaleni lweresonator; Iseti ye-AFM ibonisa ukuguda komphezulu we-nanoscale.

-

h: I-SEM enqamlezileyo ebonisa umphezulu omile okweparaboli.

FAQ kwiSICOI Wafers

I-Q1: Zeziphi iingenelo ii-wafers ze-SICOI ezinazo ngaphezu kwee-wafers ze-SiC eziqhelekileyo?

I-A1: Ngokungafani nee-substrates ze-SiC eziqhelekileyo, ii-wafers ze-SICOI ziquka i-insulating layer eyanciphisa i-parasitic capacitance kunye nokuvuza kwamanzi, okukhokelela ekusebenzeni okuphezulu, ukuphendula ngokuphindaphindiweyo, kunye nokusebenza okuphezulu kwe-thermal.

Q2: Zeziphi iisayizi zewafer ezifumanekayo?

A2: SICOI wafers ziqhele ukuveliswa 4-intshi, 6-intshi, kunye 8-intshi iifomati, kunye SiC customized kunye insulating umaleko ubukhulu ekhoyo ngokuxhomekeke kwiimfuno isixhobo.

I-Q3: Ngawaphi amashishini azuza kakhulu kwii-wafers ze-SICOI?

I-A3: Amashishini abalulekileyo abandakanya amandla e-electronics kwizithuthi zombane, i-electronics ye-RF kwiinethiwekhi ze-5G, i-MEMS ye-aerospace sensors, kunye ne-optoelectronics ezifana ne-UV LEDs.

I-Q4: I-insulating layer iphucula njani ukusebenza kwesixhobo?

I-A4: Ifilimu ye-insulating (i-SiO₂ okanye i-Si₃N₄) ikhusela ukuvuza kwangoku kunye nokunciphisa i-cross-talk yombane, eyenza ukunyamezela kwe-voltage ephezulu, ukutshintshela ngokufanelekileyo, kunye nokunciphisa ukulahleka kobushushu.

I-Q5: Ngaba ii-wafers ze-SICOI zifanelekile kwizicelo zobushushu obuphezulu?

I-A5: Ewe, nge-conductivity ephezulu ye-thermal kunye nokuchasana ngaphaya kwe-500 ° C, ii-wafers ze-SICOI zenzelwe ukusebenza ngokuthembekileyo phantsi kobushushu obugqithisileyo kunye neendawo ezinzima.

I-Q6: Ngaba ii-wafers ze-SICOI zinokwenziwa ngokwezifiso?

A6: Ngokuqinisekileyo. Abavelisi banikezela ngoyilo olulungelelanisiweyo lobunzima obuthile, amanqanaba e-doping, kunye nendibaniselwano ye-substrate ukuhlangabezana nophando olwahlukeneyo kunye neemfuno zamashishini.