I-SiC Ingot yokuKhula iFunese yeSiC Crystal eNkulu-Diameter ye-SiC Crystal TSSG/LPE Iindlela

UmGaqo wokuSebenza

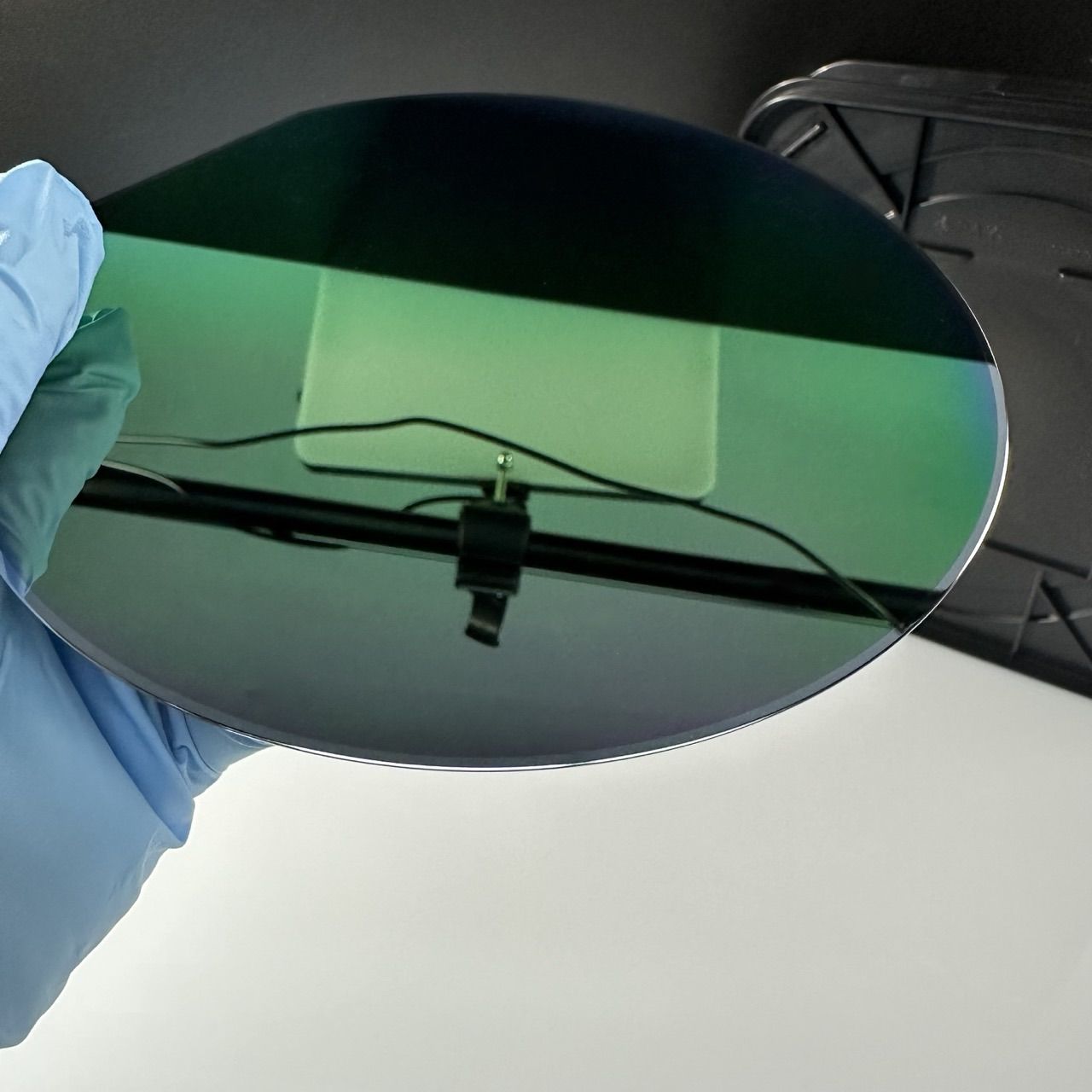

Umgaqo ongundoqo wokukhula kwe-ingot yesigaba solwelo se-silicon carbide ibandakanya ukunyibilikisa izinto ezicocekileyo ze-SiC kwisinyithi esityhidiweyo (umzekelo, i-Si, i-Cr) kwi-1800-2100 ° C ukwenza izisombululo ezigcweleyo, ezilandelwa kukukhula okulawulwayo kwe-SiC enye ikristale kwiikristale zembewu ngokuhlengahlengiswa kobushushu obuchanekileyo kunye nohlengahlengiso oluchanekileyo lobushushu. Le teknoloji ifaneleke ngokukodwa ukuvelisa ucoceko oluphezulu (> 99.9995%) 4H / 6H-SiC iikristale enye eneziphene eziphantsi (<100 / cm²), ukuhlangabezana neemfuno ezingqongqo ze-substrate zombane kunye nezixhobo ze-RF. Inkqubo yokukhula kwesigaba se-liquid yenza ulawulo oluchanekileyo lwe-crystal conductivity uhlobo (uhlobo lwe-N / P) kunye nokuxhathisa ngokubunjwa kwesisombululo esilungisiweyo kunye neeparitha zokukhula.

Amacandelo anguNdoqo

1. Inkqubo ekhethekileyo yeCrucible: I-graphite / tantalum composite crucible, ukumelana nokushisa> 2200 ° C, ukumelana ne-SiC melt corrosion.

2. Inkqubo yokufudumeza i-Multi-Zone: Ukuxhatshazwa okudibeneyo / ukufudumeza kwe-induction kunye nokuchaneka kokulawula ukushisa kwe-± 0.5 ° C (1800-2100 ° C uluhlu).

3. Inkqubo yokunyakaza okuchanekileyo: Ulawulo oluphindwe kabini lwe-loop yokujikeleza kwembewu (0-50rpm) kunye nokuphakamisa (0.1-10mm / h).

4. Inkqubo yokulawula i-Atmosphere: Ukucoceka okuphezulu kwe-argon / nitrogen ukhuseleko, uxinzelelo lokusebenza oluhlengahlengiswayo (0.1-1atm).

5. Inkqubo yoLawulo oluBukrelekrele: I-PLC + ye-PC yamashishini yolawulo olungafunekiyo kunye nexesha lokwenyani lokujonga ujongano lokukhula.

6. Inkqubo yokupholisa ngokufanelekileyo: Uyilo lokupholisa amanzi olusemgangathweni luqinisekisa ukusebenza okuzinzileyo kwexesha elide.

TSSG vs. LPE Uthelekiso

| Iimpawu | Indlela ye-TSG | Indlela ye-LPE |

| Ukukhula kweTemp | 2000-2100°C | 1500-1800°C |

| Izinga lokuKhula | 0.2-1mm/h | 5-50μm/h |

| Ubungakanani beCrystal | 4-8 intshi iingots | I-50-500μm i-epi-layers |

| Isicelo esingundoqo | Ukulungiswa kweSubstrate | Isixhobo samandla epi-amaleyi |

| Ubuninzi beSiphene | <500/cm² | <100/cm² |

| Iipolytypes ezifanelekileyo | 4H/6H-SiC | 4H/3C-SiC |

Usetyenziso oluphambili

1. I-Electronics yamandla: I-6-intshi ye-4H-SiC substrates ye-1200V + MOSFETs / diodes.

2. I-5G RF Devices: I-Semi-insulating SiC substrates ye-base station PAs.

3. Izicelo ze-EV: I-Ultra-thick (>200μm) ii-epi-layers zeemodyuli zebakala lemoto.

4. I-PV Inverters: I-substrates eneziphene ezisezantsi ezivumela> 99% ukusebenza kakuhle kokuguqulwa.

Iingenelo ezingundoqo

1. Ubungangamsha beTekhnoloji

1.1 Uyilo oluDityanisiweyo lweendlela ezininzi

Esi sigaba solwelo seSiC ingot inkqubo yokukhula idibanisa i-TSSG kunye ne-LPE crystal ukukhula kwetekhnoloji. Inkqubo ye-TSSG isebenzisa ukukhula kwesisombululo se-top-seeded kunye ne-melt convection echanekileyo kunye nokulawulwa kwe-gradient yeqondo lokushisa (ΔT≤5℃ / cm), eyenza ukukhula okuzinzile kwe-4-8 intshi enkulu ye-SiC ingots kunye nezivuno eziqhutywayo ze-15-20kg ze-crystals ze-6H / 4H-SiC. Inkqubo ye-LPE isebenzisa ukwakheka kwe-solvent ephuculweyo (inkqubo ye-alloy ye-Si-Cr) kunye nolawulo lwe-supersaturation (±1%) ukukhulisa umgangatho otyebileyo we-epitaxial layers kunye noxinano lwesiphene <100/cm² kumaqondo asezantsi kakhulu (1500-1800℃).

1.2 Inkqubo yoLawulo oluBukrelekrele

Ixhotyiswe ngesizukulwana sesi-4 solawulo lokukhula ngobuchule obuquka:

• Ukujongwa kwe-multi-spectral in-situ (400-2500nm uluhlu lwamaza amaza)

• Ukuchongwa kwenqanaba lokunyibilika okusekwe kwiLaser (±0.01mm ukuchaneka)

• Ulawulo olusekwe kwidayamitha yeCCD evaliweyo (<±1mm ukuguquguquka)

• Ukongezwa kweparamitha yokukhula ngamandla e-AI (15% yokonga amandla)

2. Izinto eziluncedo kwiNkqubo yokuSebenza

2.1 Indlela ye-TSSG Amandla angundoqo

• Isakhono sobukhulu obukhulu: Ixhasa ukuya kuthi ga kwi-8-intshi yokukhula kwekristale nge>99.5% yokufana kwedayamitha

• Ubucwebe obugqwesileyo: Uxinaniso lwe-Dilocation <500/cm², uxinano lwemicropipe <5/cm²

• I-doping uniformity: <8% ye-n-type resistivity variation (4-intshi yamawafa)

• Izinga lokukhula elilungiselelweyo: Ukulungiswa kwe-0.3-1.2mm/h, 3-5× ngokukhawuleza kuneendlela zesigaba somphunga

2.2 Indlela ye-LPE Amandla angundoqo

• I-epitaxy yesiphene esezantsi kakhulu: Ubuninzi bemeko yojongano <1×10¹¹cm⁻²·eV⁻¹

• Ulawulo lokutyeba oluchanekileyo: 50-500μm iileya ze-epi ezine <±2% umahluko wobunzima

• Ukusebenza kakuhle kobushushu: 300-500℃ ngaphantsi kweenkqubo zeCVD

• Ukukhula kolwakhiwo oluntsonkothileyo: Ukuxhasa iindawo ezidityanisiweyo ze-pn, ii-superlattices, njl.

3. Izinto eziluncedo kwiMveliso

3.1 Ukulawulwa kweendleko

• 85% yokusetyenziswa kwemathiriyeli ekrwada (vs. 60% eqhelekileyo)

• I-40% yokusetyenziswa kwamandla aphantsi (xa kuthelekiswa ne-HVPE)

• I-90% yezixhobo zokusebenza (uyilo lwemodyuli lunciphisa ixesha lokuphumla)

3.2 UQinisekiso loMgangatho

• 6σ ulawulo lwenkqubo (CPK>1.67)

• Ukuchongwa kwesiphene kwi-Intanethi (isisombululo se-0.1μm)

• Inkqubo epheleleyo yokulandelelwa kwedatha (2000+ iiparamitha zexesha lokwenyani)

3.3 Ukubaleka

• Iyahambelana ne-4H / 6H / 3C iipolytypes

• Ukuphuculwa ukuya kwiimodyuli zenkqubo ye-intshi ezili-12

• Ixhasa iSiC/GaN hetero-integration

4. Izinto eziluncedo kwiSicelo soShishino

4.1 Izixhobo zoMbane

• I-Low-resistivity substrates (0.015-0.025Ω·cm) yezixhobo ze-1200-3300V

• I-semi-insulating substrates (>10⁸Ω·cm) yosetyenziso lweRF

4.2 IiTekhnoloji ezisakhulayo

• Unxibelelwano lwesixa: Iisubstrates zengxolo ephantsi kakhulu (1/f ingxolo<-120dB)

• Iindawo ezisingqongileyo ezigqithisileyo: Iikristale ezikwaziyo ukumelana nokusasazeka kwemitha (<5% ukuthotywa emva kwe-1×10¹⁶n/cm² yokukhanya kwemitha)

Iinkonzo ze-XKH

1. Izixhobo ezilungiselelweyo: Ulungelelwaniso lwenkqubo ye-TSSG/LPE.

2. Inkqubo yoQeqesho: Iinkqubo ezibanzi zoqeqesho lobugcisa.

3. Emva kokuthengisa Inkxaso: 24/7 impendulo yobugcisa kunye nokugcinwa.

4. Izisombululo ze-Turnkey: Inkonzo ye-spectrum epheleleyo ukusuka kufakelo ukuya kwinkqubo yokuqinisekiswa.

5. Ukubonelela ngezinto eziphathekayo: 2-12 intshi ye-SiC substrates / epi-wafers ekhoyo.

Iinzuzo eziphambili ziquka:

• Ukuya kuthi ga kwi-8-intshi yesakhono sokukhula kwekristale.

• Ukuxhathisa ukufana <0.5%.

• Ixesha lokuphumla kwezixhobo>95%.

• 24/7 inkxaso yobugcisa.