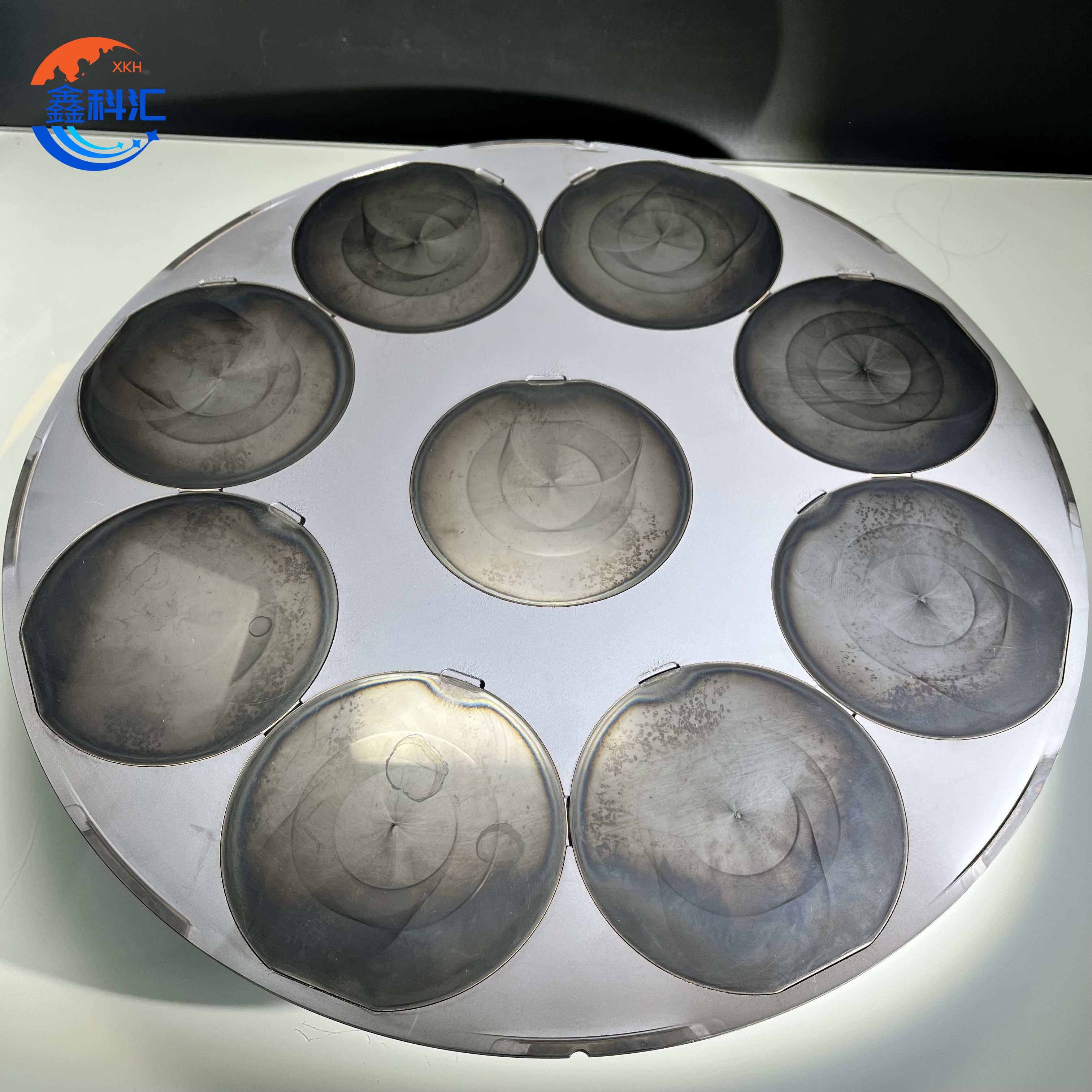

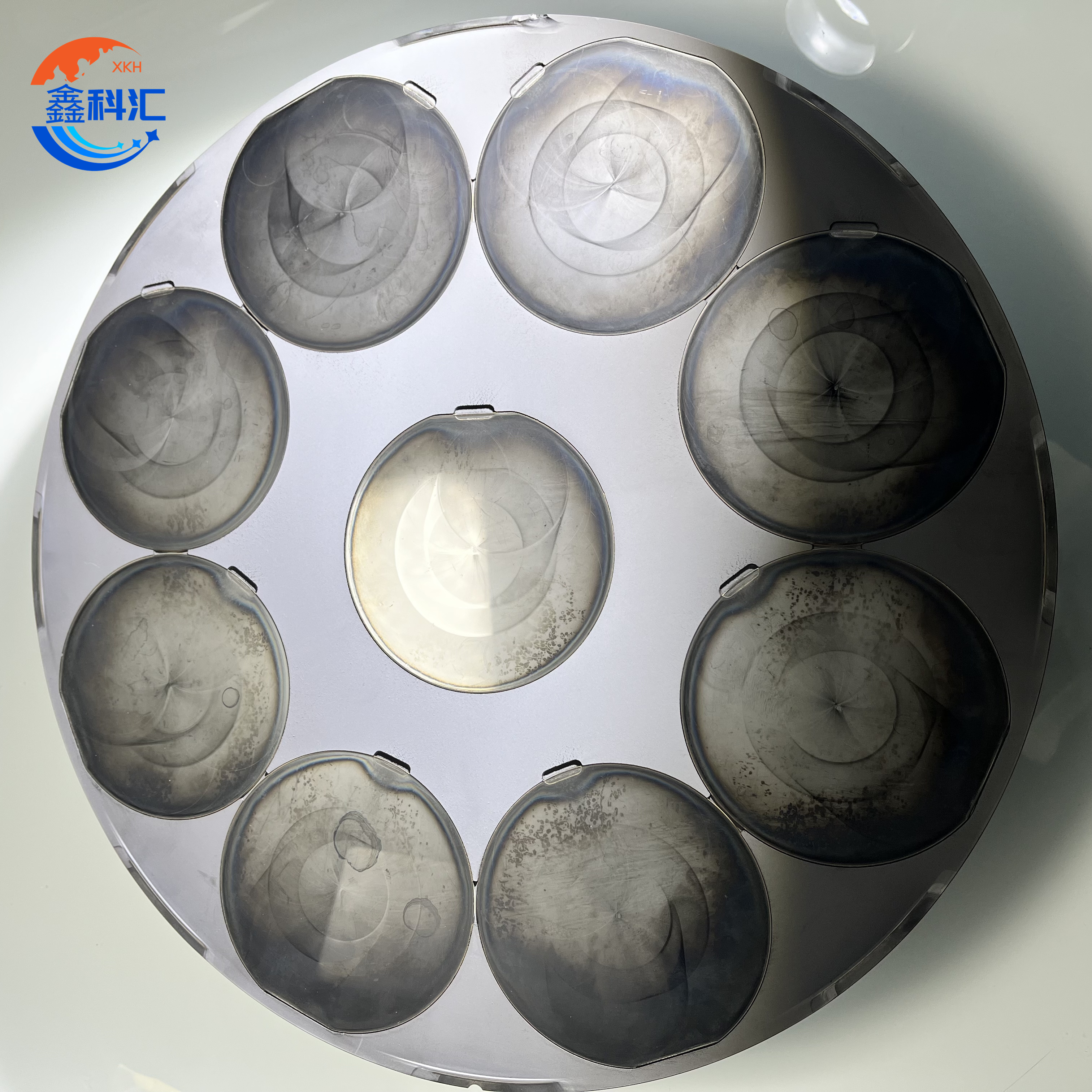

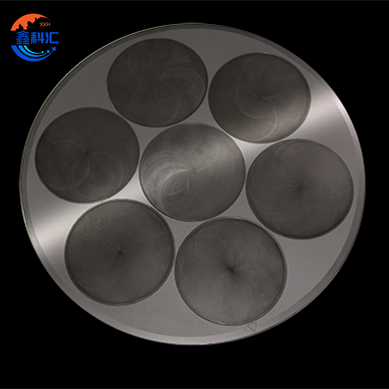

SiC ceramic ipleyiti / itreyi for 4inch 6inch isibambi wafer for ICP

Ipleyiti ye-ceramic ye-SiC Abstract

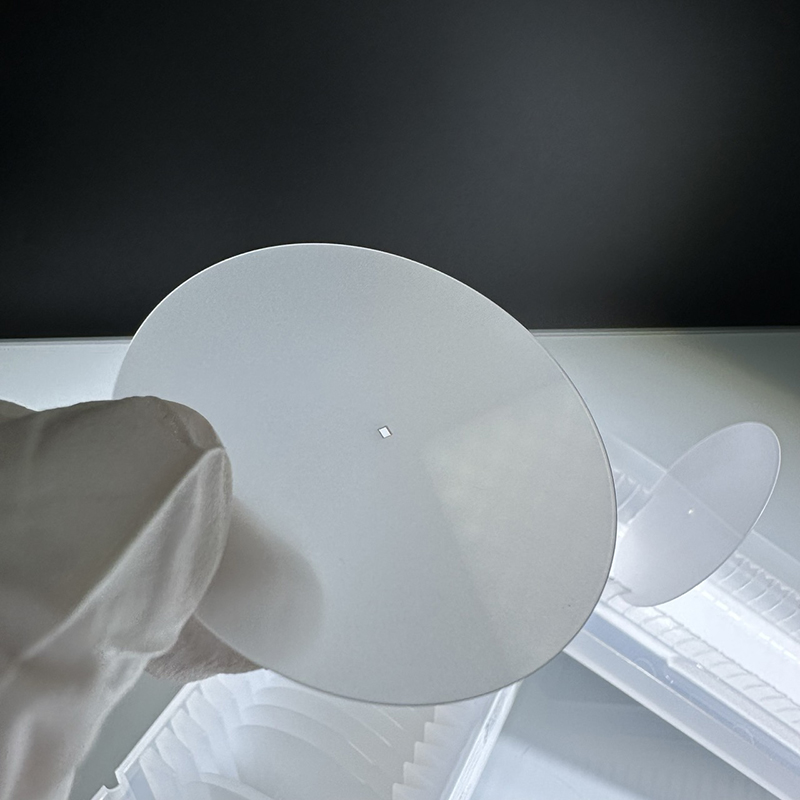

Ipleyiti ye-ceramic ye-SiC yinxalenye ephezulu yokusebenza eyinjineli esuka kwi-Silicon Carbide ephezulu, eyenzelwe ukusetyenziswa kwiindawo ezishushu kakhulu, iikhemikhali, kunye nezomatshini. Iyaziwa ngobulukhuni bayo obukhethekileyo, ukuguquguquka kwe-thermal, kunye nokuxhathisa ukubola, ipleyiti ye-SiC isetyenziswa ngokubanzi njenge-wafer carrier, i-susceptor, okanye icandelo lesakhiwo kwi-semiconductor, i-LED, i-photovoltaic, kunye ne-aerospace industry.

Ngozinzo olubalaseleyo lwe-thermal ukuya kwi-1600 ° C kunye nokuchasana okugqwesileyo kwiigesi ezisebenzayo kunye neendawo ze-plasma, i-plate ye-SiC iqinisekisa ukusebenza okuhambelanayo ngexesha lokushisa okuphezulu, ukuchithwa kunye neenkqubo zokusabalalisa. I-microstructure yayo exineneyo, engeyiyo i-porous inciphisa ukuveliswa kwamasuntswana, iyenze ibe yinto efanelekileyo kwizicelo ezicocekileyo kakhulu kwi-vacuum okanye iisetingi zegumbi lokucoca.

SiC ceramic plate Isicelo

1. Ukwenziwa kweSemiconductor

Iipleyiti ze-ceramic ze-SiC zisetyenziswa ngokuqhelekileyo njengabathwali be-wafer, i-susceptors, kunye ne-pedestal plates kwisixhobo sokwenza i-semiconductor efana ne-CVD (i-Chemical Vapor Deposition), i-PVD (i-Physical Vapor Deposition), kunye neenkqubo zokubeka. Ukuqhuba kakuhle kwe-thermal kunye nokwandiswa kwe-thermal ephantsi kubavumela ukuba bagcine ukuhanjiswa kweqondo lokushisa okufanayo, okubaluleke kakhulu ekusebenzeni okuchanekileyo kwe-wafer. Ukuchasana kwe-SiC kwiigesi ezitshabalalisayo kunye ne-plasmas kuqinisekisa ukuhlala kwiindawo ezinzima, kunceda ukunciphisa ukungcoliswa kwee-particle kunye nokugcinwa kwezixhobo.

2. Ishishini le-LED - ICP Etching

Kwicandelo lokuvelisa i-LED, iipleyiti ze-SiC zizinto eziphambili kwiinkqubo ze-ICP (Inductively Coupled Plasma) etching systems. Basebenza njengabagcini be-wafer, babonelela ngeqonga elizinzile nelinamandla lokuxhasa isafire okanye i-GaN wafers ngexesha lokusetyenzwa kweplasma. Ukuchasana kwabo kweplasma okugqwesileyo, ukuthambeka komphezulu, kunye nokuzinza komda kunceda ukuqinisekisa ukuchaneka okuphezulu kunye nokufana, okukhokelela ekwandeni kwesivuno kunye nokusebenza kwesixhobo kwiitshiphusi ze-LED.

3. I-Photovoltaics (PV) kunye neSolar Energy

Iipleyiti ze-ceramic ze-SiC zikwasetyenziswa kwimveliso yeeseli zelanga, ngakumbi ngexesha lobushushu obuphezulu be-sintering kunye namanyathelo okubamba. Ukungangeni kwabo kumaqondo obushushu aphakamileyo kunye nokukwazi ukumelana ne-warping kuqinisekisa ukusetyenzwa okungaguqukiyo kwee-wafers zesilicon. Ukongezelela, umngcipheko wabo wokungcoliseka ophantsi ubalulekile ekugcineni ukusebenza kakuhle kweeseli ze-photovoltaic.

SiC ceramic plate Properties

1. Ukomelela koomatshini obukhethekileyo kunye nobulukhuni

Iipleyiti ze-ceramic ze-SiC zibonisa amandla omatshini aphezulu kakhulu, anamandla aqhelekileyo aguquguqukayo adlula i-400 MPa kunye nobunzima beVickers bufikelela ku->2000 HV. Oku kubenza baxhathise kakhulu kwi-mechanical wear, i-abrasion, kunye ne-deformation, iqinisekisa ubomi obude benkonzo naphantsi komthwalo ophezulu okanye ukuphindaphinda ibhayisekile ye-thermal.

2. High Thermal Conductivity

I-SiC ine-thermal conductivity egqwesileyo (ngokuqhelekileyo 120–200 W/m·K), eyivumela ukuba isasaze ngokulinganayo ubushushu kumphezulu wayo. Le propati ibaluleke kakhulu kwiinkqubo ezinje nge-wafer etching, i-deposition, okanye i-sintering, apho ukufana kobushushu kuchaphazela ngokuthe ngqo imveliso kunye nomgangatho.

3. Uzinzo oluPhezulu lweThermal

Ngomgangatho ophezulu wokunyibilika (2700 ° C) kunye ne-coefficient ephantsi yokwandiswa kwe-thermal (4.0 × 10⁻⁶ / K), iipleyiti ze-ceramic ze-SiC zigcina ukuchaneka kwe-dimensional kunye nokunyaniseka kwesakhiwo phantsi kwemijikelezo yokufudumeza ngokukhawuleza kunye nokupholisa. Oku kubenza balungele ukusetyenziswa kwiziko lobushushu obuphezulu, kumagumbi okufunxa, kunye neemeko zeplasma.

| Iimpawu zobuGcisa | ||||

| Isalathiso | Iyunithi | Ixabiso | ||

| Igama leMathiriyeli | Ukusabela Sintered Silicon Carbide | Uxinzelelo lweSilicon Carbide engenaxinzelelo | Recrystallized Silicon Carbide | |

| Ukuqamba | I-RBSiC | I-SSiC | R-SiC | |

| Unizi lolwapho kuyiwa khona | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

| Amandla e-Flexural | MPa (kpsi) | 338(49) | 380(55) | 80-90 (20°C) 90-100(1400°C) |

| Amandla acinezelayo | MPa (kpsi) | 1120(158) | 3970(560) | > 600 |

| Ukuqina | Knoop | 2700 | 2800 | / |

| Ukuqhawula ukuqina | MPa m1/2 | 4.5 | 4 | / |

| I-Thermal Conductivity | W/mk | 95 | 120 | 23 |

| I-Coefficient yoKwandiswa kweThermal | 10-6.1/°C | 5 | 4 | 4.7 |

| Ubushushu obuthile | Joule/g 0k | 0.8 | 0.67 | / |

| Ubushushu obukhulu emoyeni | ℃ | 1200 | 1500 | 1600 |

| Imodyuli ye-elastic | I-Gpa | 360 | 410 | 240 |

I-SiC ipleyiti yeceramic Q&A

Q: Ziziphi iimpawu ze-silicon carbide plate?

A: Iiplati zeSilicon carbide (SiC) ziyaziwa ngamandla abo aphezulu, ukuqina, kunye nokuzinza kwe-thermal. Banikezela nge-conductivity egqwesileyo ye-thermal kunye nokwandiswa kwe-thermal ephantsi, ukuqinisekisa ukusebenza okuthembekileyo phantsi kokushisa okukhulu. I-SiC nayo i-inert yekhemikhali, iyamelana ne-acids, alkalis, kunye ne-plasma, iyenza ibe yinto efanelekileyo kwi-semiconductor kunye ne-LED processing. Umphezulu wayo oxineneyo, ogudileyo unciphisa ukuveliswa kwamasuntswana, ukugcina ukuhambelana kwegumbi elicocekileyo. Iipleyiti ze-SiC zisetyenziswa ngokubanzi njengabathwali be-wafer, i-susceptors, kunye nezixhobo zenkxaso kubushushu obuphezulu kunye neendawo ezinobungozi kuyo yonke i-semiconductor, i-photovoltaic, kunye nemizi-mveliso ye-aerospace.