Semiconductor Laser Lift-Off isixhobo Revolutionize Ingot Thinning

Idayagram eneenkcukacha

Ukwaziswa kweMveliso yeSemiconductor Laser Lift-Off Equipment

I-Semiconductor Laser Lift-Off Equipment sisisombululo esikhethekileyo semizi-mveliso eyenzelwe ukucuthwa okuchanekileyo kunye nokungaqhagamshelwanga kwee-ingots ze-semiconductor ngokusebenzisa ubuchule bokuphakanyiswa kwe-laser. Le nkqubo iphucukileyo idlala indima ebalulekileyo kwiinkqubo zale mihla zokwenziwa kwe-semiconductor, ngakumbi ekwenziweni kwee-wafers ezibhityileyo zombane osebenza kakhulu, ii-LED, kunye nezixhobo zeRF. Ngokuvumela ukwahlulwa kwamaleya abhityileyo ukusuka kwiingots ezininzi okanye ii-substrates zabanikeli, iSemiconductor Laser Lift-Off Equipment iguqula i-ingot thinning ngokususa amanyathelo okusarha ngoomatshini, ukugraya, kunye neekhemikhali.

Ukucuthwa ngokwemveli kwee-ingots ze-semiconductor, ezifana ne-gallium nitride (GaN), isilicon carbide (SiC), kunye nesafire, idla ngokuba ngumsebenzi omkhulu, imosha, kwaye ithande ukuba ne-microcracks okanye ukonakala komhlaba. Ngokwahlukileyo koko, iSemiconductor Laser Lift-Off Equipment inikezela ngokungonakalisi, enye indlela echanekileyo enciphisa ilahleko yezinto eziphathekayo kunye noxinzelelo lomphezulu ngelixa ukwandisa imveliso. Ixhasa iindidi ezininzi zekristali kunye nezixhobo ezidibeneyo kwaye zinokudibaniswa ngokungenamthungo kwi-front-end okanye i-midstream ye-semiconductor yokuvelisa imigca.

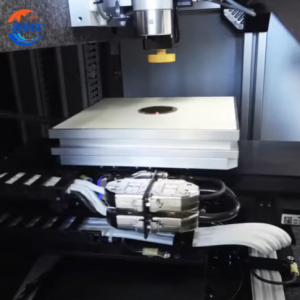

Ngobude be-laser obulungisekayo, iisistim zokugxila eziguquguqukayo, kunye ne-vacuum-compatible wafer chucks, esi sixhobo sifaneleke ngokukodwa ukunqunyulwa kwe-ingot, ukudala i-lamella, kunye ne-ultra-thin film detachment yezakhiwo zesixhobo ezithe nkqo okanye i-heteroepitaxial layer transfer.

IParameter yeSemiconductor Laser Lift-Off Equipment

| Ubude bamaza | IR/SHG/THG/FHG |

|---|---|

| Pulse Ububanzi | Nanosecond, Picosecond, Femtosecond |

| Inkqubo yokubona | Inkqubo ye-optical esisigxina okanye inkqubo ye-Galvano-optical |

| Inqanaba leXY | 500 mm × 500 mm |

| Uluhlu lokuqhubekekisa | 160 mm |

| Isantya sokuhamba | Ubuninzi 1,000 mm/sec |

| Ukuphindaphinda | ±1 μm okanye ngaphantsi |

| Ukuchaneka kwesikhundla esipheleleyo: | ±5 μm okanye ngaphantsi |

| Ubungakanani beWafer | 2–6 intshi okanye ngokwezifiso |

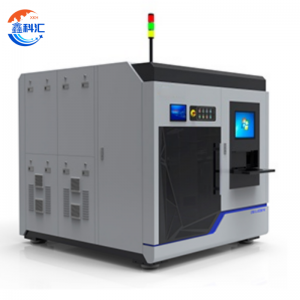

| Ulawulo | Windows 10,11 kunye ne-PLC |

| Ubonelelo lwaMandla ombane | I-AC 200 V ±20 V, isigaba esinye, 50/60 kHz |

| Imilinganiselo yangaphandle | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Ubunzima | 1,000 kg |

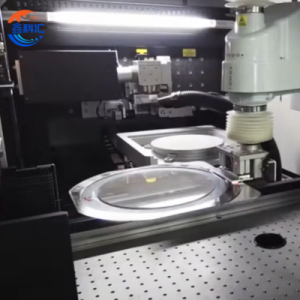

UmGaqo wokuSebenza weSemiconductor Laser Lift-Off Equipment

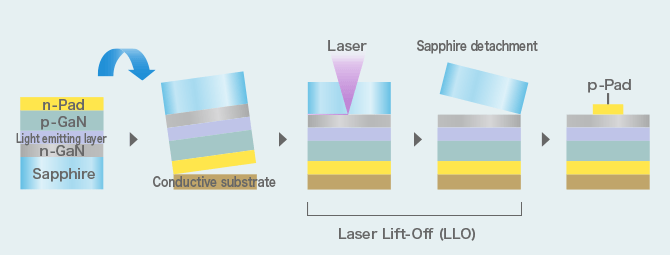

Indlela engundoqo ye-Semiconductor Laser Lift-Off Equipment ixhomekeke kwi-photothermal ekhethiweyo okanye i-ablation kwi-interface phakathi kwe-ingot yomxhasi kunye ne-epitaxial okanye i-target layer. I-laser ye-UV ene-eneji ephezulu (ngokuqhelekileyo i-KrF kwi-248 nm okanye i-laser ye-UV eqinileyo ejikeleze i-355 nm) igxininiswe ngesixhobo somnikeli esingafihliyo okanye esingafihliyo, apho amandla athatyathwa ngokukhetha kubunzulu obumiselwe kwangaphambili.

Oku kufunxwa kwamandla asekuhlaleni kudala igas yoxinzelelo oluphezulu okanye umaleko wokwandiswa kwe-thermal kwi-interface, eqalisa i-delamination ecocekileyo ye-wafer ephezulu okanye umaleko wesixhobo ukusuka kwisiseko se-ingot. Inkqubo ilungiswa ngokucokisekileyo ngokulungelelanisa iiparamitha ezifana nobubanzi be-pulse, i-laser fluence, isantya sokuskena, kunye nobunzulu be-z-axis. Isiphumo sisisilayi esibhityileyo kakhulu-kaninzi kuluhlu lwe-10 ukuya kwi-50 µm-yahlulwe ngokucocekileyo kwi-ingot yomzali ngaphandle kokulimala koomatshini.

Le ndlela yokunyuswa kwelaser yokuthoba ingot inqanda ilahleko yekerf kunye nomonakalo womphezulu onxulunyaniswa nokusarha ucingo lwedayimani okanye ukurhabula ngomatshini. Ikwagcina ingqibelelo yekristale kwaye inciphisa iimfuno zokupholisha ezantsi, ukwenza iSemiconductor Laser Lift-Off Equipment isixhobo sokutshintsha umdlalo kwisizukulwana esilandelayo sokuvelisa iwafer.

Ukusetyenziswa kweSemiconductor Laser Lift-Off Equipment

Isixhobo seSemiconductor Laser Lift-Off sifumana ukusetyenziswa okubanzi kwi-ingot ebhityileyo kuluhlu lwezixhobo eziphambili kunye neentlobo zesixhobo, kubandakanya:

-

I-GaN kunye ne-GaAs Ingot Ingot Thinning yezixhobo zamandla

Inika amandla ukudalwa kwe-wafer ebhityileyo ekusebenzeni okuphezulu, ii-transistors zamandla ezixhathisayo kunye neediode.

-

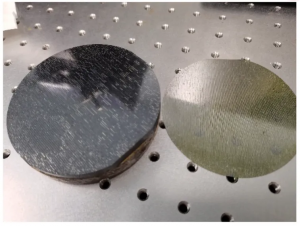

I-SiC Substrate Reclamation kunye neLamella Ukwahlula

Ivumela ukuphakanyiswa kwe-wafer-scale-off ukusuka kwisixa esikhulu se-SiC substrates kwizakhiwo zesixhobo ezithe nkqo kunye nokuphinda kusetyenziswe isiphambuka.

-

I-LED Wafer Slicing

Iququzelela ukunyuswa kweeleya ze-GaN ukusuka kwii-ingots ezishinyeneyo zesafire ukuvelisa i-ultra-thin LED substrates.

-

I-RF kunye neMicrowave Device Fabrication

Ixhasa i-ultra-thin high-electron-mobility transistor (HEMT) izakhiwo ezifunekayo kwi-5G kunye neenkqubo ze-radar.

-

I-Epitaxial Layer Transfer

Isusa ngokuchanekileyo umaleko we-epitaxial ukusuka kwi-crystalline ingots ukuze iphinde isetyenziswe okanye indibaniselwano kwi-heterostructures.

-

Iiseli zeSola eziThin-Film kunye ne-Photovoltaics

Isetyenziselwa ukwahlula iileya ezithambileyo zokufunxa kwiiseli zelanga eziguquguqukayo okanye ezisebenza ngokufanelekileyo.

Kwindawo nganye kwezi, iSemiconductor Laser Lift-Off Equipment ibonelela ngolawulo olungahambelaniyo malunga nokulingana kobukhulu, umgangatho womphezulu, kunye nentembeko yomaleko.

Izinto ezilungileyo ze-Laser-Based Ingot Thinning

-

Ilahleko yeMathiriyeli enguZero-Kerf

Xa kuthelekiswa neendlela zemveli zokusika iwafer, inkqubo yelaser ikhokelela ekusetyenzisweni kwezinto eziphantse zibe yi-100%.

-

Uxinzelelo oluncinci kunye neWarping

Ukunyuswa kwe-non-contact-off kuphelisa ukungcangcazela komatshini, ukunciphisa isaphetha se-wafer kunye nokwakheka kwe-microcrack.

-

UkuGcinwa koMgangatho womphezulu

Akukho ukupholiswa emva kokubhitya okanye ukupolisha okufunekayo kwiimeko ezininzi, njengoko ukunyuswa kwelaser kugcina ingqibelelo yomgangatho ophezulu.

-

UPhumezo oluPhezulu kunye nokuZisebenzela ngokuLungileyo

Iyakwazi ukusetyenzwa amakhulu eesubstrates kwishifti nganye ngokulayisha/ukukhulula ngokuzenzekelayo.

-

Ukulungelelaniswa kwiZixhobo ezininzi

Iyahambelana ne-GaN, i-SiC, isafire, i-GaAs, kunye nezixhobo ezivelayo ze-III-V.

-

Ikhuselekile ngokwendalo

Yehlisa ukusetyenziswa kweziqholo kunye neekhemikhali ezirhabaxa eziqhelekileyo kwiinkqubo zokuthoba ezisekelwe eludaka.

-

Ukusetyenziswa kwakhona kweSubstrate

Ii-ingots zabanikezeli zinokuphinda zisetyenziselwe imijikelo emininzi yokunyuswa, ukunciphisa kakhulu iindleko zempahla.

Imibuzo Ebuzwa Rhoqo (FAQ) yeSemiconductor Laser Lift-Off Equipment

-

I-Q1: Loluphi uluhlu lokutyeba olunokuthi iSemiconductor Laser Lift-Off Equipment lufikeleleke kwizilayi ze-wafer?

A1:Ubukhulu besilayi obuqhelekileyo busukela kwi-10 µm ukuya kwi-100 µm ngokuxhomekeke kwimathiriyeli kunye noqwalaselo.I-Q2: Ngaba esi sixhobo sinokusetyenziselwa iingots ezincinci ezenziwe ngezinto ezi-opaque ezifana ne-SiC?

A2:Ewe. Ngokulungisa i-laser wavelength kunye nokwenza ngcono ubunjineli bojongano (umzekelo, i-interlayers yombingelelo), kunye nemathiriyeli e-opaque kancinane inokusetyenzwa.I-Q3: Ingaba i-substrate yomxhasi ilungelelaniswe njani ngaphambi kokuphakanyiswa kwe-laser?

A3:Inkqubo isebenzisa iimodyuli ze-sub-micron-based based alignment modules kunye nengxelo evela kumanqaku e-fiducial kunye ne-surface reflectivity scans.I-Q4: Liliphi ixesha elilindelekileyo lomjikelo we-laser lift-off operation?

A4:Ngokuxhomekeke kubungakanani be-wafer kunye nobukhulu, imijikelo eqhelekileyo ithatha imizuzu emi-2 ukuya kweli-10.I-Q5: Ngaba inkqubo ifuna indawo ecocekileyo yegumbi?

A5:Nangona kunganyanzelekanga, ukudityaniswa kwegumbi lokucoca kuyacetyiswa ukuba kugcinwe ukucoceka kwe-substrate kunye nemveliso yesixhobo ngexesha lemisebenzi echanekileyo.

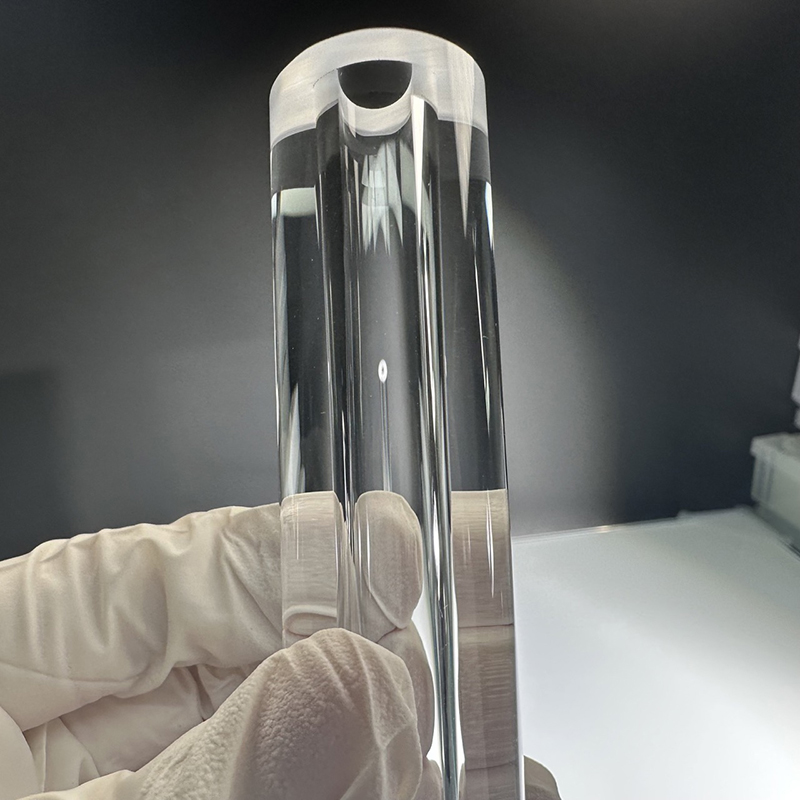

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.