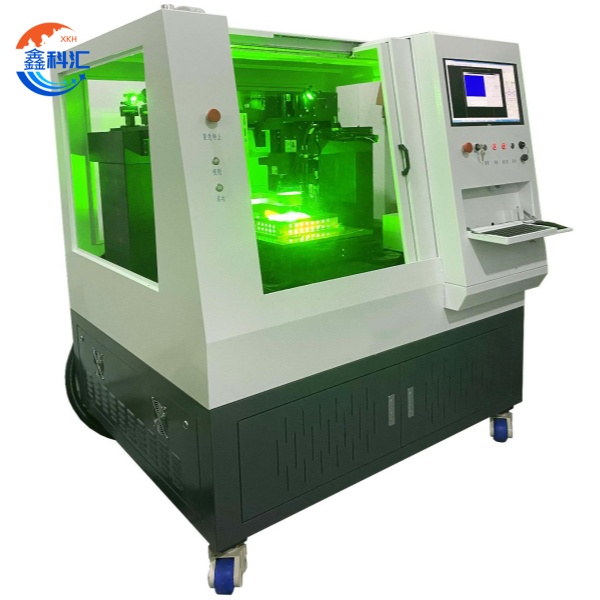

Isixhobo soKwemba iLaser yeNanosecond ye-Infrared yeGlasi yoKwemba ubukhulu≤20mm

Eyona parameter

| Uhlobo lweLaser | I-infrared nanosecond |

| Ubungakanani beqonga | 800*600(mm) |

|

| 2000*1200(mm) |

| Ubunzima bokomba | ≤20(mm) |

| Isantya sokomba | 0-5000(mm/s) |

| Drilling edge breakage | <0.5(mm) |

| Qaphela: Ubungakanani beqonga bungenziwa ngokwezifiso. | |

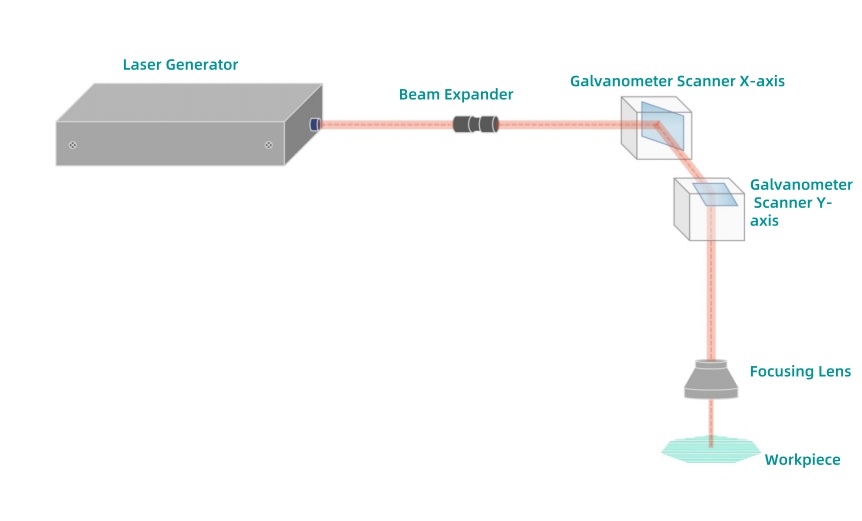

ILaser Drilling Principle

Umqa welaser ugxile kwindawo efanelekileyo xa uthelekiswa nobukhulu besixhobo sokusebenza, emva koko uskena ngeendlela ezichazwe kwangaphambili ngesantya esiphezulu. Ngokusebenzisana ne-laser ye-laser ye-eneji ephezulu, izinto ekujoliswe kuzo zisuswa umaleko-ngamaleko ukwenza iitshaneli zokusika, ukuphumeza ukutyhoboza okuchanekileyo (kwisetyhula, isikwere, okanye iijiyometri ezintsonkothileyo) kunye nokwahlulwa kwezinto ezilawulwayo.

Laser Drilling Izinto eziluncedo

· Udibaniso oluphezulu oluzenzekelayo kunye nokusetyenziswa kwamandla amancinci kunye nokusebenza lula;

· Ukusetyenzwa okungaqhagamshelwanga kwenza iijiyometri zepateni zingathintelwanga ngaphaya kweendlela eziqhelekileyo;

· Ukusebenza simahla kokusebenziseka kunciphisa iindleko zokusebenza kwaye kuphucule uzinzo lokusingqongileyo;

· Ukuchaneka okuphezulu kunye nokutshiphuzwa komphetho omncinci kunye nokupheliswa komonakalo wesibini wesixhobo;

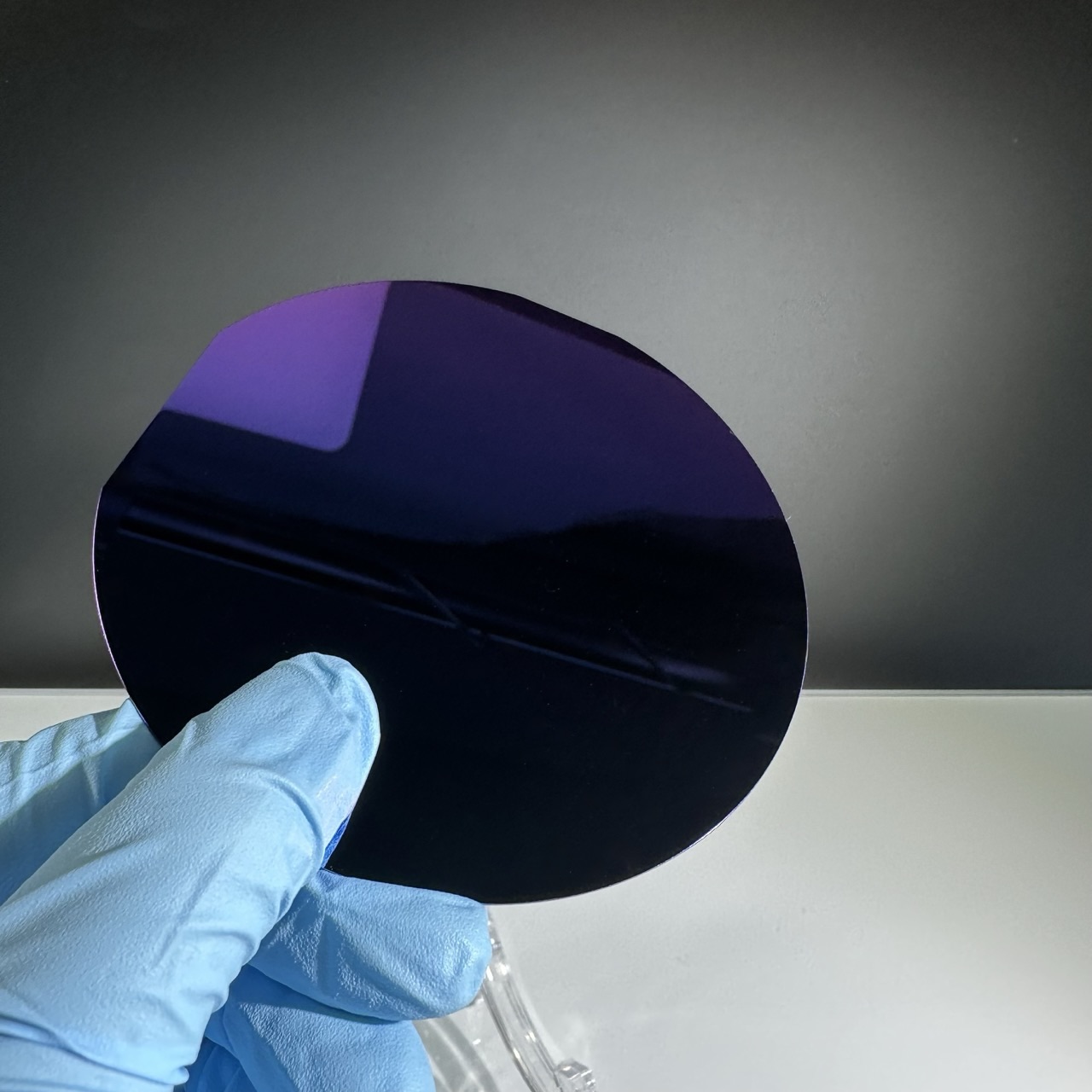

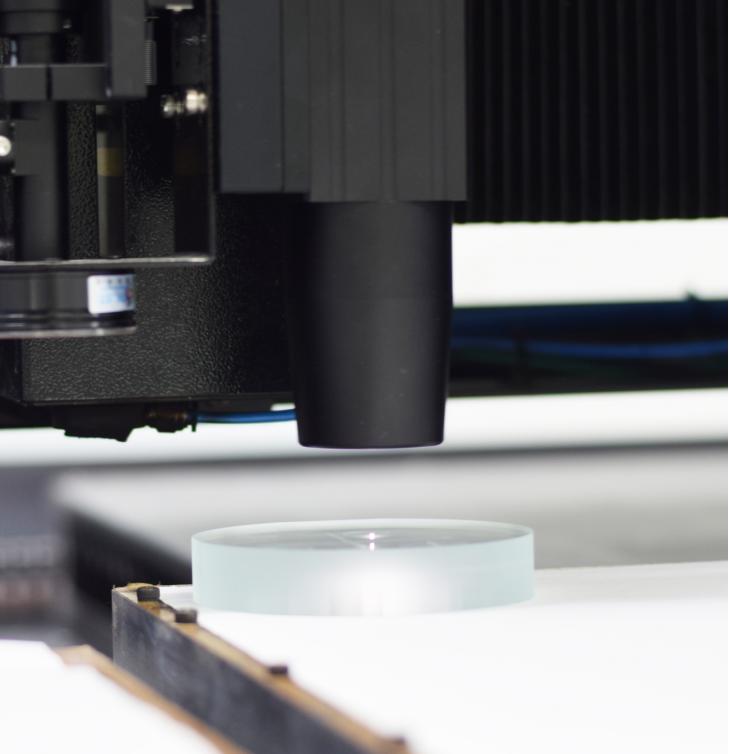

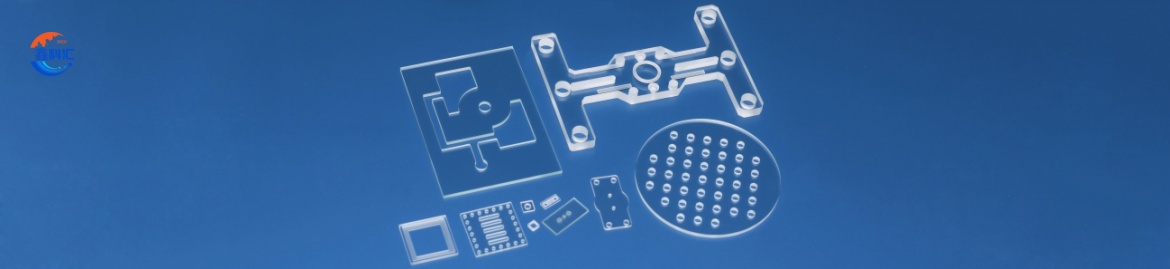

Umboniso wesampuli

Inkqubo yezicelo

Inkqubo yenzelwe ukuchaneka kokulungiswa kwezinto ezinqabileyo / ezinzima ezibandakanya ukubhola, ukugoba, ukususwa kwefilimu, kunye nokuthungwa komhlaba. Usetyenziso oluqhelekileyo lubandakanya:

1. Ukwemba kunye nokuqatshelwa kwezixhobo zocango lweshawari

2. Ukugqobhoza ngokuchanekileyo kweepaneli zeglasi yesixhobo

3. Iphaneli yelanga ngokugrunjwa

4. Tshintsha/socket cover plate perforation

5. Ukususwa kwesibuko sokugquma nge-drilling

6. Isiko lokubhaliweyo komhlaba kunye ne-grooving kwiimveliso ezikhethekileyo

Ukulungiswa kwezinto eziluncedo

1. Iqonga elinefomathi enkulu lithatha imilinganiselo eyahlukeneyo yeemveliso kuwo wonke amashishini

2. Ukomba oluntsonkothileyo lwecontour oluphunyeziweyo ekusebenzeni kwepasi enye

3. Ubuncinci be-edge chipping kunye nokugqiba okuphezulu komphezulu (Ra <0.8μm)

4. Utshintsho olungenamthungo phakathi kwenkcazo yemveliso kunye nokusebenza okucacileyo

5. Ukusebenza ngendlela eyongayo equka:

· Izivuno eziphezulu (>99.2%)

· Consumable-free processing

· Azikho izinto ezikhutshwayo ezingcolisayo

I-6.Umsebenzi ongaqhagamshelwanga uqinisekisa ukugcinwa kwengqibelelo yomhlaba

Ezona mpawu

1. ITekhnoloji yoLawulo lweThermal echanekileyo:

· Isebenzisa inkqubo yokomba eqhutywayo ye-multi-pulse ne-adjustable single-pulse energy (0.1–50 mJ)

· Inkqubo yokhuselo yomoya esecaleni yomoya ivala indawo echatshazelwe bubushushu ukuya ngaphakathi kwe-10% yobubanzi bomngxuma.

· Imodyuli yexesha lokwenyani lobushushu be-infrared ibuyekeza ngokuzenzekelayo iiparamitha zamandla (± 2% uzinzo)

2. IQonga lokuLungiselela ngobukrelekrele:

· Ixhotyiswe ngeqonga lemoto elichanekileyo elichanekileyo (phinda ukuchaneka kokumisa: ±2 μm)

· Inkqubo yokulungelelaniswa kombono edibeneyo (iCCD ye-5-megapixel, ukuchaneka kokuqaphela: ±5 μm)

· I-database yenkqubo elayishwe kwangaphambili eneparamitha ezilungiselelwe malunga ne-50+ yeentlobo zemathiriyeli yeglasi

3. Uyilo lweMveliso eFanelekileyo:

· Imowudi yokusebenza enezitishi ezimbini ezitshintshanayo kunye nexesha lokutshintsha kwezinto ≤3 imizuzwana

· Umjikelo wokusetyenzwa osemgangathweni womngxuma om-1/0.5 imizuzwana (Φ0.5 mm ngomngxuma)

· Uyilo lwemodyuli luvumela utshintshiselwano olukhawulezayo lokugxila kwiindibano zelensi (uluhlu lokucubungula: Φ0.1–10 mm)

Ii-Brittle Hard Material Processing Applications

| Uhlobo lwezinto eziphathekayo | Imeko yesicelo | Ukuqhubela phambili umxholo |

| Iglasi yeSoda-yekalika | Iingcango zeshawari | Ukunyuka kwemingxuma kunye nemijelo yokuhambisa amanzi |

| Iiphaneli zokulawula izixhobo | Uluhlu lwemingxuma yokuhambisa amanzi | |

| Iglasi epholileyo | Iifestile zokujonga i-oveni | Uluhlu lwemingxuma yokungenisa umoya |

| Ii-cooktops ze-induction | Iitshaneli zokupholisa ezineengile | |

| Iglasi yeBorosilicate | Iiphaneli zelanga | Ukunyuka kwemingxuma |

| Izinto zeglasi zeLabhoratri | Imijelo yokuhambisa amanzi emiselweyo | |

| Iglasi-i-ceramic | Imiphezulu yokupheka | Imingxunya yokubeka isitshisi |

| Abapheki bokwazisa | Isivamvo sokunyuswa kwemingxunya uluhlu | |

| Isafire | Iikhava zesixhobo esihlakaniphile | Imingxuma yokungena umoya |

| Iindawo zokujonga kwimizi-mveliso | Imingxuma eyomeleziweyo | |

| Iglasi eqatywe | Izibuko zokuhlambela | Ukunyuka kwemingxuma (ukususwa kokugquma + ukugrumba) |

| Iindonga zamakhethini | Iglasi ye-E ephantsi efihle imingxunya yokuhambisa amanzi | |

| Iglasi yeCeramicized | Tshintsha/izigqubuthelo zesokethi | Iindawo zokubeka ukhuseleko + imingxuma yocingo |

| Imiqobo yomlilo | Imingxunya yokunceda uxinzelelo olungxamisekileyo |

I-XKH ibonelela ngenkxaso yobugcisa ebanzi kunye neenkonzo ezongeziweyo zexabiso le-infrared nanosecond laser drilling izixhobo zokuqinisekisa ukusebenza ngokupheleleyo kumjikelo wobomi besixhobo. Sinikezela ngeenkonzo zophuhliso lwenkqubo elungiselelweyo apho iqela lethu lobunjineli lisebenzisana ngokusondeleyo nabathengi ukuseka amathala eencwadi epharamitha ethile, kubandakanya neenkqubo ezizodwa zokomba izinto ezicela umngeni njengesafire kunye neglasi epholileyo enoguquko olusuka ku-0.1mm ukuya kwi-20mm. Ukulungelelaniswa kwemveliso, siqhuba ukulungelelaniswa kwezixhobo ze-site kunye neemvavanyo zokuqinisekisa ukusebenza, siqinisekisa iimetriki ezibalulekileyo ezifana nokunyamezela kwedayamitha yomngxuma (± 5μm) kunye nomgangatho we-edge (Ra <0.5μm) ihlangabezana nemigangatho yoshishino.