Indlela ye-CVD yokuvelisa izixhobo ezicocekileyo ze-SiC kwi-silicon carbide synthesis synthesis e-1600 ℃

Umgaqo wokuSebenza:

1. Ubonelelo lwangaphambili. Umthombo we-silicon (umz. SiH₄) kunye nomthombo wekhabhoni (umz. C₃H₈) iigesi zixutywe ngokomlinganiselo kwaye zondliwa kwigumbi lokusabela.

2. Ukuchithwa kweqondo lokushisa eliphezulu: Kwiqondo lokushisa eliphezulu le-1500 ~ 2300 ℃, ukuchithwa kwegesi kuvelisa i-Si kunye ne-athomu esebenzayo.

3. Ukusabela komphezulu: iiathom ze-Si kunye ne-C zifakwe kumphezulu we-substrate ukuze zenze i-SiC crystal layer.

4. Ukukhula kweCrystal: Ngokulawulwa kweqondo lobushushu, ukuhamba kwegesi kunye noxinzelelo, ukufezekisa ukukhula kolwalathiso ecaleni kwe-axis okanye i-axis.

Iiparamitha eziphambili:

· Ubushushu: 1600 ~ 2200℃ (>2000℃ ye-4H-SiC)

· Uxinzelelo: 50 ~ 200mbar (uxinzelelo oluphantsi lokunciphisa i-nucleation yegesi)

· Umlinganiselo werhasi: Si/C≈1.0~1.2 (ukunqanda iSi okanye C iziphene zokutyebisa)

Iimpawu eziphambili:

(1) Umgangatho weCrystal

Uxinaniso lwesiphene esisezantsi: Uxinaniso lwemicrotubule <0.5cm ⁻², ingxinano yokususa indawo engaphantsi kwe-10⁴ cm⁻².

Ukulawulwa kohlobo lwe-Polycrystalline: inokukhula i-4H-SiC (i-mainstream), i-6H-SiC, i-3C-SiC kunye nezinye iindidi ze-crystal.

(2) Ukusebenza kwezixhobo

Uzinzo lobushushu obuphezulu: ukufudumeza kwegraphite okanye ukufudumeza ukumelana, ubushushu> 2300 ℃.

Ulawulo olufanayo: ukuguquguquka kobushushu ± 5℃, izinga lokukhula 10 ~ 50μm/h.

Inkqubo yegesi: Ukuchaneka okuphezulu kwe-flowmeter mass (MFC), ukucoceka kwegesi ≥99.999%.

(3) Iinzuzo zobuchwepheshe

Ucoceko oluphezulu: Ukugxininiswa kobumdaka ngasemva <10¹⁶ cm⁻³ (N, B, njl.).

Ubungakanani obukhulu: Inkxaso ye-6 "/8" ye-SiC substrate ukukhula.

(4) Ukusetyenziswa kwamandla kunye neendleko

Ukusetyenziswa kwamandla aphezulu (200 ~ 500kW · h kwisithando somlilo), kubalelwa kwi-30% ~ 50% yeendleko zemveliso ye-SiC substrate.

Usetyenziso olungundoqo:

1. I-substrate ye-semiconductor yamandla: I-SiC MOSFET yokuvelisa izithuthi zombane kunye ne-photovoltaic inverters.

2. Isixhobo se-Rf: Isiseko se-5G isikhululo se-GaN-on-SiC epitaxial substrate.

3.Izixhobo zokusingqongileyo ezigqithisileyo: izivamvo zobushushu obuphezulu zezixhobo ze-aerospace kunye nezixhobo zamandla enyukliya.

Iinkcukacha zobuchwephesha:

| Inkcazo | Iinkcukacha |

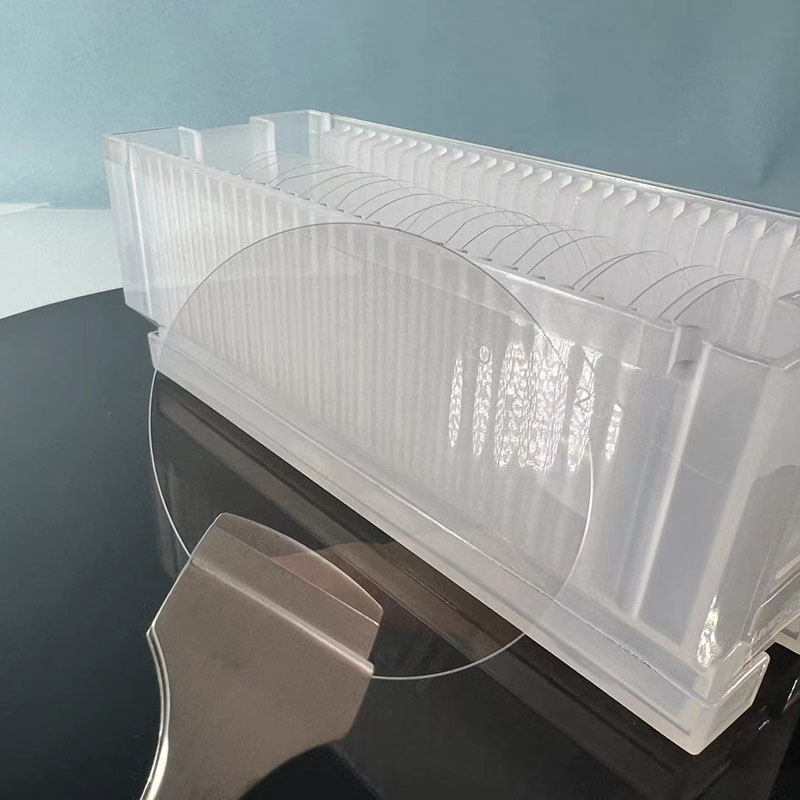

| Imilinganiselo (L × W × H) | 4000 x 3400 x 4300 mm okanye wenze ngokwezifiso |

| Isidanga segumbi lesithando somlilo | 1100mm |

| Ukulayisha umthamo | 50kg |

| Umda wokuvala iqondo | 10-2Pa(2h emva kokuba impompo yemolekyuli iqalile) |

| Inqanaba lokunyuka koxinzelelo lwegumbi | ≤10Pa/h(emva kokubala) |

| Isivalo sokuphakamisa isivalo sesithando somlilo esisezantsi | 1500mm |

| Indlela yokufudumeza | Ukufudumeza kwe-induction |

| Ubushushu obukhulu kwisithando somlilo | 2400°C |

| Ukufudumeza amandla ombane | 2X40kW |

| Umlinganiselo wobushushu | Umlinganiselo wobushushu obunemibala emibini ye-infrared |

| Uluhlu lobushushu | 900 ~ 3000℃ |

| Ukuchaneka kolawulo lobushushu | ±1°C |

| Uluhlu loxinzelelo lokulawula | 1 ~ 700mbar |

| Ukuchaneka koLawulo loxinzelelo | 1 ~ 5mbar ±0.1mbar; 5 ~ 100mbar ± 0.2mbar; 100 ~ 700mbar ± 0.5mbar |

| Indlela yokulayisha | Ukulayisha okusezantsi; |

| Ubumbeko olukhethwayo | Indawo yokulinganisa ubushushu kabini, ukothula iforklift. |

Iinkonzo ze-XKH:

I-XKH inikezela ngeenkonzo zomjikelo opheleleyo we-silicon carbide CVD furnaces, kubandakanywa ukulungiswa kwezixhobo (uyilo lwendawo yobushushu, ukulungelelaniswa kwenkqubo yegesi), uphuhliso lwenkqubo (ulawulo lwekristale, ukulungiswa kwesiphako), uqeqesho lobugcisa (ukusebenza kunye nokugcinwa) kunye nenkxaso emva kokuthengisa (iindawo ezisecaleni zokubonelela ngamacandelo aphambili, ukuxilongwa okude) ukunceda abathengi bafezekise umgangatho ophezulu we-SiC substrate yemveliso. Kwaye unikezele ngeenkonzo zokuphucula inkqubo ngokuqhubekayo ukuphucula isivuno sekristale kunye nokusebenza kakuhle kokukhula.