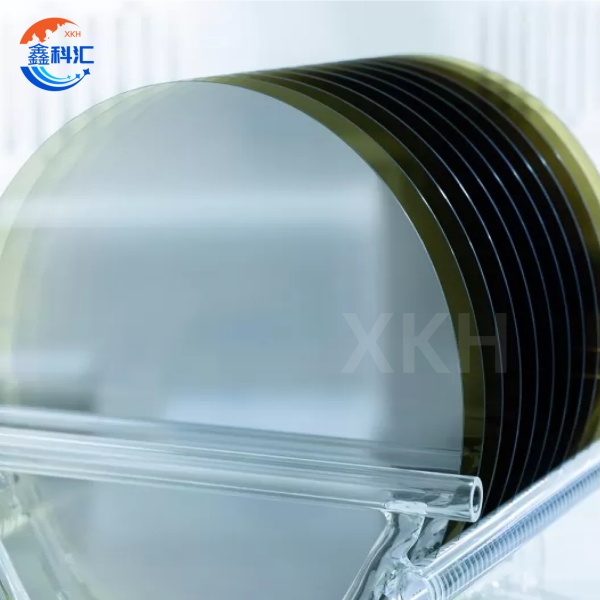

IiSubstrates zeCrystal zeMbewu zeSiC ezilungiselelweyo iDiya 205/203/208 4H-N Uhlobo loNxibelelwano olubonakalayo

Imilinganiselo yobugcisa

Silicon carbide seed imbewu | |

Iipolytype | 4H |

Imposiso yokujonga umphezulu | 4° ukuya <11-20>±0.5º |

Ukuxhathisa | ukwenza ngokwezifiso |

Ububanzi | 205±0.5mm |

Ukutyeba | 600±50μm |

Uburhabaxa | I-CMP, iRa≤0.2nm |

Ukuxinana kweMibhobho | ≤1 i/cm2 |

Imikrwelo | ≤5,UBude buBonke≤2*Ububanzi |

Iitshiphusi ze-Edge / i-indenti | Akukho nanye |

Ukumakishwa kwelaser yangaphambili | Akukho nanye |

Imikrwelo | ≤2,UBude obuBubonke≤Ububanzi |

Iitshiphusi ze-Edge / i-indenti | Akukho nanye |

Iindawo zePolytype | Akukho nanye |

Ukumakishwa kwelaser yangasemva | 1mm (ukusuka kumphetho ophezulu) |

Edge | Chamfer |

Ukupakishwa | Multi-wafer cassette |

Iimpawu eziphambili

1. Ubume beCrystal kunye nokuSebenza koMbane

· Ukuzinza kweCrystallographic: I-100% ye-4H-SiC i-polytype dominance, i-zero multicrystalline inclusions (umzekelo, i-6H / 15R), kunye ne-XRD yokugubha i-curve epheleleyo kwi-half-maximum (FWHM) ≤32.7 arcsec.

· High Carrier Mobility: Electron mobility of 5,400 cm²/V·s (4H-SiC) kunye nokushukuma komngxuma we-380 cm²/V·s, eyenza uyilo lwesixhobo esisebenza ngamaza aphezulu.

·Ubulukhuni bemitha: imelana nemitha ye-neutron eyi-1 kunye nomda womonakalo wokufuduswa we-1×10¹⁵ n/cm², ilungele i-aerospace kunye nokusetyenziswa kwenyukliya.

2. IiPropati zeThermal kunye neMechanical

· I-Exceptional Thermal Conductivity: 4.9 W / cm·K (4H-SiC), i-triple ye-silicon, umsebenzi oxhasayo ngaphezu kwe-200 ° C.

· I-Coefficient yoKwandiswa kwe-Thermal ephantsi: i-CTE ye-4.0 × 10⁻⁶/K (25-1000 ° C), iqinisekisa ukuhambelana nokupakishwa kwe-silicon kunye nokunciphisa uxinzelelo lwe-thermal.

3. Ukulawulwa kweSiphene kunye nokuLungisa ukuChaneka

Uxinaniso lweMibhobho yeMicropipe: <0.3 cm⁻² (ii-intshi ezisi-8-intshi), ingxinano yokususa indawo engaphantsi kwe-1,000 cm⁻² (iqinisekiswe nge-KOH etching).

· Umgangatho woMphezulu: I-CMP-imenyezeliswe ukuya kwi-Ra <0.2 nm, ihlangabezana neemfuno ze-EUV lithography-grade flatness.

Usetyenziso oluphambili

| I-Domain | Iimeko zosetyenziso | Izinto eziluncedo kwezobuGcisa |

| Unxibelelwano lwe-Optical | I-100G / 400G lasers, iimodyuli ze-silicon photonics hybrid | I-substrates yembewu ye-InP yenza i-bandgap ngqo (i-1.34 eV) kunye ne-Si-based heteroepitaxy, ukunciphisa ilahleko yokudibanisa i-optical. |

| Izithuthi zaMandla amatsha | Iziguquli ze-800V eziphezulu ze-voltage, iitshaja ezisebhodini (OBC) | I-4H-SiC substrates ukumelana> 1,200 V, ukunciphisa ilahleko yokuqhuba nge-50% kunye nomthamo wenkqubo nge-40%. |

| Unxibelelwano lwe-5G | Izixhobo zeRF zeMillimeter-wave (PA/LNA), ii-amplifiers zamandla kwisikhululo sesiseko | ISemi-insulating SiC substrates (i-resistivity >10⁵ Ω·cm) yenza i-high-frequency (60 GHz+) indibaniselwano yokwenziwa. |

| Izixhobo zoShishino | Izinzwa zobushushu obuphezulu, iziguquli zangoku, iimonitha zereactor yenyukliya | I-InSb seed substrates (0.17 eV bandgap) ihambisa ubuntununtunu bemagnethi ukuya kuthi ga kwi-300%@10 T. |

Izinto Eziluncedo Ezingundoqo

I-SiC (i-silicon carbide) i-crystal substrates yembewu ihambisa ukusebenza okungafaniyo kunye ne-4.9 W / cm·K conductivity ye-thermal, i-2-4 MV / cm amandla entsimi yokuphuka, kunye ne-3.2 eV bandgap ebanzi, eyenza amandla aphezulu, i-high-frequency, kunye nezicelo eziphezulu zokushisa. Ibandakanya uxinano lwemicropipe engu-zero kunye ne-<1,000 cm⁻² ingxinano yokususa, ezi substrates ziqinisekisa ukuthembeka kwiimeko ezinzima. I-inertness yabo yeekhemikhali kunye ne-CVD-compatible surfaces (Ra <0.2 nm) ixhasa ukukhula kwe-heteroepitaxial ephezulu (umzekelo, i-SiC-on-Si) ye-optoelectronics kunye ne-EV power systems.

Iinkonzo ze-XKH:

1. IMveliso eLungisiweyo

· Iifomathi ze-Wafer eziguquguqukayo: ii-wafers ezi-2-12-intshi ezinesetyhula, uxande, okanye ukusika okwemilo ngokwesiko (±0.01 mm ukunyamezela).

· Ulawulo lwe-Doping: I-nitrogen echanekileyo (N) kunye ne-aluminiyam (Al) idoping nge-CVD, ukufezekisa amanqanaba okuxhathisa ukusuka kwi-10⁻³ ukuya kwi-10⁶ Ω·cm.

2. Ubuchwephesha beNkqubo yoBuchule.

· I-Heteroepitaxy: I-SiC-on-Si (ihambelana nemigca ye-silicon ye-8 intshi) kunye ne-SiC-on-Diamond (i-thermal conductivity> 2,000 W / m · K).

· Unciphiso lweSiphene: Ukucinywa kweHydrojeni kunye nokuqhotyoshela ukunciphisa imicropipe/iziphene zoxinaniso, ukuphucula isivuno sewafer ukuya kuma>95%.

3. IiNkqubo zoLawulo loMgangatho.

· Uvavanyo lokuphela kokuphela: I-Raman spectroscopy (ukuqinisekiswa kwe-polytype), i-XRD (i-crystallinity), kunye ne-SEM (uhlalutyo lwesiphene).

· Iziqinisekiso: Ukuthobela i-AEC-Q101 (imoto), iJEDEC (JEDEC-033), kunye ne-MIL-PRF-38534 (ibakala lomkhosi).

4. INkxaso yoBonelelo lwehlabathi.

· Umthamo weMveliso: Imveliso yenyanga> ii-wafers eziyi-10,000 (60% 8-intshi), kunye nokuhanjiswa okungxamisekileyo kweeyure ezingama-48.

· Uthungelwano loLungiselelo: Ukuhanjiswa kweYurophu, kuMntla Melika, kunye ne-Asia-Pacific ngothutho lomoya/lolwandle ngokupakishwa okulawulwa ngamaqondo obushushu.

5. UPhuhliso lokuBambisana kwezobuGcisa.

· IiLab zeR&D eziDityanisiweyo: Ukusebenzisana kwimodyuli yamandla e-SiC yokupakishwa kolungiselelo (umzekelo, ukuhlanganiswa kwe-DBC substrate).

· Ilayisensi ye-IP: Ukubonelela ngelayisensi ye-GaN-on-SiC RF epitaxial yeteknoloji yokukhula ukunciphisa iindleko ze-R&D zabaxumi.

Isishwankathelo

I-SiC (i-silicon carbide) i-crystal substrates yembewu, njengesixhobo sobuchule, ilungisa amatyathanga oshishino lwehlabathi ngokuphumelela ekukhuleni kwekristale, ulawulo lwesiphene, kunye nokudibanisa okungafaniyo. Ngokuqhubekayo ukuqhubela phambili ukucutha i-wafer defect, ukunyusa i-8-intshi yemveliso, kunye nokwandisa amaqonga e-heteroepitaxial (umzekelo, i-SiC-on-Diamond), i-XKH ihambisa ukuthembeka okuphezulu, izisombululo ezingabizi kakhulu kwi-optoelectronics, amandla amatsha, kunye nokuveliswa okuphezulu. Ukuzibophelela kwethu kwizinto ezintsha kuqinisekisa ukuba abathengi bakhokele ekungathathi hlangothi kwekhabhoni kunye neenkqubo ezikrelekrele, ukuqhuba ixesha elilandelayo le-wide-bandgap semiconductor ecosystems.