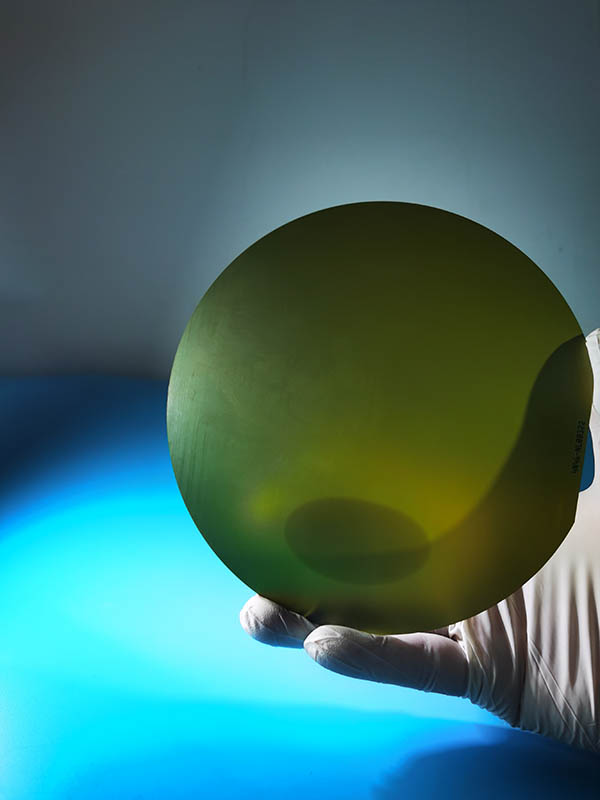

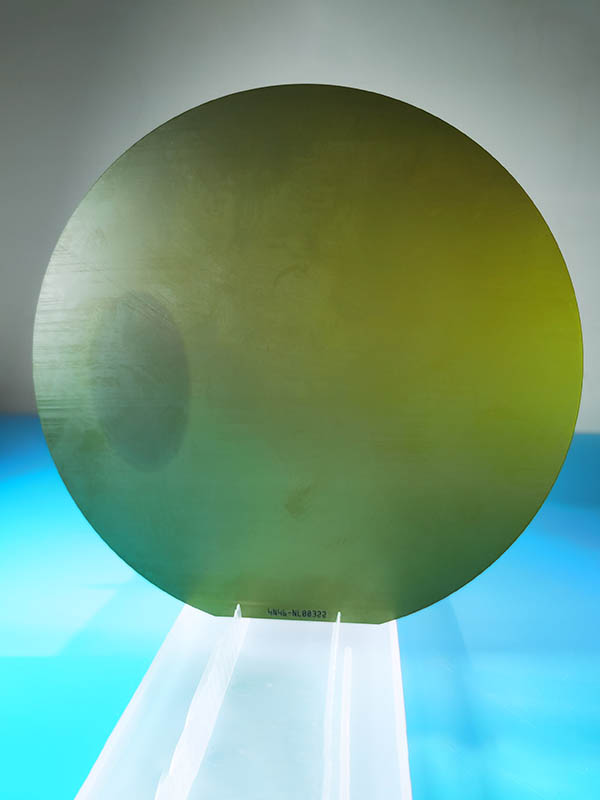

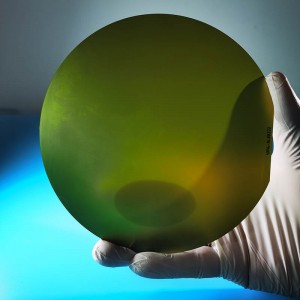

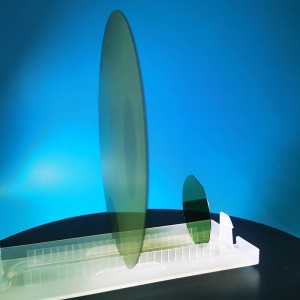

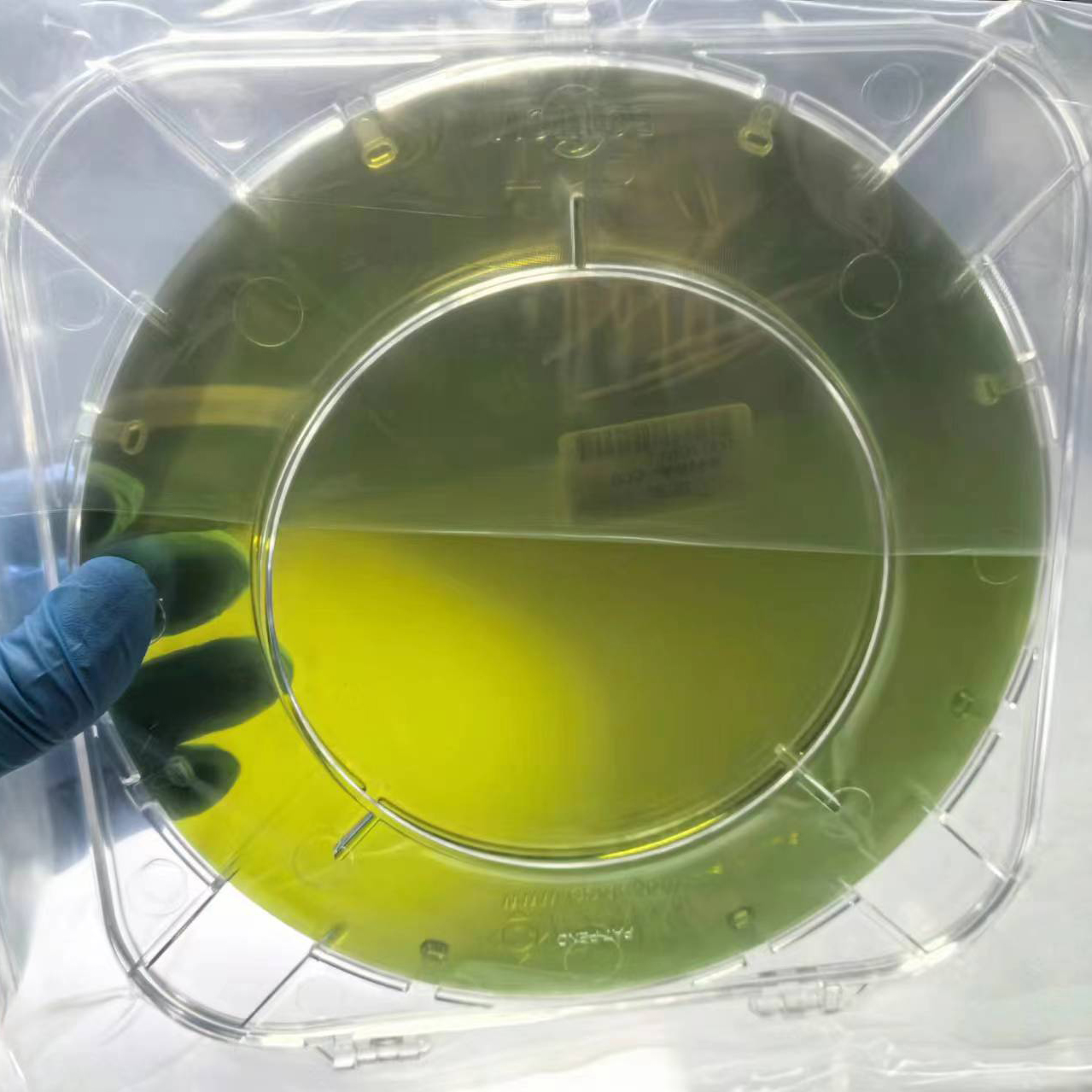

I-8Inch 200mm 4H-N SiC Wafer Ibanga lophando lwe-dummy

Ngenxa yeempawu zayo ezizodwa kunye ne-elektroniki, i-200mm SiC wafer semiconductor imathiriyeli isetyenziselwa ukwenza ukusebenza okuphezulu, ubushushu obuphezulu, ukumelana nemitha, kunye nezixhobo zombane ezisebenza kakhulu. Ixabiso le-substrate ye-8inch SiC liyehla ngokuthe ngcembe njengoko itekhnoloji ihambela phambili ngakumbi kwaye imfuno ikhula. Uphuhliso lwetekhnoloji yakutsha nje lukhokelela ekuvelisweni kwesikali sokwenziwa kwee-wafers ze-SiC ezingama-200mm. Iinzuzo eziphambili ze-SiC wafer semiconductor materials xa kuthelekiswa ne-Si kunye ne-GaAs wafers: Amandla ombane ombane we-4H-SiC ngexesha lokuphuka kwe-avalanche ingaphezulu komyalelo wobukhulu obuphezulu kunexabiso elihambelanayo le-Si kunye ne-GaAs. Oku kukhokelela ekunciphiseni okubonakalayo kwi-restivity ye-Ron. I-Low on-state resistivity, edityaniswe noxinano oluphezulu lwangoku kunye ne-thermal conductivity, ivumela ukusetyenziswa kokufa okuncinci kakhulu kwizixhobo zamandla. I-conductivity ephezulu ye-thermal ye-SiC inciphisa ukuxhathisa kwe-thermal ye-chip. Iimpawu ze-elektroniki zezixhobo ezisekelwe kwii-wafers ze-SiC zizinzile kakhulu ngexesha kunye neqondo lokushisa elizinzileyo, eliqinisekisa ukuthembeka okuphezulu kweemveliso. I-silicon carbide ixhathisa ngokugqithiseleyo kwi-radiation enzima, engayithobiyo i-electronic properties ye-chip. Ukushisa okuphezulu kokusebenza kwekristale (ngaphezulu kwe-6000C) kukuvumela ukuba wenze izixhobo ezinokwethenjelwa kakhulu kwiimeko zokusebenza ezinzima kunye nezicelo ezizodwa. Okwangoku, sinokubonelela ngee-wafers ezincinci ze-200mmSiC ngokuthe ngcembe kwaye ngokuqhubekayo kwaye sibe nesitokhwe kwindawo yokugcina.

Inkcazo

| Inani | Into | Iyunithi | Imveliso | Uphando | Dummy |

| 1. Iiparamitha | |||||

| 1.1 | i-polytype | -- | 4H | 4H | 4H |

| 1.2 | ukuqhelaniswa nomphezulu | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Ipharamitha yombane | |||||

| 2.1 | dopant | -- | n-uhlobo lweNitrojeni | n-uhlobo lweNitrojeni | n-uhlobo lweNitrojeni |

| 2.2 | ukumelana | ohm ·cm | 0.015~0.025 | 0.01~0.03 | NA |

| 3. Mechanical parameter | |||||

| 3.1 | ububanzi | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | ubukhulu | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | Ukuqhelaniswa nenotshi | ° | [1- 100] ±5 | [1- 100] ±5 | [1- 100] ±5 |

| 3.4 | Ubunzulu beNotshi | mm | 1~1.5 | 1~1.5 | 1~1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Ukuqubuda | μm | -25~25 | -45~45 | -65~65 |

| 3.8 | I-Wap | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Ubume | |||||

| 4.1 | ukuxinana kwemibhobho | uya/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | umxholo wesinyithi | iiathom/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | uya/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | I-BPD | uya/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | uya/cm2 | ≤7000 | ≤10000 | NA |

| 5. Umgangatho oncomekayo | |||||

| 5.1 | ngaphambili | -- | Si | Si | Si |

| 5.2 | umphezulu wokugqiba | -- | Si-ubuso CMP | Si-ubuso CMP | Si-ubuso CMP |

| 5.3 | isuntswana | i-ea/wafer | ≤100(ubukhulu≥0.3μm) | NA | NA |

| 5.4 | umkrwelo | i-ea/wafer | ≤5, UBude buBonke≤200mm | NA | NA |

| 5.5 | Edge iitshiphusi/iziindenti/iintanda/amabala/ungcoliseko | -- | Akukho nanye | Akukho nanye | NA |

| 5.6 | Iindawo zePolytype | -- | Akukho nanye | Indawo ≤10% | Indawo ≤30% |

| 5.7 | uphawu lwangaphambili | -- | Akukho nanye | Akukho nanye | Akukho nanye |

| 6. Umgangatho wasemva | |||||

| 6.1 | emva kokugqiba | -- | C-ubuso MP | C-ubuso MP | C-ubuso MP |

| 6.2 | umkrwelo | mm | NA | NA | NA |

| 6.3 | Umqolo uneziphene edge iitshiphusi/iindidi | -- | Akukho nanye | Akukho nanye | NA |

| 6.4 | Umqolo uburhabaxa | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Ukumakisha ngasemva | -- | Inotshi | Inotshi | Inotshi |

| 7. Ungqameko | |||||

| 7.1 | edge | -- | Chamfer | Chamfer | Chamfer |

| 8. Iphakheji | |||||

| 8.1 | ukupakishwa | -- | I-Epi-ilungile kunye ne-vacuum ukupakishwa | I-Epi-ilungile kunye ne-vacuum ukupakishwa | I-Epi-ilungile kunye ne-vacuum ukupakishwa |

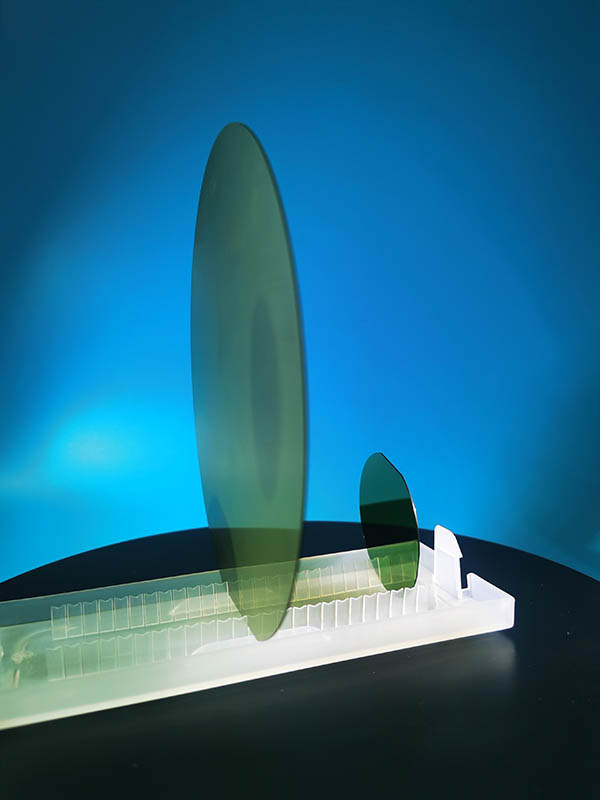

| 8.2 | ukupakishwa | -- | I-Multi-wafer ukupakishwa kweekhasethi | I-Multi-wafer ukupakishwa kweekhasethi | I-Multi-wafer ukupakishwa kweekhasethi |

Idayagram eneenkcukacha