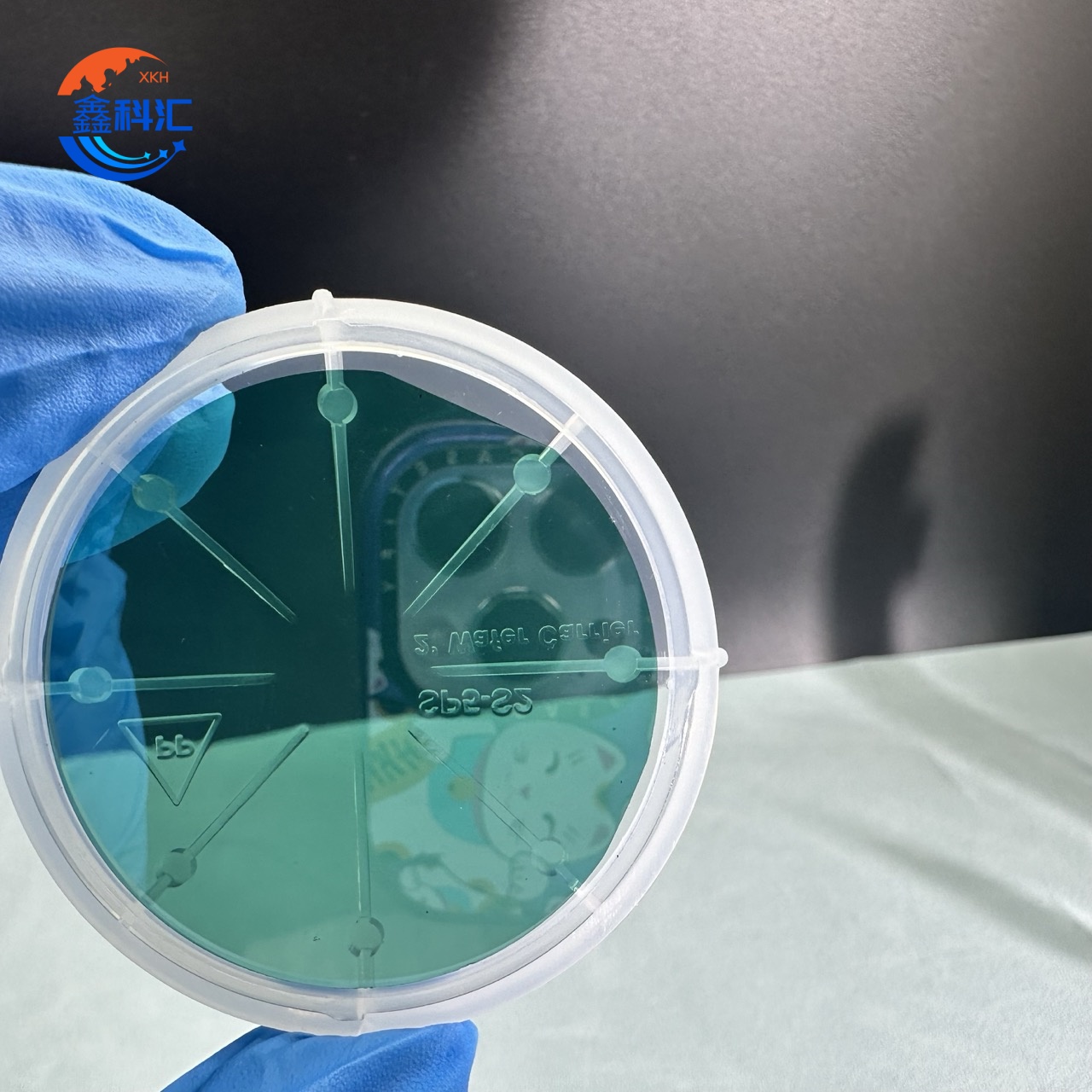

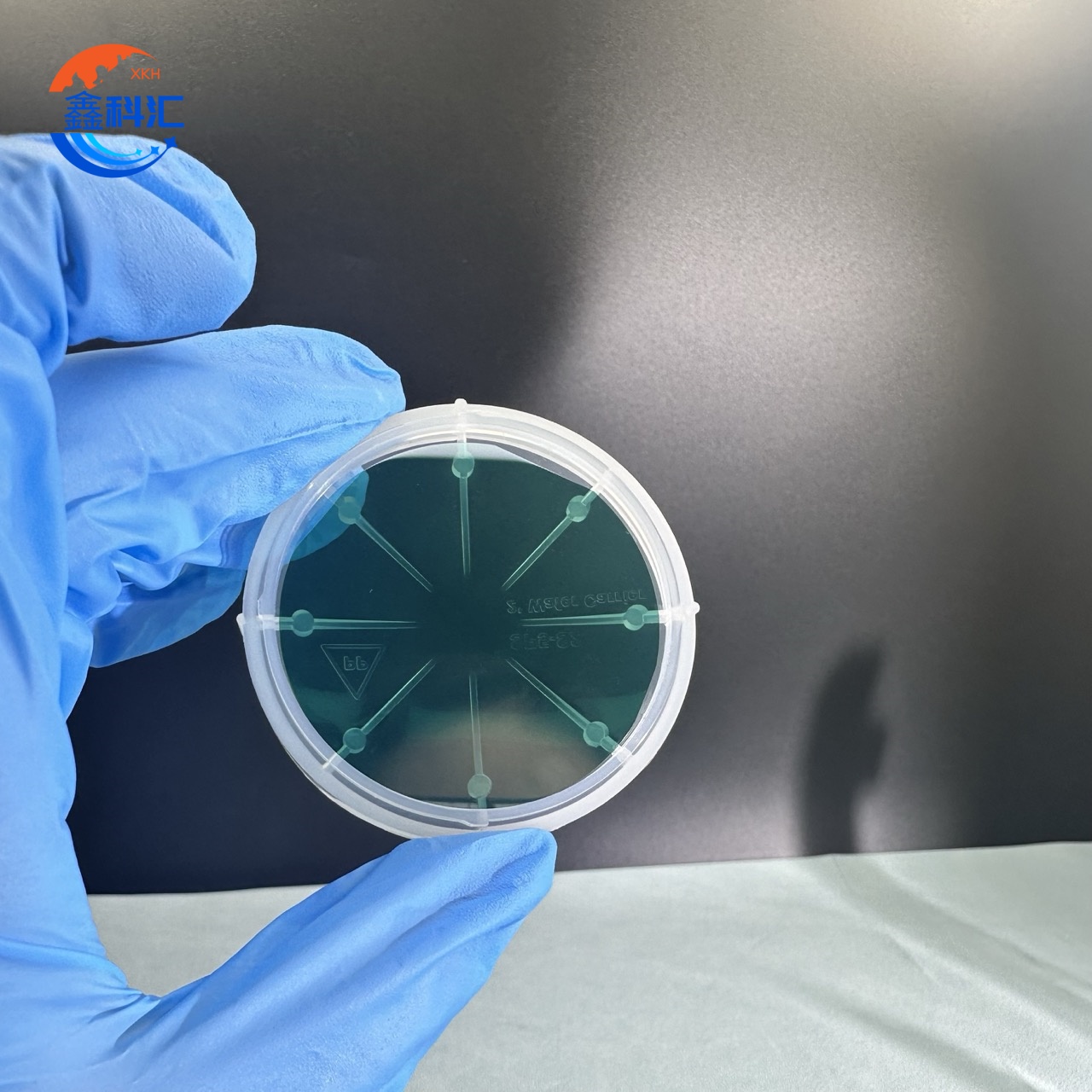

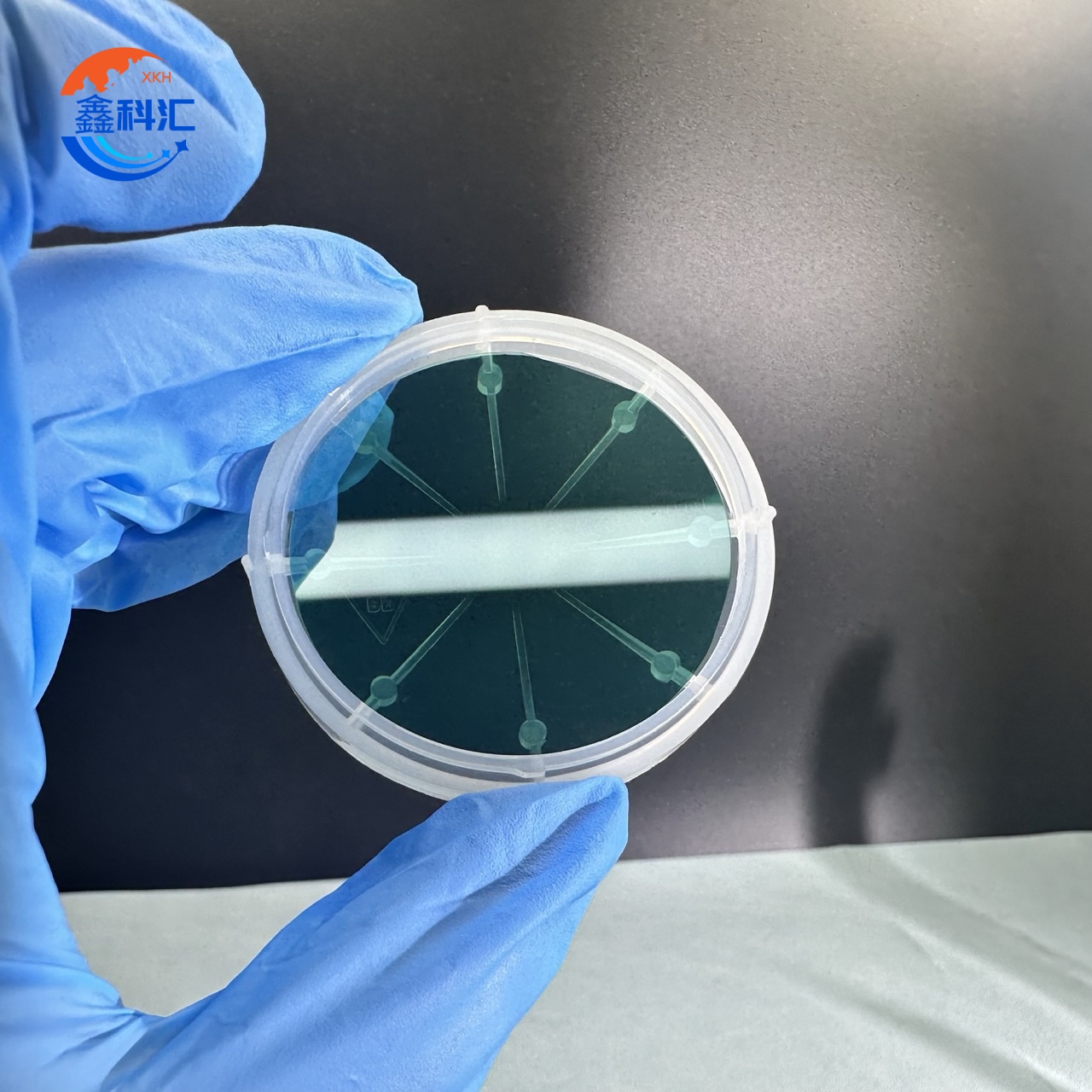

2inch Silicon Carbide Wafer 6H-N Uhlobo lwePrime iBanga loPhando IBanga leDummy iBanga 330μm 430μm Ukutyeba

Ezi zilandelayo ziimpawu ze-silicon carbide wafer:

I-1.I-Silicon carbide (i-SiC) i-wafer ineepropati ezinkulu zombane kunye neempawu ezibalaseleyo ze-thermal. I-Silicon carbide (i-SiC) i-wafer inokwandiswa kwe-thermal ephantsi.

I-2.Silicon carbide (SiC) i-wafer ineempawu eziphezulu zobunzima. I-silicon carbide (i-SiC) i-wafer iqhuba kakuhle kumaqondo aphezulu.

I-3.I-Silicon carbide (i-SiC) i-wafer inokuchasana okuphezulu kwi-corrosion, i-rosion kunye ne-oxidation. Ukongeza koku, i-silicon carbide (SiC) wafer ikwacwebezela ngakumbi kunedayimani okanye i-cubic zirconia.

I-4.Ngcono ukumelana nemitha: Ii-wafers ze-SIC zinamandla okumelana nemitha, zizenza zilungele ukusetyenziswa kwiindawo zokusasazeka kwemitha. Imizekelo ibandakanya iziphekepheke kunye nezixhobo zenyukliya.

I-5.Ubunzima obuphezulu: Ii-wafers ze-SIC zinzima kune-silicon, eziphakamisa ukuqina kwee-wafers ngexesha lokucubungula.

I-6.I-dielectric constant constant: I-dielectric constant of SIC wafers iphantsi kune-silicon, enceda ukunciphisa i-parasitic capacitance kwisixhobo kunye nokuphucula ukusebenza kwe-high-frequency.

I-Silicon carbide wafer inezicelo ezininzi

I-SiC isetyenziselwa ukwenza izixhobo ezine-voltage ephezulu kakhulu kunye nezixhobo ezinamandla kakhulu ezifana ne-diode, ii-transistors zamandla, kunye nezixhobo eziphezulu ze-microwave zamandla. Xa kuthelekiswa nezixhobo eziqhelekileyo ze-Si, izixhobo zamandla ezisekelwe kwi-SiC zinesantya sokutshintsha ngokukhawuleza i-voltages ephezulu, ukuchasana kwe-parasitic ephantsi, ubungakanani obuncinci, ukupholisa okuncinci okufunekayo ngenxa yesakhono sobushushu obuphezulu.

Ngelixa i-Silicon carbide (i-SiC-6H) - i-6H i-wafer ineepropati eziphezulu ze-elektroniki, i-silicon carbide (i-SiC-6H) - i-6H i-wafer ilungiselelwe ngokulula kwaye ifundwe kakuhle.

I-1.I-Electronics ye-Electronics: I-Silicon Carbide Wafers isetyenziselwa ukuveliswa kwe-Power Electronics, esetyenziswa kwiintlobo ezininzi zezicelo, kubandakanywa izithuthi zombane, iinkqubo zamandla avuselelekayo, kunye nezixhobo zoshishino. Ukuqhuba okuphezulu kwe-thermal kunye nokulahlekelwa kwamandla aphantsi kwe-Silicon Carbide kuyenza ibe yinto efanelekileyo kwezi zicelo.

I-2.Ukukhanya kwe-LED: I-Silicon Carbide Wafers isetyenziselwa ukuveliswa kokukhanya kwe-LED. Amandla aphezulu e-Silicon Carbide enza kube lula ukuvelisa ii-LED ezihlala ixesha elide kwaye zihlala ixesha elide kunemithombo yokukhanyisa yesiko.

I-3.Izixhobo ze-Semiconductor: Ii-Silicon Carbide Wafers zisetyenziselwa ukuveliswa kweeSemiconductor Devices, ezisetyenziselwa uluhlu olubanzi lwezicelo, kubandakanywa unxibelelwano, i-computing, kunye ne-electronics yabathengi. Ukuqhuba okuphezulu kwe-thermal kunye nokulahlekelwa kwamandla aphantsi kwe-Silicon Carbide kuyenza ibe yinto efanelekileyo kwezi zicelo.

I-4.Iiseli zeSolar: Ii-Silicon Carbide Wafers zisetyenziselwa ukuveliswa kweeSeli zeSolar. Amandla aphezulu e-Silicon Carbide enza kube lula ukuvelisa iiSeli zeSolar ezihlala ixesha elide kwaye zihlala ixesha elide kuneeSeli zeSolar zemveli.

Ngokubanzi, i-ZMSH Silicon Carbide Wafer yimveliso eguquguqukayo kunye nekhwalithi ephezulu enokusetyenziswa kuluhlu olubanzi lwezicelo. I-thermal conductivity yayo ephezulu, ukulahleka kwamandla aphantsi, kunye namandla aphezulu kuyenza ibe yinto efanelekileyo kubushushu obuphezulu kunye nezixhobo zombane eziphezulu. NgeSaphetha/I-Warp ye-≤50um, Uburhabaxa boMphezulu be-≤1.2nm, kunye ne-Resistivity of High/Low Resistivity, i-Silicon Carbide Wafer lukhetho oluthembekileyo nolusebenzayo lwaso nasiphi na isicelo esifuna indawo ethe tyaba negudileyo.

Imveliso yethu yeSiC Substrate iza nenkxaso yobuchwephesha kunye neenkonzo zokuqinisekisa ukusebenza ngokupheleleyo kunye nokwaneliseka kwabathengi.

Iqela lethu leengcaphephe liyafumaneka ukuncedisa ngokukhethwa kwemveliso, ukufakwa, kunye nokusombulula ingxaki.

Sinikezela ngoqeqesho kunye nemfundo malunga nokusetyenziswa kunye nokugcinwa kweemveliso zethu ukunceda abathengi bethu bakhulise utyalo-mali lwabo.

Ukongeza, sinikezela ngohlaziyo lwemveliso oluqhubekayo kunye nezixhasi zokuqinisekisa ukuba abathengi bethu bahlala befikelela kubuchwephesha bamva nje.

Idayagram eneenkcukacha