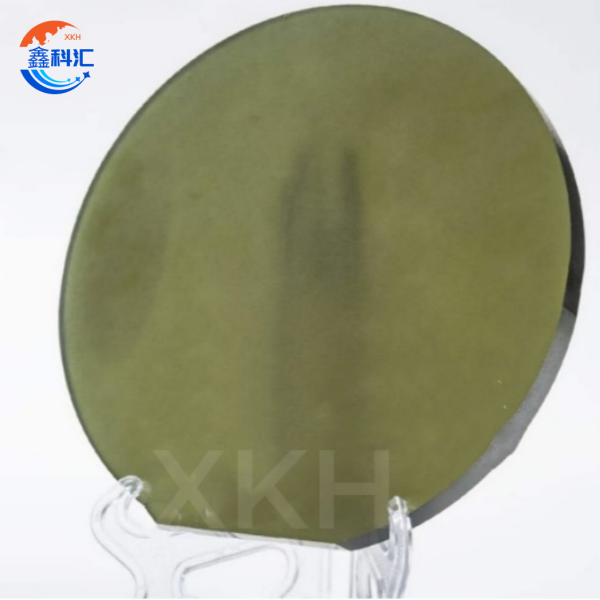

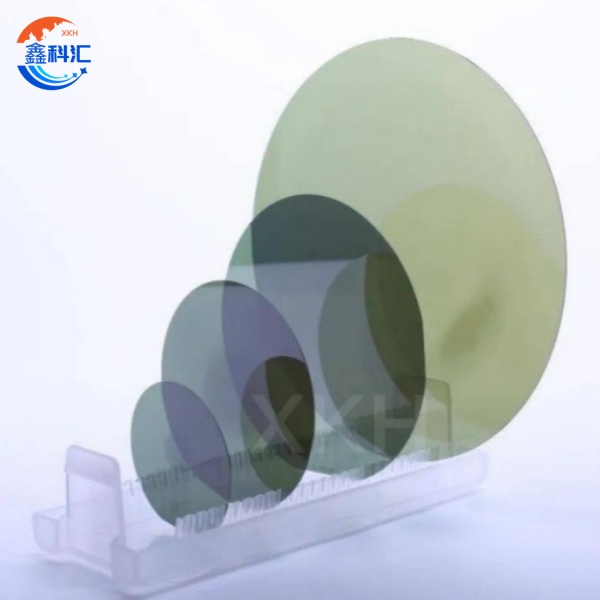

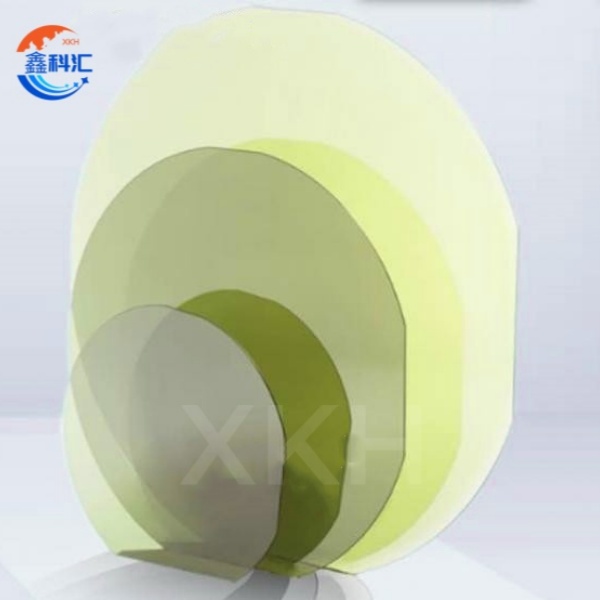

I-12 intshi ye-SIC i-substrate ye-silicon carbide yodidi oluphambili ubukhulu be-300mm ubukhulu obukhulu 4H-N Ifanele ukuchithwa kobushushu kwisixhobo esinamandla aphezulu

Iimpawu zemveliso

1. I-conductivity ephezulu ye-thermal: i-thermal conductivity ye-silicon carbide ingaphezu kwamaxesha e-3 ye-silicon, efanelekileyo kwisixhobo esinamandla esiphezulu sokutshatyalaliswa kokushisa.

2. Amandla entsimi yokuphuka okuphezulu: Amandla entsimi yokuphuka ngamaxesha angama-10 e-silicon, afanelekile kwizicelo zoxinzelelo oluphezulu.

I-3.I-Bandgap ebanzi: I-bandgap yi-3.26eV (4H-SiC), ifanelekile kwiqondo lokushisa eliphezulu kunye nezicelo eziphezulu.

4. Ubunzima obuphezulu: Ubunzima be-Mohs yi-9.2, okwesibini kuphela kwidayimane, ukuxhathisa okugqwesileyo kokugqoka kunye namandla omatshini.

5. Ukuzinza kweekhemikhali: ukuxhathisa okuqinileyo kwe-corrosion, ukusebenza okuzinzileyo kwiqondo lokushisa eliphezulu kunye nokusingqongileyo okunzima.

6. Ubungakanani obukhulu: i-intshi eyi-12 (300mm) i-substrate, ukuphucula ukusebenza kakuhle kwemveliso, ukunciphisa iindleko zeyunithi.

I-7.I-defect defectity density: umgangatho ophezulu we-crystal eyodwa yokukhula iteknoloji yokuqinisekisa ubuninzi besiphako esiphantsi kunye nokuhambelana okuphezulu.

Ulwalathiso lwesicelo oluphambili lwemveliso

1. Ii-elektroniki zamandla:

I-Mosfets: Isetyenziswa kwizithuthi zombane, iimoto zemizi-mveliso kunye neziguquli zamandla.

IiDiodes: ezifana ne-Schottky diodes (SBD), esetyenziselwa ukulungiswa ngokufanelekileyo kunye nokutshintsha izixhobo zombane.

2. Izixhobo ze-RF:

I-amplifier yamandla e-Rf: isetyenziswe kwizikhululo zesiseko zonxibelelwano ze-5G kunye nonxibelelwano lwesathelayithi.

Izixhobo zeMicrowave: Ifanelekile kwi-radar kunye neenkqubo zonxibelelwano ezingenazintambo.

3. Izithuthi zamandla amatsha:

Iinkqubo zokuqhuba umbane: abalawuli beemoto kunye nee-inverters zezithuthi zombane.

Inqwaba yokutshaja: Imodyuli yamandla yezixhobo zokutshaja ngokukhawuleza.

4. Izicelo zamashishini:

I-inverter yamandla aphezulu: kulawulo lweemoto zamashishini kunye nolawulo lwamandla.

Igridi ye-Smart: Kusasazo lwe-HVDC kunye neziguquli zombane zombane.

5. I-Aerospace:

Ubushushu obuphezulu be-elektroniki: bulungele imekobume yobushushu obuphezulu bezixhobo ze-aerospace.

6. Indawo yophando:

Uphando olubanzi lwe-bandgap semiconductor: kuphuhliso lwezixhobo ezintsha ze-semiconductor kunye nezixhobo.

I-12-intshi ye-silicon carbide substrate luhlobo lwe-substrate ye-semiconductor ye-high-performance ye-semiconductor eneempawu ezintle ezifana ne-conductivity ephezulu ye-thermal, amandla aphezulu okuphuka kunye ne-wide band gap. Isetyenziswa kakhulu kumbane we-elektroniki, izixhobo zerediyo zamaza, izithuthi zamandla amatsha, ulawulo lwamashishini kunye ne-aerospace, kwaye iyimathiriyeli ephambili yokukhuthaza uphuhliso lwesizukulwana esilandelayo sezixhobo zombane ezisebenzayo neziphezulu.

Ngelixa i-silicon carbide substrates okwangoku inezicelo ezimbalwa ezithe ngqo kubathengi be-electronics ezifana neeglasi ze-AR, amandla abo kulawulo olusebenzayo lwamandla kunye ne-electronics miniaturized inokuxhasa ukukhaphukhaphu, izisombululo zonikezelo lwamandla aphezulu kwizixhobo ze-AR / VR zexesha elizayo. Okwangoku, uphuhliso oluphambili lwe-silicon carbide substrate lugxininiswe kwiinkalo zoshishino ezifana neenqwelo zamandla amatsha, iziseko zonxibelelwano kunye ne-automation ye-industrial, kwaye ikhuthaza imboni ye-semiconductor ukuba iphuhlise ngendlela efanelekileyo kunye nethembekileyo.

I-XKH izibophelele ekuboneleleni ngomgangatho ophezulu we-12 "ii-SIC substrates ezinenkxaso ebanzi yobugcisa kunye neenkonzo, kuquka:

1. Imveliso eyenziwe ngokwezifiso: Ngokweemfuno zabathengi ukubonelela nge-resistivity eyahlukileyo, i-crystal orientation kunye ne-substrate yonyango lomhlaba.

2. Ukulungiswa kwenkqubo: Ukubonelela abathengi ngenkxaso yobugcisa bokukhula kwe-epitaxial, ukuveliswa kwesixhobo kunye nezinye iinkqubo zokuphucula ukusebenza kwemveliso.

3. Uvavanyo kunye nesiqinisekiso: Ukubonelela ngokufunyaniswa kwesiphene esingqongqo kunye nesiqinisekiso somgangatho wokuqinisekisa ukuba i-substrate ihlangabezana nemigangatho yoshishino.

Intsebenziswano ye-4.R&d: Ngokudibeneyo phuhlisa izixhobo ezitsha ze-silicon carbide kunye nabathengi ukukhuthaza ukutsha kwetekhnoloji.

Itshathi yedatha

| I-1 2 intshi yeSilicon Carbide (SiC) Inkcazo yeSubstrate | |||||

| IBanga | Imveliso yeZeroMPD IBanga (Z Grade) | Imveliso esemgangathweni IBanga (P Grade) | IBanga leDummy (D Grade) | ||

| Ububanzi | 3 0 0 mm~305mm | ||||

| Ukutyeba | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| I-Wafer Orientation | I-off axis : 4.0 ° ukuya ku- <1120 > ±0.5 ° ye-4H-N, Kwi-axis : <0001>±0.5 ° ye-4H-SI | ||||

| Ukuxinana kweMibhobho | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ukuxhathisa | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Ukuqhelaniswa neFlethi okuPhambili | {10-10} ±5.0° | ||||

| Ubude beFlethi obuPhambili | 4H-N | N / A | |||

| 4H-SI | Inotshi | ||||

| Ukungabandakanywa kuMda | 3 mm | ||||

| LTV/TTV/Saphetha/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Uburhabaxa | IsiPolish Ra≤1 nm | ||||

| I-CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| I-Edge Cracks ngokuKhanya okuPhakamileyo Iipleyiti zeHex ngokuKhanya okuPhakamileyo Iindawo zePolytype NgokuKhanya okuPhakamileyo Ukubandakanywa kweCarbon ebonakalayo I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Akukho nanye Indawo eyongezelekayo ≤0.05% Akukho nanye Indawo eyongezelekayo ≤0.05% Akukho nanye | Ubude obongezelekayo ≤ 20 mm, ubude obunye≤2 mm Indawo eyongezelekayo ≤0.1% Indawo eyongezelekayo≤3% Indawo eyongezelekayo ≤3% Ubude obongezelekayo≤1×i-wafer idayamitha | |||

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥0.2mm ububanzi nobunzulu | I-7 ivunyelwe, ≤1 mm nganye | |||

| (TSD) Ukushenxiswa kwesikrufu somsonto | ≤500 cm-2 | N / A | |||

| (BPD) Isiseko sokuchithwa kwenqwelomoya | ≤1000 cm-2 | N / A | |||

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | Akukho nanye | ||||

| Ukupakishwa | Multi-wafer Cassette Okanye Single Wafer Container | ||||

| Amanqaku: | |||||

| 1 Imida yeziphene isebenza kuwo wonke umphezulu we-wafer ngaphandle kwendawo yokukhutshwa komphetho. 2Imikrwelo kufuneka ijongwe kuSi face kuphela. 3 Idatha yokususa isuka kwi-KOH etshisiweyo kuphela. | |||||

I-XKH iya kuqhubeka ityalomali kuphando kunye nophuhliso ukukhuthaza ukuphumelela kwe-12-intshi ye-silicon carbide substrates ngobukhulu obukhulu, iziphene eziphantsi kunye nokuhambelana okuphezulu, ngelixa i-XKH ihlola izicelo zayo kwiindawo ezikhulayo ezifana ne-electronics zabathengi (ezifana neemodyuli zamandla ze-AR / VR izixhobo) kunye ne-computing ye-quantum. Ngokunciphisa iindleko kunye nokwandisa umthamo, i-XKH iya kuzisa ukuchuma kwishishini le-semiconductor.

Idayagram eneenkcukacha