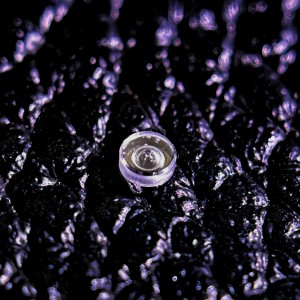

Nge-Hole Transparent Sapphire Components

Idayagram eneenkcukacha

Isishwankathelo

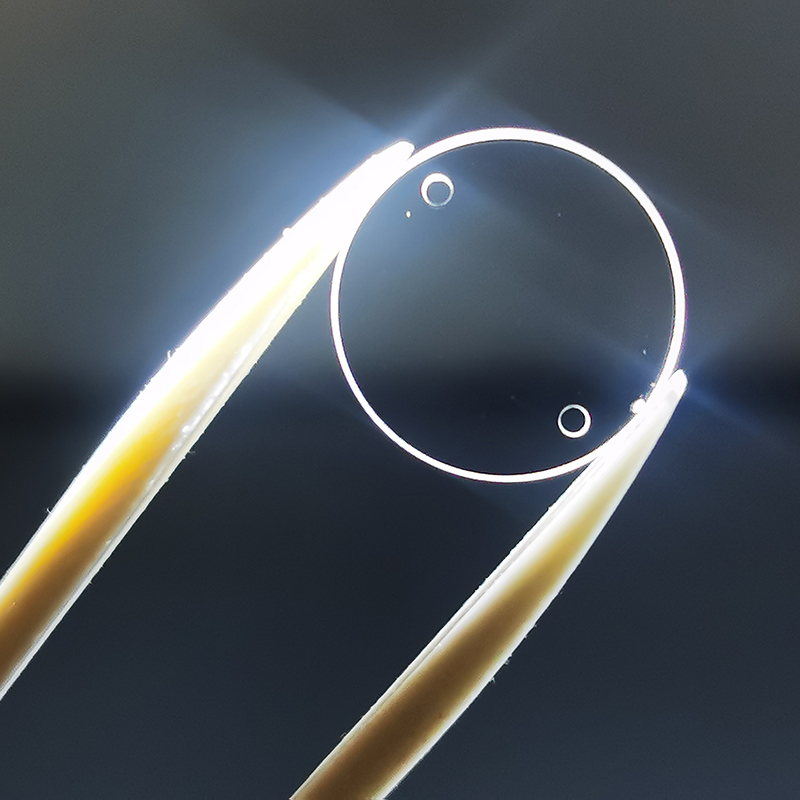

Amalungu esafire asemngxunyeni angena gingci zizinto eziyinjineli ezichanekileyo ezenziwe kwi-single-crystal aluminiyam oxide (Al₂O₃), into eyaziwayo ngokudityaniswa kwayo nokungafihli okubonakalayo, ubulukhuni obuphezulu, kunye nokungangeni kwemichiza. Ezi zixhobo zibonakalisa imingxuma echanekileyo eyenza ukudityaniswa komatshini, ukulungelelaniswa kwe-optical, okanye i-flow channels elawulwayo ngelixa igcina ukusebenza okugqwesileyo kwe-optical kunye nesakhiwo. Indibaniselwano yabo ekhethekileyo yemisebenzi yamehlo kunye noomatshini ibenza babaluleke kakhulu kwi-semiconductor, i-aerospace, ifotonics, kunye namashishini ezixhobo.

Iimpawu zeMathiriyeli

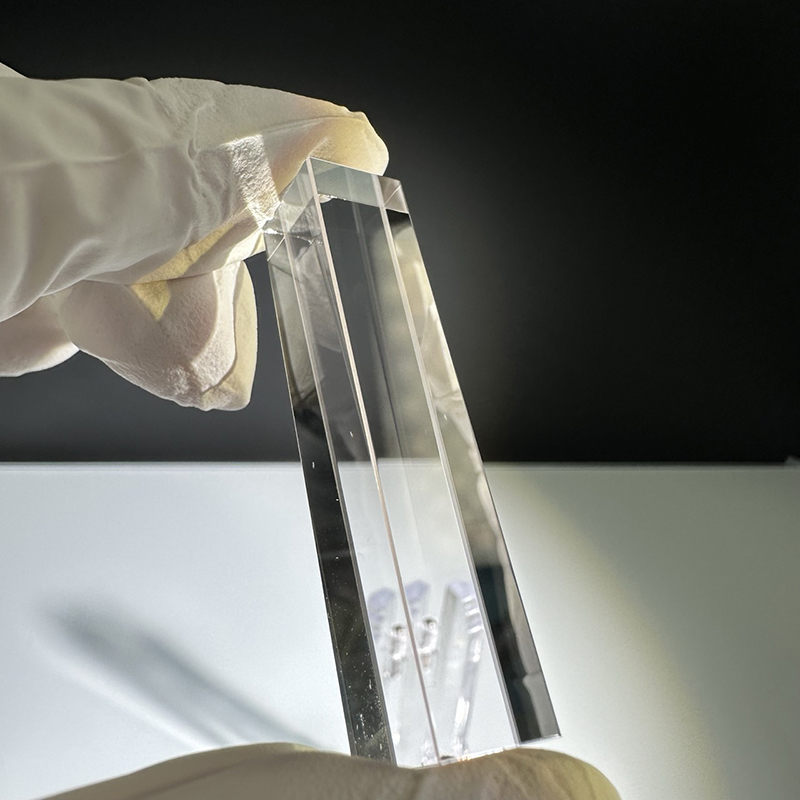

Iimpawu ezikhethekileyo zeSapphire zivela kubume bekristale enye kunye nokuzinza kweekhemikhali. Ngobulukhuni be-9 kwisikali se-Mohs, isafire inikezela ngokugqwesileyo kokuxhathisa kwe-abrasion kunye nozinzo lwe-dimensional naphantsi kwemithwalo ephezulu. I-optically transparent kuluhlu olubanzi lwe-spectral-ukusuka kwi-ultraviolet enzulu (UV) ngokukhanya okubonakalayo ukuya kwi-infrared ephakathi (IR) -kwaye igcina ukucaca phantsi koxinzelelo oluphezulu lwe-thermal. Indawo yokunyibilika yeSapphire idlula 2000°C, kwaye ibonisa ukuxhathisa okugqwesileyo kwi-asidi, ialkali, kunye nokutyhileka kweplasma.

IiNzuzo ezingundoqo

-

UNgaphandle kokuNgaphandle:Ukuhanjiswa koluhlu ukusuka kwi-190 nm ukuya kwi-5000 nm, kuqinisekisa ilahleko encinci yamehlo kwiinkqubo ze-UV-IR.

-

Amandla oomatshini aBalaseleyo:Amandla aphezulu oxinzelelo kunye ne-flexural yokusetyenziswa kuxinzelelo kunye namagumbi okucoca.

-

Ukomelela kweThermal:Igcina ukusebenza kwesakhiwo kunye ne-optical kumaqondo okushisa aphezulu.

-

Ukuxhathisa kwiMichiza kunye nePlasma:I-Non-reactive to most chemical reagents kwaye izinzile kwi-plasma okanye kwi-atmospheres edlekayo.

-

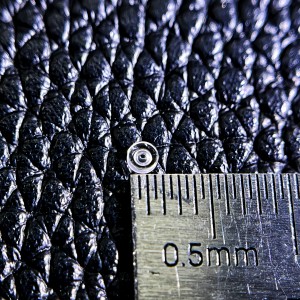

Ubunjineli obuchanekileyo:Imingxunya inokugrunjwa, itshonelwe, okanye icolwe ngokunyamezela ngaphakathi kwe ±5 µm.

-

Ukuthembeka kwexesha elide:Akukho kuthotywa kweepropathi ezibonakalayo okanye zoomatshini ngokusetyenziswa ixesha elide.

Usetyenziso

-

Ukwenziwa kweSemiconductor:

Isetyenziswe njengeefestile zokuhlola, i-nozzles yegesi, okanye i-isolation components kwi-CVD, i-PECVD, kunye nezixhobo zokudibanisa, apho ukuzinza kwe-thermal kunye nokucoceka kubalulekile. -

Izixhobo zokubona kunye neFotonic:

Imisebenzi njengezinto zokunyuswa zamehlo, iifestile zesivamvo, okanye ujongano lwesikhokelo esikhanyayo esifuna imingxunya yolungelelwaniso, ukudibanisa ifayibha, okanye i-laser beam passage. -

I-Aerospace kunye noKhuseleko:

Idityaniswe kwi-high-precision optical sensors, i-imaging systems, kunye nezixhobo ezikhuselayo ezisebenza phantsi kwe-vibration, impembelelo, okanye uxinzelelo lwe-thermal. -

Uhlahlelo kunye neZixhobo zoNyango:

Isetyenziswe kwiiseli zokuhamba, amagumbi esampula, kunye neenkqubo zokuxilonga kwi-spectroscopy okanye uhlalutyo lwe-microfluidic. -

Isixhobo soShishino kunye noPhando:

Isebenza njengezikhewu ezikwaziyo ukunxiba, iijigi zolungelelwaniso, kunye nezibambi ezichanekileyo kuvavanyo kunye nokuseta i-metrology.

Iimpawu eziqhelekileyo

| Ipropati | Inkcazo |

|---|---|

| Izinto eziphathekayo | I-Single-Crystal Sapphire (Al₂O₃ ≥ 99.99%) |

| Ukuqhelaniswa | I-C-axis, i-A-xis, okanye i-R-axis (ukhetho) |

| Ububanzi bangaphandle | 2 mm - 100 mm |

| Ukutyeba | 0.3 mm - 20 mm |

| Umngxuma Diameter | 0.2 mm – 10 mm (inokwenziwa ngokwezifiso) |

| Ukuhanjiswa kwamehlo | >85% (400–2000 nm) |

| Umphezulu oMcaba | λ/10 okanye ngcono |

| Ukufana | ≤3 arcmin |

| Scratch-Dig | 10-5, 20-10 ukhetho |

| Uluhlu lobushushu | −200°C ukuya +2000°C |

| Iinketho zoKwaleka | I-AR, i-HR, i-DLC, okanye iingubo zefilimu ezicekethekileyo |

FAQ

I-Q1: Yintoni eyenza isafire ngokusebenzisa i-hole components zilungele iinkqubo ze-semiconductor?

I-A1: I-Sapphire idibanisa ukugquma kombane ngokucoceka okuphezulu, ukumelana nobushushu, kunye nokuzinza kweekhemikhali, okwenza kube yinto efanelekileyo kumagumbi e-plasma, ii-ports optical monitoring, kunye namacandelo okulungelelanisa.

I-Q2: Ngaba imingxuma ephumayo inokugrunjwa nge-engile okanye nge-conical geometry?

A2: Ewe. I-Sapphire inokwenziwa nge-laser-drilled okanye i-ultrasonically machined kwii-angles ezahlukeneyo ukufezekisa ukulungelelaniswa kwe-optical axis okanye imisebenzi yokulawula ulwelo.

I-Q3: Ngaba i-coatings okanye unyango olungaphezulu luyafumaneka?

I-A3: Iingubo ezininzi ezifana ne-anti-reflective, i-infrared-enhanced, okanye i-diamond-like carbon (DLC) ingasetyenziselwa ukuphucula ukusebenza phantsi kweemeko ezithile ze-spectral okanye zemishini.

I-Q4: Kukuphi ukunyamezela okunokuthi kuphunyezwe?

I-A4: Ukunyamezela kwe-Dimensional ngaphakathi kwe-±5 µm kunye nokunyamezela kwe-angular phantsi kwe-arcmin ye-3 kunokufezekiswa ngokuchaneka kwe-CNC kunye nolawulo lokupolisha.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.