I-TGV Glass substrates 12inch wafer Ukubetha kweGlass

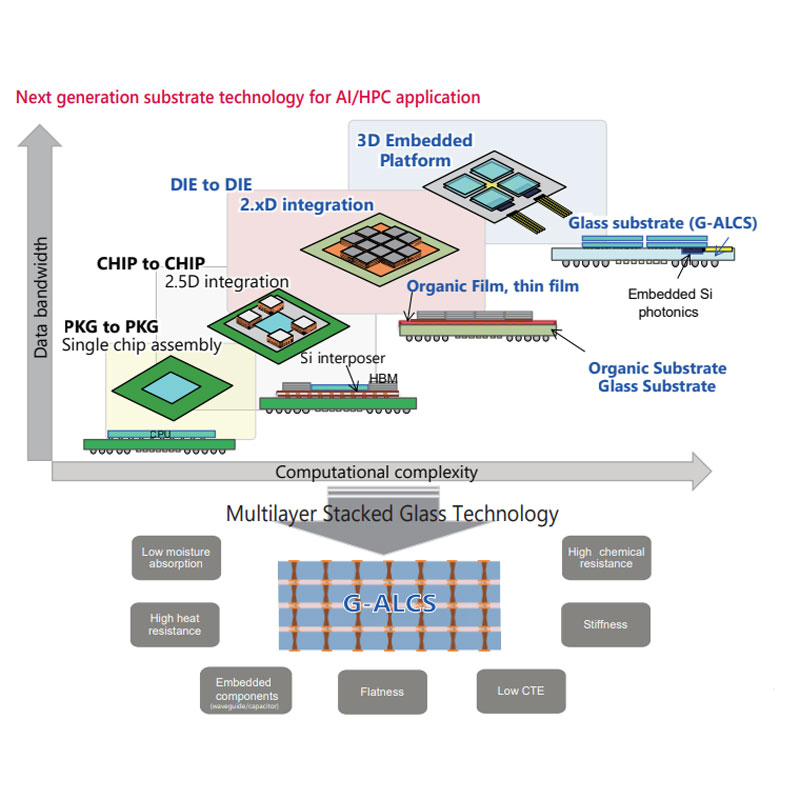

Ii-substrates zeglasi zenza ngcono ngokweempawu ze-thermal, ukuzinza komzimba, kwaye ziyakwazi ukumelana nobushushu kwaye zingaphantsi kokuphazamiseka okanye iingxaki zokuguqulwa ngenxa yokushisa okuphezulu;

Ukongezelela, iimpawu zombane eziyingqayizivele zesiseko seglasi zivumela ukulahleka kwe-dielectric ephantsi, ukuvumela umqondiso ocacileyo kunye nokuhanjiswa kwamandla. Ngenxa yoko, ukulahlekelwa kwamandla ngexesha lokuhanjiswa kwesignali kuncitshisiwe kwaye ukusebenza kakuhle kwe-chip kuphakanyiswe ngokwemvelo. Ubukhulu beglasi engundoqo ye-substrate inokuncitshiswa malunga nesiqingatha xa kuthelekiswa neplastiki ye-ABF, kwaye ukucotha kuphucula isantya sokuhanjiswa kwesignali kunye nokusebenza kakuhle kwamandla.

Itekhnoloji yokwenza umngxuma we-TGV:

I-Laser-induced etching method isetyenziselwa ukuphembelela ummandla oqhubekayo we-denaturation ngokusebenzisa i-pulsed laser, kwaye emva koko iglasi enyangwa nge-laser ifakwe kwisisombululo se-hydrofluoric ye-etching. Izinga lokurhweba kweglasi ye-denaturation zone kwi-hydrofluoric acid ikhawuleza kunaleyo yeglasi engafakwanga ukuba yenze imingxunya.

TGV ukugcwalisa:

Okokuqala, imingxuma eyimfama ye-TGV yenziwa. Okwesibini, umaleko wembewu wafakwa ngaphakathi kumngxuma oyimfama we-TGV ngokufakwa komphunga womzimba (PVD). Okwesithathu, i-electroplating ephantsi-phezulu ifezekisa ukuzaliswa kwe-TGV ngokungenamthungo; Ekugqibeleni, ngokudibanisa okwethutyana, ukugaya umva, ukuchithwa kwe-chemical mechanical polishing (CMP) i-copper exposure, i-unbonding, eyenza i-TGV yentsimbi egcwele ipleyiti yokudlulisa.

Idayagram eneenkcukacha