Itafile encinci ye-laser punching machine 1000W-6000W ubuncinane bokuvula i-0.1MM ingasetyenziselwa izinto zentsimbi zeglasi yeceramic.

Izinto ezisebenzayo

1. Izinto zensimbi: ezifana ne-aluminium, ubhedu, i-titanium alloy, insimbi engenasici, njl.

2. Izinto ezingezizo ezentsimbi: ezifana neplastiki (kubandakanywa i-polyethylene PE, i-polypropylene PP, i-polyester PET kunye nezinye iifilimu zeplastiki), iglasi (kubandakanywa neglasi eqhelekileyo, iglasi ekhethekileyo njengeglasi emhlophe, iglasi ye-K9, iglasi ye-borosilicate ephezulu, iglasi ye-quartz, njl. kwi.

3. Izinto ezidityanisiweyo: zenziwe ngezinto ezimbini okanye ngaphezulu ezineempawu ezahlukeneyo ngeendlela zomzimba okanye zekhemikhali, ezineempawu ezigqibeleleyo ezibanzi.

4.Izinto ezikhethekileyo: Kwiindawo ezithile, oomatshini be-laser punching bangasetyenziselwa ukucubungula ezinye izinto ezikhethekileyo.

Iiparamitha zokuchaza

| Igama | Idatha |

| Amandla eLaser: | 1000W-6000W |

| Ukuchaneka kokusika: | ±0.03MM |

| Isithuba sexabiso eliphantsi: | 0.1MM |

| Ubude bokusika: | 650MM×800MM |

| Ukuchaneka kwendawo: | ≤±0.008MM |

| Ukuchaneka okuphindiweyo: | 0.008MM |

| Irhasi yokusika: | Umoya |

| Imodeli ezinzileyo: | I-pneumatic edge clamping, inkxaso ye-fixture |

| Inkqubo yokuqhuba: | Ukunqunyanyiswa kweMagnetic linear motor |

| Ukusika ubukhulu | 0.01MM-3MM |

Iinzuzo zobugcisa

I-1.I-drilling esebenzayo: Ukusetyenziswa kwe-laser ye-high-energy beam ye-non-contact processing, ngokukhawuleza, i-1 yesibini ukugqiba ukucutshungulwa kwemingxuma emincinci.

I-2.Ukuchaneka okuphezulu: Ngokulawula ngokuchanekileyo amandla, i-pulse frequency kunye nokugxila kwisikhundla se-laser, umsebenzi wokugaya ngokuchaneka kwe-micron unokufezekiswa.

3. Isebenza ngokubanzi: iyakwazi ukucubungula iintlobo ezahlukeneyo ze-brittle, ezinzima ukucubungula kunye nezinto ezikhethekileyo, ezifana neplastiki, i-rubber, isinyithi (insimbi engenasici, i-aluminium, ubhedu, i-titanium alloy, njl.), iglasi, i-ceramics kunye nokunye.

4. Ukusebenza ngobukrelekrele: Umatshini we-laser punching uxhotyiswe ngenkqubo yolawulo lwamanani oluphezulu, olukrelekrele kakhulu kwaye kulula ukudibanisa kunye noyilo oluncediswa yikhompyuter kunye nenkqubo yokuvelisa ikhompyuter yokuncedisa ukuqaphela inkqubo ekhawulezayo kunye nokulungiswa kokupasa okuntsonkothileyo kunye nendlela yokucubungula.

Iimeko zokusebenza

1.Ukwahluka: ungenza iintlobo ezahlukeneyo zemilo entsonkothileyo yokucubungula umngxuma, njengemingxuma engqukuva, imingxuma yesikwere, imingxuma engunxantathu kunye neminye imingxunya ekhethekileyo.

I-2.Umgangatho ophezulu: Umgangatho womngxuma uphezulu, umphetho ulungile, akukho mvakalelo enzima, kwaye i-deformation incinci.

I-3.I-Automation: Iyakwazi ukugqiba ukuqhutyelwa kwe-micro-hole kunye nobukhulu obufanayo bokuvula kunye nokusabalalisa okufanayo ngexesha elinye, kwaye ixhasa ukuqhutyelwa komngxuma weqela ngaphandle kokungenelela ngesandla.

Iimpawu zezixhobo

■ Ubungakanani obuncinci besixhobo, ukusombulula ingxaki yendawo emxinwa.

■ Ukuchaneka okuphezulu, umngxuma ophezulu unokufikelela kwi-0.005mm.

■ Isixhobo kulula ukusebenza kwaye kulula ukusisebenzisa.

■ Umthombo wokukhanya unokutshintshwa ngokwezixhobo ezahlukeneyo, kwaye ukuhambelana kunamandla.

■ Indawo encinci echatshazelwa bubushushu, i-oxidation encinci ejikeleze imingxunya.

Indawo yosetyenziso

1. Ishishini le-elektroniki

●Ukubetha ngenqindi kwiBhodi yeSekethe eprintiweyo (PCB):

IMicrohole machining: Isetyenziselwa ukwenza ii-microholes ezinobubanzi obungaphantsi kwe-0.1mm kwi-PCBS ukuhlangabezana neemfuno zeebhodi ze-high-density interconnect (HDI).

Imingxunya eyimfama nengcwatywayo: Ukutshiza imingxuma eyimfama kwaye yangcwatywa kwi-PCBS enamaleko amaninzi ukuphucula ukusebenza kunye nokudityaniswa kwebhodi.

● Ukupakishwa kweSemiconductor:

Ukuqhuba isakhelo esikhokelayo: Imingxuma echanekileyo ifakwe kwisakhelo sokukhokela semiconductor yokudibanisa i-chip kwisekethe yangaphandle.

I-wafer cutting aid: Gubungela imingxuma kwi-wafer ukunceda ekusikeni okulandelayo kunye neenkqubo zokupakisha.

2. Oomatshini abachanekileyo

● Ukusetyenzwa kwamalungu amancinci:

Ukugrumba izixhobo ezichanekileyo: Ukwenza imingxunya echanekileyo ephezulu kwiigiya ezincinci zeenkqubo zokuhambisa ezichanekileyo.

I-sensor component drilling: Machining microholes kwi-sensor components ukuphucula uvakalelo kunye nesantya sokuphendula senzwa.

●Ukwenziwa koMngundo:

Umngxunya wokupholisa umngundo: Ukwenza umngxuma wokupholisa kwisitofu sokungunda okanye ukungunda okufayo ukuze kuphuculwe ukusebenza kokutshabalalisa ubushushu.

Ukusetyenzwa kwe-vent: Ukwenza imingxuma emincinci kumngundo ukunciphisa ukwenza iziphene.

3. Izixhobo zonyango

● IziXhobo zoTyando ezihlaselayo kancinci:

Ukugqobhoza kweCatheter: IiMicroholes zicutshungulwa kwii-catheter zotyando ezingephi ukuze kuhanjiswe ichiza okanye ukukhupha amanzi.

Amacandelo e-Endoscope: Imingxuma echanekileyo ifakwe kwi-lens okanye intloko yesixhobo se-endoscope ukuphucula ukusebenza kwesixhobo.

● Inkqubo yokuhanjiswa kweziyobisi:

I-Microneedle array drilling: Ukucoca i-microholes kwi-patch yeziyobisi okanye i-microneedle array ukulawula izinga lokukhutshwa kweziyobisi.

I-Biochip drilling: Ii-Microholes zicutshungulwa kwii-biochips zenkcubeko yeseli okanye ukubonwa.

4. Izixhobo zamehlo

● Isidibanisi seFiber optic:

I-fiber ye-Optical end hole yokugrumba: Ukutshiza i-microholes ekupheleni kobuso bomdibaniso obonakalayo ukuphucula ukuhanjiswa kwesignali ye-optical.

I-Fiber array machining: Ukwenza imingxunya echanekileyo ephezulu kwipleyiti ye-fiber array yonxibelelwano lwamachaneli amaninzi.

● Isihluzi esibonakalayo:

Ukucoca ukugrumba: Ukucoca i-microholes kwisihluzo se-optical ukuphumeza ukhetho lwamaza obude obuthile.

I-Diffractive element machining: Ukucoca i-microholes kwizinto ezibonakalayo ezibonakalayo zokwahlula okanye ukubunjwa kwe-laser beam.

5. Ukwenziwa kweemoto

● Inkqubo yokutofa ngamafutha:

Ukugqojozwa kombhobho wesitofu: Ukusetyenzwa kwemingxunya emincinci kumbhobho wokutofa ukuze kuphuculwe ifuthe le-atomization yamafutha kunye nokuphucula ukusebenza kakuhle kokutsha.

●Ukwenziwa koluvo:

I-pressure sensor drilling: Ukucoca i-microholes kwi-diaphragm yoxinzelelo lwenzwa ukuphucula uvakalelo kunye nokuchaneka kwenzwa.

● Ibhetri yamandla:

Ibattery pole chip drilling: Machining microholes kwi-lithium battery pole chips ukuphucula ukungena kwe-electrolyte kunye nokuthutha i-ion.

I-XKH inikezela ngoluhlu olupheleleyo lweenkonzo zokumisa enye yeetafile ezincinci ze-laser perforators, kubandakanywa kodwa kungaphelelanga apho: Ukubonisana nokuthengiswa kobuchwephesha, uyilo lwenkqubo elungelelanisiweyo, ukubonelela ngezixhobo ezikumgangatho ophezulu, ukufakwa kakuhle kunye nokugunyaziswa, uqeqesho olucacileyo lomsebenzi, ukuqinisekisa ukuba abathengi bafumana eyona nkonzo isebenzayo, echanekileyo kunye nenkonzo yamava angenankathalo kwinkqubo yokubhoboza.

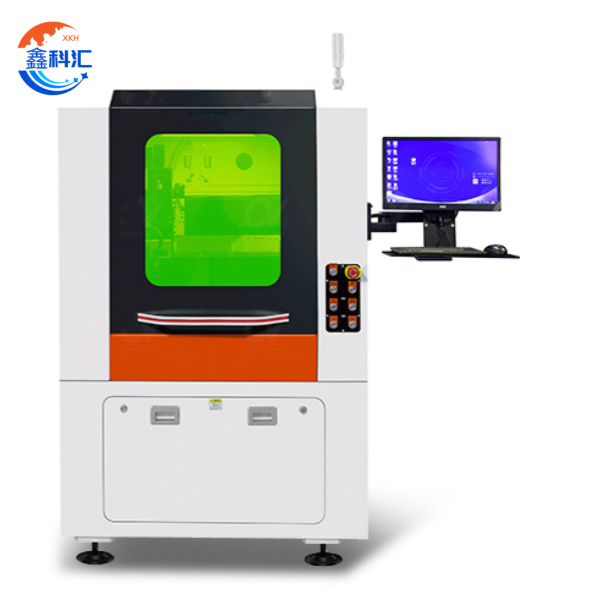

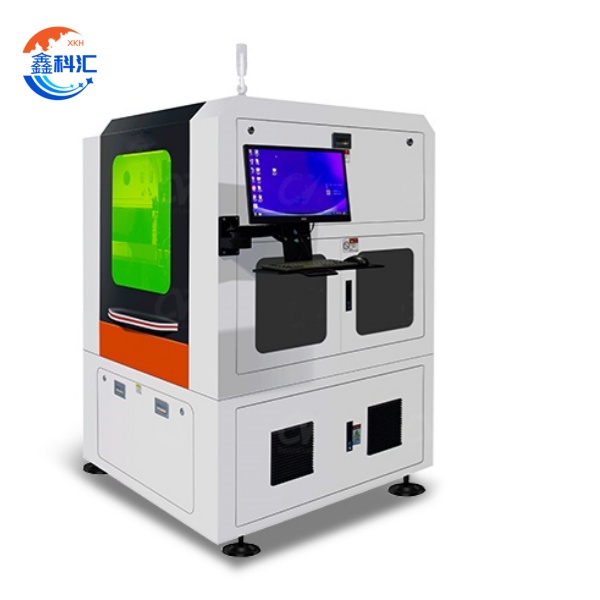

Idayagram eneenkcukacha