SiO₂ Quartz Wafer Quartz Wafers SiO₂ MEMS Ubushushu 2″ 3″ 4″ 6″ 8″ 12″

Idayagram eneenkcukacha

Intshayelelo

Iiwafers zequartz zidlala indima ebaluleke kakhulu ekuqhubeleni phambili i-electronics, isemiconductor, kunye nemizi-mveliso ye-optics. Ifunyanwe kwii-smartphones ezikhokela i-GPS yakho, ezifakwe kwizikhululo ezisisiseko ezixhaphakileyo ezinika amandla uthungelwano lwe-5G, kwaye zidityaniswe kwizixhobo zokwenza i-microchips ye-gen-gen elandelayo, iiwafers zequartz zibalulekile. Ezi substrates zicocekile ziphezulu zinika amandla amatsha kuyo yonke into ukusuka kwicomputing ye-quantum ukuya kwiifotonic eziphambili. Ngaphandle kokuba zithathwe kwenye yezona zimbiwa zininzi emhlabeni, iiwafer zequartz zenziwe zaya kumgangatho ongaqhelekanga wokuchaneka kunye nokusebenza.

Ziziphi iiWafers zeQuartz

Iiwafer zequartz zibhityile, iidiski ezijikelezayo ezenziwe ngekristale yequartz yokwenziwa kwe-ultra-pure. Ifumaneka kwi-diameters esemgangathweni ukusuka kwi-2 ukuya kwi-intshi ze-12, ii-wafers ze-quartz zihlala zihamba ngobukhulu ukusuka kwi-0.5 mm ukuya kwi-6 mm. Ngokungafaniyo ne-quartz yendalo, eyenza iikristale zeprismatic ezingaqhelekanga, i-quartz yokwenziwa ikhuliswa phantsi kweemeko zelebhu ezilawulwa ngokuqinileyo, ivelisa izakhiwo zekristale ezifanayo.

Ubukhazikhazi bendalo be-quartz wafers bubonelela ngokumelana neekhemikhali ezingenakuthelekiswa nanto, ukucaca okubonakalayo, kunye nokuzinza phantsi kobushushu obuphezulu kunye noxinzelelo lomatshini. Ezi mpawu zenza iiwafer zequartz zibe sisiseko sezixhobo ezichanekileyo ezisetyenziselwa ukuhanjiswa kwedatha, ukuva, ukubala, kunye ne-laser-based technologies.

Iimpawu zeQuartz Wafer

| Uhlobo lweQuartz | 4 | 6 | 8 | 12 |

|---|---|---|---|---|

| Ubungakanani | ||||

| Ububanzi (intshi) | 4 | 6 | 8 | 12 |

| Ukutyeba (mm) | 0.05–2 | 0.25–5 | 0.3–5 | 0.4–5 |

| Ukunyamezelwa kweDiameter (intshi) | ±0.1 | ±0.1 | ±0.1 | ±0.1 |

| Ukunyamezela ukutyeba (mm) | Customizable | Customizable | Customizable | Customizable |

| IiPropathi zokubona | ||||

| Refractive Index @365 nm | 1.474698 | 1.474698 | 1.474698 | 1.474698 |

| Refractive Index @546.1 nm | 1.460243 | 1.460243 | 1.460243 | 1.460243 |

| Refractive Index @1014 nm | 1.450423 | 1.450423 | 1.450423 | 1.450423 |

| UThutho lwaNgaphakathi (1250–1650 nm) | >99.9% | >99.9% | >99.9% | >99.9% |

| UThutho lulonke (1250–1650 nm) | >92% | >92% | >92% | >92% |

| Umgangatho woMatshini | ||||

| I-TTV (Uguquko lokutyeba lulonke, µm) | <3 | <3 | <3 | <3 |

| Ukucaba (µm) | ≤15 | ≤15 | ≤15 | ≤15 |

| Uburhabaxa boMphezulu (nm) | ≤1 | ≤1 | ≤1 | ≤1 |

| Ukuthoba (µm) | <5 | <5 | <5 | <5 |

| Iipropati Zomzimba | ||||

| Ubuninzi (g/cm³) | 2.20 | 2.20 | 2.20 | 2.20 |

| I-Modulus eselula (GPA) | 74.20 | 74.20 | 74.20 | 74.20 |

| Mohs Ubunzima | 6–7 | 6–7 | 6–7 | 6–7 |

| I-Shear Modulus (GPa) | 31.22 | 31.22 | 31.22 | 31.22 |

| Umlinganiselo wePoisson | 0.17 | 0.17 | 0.17 | 0.17 |

| Amandla acinezelayo (GPA) | 1.13 | 1.13 | 1.13 | 1.13 |

| Amandla Okuqina (MPa) | 49 | 49 | 49 | 49 |

| IDielectric Constant (1 MHz) | 3.75 | 3.75 | 3.75 | 3.75 |

| Iipropati zoThermal | ||||

| Indawo yoxinzelelo (10¹⁴.⁵ Pa·s) | 1000°C | 1000°C | 1000°C | 1000°C |

| Indawo yeAnealing (10¹³ Pa·s) | 1160°C | 1160°C | 1160°C | 1160°C |

| Indawo yokuthambisa (10⁷.⁶ Pa·s) | 1620°C | 1620°C | 1620°C | 1620°C |

Ukusetyenziswa kweeWafers zeQuartz

Ii-wafers ze-quartz zenziwe ngobunjineli ukuze zihlangabezane nezicelo eziyimfuneko kuwo wonke amashishini kubandakanya:

I-Electronics kunye nezixhobo zeRF

- Ii-wafers ze-quartz zingundoqo kwi-quartz crystal resonators kunye ne-oscillators ezibonelela ngemiqondiso yewotshi kwii-smartphones, iiyunithi ze-GPS, iikhomputha kunye nezixhobo zonxibelelwano ezingenazingcingo.

- Ukwandiswa kwe-thermal ephantsi kunye ne-Q-factor ephezulu zenza ii-wafers ze-quartz zigqibelele kwiisekethe zozinzo oluphezulu kunye nezihluzi ze-RF.

I-Optoelectronics kunye nomfanekiso

- Ii-wafers ze-quartz zibonelela ngokugqwesileyo kwe-UV kunye nokuhanjiswa kwe-IR, zizenza zilungele iilensi zamehlo, ii-beam splitters, iifestile ze-laser, kunye ne-detectors.

- Ukuxhathisa kwabo kwimitha kwenza ukuba kusetyenziswe i-high-energy physics kunye nezixhobo zendawo.

Semiconductor kunye ne-MEMS

- Ii-wafers ze-quartz zisebenza njengeenxalenye ezincinci zeesekethe ze-semiconductor ze-high-frequency, ingakumbi kwi-GaN kunye ne-RF applications.

- Kwi-MEMS (iMicro-Electro-Mechanical Systems), iiwafers zequartz ziguqula imiqondiso yomatshini zibe zezombane ngesiphumo se-piezoelectric, ezenza abenzi boluvo njenge-gyroscopes kunye ne-accelerometers.

uVeliso oluPhezulu kunye neeLebhu

- Iziqwenga zequartz ezicocekileyo zisetyenziswa kakhulu kwiikhemikhali, iilebhu zebhayoloji, kunye neefotonic zeeseli zamehlo, iicuvettes ze-UV, kunye nokuphathwa kwesampulu ephezulu.

- Ukuhambelana kwazo neendawo ezingqongileyo ezigqithisileyo kuzenza zilungele amagumbi eplasma kunye nezixhobo zokubeka.

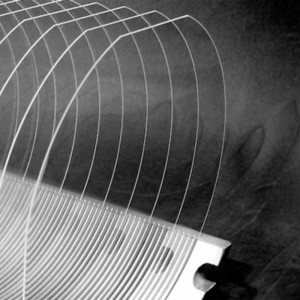

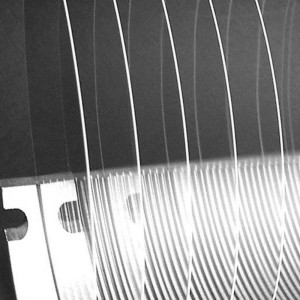

Zenziwa njani iiWafers zeQuartz

Kukho iindlela ezimbini eziphambili zokwenziwa kwee-wafers ze-quartz:

IiWafers zeQuartz ezidityanisiweyo

Iiwafers zequartz ezidityanisiweyo zenziwe ngokunyibilikisa iigranule zequartz zendalo kwiglasi yeamorphous, emva koko kunqunqwe kwaye kupolishwe ibhloko eyomeleleyo ibe ngamaqhekeza amancinci. Ezi zonka zequartz zibonelela:

- Ukukhanya okukhethekileyo kweUV

- Uluhlu olubanzi lwe-thermal yokusebenza (>1100°C)

- Ukuxhathisa ukothuka kwe-thermal

Zilungele izixhobo ze-lithography, ii-furnaces eziphezulu, kunye neefestile ze-optical kodwa azifanelekanga kwizicelo ze-piezoelectric ngenxa yokungabikho kwe-crystalline order.

IiWafers zeQuartz eziKhulisiweyo

Iiwafers zequartz ezikhulisiwe zikhuliswa ngokokwenziwa ukuvelisa iikristale ezingenasiphako kunye nokuqhelaniswa kwelathisi echanekileyo. La mawafa enzelwe izicelo ezifuna:

- Ii-engile ezisikiweyo ngqo (X-, Y-, Z-, AT-cut, njl.)

- I-oscillator ephezulu-frequency kunye nezihlungi ze-SAW

- Iipolarizer zamehlo kunye nezixhobo eziphambili zeMEMS

Inkqubo yemveliso ibandakanya ukukhula kwembewu kwii-autoclaves, kulandelwa kukunqunyulwa, ukuqhelaniswa, ukunyuswa, kunye nokupholisha.

Ababoneleli beQuartz Wafer abaPhambili

Ababoneleli behlabathi abasebenza kwiiwafa zequartz ezichaneke kakhulu babandakanya:

- Heraeus(eJamani) - i-quartz edibeneyo kunye neyokwenziwa

- Shin-Etsu Quartz(eJapan) - izisombululo ze-wafer ezicocekileyo

- WaferPro(I-USA) - ii-wafers ze-quartz ezibanzi kunye ne-substrates

- Korth Kristalle(eJamani) - iiwafa zekristale zokwenziwa

Indima eGuquguqukayo yeeWafers zeQuartz

Ii-wafers ze-quartz ziyaqhubeka nokuvela njengezinto ezibalulekileyo kumhlaba okhulayo wetekhnoloji:

- Miniaturization-Ii-wafers ze-quartz zenziwe ngonyamezelo olungqongqo lokudityaniswa kwesixhobo esibambeneyo.

- I-Eletroniki ePhakamileyo-Uyilo olutsha lwe-quartz wafer lutyhala kwi-mmWave kunye ne-THz kwimimandla ye-6G kunye ne-radar.

- Okulandelayo-Gen Sensing-Ukusuka kwiimoto ezizimeleyo ukuya kwi-IoT yoshishino, izinzwa ezisekwe kwi-quartz ziba zibaluleke ngakumbi.

Imibuzo ebuzwa rhoqo malunga neewafers zequartz

1. Yintoni iwafa yequartz?

I-wafer ye-quartz yi-disc ebhityileyo, ecwecwe eyenziwe kwi-crystalline silicon dioxide (SiO₂), eveliswa ngokwemilinganiselo eqhelekileyo ye-semiconductor (umzekelo, 2", 3", 4", 6", 8", okanye 12 "). Eyaziwayo ngokucoceka kwayo okuphezulu, ukuzinza kwe-thermal, kunye nokubonakala kwe-optical, i-quartz wafer isetyenziswe njenge-substrate okanye i-carrier kwizicelo ezahlukeneyo ezichanekileyo ezifana ne-semiconductor fabrication, izixhobo ze-MEMS, iinkqubo ze-optical kunye neenkqubo ze-vacuum.

2. Uthini umahluko phakathi kwe-quartz kunye nejeli ye-silica?

I-Quartz yi-crystalline form eqinileyo ye-silicon dioxide (SiO₂), ngelixa i-silica gel i-amorphous kunye ne-porous form ye-SiO₂, esetyenziswa ngokuqhelekileyo njenge-desiccant yokuthatha umswakama.

- I-Quartz ilukhuni, icacile, kwaye isetyenziswa kwi-elektroniki, i-optical, kunye ne-industrial applications.

- Ijeli ye-silica ibonakala njengamaso amancinci okanye i-granules kwaye isetyenziselwa ukulawula ukufuma kwipakethe, i-electronics kunye nokugcinwa.

3. Zisetyenziselwa ntoni iikristale zequartz?

Iikristale ze-quartz zisetyenziswa ngokubanzi kwi-electronics kunye ne-optics ngenxa yeempawu zabo ze-piezoelectric (zivelisa intlawulo yombane phantsi koxinzelelo lomatshini). Usetyenziso oluqhelekileyo lubandakanya:

- Oscillators kunye nolawulo frequency(umzekelo, iiwotshi zequartz, iiwotshi, izilawuli ezincinci)

- Amacandelo okubona(umzekelo, iilensi, iipleyiti zamaza, iifestile)

- Iiresonators kunye nezihluzikwiRF kunye nezixhobo zonxibelelwano

- Izivamvongenxa yoxinzelelo, isantya, okanye amandla

- Ukwenziwa kweSemiconductornjengama-substrates okanye iifestile zenkqubo

4. Kutheni iquartz isetyenziswa kwiimicrochips?

I-quartz isetyenziswa kwizicelo ezinxulumene ne-microchip kuba ibonelela:

- Ukuzinza kwe-Thermalngexesha leenkqubo zobushushu obuphezulu ezifana nokusasazwa kunye nokufunxa

- Ukugquma kombanengenxa yeempawu zayo ze-dielectric

- Ukumelana nemichizakwiiasidi kunye nezinyibilikisi ezisetyenziselwa ukwenziwa kwe-semiconductor

- Ukuchaneka komgangathokunye nokwandiswa kwe-thermal ephantsi yokulungelelaniswa kwe-lithography ethembekileyo

- Ngelixa i-quartz ngokwayo ingasetyenziswa njenge-semiconductor esebenzayo (njenge-silicon), idlala indima ebalulekileyo exhasayo kwindawo yokwenziwa-ingakumbi kwiziko, amagumbi, kunye ne-photomask substrates.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.