Ikristale enye yeSilicon wafer Si Substrate Uhlobo N/P Optional Silicon Carbide Wafer

Ukusebenza okungaqhelekanga kwe-monocrystal Silicon Wafer kubangelwa bubunyulu bayo obuphezulu kunye nesakhiwo esichanekileyo se-crystalline. Esi sakhiwo siqinisekisa ukufana kunye nokuhambelana kwe-Silicon wafer, ngaloo ndlela kuphucula ukusebenza kunye nokuthembeka kwezixhobo. Ngaphantsi kweemeko zokusebenza ezinzima, ezifana nokushisa okuphezulu, umswakama ophezulu, okanye i-radiation ephezulu, i-substrate ye-Si iyakwazi ukugcina ukusebenza kwayo, iqinisekisa ukusebenza okuzinzile kwezixhobo zombane kwiindawo ezigqithiseleyo.

Ngaphaya koko, i-thermal conductivity ephezulu ye-Silicon wafer iyenza ibe lolona khetho lufanelekileyo kwizicelo zamandla aphezulu. Iqhuba ngokufanelekileyo ukushisa kude nesixhobo, ukuthintela ukuqokelelwa kwe-thermal kunye nokukhusela isixhobo kumonakalo wokushisa, ngaloo ndlela sandise ixesha lokuphila. Kwintsimi yombane we-elektroniki, ukusetyenziswa kweSilicon wafer kunokuphucula ukusebenza kakuhle koguqulo, ukunciphisa ilahleko yamandla, kunye nokwenza uguqulo lwamandla olusebenzayo.

Kwiisekethe ezidibeneyo kunye neemodyuli zamandla aphambili, ukuzinza kweekhemikhali zeSilicon wafer nako kudlala indima ebalulekileyo. Ihlala izinzile kwiindawo ezinobungozi bekhemikhali, iqinisekisa ukuthembeka kwexesha elide lezixhobo. Ukongeza, ukuhambelana kweSilicon wafer kunye neenkqubo ezikhoyo zokwenziwa kwe-semiconductor kunceda ukudityaniswa kunye nokuveliswa kobuninzi.

I-wafer yethu ye-Silicon lolona khetho lufanelekileyo kwizicelo eziphezulu ze-semiconductor. Ngomgangatho okhethekileyo wekristale, ulawulo olungqongqo lomgangatho, iinkonzo zokwenza ngokwezifiso, kunye noluhlu olubanzi lwezicelo, sinokulungiselela ukwenza ngokwezifiso ngokweemfuno zakho. Imibuzo yamkelekile!

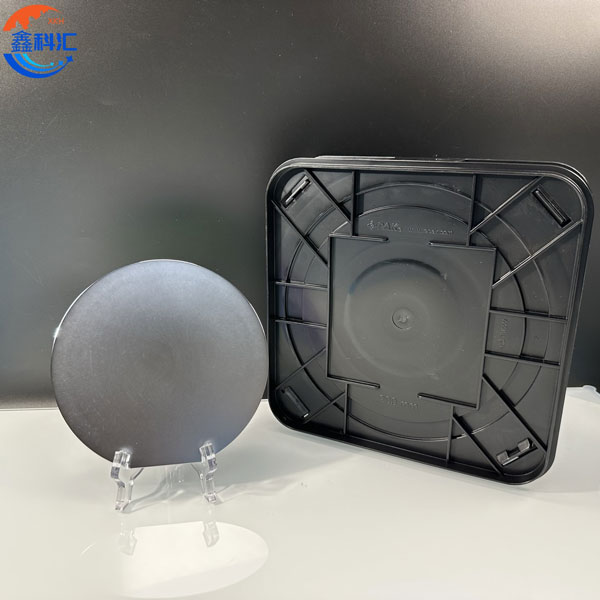

Idayagram eneenkcukacha