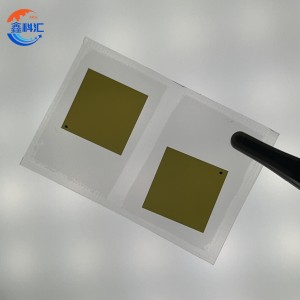

ISilicon Carbide (SiC) ISubstrate yeCrystal enye-10×10mm Wafer

Idayagram eneenkcukacha yeSilicon Carbide (SiC) substrate wafer

Amagqabantshintshi ngeSilicon Carbide (SiC) substrate wafer

II-10 × 10mm ye-Silicon Carbide (SiC) i-single-crystal substrate waferyimathiriyeli ye-semiconductor ephezulu yokusebenza eyenzelwe umbane wesizukulwana esilandelayo kunye nezicelo ze-optoelectronic. Ibandakanya ukuhanjiswa kwe-thermal ekhethekileyo, i-bandgap ebanzi, kunye nokuzinza kwekhemikhali okugqwesileyo, iSilicon Carbide (SiC) substrate wafer ibonelela ngesiseko sezixhobo ezisebenza ngokufanelekileyo phantsi kobushushu obuphezulu, amaza omoya aphezulu, kunye neemeko zombane ophezulu. Ezi substrates zichaneke-zinqunyulwe10 × 10mm iitshiphusi square, ilungele uphando, iprototyping, kunye nokwenziwa kwesixhobo.

Umgaqo-siseko weMveliso weSilicon Carbide (SiC) substrate wafer

I-Silicon Carbide (i-SiC) i-substrate wafer yenziwa ngokusebenzisa i-Physical Vapor Transport (PVT) okanye iindlela zokukhula kwe-sublimation. Inkqubo iqala nge-high-purity SiC powder elayishwe kwi-graphite crucible. Ngaphantsi kobushushu obugqithisileyo obudlula i-2,000 ° C kunye nemeko-bume elawulwayo, i-powder sublimates ibe ngumphunga kwaye iphinde idipozithi kwi-crystal yembewu ejoliswe ngononophelo, yenze i-crystal ingot enkulu, enesiphene-encinci.

Nje ukuba i-SiC boule ikhule, idlula:

- Ukusika i-ingot: Iisarha zocingo lwedayimani ezichanekileyo zisika i-ingot ye-SiC ibe ngamaqhekeza okanye iitshiphusi.

- Ukuqhawula kunye nokusila: Imiphezulu iyacandwa ukuze kususwe amanqaku esarha kwaye kuzuzwe ubukhulu obufanayo.

- I-Chemical Mechanical polishing (CMP): Ukuphumelela isipili esilungele i-epi kunye noburhabaxa obuphantsi kakhulu bomphezulu.

- I-doping yokuzikhethela: I-Nitrogen, i-aluminiyam, okanye i-boron doping inokwaziswa ukuze ilungelelanise iimpawu zombane (uhlobo lwe-n okanye uhlobo lwe-p).

- Ukuhlolwa komgangatho: I-metrology ephucukileyo iqinisekisa ukuthambeka kwe-wafer, ukufana kobuninzi, kunye noxinaniso lwesiphene luhlangabezana neemfuno ezingqongqo zebakala le-semiconductor.

Le nkqubo yamanyathelo amaninzi iphumela kwi-10 × 10mm ye-Silicon Carbide (SiC) engaphantsi kwe-substrate chips ezilungele ukukhula kwe-epitaxial okanye ukwenziwa kwesixhobo ngokuthe ngqo.

Iimpawu zezinto eziphathekayo zeSilicon Carbide (SiC) i-substrate wafer

I-Silicon Carbide (SiC) i-substrate wafer yenziwe ngokuyinhlokoI-4H-SiC or 6H-SiCiipolytypes:

-

4H-SiC:Ibonisa ukuhamba kwe-electron ephezulu, iyenza ilungele izixhobo zamandla ezifana ne-MOSFETs kunye ne-Schottky diode.

-

6H-SiC:Inikezela ngeempawu ezizodwa zeRF kunye nezixhobo ze-optoelectronic.

Iimpawu eziphambili zeSilicon Carbide (SiC) substrate wafer:

-

Umsantsa obanzi:~ 3.26 eV (4H-SiC) - yenza i-voltage ephezulu yokuphuka kunye nelahleko ephantsi yokutshintsha.

-

I-Thermal conductivity:3-4.9 W / cm·K - ikhupha ukushisa ngokufanelekileyo, iqinisekisa ukuzinza kwiinkqubo zamandla aphezulu.

-

Ukuqina:~ 9.2 kwisikali se-Mohs - iqinisekisa ukuqina komatshini ngexesha lokucubungula kunye nokusebenza kwesixhobo.

Ukusetyenziswa kweSilicon Carbide (SiC) substrate wafer

Ukuguquguquka kweSilicon Carbide (SiC) substrate wafer kubenza baxabiseke kuwo onke amashishini amaninzi:

I-Electronics yoMbane: Isiseko see-MOSFETs, ii-IGBTs, kunye ne-Schottky diode ezisetyenziswa kwizithuthi zombane (EVs), izixhobo zombane kwimizi-mveliso, kunye nee-inverters zamandla avuselelekayo.

I-RF kunye ne-Microwave Devices: Ixhasa i-transistors, i-amplifiers, kunye namacandelo e-radar ye-5G, i-satellite, kunye nezicelo zokukhusela.

I-Optoelectronics: Isetyenziswa kwii-LED ze-UV, ii-photodetectors, kunye ne-laser diode apho ukukhanya okuphezulu kwe-UV kunye nokuzinza kubaluleke kakhulu.

I-Aerospace & Defense: I-substrate ethembekileyo yobushushu obuphezulu, i-electronics-hardened electronics.

Amaziko oPhando kunye neeDyunivesithi: Ilungele izifundo zesayensi yezinto, uphuhliso lwesixhobo somzekelo, kunye nokuvavanya iinkqubo ezintsha ze-epitaxial.

Iinkcukacha zeSilicon Carbide (SiC) i-substrate wafer Chips

| Ipropati | Ixabiso |

|---|---|

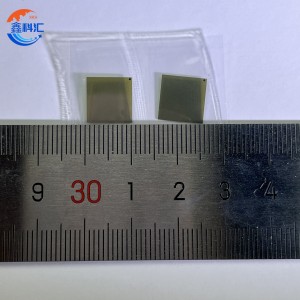

| Ubungakanani | 10mm × 10mm isikwere |

| Ukutyeba | 330–500 μm (inokwenziwa ngokwezifiso) |

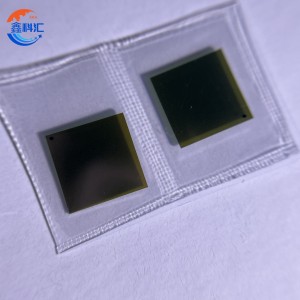

| Iipolytype | I-4H-SiC okanye i-6H-SiC |

| Ukuqhelaniswa | I-C-plane, i-off-axis (0°/4°) |

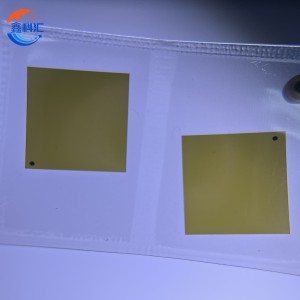

| Umphezulu Gqiba | Icala elinye okanye icala eliphindwe kabini elipolishiwe; epi-ready ekhoyo |

| Iinketho zeDoping | N-uhlobo okanye P-uhlobo |

| IBanga | Ibakala lophando okanye ibakala lesixhobo |

FAQ of Silicon Carbide (SiC) substrate wafer

I-Q1: Yintoni eyenza i-Silicon Carbide (i-SiC) i-substrate wafer ibe ngaphezu kwe-silicon yafers yendabuko?

I-SiC inikezela nge-10 × amandla aphezulu ebala lokuqhekeka, ukumelana nobushushu obuphezulu, kunye nelahleko esezantsi yokutshintsha, oko kuyenza ilungele ukusebenza kakuhle, izixhobo ezinamandla kakhulu ezingenakuxhaswa yi-silicon.

I-Q2: Ngaba i-10 × 10mm i-Silicon Carbide (i-SiC) ye-substrate wafer inokubonelelwa nge-epitaxial layers?

Ewe. Sibonelela ngee-epi-ready substrates kwaye sinokuzisa ii-wafers ezinomaleko we-epitaxial esiko ukuhlangabezana nesixhobo esithile samandla okanye iimfuno zokwenziwa kwe-LED.

I-Q3: Ngaba ubungakanani besiko kunye namanqanaba e-doping akhoyo?

Ngokuqinisekileyo. Ngelixa iitshiphusi ze-10 × 10mm zisemgangathweni wophando kunye nesampulu yesixhobo, imilinganiselo yesiko, ubukhulu, kunye neeprofayili zedoping ziyafumaneka xa uceliwe.

I-Q4: Zihlala zomelele kangakanani ezi ziqwenga kwindawo ezingqongileyo?

I-SiC igcina ingqibelelo yesakhiwo kunye nokusebenza kombane ngaphezu kwe-600 ° C naphantsi kwemitha ephezulu yemitha, iyenza ilungele i-aerospace kunye ne-electronic-grade-grade electronics.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.