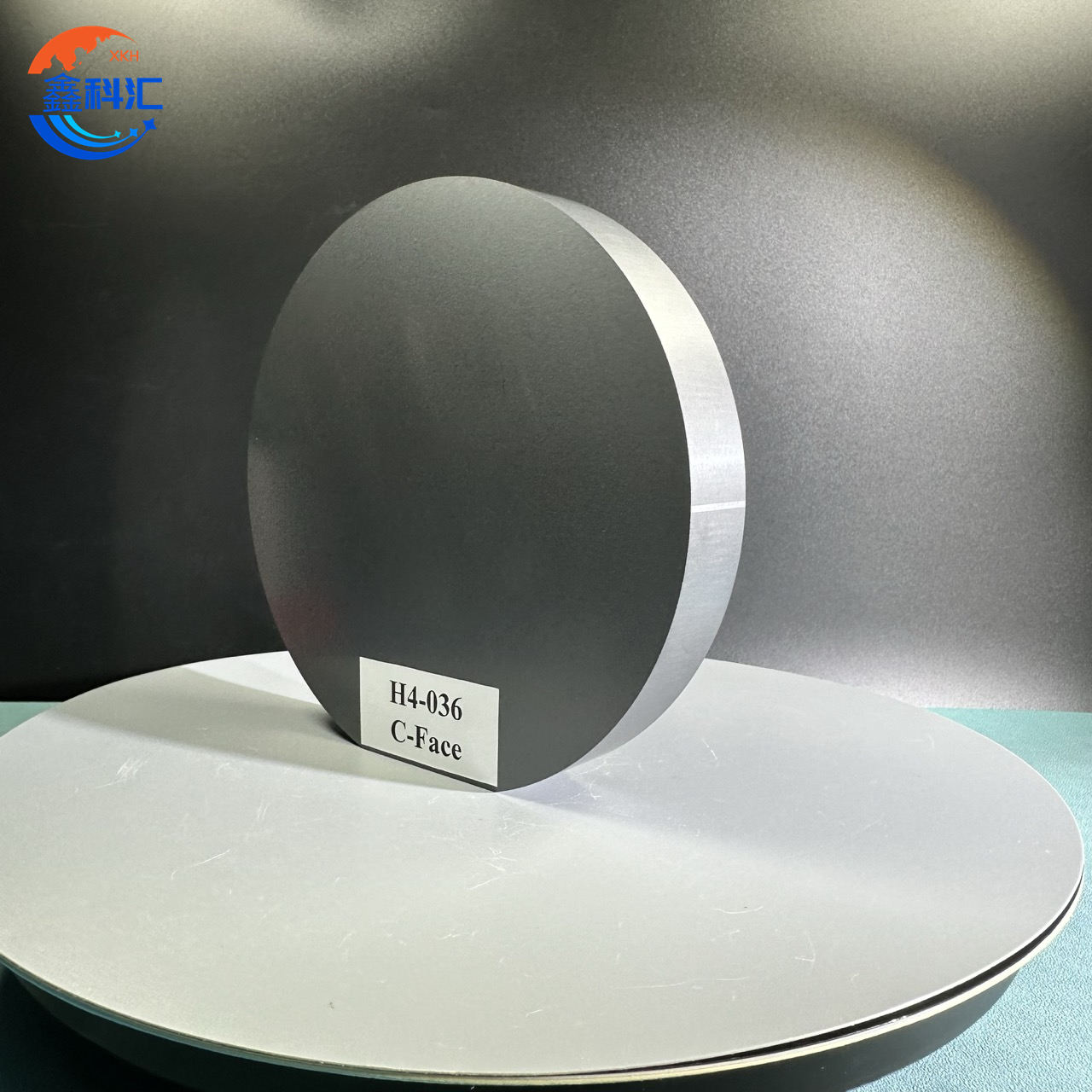

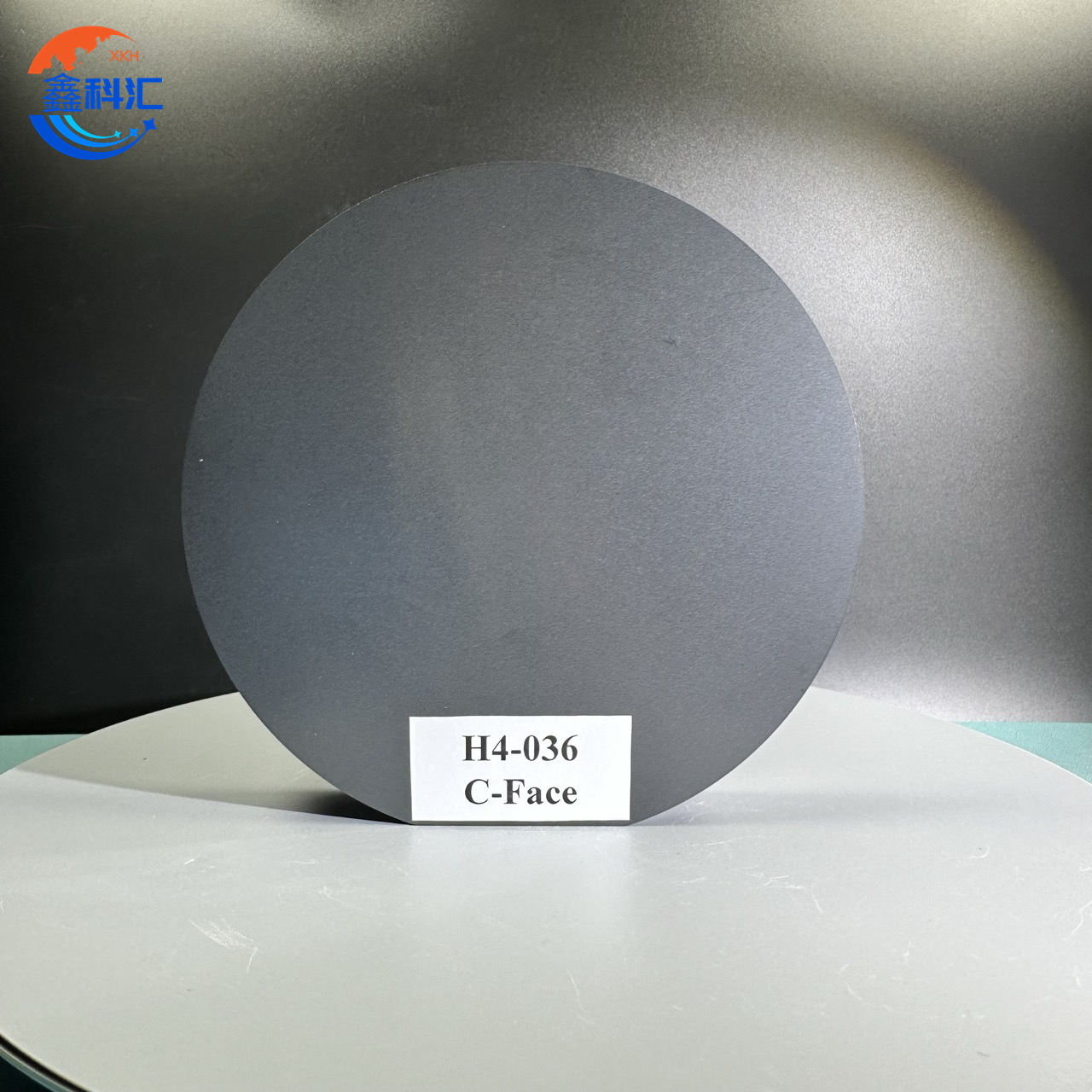

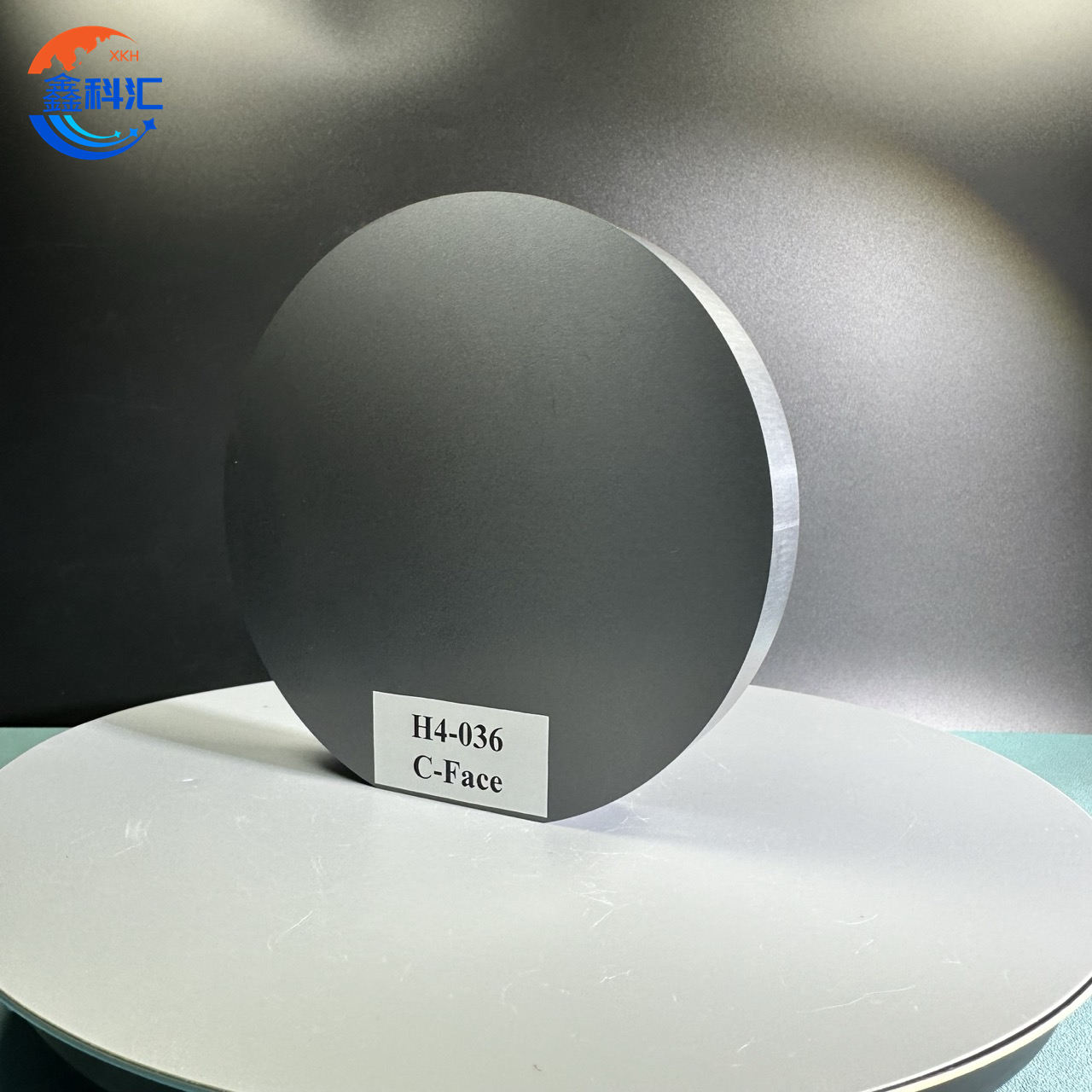

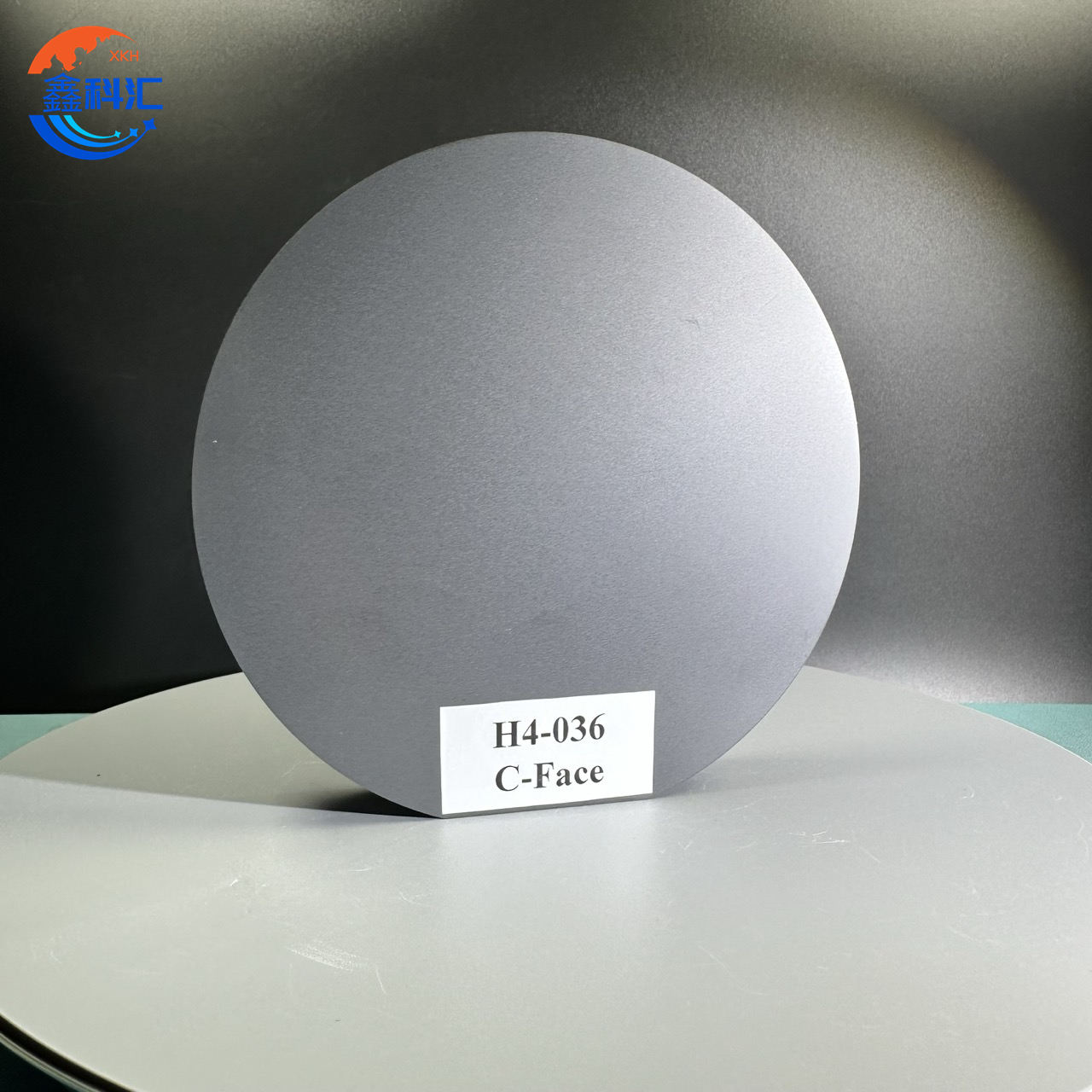

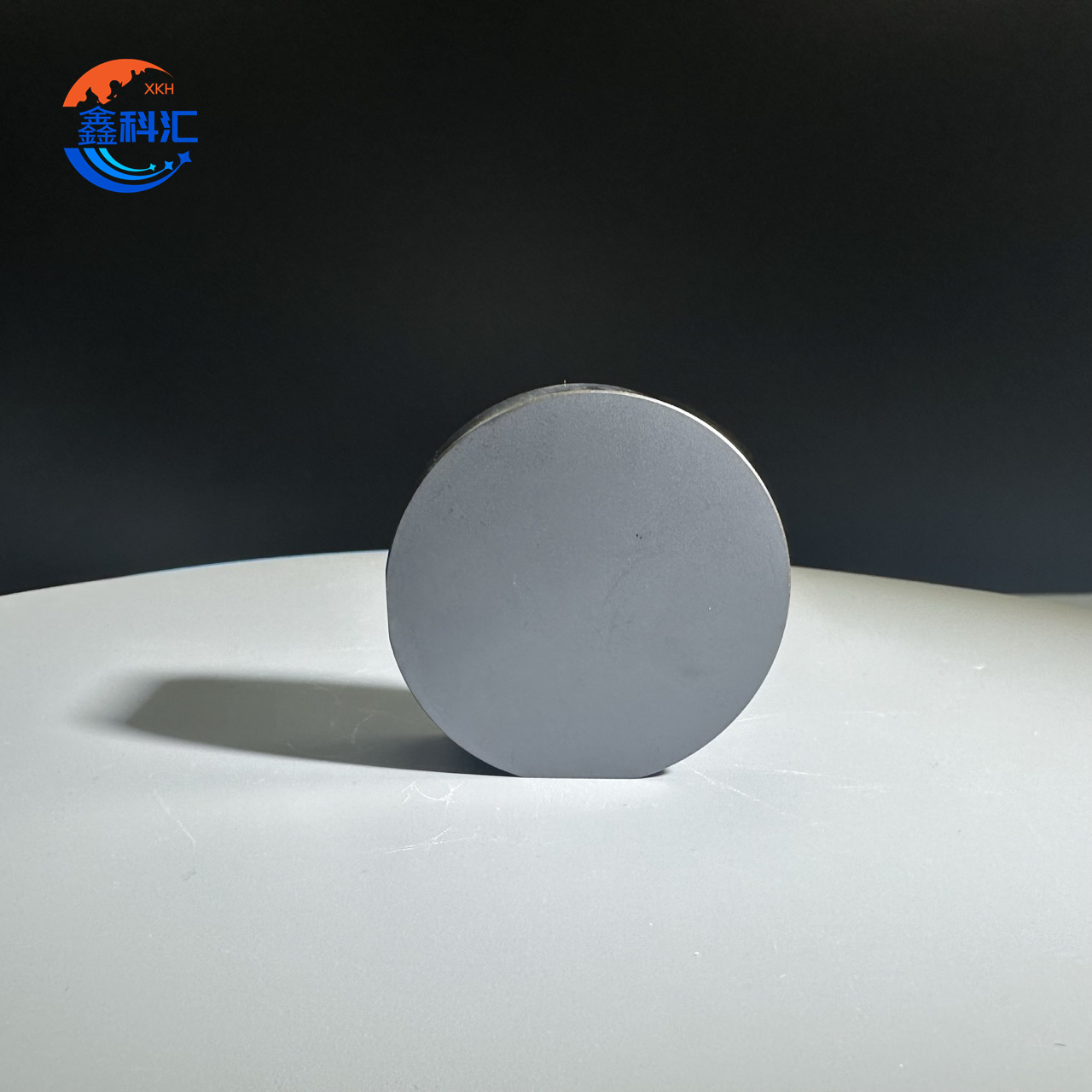

ISilicon Carbide SiC Ingot 6inch N uhlobo lweDummy/ubukhulu bebakala lokuqala lunokuba ngokwezifiso

Iipropati

IBanga: iBanga leMveliso (iDummy/Prime)

Ubungakanani: 6-intshi ubukhulu

Ububanzi: 150.25mm ± 0.25mm

Ukutyeba:> 10mm (ubukhulu obunokwenzeka xa uceliwe)

I-Surface Orientation: i-4 ° ngokubhekiselele ku-<11-20> ± 0.2 °, eqinisekisa umgangatho ophezulu wekristale kunye nokulungelelaniswa ngokuchanekileyo kokwenziwa kwesixhobo.

I-Primary Flat Orientation: <1-100> ± 5 °, inqaku eliphambili lokusikwa ngokufanelekileyo kwe-ingot kwii-wafers kunye nokukhula kwekristale.

Ubude obuPhambili beFlat: 47.5mm ± 1.5mm, eyenzelwe ukuphatha lula kunye nokusika ngokuchanekileyo.

Ukuxhathisa: 0.015–0.0285 Ω · cm, ilungele usetyenziso kwizixhobo zamandla ezisebenza ngamandla.

Ubuninzi beMibhobho: <0.5, ukuqinisekisa iziphene ezincinci ezinokuchaphazela ukusebenza kwezixhobo ezenziweyo.

I-BPD (i-Boron Pitting Density): <2000, ixabiso eliphantsi elibonisa ukucoceka kwe-crystal ephezulu kunye noxinzelelo oluphantsi.

I-TSD (i-Threading Screw Dislocation Density): <500, iqinisekisa ingqibelelo yezinto eziphathekayo kwizixhobo eziphezulu zokusebenza.

Iindawo zePolytype: Akukho nanye - i-ingot ikhululekile kwiziphene ze-polytype, inikezela umgangatho ophezulu wezinto eziphathekayo kwizicelo eziphezulu.

I-Edge Indents: <3, ene-1mm ububanzi kunye nobunzulu, iqinisekisa umonakalo omncinci wendawo kunye nokugcina ingqibelelo ye-ingot ye-wafer slicing esebenzayo.

I-Edge Cracks: 3, <1mm nganye, kunye nesiganeko esincinci somonakalo owenziweyo, ukuqinisekisa ukuphathwa ngokukhuselekileyo kunye nokuqhubekela phambili.

Ukupakisha: I-Wafer case - i-ingot ye-SiC ipakishwe ngokukhuselekileyo kwi-wafer case ukuqinisekisa ukuthuthwa okukhuselekileyo kunye nokuphathwa.

Usetyenziso

Umbane woMbane:I-6-intshi ye-SiC ingot isetyenziswa kakhulu ekuveliseni izixhobo zombane zamandla ezifana ne-MOSFET, IGBTs, kunye ne-diodes, eziyinxalenye ebalulekileyo kwiinkqubo zokuguqula amandla. Ezi zixhobo zisetyenziswa kakhulu kwii-inverters zemoto yombane (EV), iimoto zokuqhuba kwimizi-mveliso, izixhobo zombane, kunye neenkqubo zokugcina amandla. Ukukwazi kwe-SiC ukusebenza kumbane ophezulu, i-frequencies ephezulu, kunye namaqondo obushushu agqithisileyo ayenza ilungele usetyenziso apho izixhobo ze-silicon (Si) zemveli ziza kusokola ukuze zisebenze ngokufanelekileyo.

Izithuthi zoMbane (EVs):Kwizithuthi zombane, amacandelo asekelwe kwi-SiC abalulekile ekuphuhliseni iimodyuli zamandla kwii-inverters, ii-DC-DC converters, kunye neetshaja ezikwibhodi. I-conductivity ephezulu ye-thermal ye-SiC ivumela ukunciphisa ukuveliswa kobushushu kunye nokusebenza okungcono ekuguquleni amandla, okubalulekileyo ekuphuculeni ukusebenza kunye nokuqhuba uluhlu lwezithuthi zombane. Ukongeza, izixhobo ze-SiC zenza izinto ezincinci, ezikhaphukhaphu, kunye nezithembekileyo, ezinegalelo ekusebenzeni ngokubanzi kweenkqubo ze-EV.

IiNkqubo zaMandla aVuselelwayo:Ii-ingots ze-SiC zizinto eziyimfuneko ekuphuhliseni izixhobo zokuguqula amandla ezisetyenziswa kwiinkqubo zamandla avuselelekayo, kubandakanywa ii-inverters zelanga, ii-injini zomoya, kunye nezisombululo zokugcina amandla. Amandla aphezulu okuphatha amandla e-SiC kunye nolawulo olululo lwe-thermal luvumela ukuguqulwa kwamandla aphezulu kunye nokuthembeka okuphuculweyo kwezi nkqubo. Ukusetyenziswa kwayo kumandla ahlaziyekayo kunceda ukuqhuba iinzame zehlabathi jikelele ekuzinzeni kwamandla.

Unxibelelwano:I-6-intshi ye-SiC ingot ikwafanelekile ukuvelisa amacandelo asetyenziswa kwi-high-power RF (i-radio frequency) izicelo. Ezi ziquka i-amplifiers, i-oscillators, kunye nezihluzo ezisetyenziswa kwiinkqubo zonxibelelwano kunye ne-satellite yonxibelelwano. Ukukwazi kwe-SiC ukuphatha i-frequency ephezulu kunye namandla aphezulu kwenza kube yinto efanelekileyo kakhulu yezixhobo zonxibelelwano ezifuna ukusebenza ngamandla kunye nokulahlekelwa kwesignali encinci.

I-Aerospace kunye noKhuseleko:I-voltage ephezulu yokuqhekeka kwe-SiC kunye nokuchasana nobushushu obuphezulu buyenza ilungele ukusetyenziswa kwe-aerospace kunye nokukhusela. Izixhobo ezenziwe kwii-ingots ze-SiC zisetyenziswa kwiinkqubo ze-radar, unxibelelwano lwesathelayithi, kunye nombane we-elektroniki wenqwelomoya kunye ne-spacecraft. Izinto ezisekelwe kwi-SiC zenza ukuba iinkqubo ze-aerospace ziqhube phantsi kweemeko ezigqithisileyo ezifunyenwe kwindawo kunye neendawo eziphakamileyo.

I-Industrial Automation:Kwi-automation ye-industrial, amacandelo e-SiC asetyenziswa kwiinzwa, ii-activators, kunye neenkqubo zokulawula ezifuna ukusebenza kwiindawo ezinzima. Izixhobo ezisekelwe kwi-SiC ziqeshwe koomatshini abafuna izinto ezisebenzayo, ezihlala ixesha elide ezikwaziyo ukumelana nokushisa okuphezulu kunye noxinzelelo lombane.

Itheyibhile yokuchaza iMveliso

| Ipropati | Inkcazo |

| IBanga | Imveliso (iDummy/Prime) |

| Ubungakanani | 6-intshi |

| Ububanzi | 150.25mm ± 0.25mm |

| Ukutyeba | > 10mm (Okwenzekayo) |

| Ukuqhelaniswa nomphezulu | 4 ° ukuya <11-20> ± 0.2 ° |

| Ukuqhelaniswa neFlethi okuPhambili | <1-100> ± 5 ° |

| Ubude beFlethi obuPhambili | 47.5mm ± 1.5mm |

| Ukuxhathisa | 0.015–0.0285 Ω·cm |

| Ukuxinana kweMibhobho | <0.5 |

| Uxinzelelo lweBoron Pitting (BPD) | <2000 |

| Uxinaniso lwe-Treading Screw Dislocation Density (TSD) | <500 |

| Iindawo zePolytype | Akukho nanye |

| I-Edge Indents | <3, 1mm ububanzi nobunzulu |

| Edge Cracks | 3, <1mm/ea |

| Ukupakisha | Icala le-wafer |

Ukuqukumbela

I-6-intshi ye-SiC Ingot - i-N-type Dummy / i-Prime grade yimathiriyeli yeprimiyamu ehlangabezana neemfuno ezingqongqo kwishishini le-semiconductor. I-conductivity yayo ephezulu ye-thermal, ukuxhathisa okukhethekileyo, kunye noxinano oluphantsi lwesiphene kuyenza ibe lolona khetho lubalaseleyo kwimveliso yezixhobo ze-elektroniki zamandla aphezulu, izixhobo zemoto, iinkqubo zonxibelelwano kunye neenkqubo zamandla avuselelekayo. Ubungakanani obunokwenziwa ngokwezifiso kunye neenkcukacha ezichanekileyo ziqinisekisa ukuba le SiC ingot inokulungelelaniswa noluhlu olubanzi lwezicelo, ukuqinisekisa ukusebenza okuphezulu kunye nokuthembeka kwiindawo ezifunayo. Ngolwazi oluthe vetshe okanye ukwenza iodolo, nceda uqhagamshelane neqela lethu labathengisi.

Idayagram eneenkcukacha