I-silicon ye-carbide ye-ceramic tray yokufunxa i-Silicon carbide ityhubhu ye-ceramic ibonelela ngobushushu obuphezulu be-sintering ukusetyenzwa kwesiko

Iimpawu eziphambili:

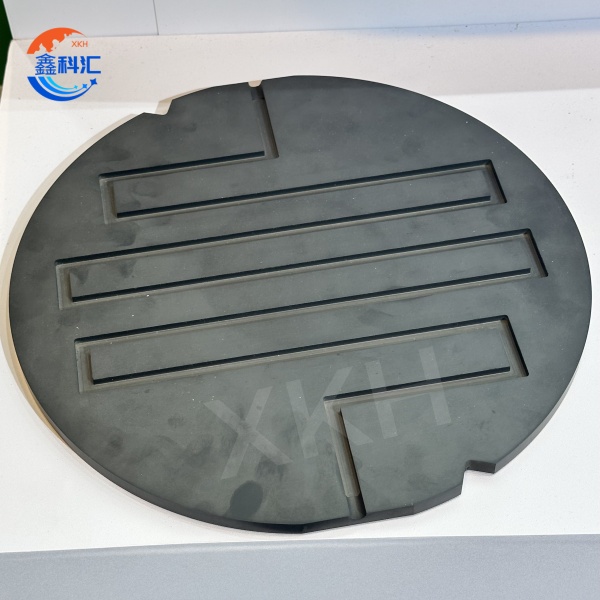

1. I-Silicon carbide i-ceramic tray

- Ubunzima obuphezulu kunye nokumelana nokunxiba: ukuqina kusondele kwidayimane, kwaye kunokumelana nokunxiba ngoomatshini kwi-wafer processing ixesha elide.

- I-conductivity ephezulu ye-thermal kunye ne-coefficient ephantsi yokwandiswa kwe-thermal: ukutshatyalaliswa kobushushu okukhawulezayo kunye nokuzinza kwe-dimensional, ukuphepha ukuguqulwa okubangelwa uxinzelelo lwe-thermal.

- I-flatness ephezulu kunye nokugqitywa komphezulu: I-flatness ye-surface iphezulu kwinqanaba le-micron, iqinisekisa uqhagamshelwano olupheleleyo phakathi kwe-wafer kunye nediski, ukunciphisa ukungcoliswa kunye nomonakalo.

Ukuzinza kweMichiza: Ukuxhathisa okuqinileyo kwe-corrosion, kulungele ukucocwa okumanzi kunye neenkqubo zokubethelwa kwimveliso ye-semiconductor.

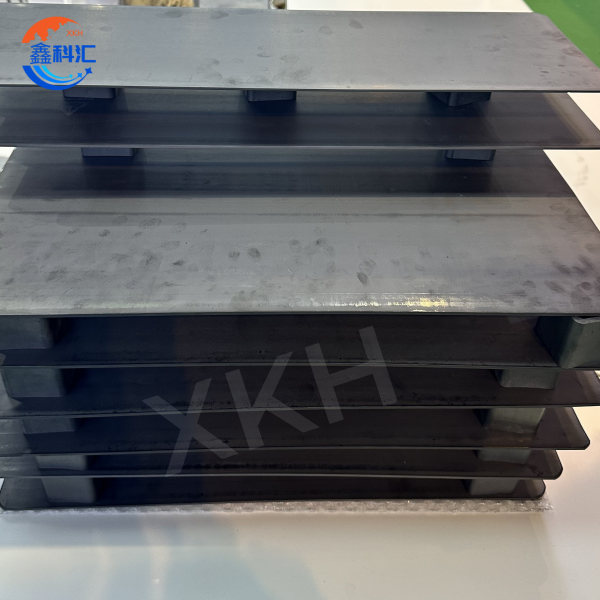

2. I-silicon carbide ityhubhu ye-ceramic

- Ukumelana nokushisa okuphezulu: Inokusebenza kwindawo yokushisa ephezulu ngaphezu kwe-1600 ° C ixesha elide, ilungele inkqubo ye-semiconductor ephezulu yokushisa.

Ukuchasana nokugqwesa okugqwesileyo: ukumelana ne-acids, i-alkalis kunye neentlobo ezahlukeneyo ze-solvents zamakhemikhali, ezifanelekileyo kwiindawo ezinzima zenkqubo.

-Ubunzima obuphezulu kunye nokumelana nokunxiba: ukuxhathisa ukhukuliseko lwamasuntswana kunye nokunxiba koomatshini, ukwandisa ubomi benkonzo.

- I-conductivity ephezulu ye-thermal kunye ne-coefficient ephantsi yokwandiswa kwe-thermal: ukuqhuba ngokukhawuleza ukushisa kunye nokuzinza kwe-dimensional, ukunciphisa ukuguqulwa okanye ukuqhekeka okubangelwa uxinzelelo lwe-thermal.

Ipharamitha yeMveliso:

Iparamitha yetreyi ye-silicon carbide:

| (Impahla yezinto) | (Iyunithi) | (sic) | |

| (Umxholo weSiC) | (Wt)% | >99 | |

| (Ubungakanani obuphakathi kweenkozo) | micron | 4-10 | |

| (Ukuxinana) | kg/dm3 | >3.14 | |

| (Ibonakala ngathi i-porosity) | Vo1% | <0.5 | |

| (Vickers ubulukhuni) | HV 0.5 | GPA | 28 |

| *() Amandla e-Flexural* (amanqaku amathathu) | 20ºC | MPa | 450 |

| (Amandla acinezelayo) | 20ºC | MPa | 3900 |

| (Elastic Modulus) | 20ºC | GPA | 420 |

| (Ukuqina kokwaphuka) | MPa/m'% | 3.5 | |

| (I-Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Ukuxhathisa) | 20°C | Ohm.cm | 106-108 |

(I-coefficient yokwandisa ubushushu) | a(RT**...80ºC) | K-1*10-6 | 4.3 |

(Obona bushushu bokusebenza) | oºC | 1700 | |

Ipharamitha yetyhubhu ye-silicon carbide ceramic:

| Izinto | Isalathiso |

| α-SIC | 99% imizuzu |

| I-Porosity ebonakalayo | 16% ubukhulu |

| Unizi lolwapho kuyiwa khona | 2.7g/cm3 min |

| Ukugoba Amandla kubushushu obuphezulu | 100 Mpa imiz |

| I-Coefficient yoKwandiswa kweThermal | K-1 4.7x10 -6 |

| I-Coefficient ye-Thermal Conductivity (1400ºC) | 24 W/mk |

| Max. Ubushushu bokusebenza | 1650ºC |

Usetyenziso oluphambili:

1. I-silicon carbide ipleyiti ye-ceramic

- I-wafer cut and polishing: isebenza njengeqonga lokuthwala ukuqinisekisa ukuchaneka okuphezulu kunye nokuzinza ngexesha lokusika kunye nokupholisa.

- Inkqubo ye-Lithography: I-wafer igxininiswe kumatshini we-lithography ukuqinisekisa ukuchaneka okuphezulu kokuma ngexesha lokuvezwa.

- I-Chemical Mechanical Polishing (CMP) : isebenza njengeqonga lenkxaso yokupholisa iipads, ukubonelela ngoxinzelelo olufanayo kunye nokusabalalisa ukushisa.

2. I-silicon carbide ityhubhu ye-ceramic

-Ityhubhu yobushushu obuphezulu bobushushu obuphezulu: isetyenziselwa izixhobo zobushushu obuphezulu ezifana nesithando somlilo kunye nesithando se-oxidation ukuthwala ii-wafers kunyango lwenkqubo yobushushu obuphezulu.

- Inkqubo ye-CVD / PVD: Njengombhobho wokuthwala kwigumbi lokuphendula, ukumelana nokushisa okuphezulu kunye neegesi ezidliwayo.

- Izixhobo zezixhobo ze-Semiconductor: kubatshintshi bokushisa, iipayipi zegesi, njl., Ukuphucula ulawulo lwe-thermal lwezixhobo.

I-XKH ibonelela ngoluhlu olupheleleyo lweenkonzo zesiko kwiitreyi ze-silicon carbide ceramic, iikomityi zokufunxa kunye ne-silicon carbide ceramic tubes. Iitreyi ze-silicon carbide ceramic kunye neekomityi zokufunxa, i-XKH inokwenziwa ngokwezifiso ngokuhambelana neemfuno zabathengi zobukhulu obahlukeneyo, iimilo kunye noburhabaxa bomphezulu, kunye nokuxhasa unyango olukhethekileyo lokugquma, ukunyusa ukuxhathisa ukunxiba kunye nokuxhathisa ukubola; Kwiityhubhu ze-silicon carbide ceramic, i-XKH inokwenza ngokwezifiso iintlobo ezahlukeneyo zangaphakathi, ububanzi bangaphandle, ubude kunye nesakhiwo esiyinkimbinkimbi (njenge-tube eqingqiweyo okanye ityhubhu ye-porous), kunye nokubonelela ngepolishi, i-anti-oxidation coating kunye nezinye iinkqubo zonyango lomhlaba. I-XKH iqinisekisa ukuba abathengi banokusebenzisa ngokupheleleyo inzuzo yokusebenza kweemveliso ze-silicon carbide ze-ceramic ukuhlangabezana neemfuno ezifunekayo kwiindawo eziphezulu zokuvelisa ezifana ne-semiconductors, ii-led kunye ne-photovoltaics.

Idayagram eneenkcukacha