I-Silicon Carbide Ceramic Tray-Ihlala ixesha elide, iiTreyi eziSebenza ngokuPhezulu kwi-Thermal kunye ne-Chemical Applications.

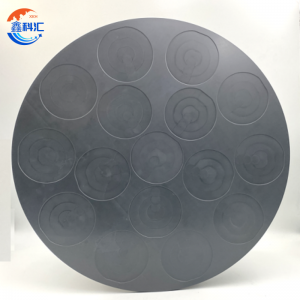

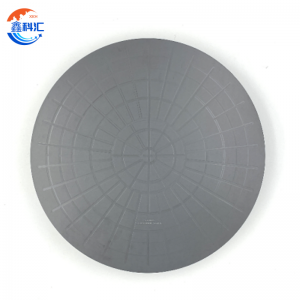

Idayagram eneenkcukacha

Intshayelelo yeMveliso

I-silicon carbide (i-SiC) iitreyi ze-ceramic zizinto eziphezulu zokusebenza ezisetyenziswa ngokubanzi kwindawo yokushisa ephezulu, imithwalo ephezulu, kunye neekhemikhali ezinobunzima bezoshishino. Eyenziwe ngobuchwephesha obuphezulu be-silicon carbide izixhobo ze-ceramic, ezi itreyi ziyilelwe ukuhambisa amandla akhethekileyo omatshini, ukuhanjiswa okuphezulu kwe-thermal, kunye nokumelana okugqwesileyo kumothuko we-thermal, i-oxidation kunye nokugqwala. Ubume babo bomelele bubenza bafaneleke kakhulu kwizicelo ezahlukeneyo zemizi-mveliso kubandakanya ukwenziwa kwe-semiconductor, ukusetyenzwa kwe-photovoltaic, ukucwiliswa kwamalungu esinyithi somgubo, nokunye.

Iitreyi ze-Silicon carbide zisebenza njengabathwali abayimfuneko okanye zixhasa ngexesha leenkqubo zonyango lwe-thermal apho ukuchaneka kwe-dimensional, ukunyaniseka kwesakhiwo, kunye nokuchasana kweekhemikhali kubalulekile. Xa kuthelekiswa nezixhobo ze-ceramic zemveli ezifana ne-alumina okanye i-mullite, iitreyi ze-SiC zibonelela ngokusebenza okuphezulu kakhulu, ngakumbi kwiimeko ezibandakanya ukuphinda ibhayisekile eshushu kunye nomoya ondlongondlongo.

Inkqubo yokuVelisa kunye noBume beMaterial

Ukuveliswa kweetreyi ze-ceramic ze-SiC kubandakanya ubunjineli obuchanekileyo kunye nobuchwepheshe be-sintering obuphambili ukuqinisekisa ukuxinana okuphezulu, i-microstructure efanayo, kunye nokusebenza okungaguqukiyo. Amanyathelo ngokubanzi aquka:

-

UKhetho lweMathiriyeli ekrwada

Ucoceko oluphezulu lwe-silicon carbide powder (≥99%) lukhethiwe, rhoqo ngolawulo oluthile lobungakanani besuntswana kunye nokungcola okuncinci ukuqinisekisa iipropati eziphezulu zoomatshini kunye ne-thermal. -

Iindlela Zokwenza

Ngokuxhomekeke kwiinkcukacha zetreyi, iindlela ezahlukeneyo zokubumba ziyasetyenziswa:-

I-Cold Isostatic Pressing (CIP) ye-high-density, i-compact compacts

-

I-Extrusion okanye i-slip casting kwiimilo ezinzima

-

Isitofu sokubumba ngokuchanekileyo, iijiyometri ezineenkcukacha

-

-

Iindlela zokuSintering

Umzimba oluhlaza utshiswe kumaqondo obushushu aphezulu, ngokuqhelekileyo kuluhlu lwe-2000 ° C, phantsi kwe-inert okanye i-vacuum atmospheres. Iindlela eziqhelekileyo ze-sintering ziquka:-

I-Reaction Bonded SiC (RB-SiC)

-

I-Pressureless Sintered SiC (SSiC)

-

iRecrystallized SiC (RBSiC)

Indlela nganye iphumela kwiipropathi zemathiriyeli ezahlukileyo, ezifana ne-porosity, amandla, kunye ne-thermal conductivity.

-

-

Precision Machining

Emva kokucoca, iitreyi zitshintshwa ukuze zikwazi ukunyamezela ubungakanani obuqinileyo, ukugqiba umphezulu ogudileyo, kunye nokuba tyaba. Unyango lomphezulu olufana nokuqhwaba, ukucola, kunye nokupholisha kunokusetyenziswa ngokusekwe kwiimfuno zabathengi.

Usetyenziso oluqhelekileyo

Iitreyi ze-silicon carbide ceramic zisetyenziswa kwiintlobo ngeentlobo zamashishini ngenxa yokuguquguquka kwazo kunye nokomelela. Usetyenziso oluqhelekileyo lubandakanya:

-

Ishishini leSemiconductor

Iitreyi zeSiC zisetyenziswa njengabathwali ngexesha le-wafer annealing, diffusion, oxidation, epitaxy, kunye neenkqubo zokufakelwa. Ukuzinza kwabo kuqinisekisa ukusabalalisa ukushisa okufanayo kunye nokungcoliswa okuncinci. -

I-Photovoltaic (PV) Ishishini

Kwimveliso yeeseli zelanga, iitreyi zeSiC zixhasa i-silicon ingots okanye iiwafers ngexesha lokusasazwa kobushushu obuphezulu kunye namanyathelo okuthambisa. -

Umgubo weMetallurgy kunye neeCeramics

Isetyenziselwa ukuxhasa amacandelo ngexesha lokucwiliswa komgubo wesinyithi, iiseramikhi, kunye nemathiriyeli edibeneyo. -

Iglasi kunye neePaneli zokubonisa

Isetyenziswa njengeetreyi ze-kiln okanye amaqonga okwenza iiglasi ezikhethekileyo, ii-LCD substrates, okanye ezinye izinto ezibonakalayo. -

Ukwenziwa kweeKhemikhali kunye neeFurnaces zeThermal

Ukukhonza njengabathwali be-corrosion-resistant kwi-reactors ze-chemical reactors okanye njenge-thermal support trays kwi-vacuum kunye ne-controlled-atmosphere furnaces.

Iimpawu eziphambili zokuSebenza

-

✅Uzinzo lweThermal oluKhethekileyo

Ukumelana nokusetyenziswa ngokuqhubekayo kumaqondo okushisa ukuya kwi-1600-2000 ° C ngaphandle kokulwa okanye ukuthotywa. -

✅Amandla oomatshini aphakamileyo

Inika amandla aphezulu okuguquguquka (ngokuqhelekileyo> 350 MPa), iqinisekisa ukuqina kwexesha elide naphantsi kweemeko eziphezulu zomthwalo. -

✅Ukunyangwa kweThermal Shock

Ukusebenza okugqwesileyo kwiindawo ezinokutshintsha kweqondo lokushisa ngokukhawuleza, ukunciphisa umngcipheko wokuqhekeka. -

✅Ukonakala kunye noKunyangwa kwe-Oxidation

Uzinzile ngokwekhemikhali kwiiasidi ezininzi, i-alkali, kunye ne-oxidizing / ukunciphisa iigesi, ezifanelekileyo kwiinkqubo zeekhemikhali ezinzima. -

✅Ukuchaneka koMda kunye nokuBucana

Yenzelwe ukuchaneka okuphezulu, ukuqinisekisa ukusetyenzwa okufanayo kunye nokuhambelana neenkqubo ezizenzekelayo. -

✅Ubomi obude kunye nokuSebenza kweendleko

Amazinga asezantsi okutshintshwa kunye neendleko ezincitshisiweyo zokulondolozwa kwenza kube sisisombululo esinendleko ngokuhamba kwexesha.

IiNgcaciso zobuGcisa

| Ipharamitha | Ixabiso eliqhelekileyo |

|---|---|

| Izinto eziphathekayo | I-Reaction Bonded SiC / Sintered SiC |

| Max. Ubushushu bokusebenza | 1600–2000°C |

| Amandla e-Flexural | ≥350 MPa |

| Ukuxinana | ≥3.0 g/cm³ |

| I-Thermal Conductivity | ~120–180 W/m·K |

| Umphezulu oMcaba | ≤ 0.1 mm |

| Ukutyeba | 5–20 mm (inokwenziwa ngokwezifiso) |

| Imilinganiselo | Umgangatho: 200×200 mm, 300×300 mm, njl. |

| Umphezulu Gqiba | Yenziwe ngomatshini, yakhazimliswa (ngesicelo) |

Imibuzo Ebuzwa Rhoqo (FAQ)

I-Q1: Ngaba iitreyi ze-silicon carbide zingasetyenziswa kwiziko lokufunxa?

A:Ewe, iitreyi ze-SiC zifanelekile kwindawo zokufunxa ngenxa yokuphuma kwazo okuphantsi, ukuzinza kweekhemikhali, kunye nokumelana nobushushu obuphezulu.

I-Q2: Ngaba iimilo eziqhelekileyo okanye iindawo zokubeka zikhona?

A:Ngokuqinisekileyo. Sinikezela ngeenkonzo zokwenza ngokwezifiso ezibandakanya ubungakanani betreyi, imilo, iimpawu zomphezulu (umzekelo, iigrooves, imingxunya), kunye nokupholisha umphezulu ukuhlangabezana neemfuno ezizodwa zabathengi.

I-Q3: I-SiC ithelekisa njani ne-alumina okanye iitreyi ze-quartz?

A:I-SiC inamandla aphezulu, i-conductivity engcono ye-thermal, kunye nokuchasana okuphezulu kwi-thermal shock kunye nokubola kweekhemikhali. Ngelixa i-alumina inexabiso elithe kratya, i-SiC iqhuba ngcono kwiindawo ezibangwayo.

I-Q4: Ngaba kukho ukutyeba okusemgangathweni kwezi tray?

A:Ukutyeba ngokuqhelekileyo kuluhlu lwe-5-20 mm, kodwa sinokuhlengahlengisa ngokusekelwe kwisicelo sakho kunye neemfuno zokuthwala umthwalo.

I-Q5: Leliphi ixesha eliqhelekileyo lokukhokelela kwiitreyi zeSiC ezilungiselelweyo?

A:Amaxesha okukhokela ayahluka ngokuxhomekeke kubunzima kunye nobuninzi kodwa ngokubanzi asusela kwiiveki ezi-2 ukuya kwezi-4 kwiiodolo ezilungiselelwe wena.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.