Silicon Carbide Ceramic Fork Ingalo/Isandla

Idayagram eneenkcukacha

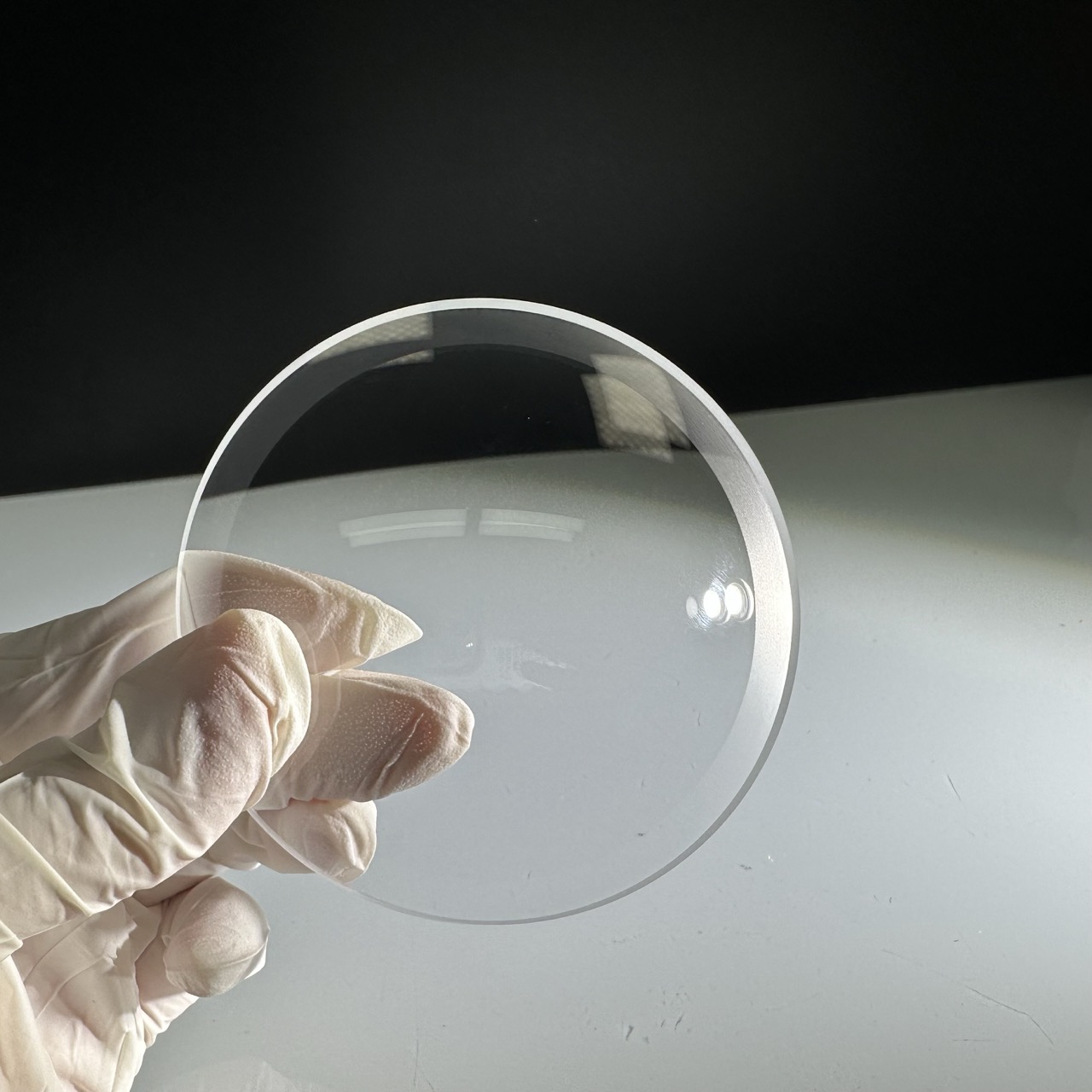

Ukwazisa ngeSilicon Carbide Ceramic Fork Arm/Hand

ISilicon Carbide Ceramic Fork Ingalo/Isandlalicandelo eliphambili lokuphatha eliphuhliswe kwiinkqubo ezizihambelayo ezichanekileyo, ngakumbi kwi-semiconductor kunye namashishini abonayo. Eli candelo libonisa uyilo olwahlukileyo lwe-U-shape elungiselelwe ukuphatha i-wafer, iqinisekisa amandla omatshini kunye nokuchaneka komda phantsi kweemeko ezigqithisileyo zokusingqongileyo. Yenziwe ukusuka kwi-silicon carbide ceramic ecocekileyo ephezulu, iifolokhwe ingalo/isandlainika ukuqina okukhethekileyo, ukuzinza kwe-thermal, kunye nokumelana neekhemikhali.

Njengoko izixhobo ze-semiconductor ziguqukela kwiijometri ezigqwesileyo kunye nokunyamezelana okungqongqo, imfuno yezinto ezingangcolisekiyo kunye nezizinzileyo ngokwethermal iba baluleke kakhulu. ISilicon Carbide Ceramic Fork Ingalo/Isandlaihlangabezana nalo mceli mngeni ngokubonelela ngokuveliswa kwamasuntswana asezantsi, imiphezulu egudileyo kakhulu, kunye nemfezeko eyomeleleyo yesakhiwo. Nokuba kukuthutho lwe-wafer, indawo ye-substrate, okanye iintloko zezixhobo zerobhothi, eli candelo lenzelwe ukuthembeka kunye nokuphila ixesha elide.

Izizathu eziphambili zokukhetha okuSilicon Carbide Ceramic Fork Ingalo/Isandlaziquka:

-

Ukwandiswa kwe-thermal encinci yokuchaneka kwe-dimensional

-

Ubunzima obuphezulu kubomi benkonzo ende

-

Ukumelana neeasidi, iialkali, kunye neegesi ezisebenzayo

-

Ukuhambelana ne-ISO Class 1 yeendawo ezicocekileyo zegumbi

UmGaqo wokuVelisa weSilicon Carbide yeCeramic Fork Ingalo/Isandla

ISilicon Carbide Ceramic Fork Ingalo/Isandlaiveliswa ngolawulo oluphezulu lwe-ceramic processing workflow eyilelwe ukuqinisekisa iipropathi zemathiriyeli eziphezulu kunye nokuhambelana komgangatho.

1. Ukulungiselela Umgubo

Inkqubo iqala ngokukhethwa kwe-ultra-fine silicon carbide powders. Ezi powders zixutywe kunye ne-binders kunye ne-sintering aids ukuququzelela ukuxinana kunye nokuxinana. Yaleifolokhwe ingalo/isandla, i-β-SiC okanye i-α-SiC powders isetyenziselwa ukuqinisekisa zombini ubunzima kunye nokuqina.

2. Ukubunjwa kunye nokuLungisa kwangaphambili

Kuxhomekeke kubunzima beifolokhwe ingalo/isandlauyilo, inxalenye iyilwe kusetyenziswa ukucinezela kwe-isostatic, ukubumba inaliti, okanye ukuphosa ukutyibilika. Oku kuvumela iijometri ezintsonkothileyo kunye nezakhiwo ezibhityileyo zodonga, zibalulekile kubume obukhaphukhaphu beSilicon Carbide Ceramic Fork Ingalo/Isandla.

3. High-ubushushu Sintering

I-Sintering yenziwa kumaqondo obushushu angaphezu kwe-2000 ° C kwi-vacuum okanye i-argon atmospheres. Eli nqanaba liguqula umzimba oluhlaza ube licandelo le-ceramic elixinaniswa ngokupheleleyo. I sinteredifolokhwe ingalo/isandlaifezekisa uxinaniso olusondeleyo lwethiyori, ibonelela ngeempawu ezibalaseleyo zoomatshini kunye ne-thermal.

4. Precision Machining

Emva kokucula, iSilicon Carbide Ceramic Fork Ingalo/Isandlaugaya idayimani kunye nomatshini weCNC. Oku kuqinisekisa ukuvuleka ngaphakathi kwe-± 0.01 mm kwaye ivumela ukubandakanywa kwemingxuma yokunyuka kunye nokubeka iimpawu ezibalulekileyo ekufakweni kwayo kwiinkqubo ezizenzekelayo.

5. UkuQeda komphezulu

Ukupholisha kunciphisa uburhabaxa bomphezulu (Ra <0.02 μm), kubalulekile ekunciphiseni isizukulwana senxalenye. Iingubo ezikhethiweyo ze-CVD zingasetyenziselwa ukuphucula ukumelana neplasma okanye ukongeza ukusebenza okufana nokuziphatha okuchasayo.

Kuyo yonke le nkqubo, iiprothokholi zolawulo lomgangatho ziyasetyenziswa ukuqinisekisaSilicon Carbide Ceramic Fork Ingalo/Isandlayenza ngokuthembekileyo kwezona zicelo zibuthathaka.

Iiparameters zeSilicon Carbide Ceramic Fork Arm/Hand

| IiNgcaciso eziphambili ze-CVD-SIC Coating | ||

| Iipropati zeSiC-CVD | ||

| Ulwakhiwo lweCrystal | FCC isigaba β | |

| Ukuxinana | g/cm ³ | 3.21 |

| Ukuqina | Vickers ubulukhuni | 2500 |

| Ubungakanani benkozo | μm | 2~10 |

| Ucoceko lweMichiza | % | 99.99995 |

| Ubushushu Umthamo | J·kg-1 ·K-1 | 640 |

| Iqondo lobushushu elisezantsi | ℃ | 2700 |

| Amandla eFelexural | MPa (RT 4-point) | 415 |

| Imodulus eselula | I-Gpa (4pt bend, 1300℃) | 430 |

| Ukwandiswa kweThermal (CTE) | 10-6K-1 | 4.5 |

| I-Thermal conductivity | (W/mK) | 300 |

Ukusetyenziswa kweSilicon Carbide Ceramic Fork Arm/Hand

ISilicon Carbide Ceramic Fork Ingalo/Isandlaisetyenziswa ngokubanzi kuwo wonke amashishini apho ukucoceka okuphezulu, ukuzinza, kunye nokuchaneka koomatshini kubalulekile. Ezi ziquka:

1. Ukwenziwa kweSemiconductor

Kwimveliso ye-semiconductor, iSilicon Carbide Ceramic Fork Ingalo/Isandlaisetyenziselwa ukuthutha ii-silicone wafers ngaphakathi kwezixhobo zenkqubo ezifana namagumbi e-etching, iinkqubo zokubeka, kunye nezixhobo zokuhlola. Ukumelana ne-thermal kunye nokuchaneka kwe-dimensional kuyenza ilungele ukunciphisa i-wafer misalignment kunye nosulelo.

2. Uveliso lwePaneli yokuBonisa

Kwimveliso ye-OLED kunye ne-LCD, iifolokhwe ingalo/isandlaisetyenziswa kwiinkqubo zokuchola kunye neendawo, apho iphatha i-glass substrates ebuthathaka. Ubunzima bayo obuphantsi kunye nokuqina okuphezulu kwenza ukunyakaza okukhawulezayo kunye nokuzinza ngaphandle kokungcangcazela okanye ukuphambuka.

3. IiNkqubo ze-Optical kunye neFotonic

Ukulungelelaniswa kunye nokubeka iilensi, izibuko, okanye i-photonic chips, iSilicon Carbide Ceramic Fork Ingalo/Isandlaibonelela ngenkxaso engashukumiyo, ebaluleke kakhulu ekusetyenzweni kwelaser kunye nosetyenziso oluchanekileyo lwe-metrology.

4. IAerospace & Vacuum Systems

Kwiinkqubo ze-aerospace optical kunye nezixhobo ze-vacuum, le nxalenye ye-non-magnetic, i-corrosion-resistant structure iqinisekisa ukuzinza kwexesha elide. Iifolokhwe ingalo/isandlainokusebenza nakwi-ultra-high vacuum (UHV) ngaphandle kokukhupha umoya.

Kuzo zonke ezi nkalo, iSilicon Carbide Ceramic Fork Ingalo/Isandlaigqwesa isinyithi semveli okanye ezinye iindlela zepolymer ngokuthembeka, ukucoceka, kunye nobomi benkonzo.

FAQ yeSilicon Carbide Ceramic Fork Arm/Hand

I-Q1: Ziziphi iisayizi ze-wafer ezixhaswa yi-Silicon Carbide Ceramic Fork Arm / Hand?

Iifolokhwe ingalo/isandlaingenziwa ngokwezifiso ukuxhasa i-150 mm, 200 mm, kunye ne-300 mm yafers. Ubude befolokhwe, ububanzi bengalo, kunye neepateni zomngxunya zinokulungiswa ukuze zilingane neqonga lakho elizenzekelayo.

I-Q2: Ngaba i-Silicon Carbide Ceramic Fork Arm / Hand iyahambelana neenkqubo ze-vacuum?

Ewe. Iifolokhwe ingalo/isandlailungele zombini i-vacuum ephantsi kunye ne-ultra-high vacuum systems. Inemilinganiselo ephantsi yokukhupha umoya kwaye ayikhuphi iinxalenye, iyenza ilungele indawo ecocekileyo neyokutshayela.

I-Q3: Ngaba ndinokongeza iingubo okanye ukuguqulwa kwendawo kwi-fork arm / isandla?

Ngokuqinisekileyo. ISilicon Carbide Ceramic Fork Ingalo/Isandlainokufakwa nge-CVD-SiC, i-carbon, okanye i-oxide layers ukunyusa ukuxhathisa kwayo kwi-plasma, iipropati ezichasayo, okanye ubunzima bomhlaba.

I-Q4: Uqinisekiswa njani umgangatho wengalo yefolokhwe / yesandla?

NgamnyeSilicon Carbide Ceramic Fork Ingalo/Isandlaihlolwa ngokulinganayo kusetyenziswa izixhobo zeCMM kunye nelaser metrology. Umgangatho womphezulu uvavanywa nge-SEM kunye ne-non-contact profilometry ukuhlangabezana nemigangatho ye-ISO kunye ne-SEMI.

I-Q5: Liliphi ixesha elihamba phambili le-fork yesiqhelo ingalo / imiyalelo yesandla?

Ixesha lokukhokela ngokuqhelekileyo liqala kwiiveki ezi-3 ukuya kwezi-5 ngokuxhomekeke kubunzima kunye nobuninzi. Iprototyping ekhawulezileyo iyafumaneka kwizicelo ezingxamisekileyo.

Ezi FAQs zijolise ekuncedeni iinjineli kunye namaqela okuthenga aqonde amandla kunye nokhetho olukhoyo xa ukhetha aSilicon Carbide Ceramic Fork Ingalo/Isandla.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.