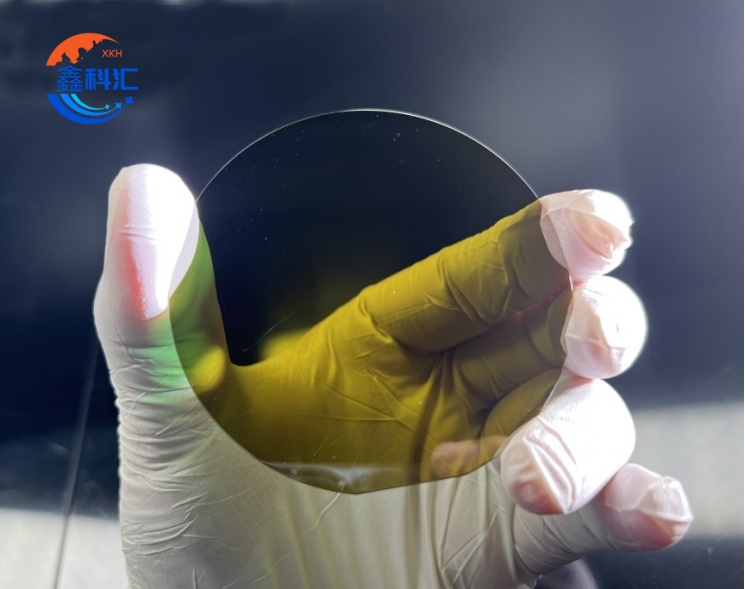

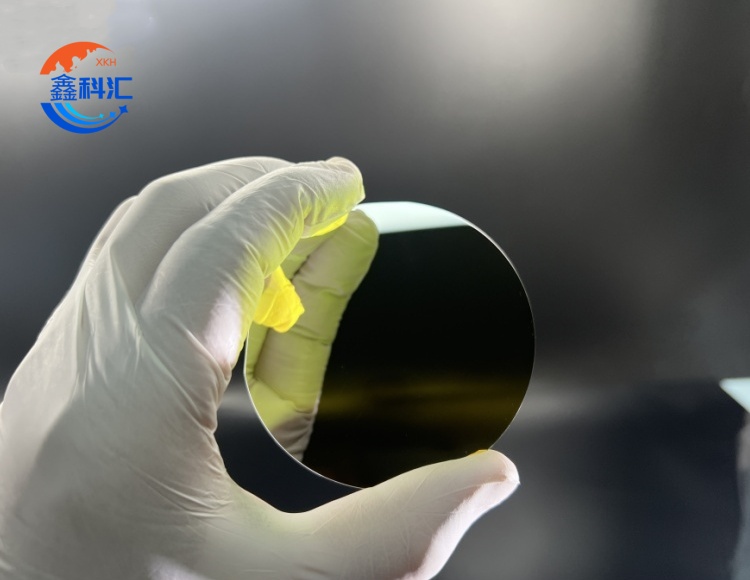

I-Sic Substrate yeSilicon Carbide Wafer 4H-N Uhlobo oluPhezulu loBulukhuni bokuRhakala Ukuchasa iBanga lokupholisha

Ezi zilandelayo ziimpawu ze-silicon carbide wafer

1. I-Thermal conductivity ephezulu: I-thermal conductivity ye-SIC yafers iphezulu kakhulu kune-silicon, oko kuthetha ukuba ii-wafers ze-SIC zinokutshabalalisa ngokufanelekileyo ukushisa kwaye zilungele ukusebenza kwiindawo eziphezulu zokushisa.

2. Ukuhamba kwe-electron ephezulu: Ii-wafers ze-SIC zinokuhamba kwe-electron ephezulu kune-silicon, evumela ukuba izixhobo ze-SIC zisebenze ngesantya esiphezulu.

3. I-voltage ephezulu yokuphuka: I-SIC wafer material inomthamo ophezulu wokuphuka, okwenza ukuba ifanele ukuvelisa izixhobo eziphezulu ze-semiconductor.

4. Ukuzinza kweekhemikhali eziphakamileyo: Ii-wafers ze-SIC zinamandla okumelana nokubola kweekhemikhali, ezinceda ukuphucula ukuthembeka kunye nokuqina kwesixhobo.

5. I-gap yebhendi ebanzi: Ii-wafers ze-SIC zine-gap yebhendi ebanzi kune-silicon, okwenza izixhobo ze-SIC zibe ngcono kwaye zizinzile kumaqondo aphezulu.

I-Silicon carbide wafer inezicelo ezininzi

I-1.Intsimi ye-Mechanical: izixhobo zokusika kunye nezinto zokugaya; Amalungu angagugiyo kunye namatyholo; Iivalvu zoshishino kunye netywina; Iibheringi kunye neebhola

2.Intsimi yamandla e-elektroniki: izixhobo ze-semiconductor zamandla; Isixhobo sombane esine-microwave esiphezulu; amandla ombane aphezulu kunye nobushushu obuphezulu be-elektroniki; Imathiriyeli yolawulo lobushushu

3.Ishishini leChemical: i-reactor yeekhemikhali kunye nezixhobo; imibhobho enganyangekiyo ekutyeni kunye neetanki zokugcina; Inkxaso ye-Chemical catalyst

4.Icandelo lezaMandla: i-gas turbine kunye ne-turbocharger components; Undoqo wamandla enyukliya kunye namalungu esakhiwo kubushushu obuphezulu bezixhobo zeeseli zamafutha

I-5.I-Aerospace: iinkqubo zokukhusela i-thermal kwimijukujelwa kunye neenqwelo zesithuba; amagqabi einjini yeJet; Udidi oluphezulu

6.Ezinye iindawo: Izinzwa eziphezulu zeqondo lokushisa kunye ne-thermopiles; Dies kunye nezixhobo inkqubo sintering; Ukusila kunye nokupolisha kunye nokusika amasimi

I-ZMKJ inokubonelela ngomgangatho ophezulu we-crystal SiC wafer enye (iSilicon Carbide) kwishishini lombane kunye ne-optoelectronic. I-SiC wafer yimathiriyeli ye-semiconductor yesizukulwana esilandelayo, eneepropati zombane ezizodwa kunye neempawu ezibalaseleyo ze-thermal, xa kuthelekiswa ne-silicon wafer kunye ne-GaAs wafer, i-wafer ye-SiC ifaneleke ngakumbi kubushushu obuphezulu kunye nesicelo sesixhobo samandla aphezulu . I-SiC wafer inokubonelelwa ngobubanzi be-intshi ye-2-6, zombini i-4H kunye ne-6H SiC, uhlobo lwe-N, i-Nitrogen doped, kunye nohlobo lwe-semi-insulating olukhoyo. Nceda uqhagamshelane nathi ngolwazi olungakumbi lwemveliso.

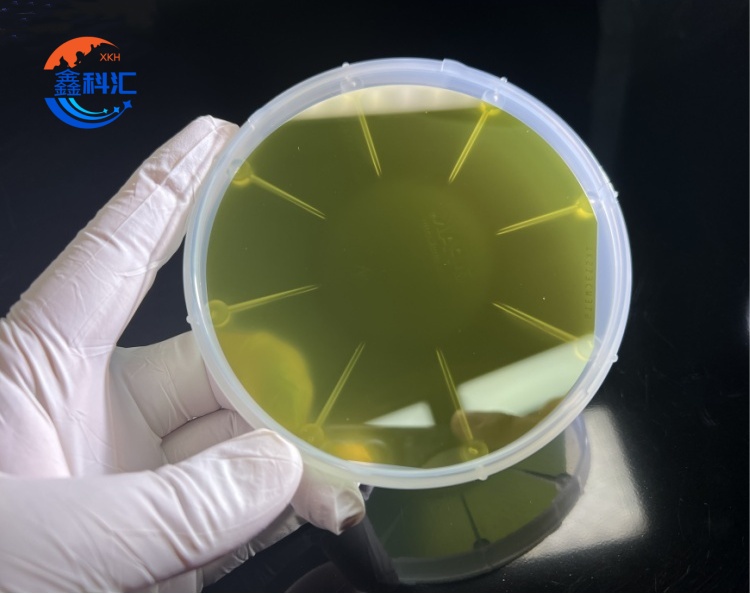

Umzi-mveliso wethu unezixhobo zokuvelisa eziphambili kunye neqela lobugcisa, elinokwenza ngokwezifiso iinkcukacha ezahlukeneyo, ubukhulu kunye neemilo ze-SiC wafer ngokweemfuno ezithile zabathengi.

Idayagram eneenkcukacha