I-SiC Ceramic Tray ye-Wafer Carrier enokumelana nobushushu obuphezulu

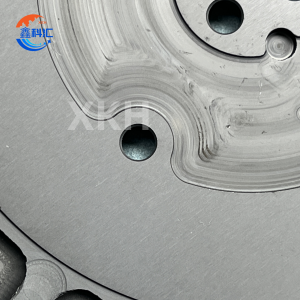

I-Silicon Carbide Ceramic Tray (iTreyi yeSiC).

Icandelo le-ceramic elisebenza kakhulu elisekelwe kwi-silicon carbide (SiC), eyenzelwe usetyenziso oluphezulu lwemizi-mveliso efana nokuveliswa kwe-semiconductor kunye nokuveliswa kwe-LED. Imisebenzi yayo ephambili ibandakanya ukusebenza njenge-wafer carrier, i-etching process platform, okanye inkxaso yenkqubo yobushushu obuphezulu, i-leveraging i-conductivity ekhethekileyo ye-thermal, ukumelana nobushushu obuphezulu, kunye nokuzinza kweekhemikhali ukuqinisekisa ukufana kwenkqubo kunye nemveliso yemveliso.

Iimpawu eziphambili

1. Ukusebenza kweThermal

- I-High Thermal Conductivity: 140–300 W/m·K, igqwesa ngokubonakalayo igraphite yesintu (85 W/m·K), eyenza ukutshatyalaliswa kobushushu ngokukhawuleza kunye nokunciphisa uxinzelelo lobushushu.

- I-Low Thermal Expansion Coefficient: 4.0×10⁻⁶/℃ (25–1000℃), ehambelana ngokusondeleyo nesilicon (2.6×10⁻⁶/℃), ukunciphisa imingcipheko ye-thermal deformation.

2. IiPropati zoomatshini

- Amandla aphezulu: Amandla e-Flexural ≥320 MPa (20℃), ukumelana noxinzelelo kunye nefuthe.

- Ukuqina okuphezulu: Ukuqina kwe-Mohs 9.5, okwesibini kuphela kwidayimane, enikezela ukuxhathisa okungaphezulu kokunxiba.

3. Uzinzo lweMichiza

- I-Corrosion Resistance: Ukumelana ne-acids ezomeleleyo (umzekelo, i-HF, i-H₂SO₄), ilungele imeko-bume yenkqubo yokufaka.

- I-Non-Magnetic: I-Intrinsic magnetic susceptibility <1×10⁻⁶ emu/g, ukuphepha ukuphazamisana nezixhobo ezichanekileyo.

4. Unyamezelo olugqithisileyo lokusiNgqongileyo

- Ukuqina kobushushu obuphezulu: Ubushushu bokusebenza ixesha elide ukuya kuthi ga kwi-1600-1900 ℃; ukuxhathisa ixesha elifutshane ukuya kuthi ga kwi-2200 ℃ (imeko-bume engena-oksijini).

- I-Thermal Shock Resistance: Imelana notshintsho olukhawulezileyo lobushushu (ΔT>1000℃) ngaphandle kokuqhekeka.

Usetyenziso

| Indawo yosetyenziso | Iimeko ezithile | Ixabiso loBugcisa |

| Ukwenziwa kweSemiconductor | I-Wafer etching (ICP), i-deposition-film deposition (MOCVD), i-CMP yokupolisha | I-high conductivity ye-thermal iqinisekisa amasimi afanayo obushushu; Ukwandiswa kwe-thermal ephantsi kunciphisa iwafer warpage. |

| Ukuveliswa kwe-LED | Ukukhula kwe-Epitaxial (umzekelo, i-GaN), i-wafer dicing, ukupakishwa | Icinezela iziphene zeentlobo ezininzi, iphucula ukusebenza kakuhle kokukhanya kwe-LED kunye nexesha lokuphila. |

| Ishishini lePhotovoltaic | Iziko leSilicon wafer sintering, izixhobo ze-PECVD zixhasa | Ubushushu obuphezulu kunye nokumelana nokothuka kwe-thermal kwandisa ubomi besixhobo. |

| ILaser kunye neOptics | Amandla aphezulu okupholisa i-laser substrates, i-optical system ixhasa | I-conductivity ephezulu ye-thermal yenza ukutshatyalaliswa kobushushu ngokukhawuleza, ukuzinzisa amacandelo optical. |

| Izixhobo zokuHlalutya | TGA/DSC abanini isampulu | Umthamo wokushisa ophantsi kunye nokuphendula ngokukhawuleza kwe-thermal kuphucula ukuchaneka komlinganiselo. |

Izinto eziluncedo kwiMveliso

- Ukusebenza okuBanzi: Ukuhanjiswa kwe-Thermal, amandla, kunye nokumelana nomhlwa kungaphezulu kakhulu kwe-alumina kunye ne-silicon nitride ceramics, ukuhlangabezana neemfuno zokusebenza ezigqithisileyo.

- Uyilo oluKhala: Uxinzelelo lwe-3.1–3.2 g/cm³ (40% yentsimbi), ukunciphisa umthwalo ongasebenziyo kunye nokuphucula ukuchaneka kwentshukumo.

- Ubomi obude kunye nokuthembeka: Ubomi benkonzo budlula iminyaka emi-5 kwi-1600 ℃, ukunciphisa ixesha lokuphumla kunye nokuthoba iindleko zokusebenza ngama-30%.

- Ukwenziwa ngokwezifiso: Ixhasa iijiyometri ezintsonkothileyo (umzekelo, iikomityi ezifunxayo ezinabileyo, iitreyi ezinomaleko amaninzi) ezinempazamo yobude obungaphantsi kwe-15 μm yosetyenziso oluchanekileyo.

Iinkcukacha zobuGcisa

| Uluhlu lweParameter | Isalathisi |

| IiPropati zoMzimba | |

| Ukuxinana | ≥3.10 g/cm³ |

| Amandla e-Flexural (20℃) | 320–410 MPa |

| I-Thermal Conductivity (20℃) | 140–300 W/(m·K) |

| Ukwandiswa kweNgcaciso yoMmandla (25–1000℃) | 4.0×10⁻⁶/℃ |

| IiPropati zeKhemikhali | |

| Ukumelana ne-Acid (HF/H₂SO₄) | Akukho mhlwa emva kokuntywiliselwa iiyure ezingama-24 |

| Ukuchaneka koMatshini | |

| Ukucaba | ≤15 μm (300×300 mm) |

| Uburhabaxa boMphezulu (Ra) | ≤0.4 μm |

Iinkonzo ze-XKH

I-XKH ibonelela ngezisombululo ezibanzi zamashishini ezithatha uphuhliso lwesiko, ukuchaneka komatshini, kunye nolawulo olungqongqo lobulunga. Kuphuhliso lwesiko, ibonelela ngococeko oluphezulu (> 99.999%) kunye nezisombululo zemathiriyeli ze-porous (30-50% porosity), ezidityaniswe nemodeli ye-3D kunye nokulinganisa ukwenza iijometri ezintsonkothileyo zezicelo ezinjenge-semiconductors kunye ne-aerospace. Ukwenziwa komatshini ngokuchanekileyo kulandela inkqubo elungelelanisiweyo: ukusetyenzwa komgubo → ukucofa isostatic/okomileyo → 2200°C sintering → CNC/diamond grinding → ukuhlolwa, ukuqinisekisa ukugujwa komgangatho wenanometer kunye ±0.01 mm unyamezelo lwedimensional. Ulawulo lomgangatho lubandakanya uvavanyo lwenkqubo epheleleyo (ukwakheka kwe-XRD, ulwakhiwo lwe-SEM, ukugoba amanqaku ama-3) kunye nenkxaso yobugcisa (ukulungiswa kwenkqubo, ukubonisana kwe-24/7, ukuhanjiswa kwesampulu yeeyure ezingama-48), ukuhambisa izinto ezinokuthenjwa, ezisebenza kakhulu kwiimfuno eziphambili zemizi-mveliso.

Imibuzo Ebuzwa Rhoqo (FAQ)

1. Q: Ngawaphi amashishini asebenzisa iitreyi ze-silicon carbide ceramic?

A: Isetyenziswa kakhulu kwimveliso ye-semiconductor (i-wafer handling), amandla elanga (iinkqubo ze-PECVD), izixhobo zonyango (izixhobo ze-MRI), kunye ne-aerospace (indawo ezinobushushu obuphezulu) ngenxa yokumelana nobushushu obugqithisileyo kunye nokuzinza kweekhemikhali.

2. Umbuzo: I-silicon carbide iyigqwesa njani iquartz/itreyi zeglasi?

A: Ukumelana nokothuka kwe-thermal ephezulu (ukuya kuthi ga kwi-1800 ° C vs. i-quartz's 1100 ° C), uphazamiseko lwemagnethi, kunye nobomi obude (iminyaka emi-5+ ngokuchasene neenyanga ezi-6-12 zequartz).

3. Umbuzo: Ngaba iitreyi ze-silicon ze-carbide ziyakwazi ukujongana neendawo ezineasidi?

A: Ewe. Ukumelana ne-HF, i-H2SO4, kunye ne-NaOH, kunye ne-<0.01mm i-corrosion/unyaka, ibenza ukuba bafanelekele ukufakwa kweekhemikhali kunye nokucoca i-wafer.

4. Q: Ngaba iitreyi ze-silicon carbide ziyahambelana ne-automation?

A: Ewe. Yenzelwe i-vacuum pickup kunye nokuphathwa kwerobhothi, kunye nokukhanya komphezulu <0.01mm ukunqanda ukungcoliseka kwamasuntswana kwiilaphu ezizenzekelayo.

5. Umbuzo: Ithini indleko yokuthelekisa izinto zemveli?

A: Iindleko eziphezulu zangaphambili (i-3-5x quartz) kodwa i-30-50% iphantsi kwe-TCO, ngenxa yobude bobomi obongezelelweyo, ixesha lokuphumla elincitshisiweyo, kunye nokongiwa kwamandla kwi-thermal conductivity ephezulu.