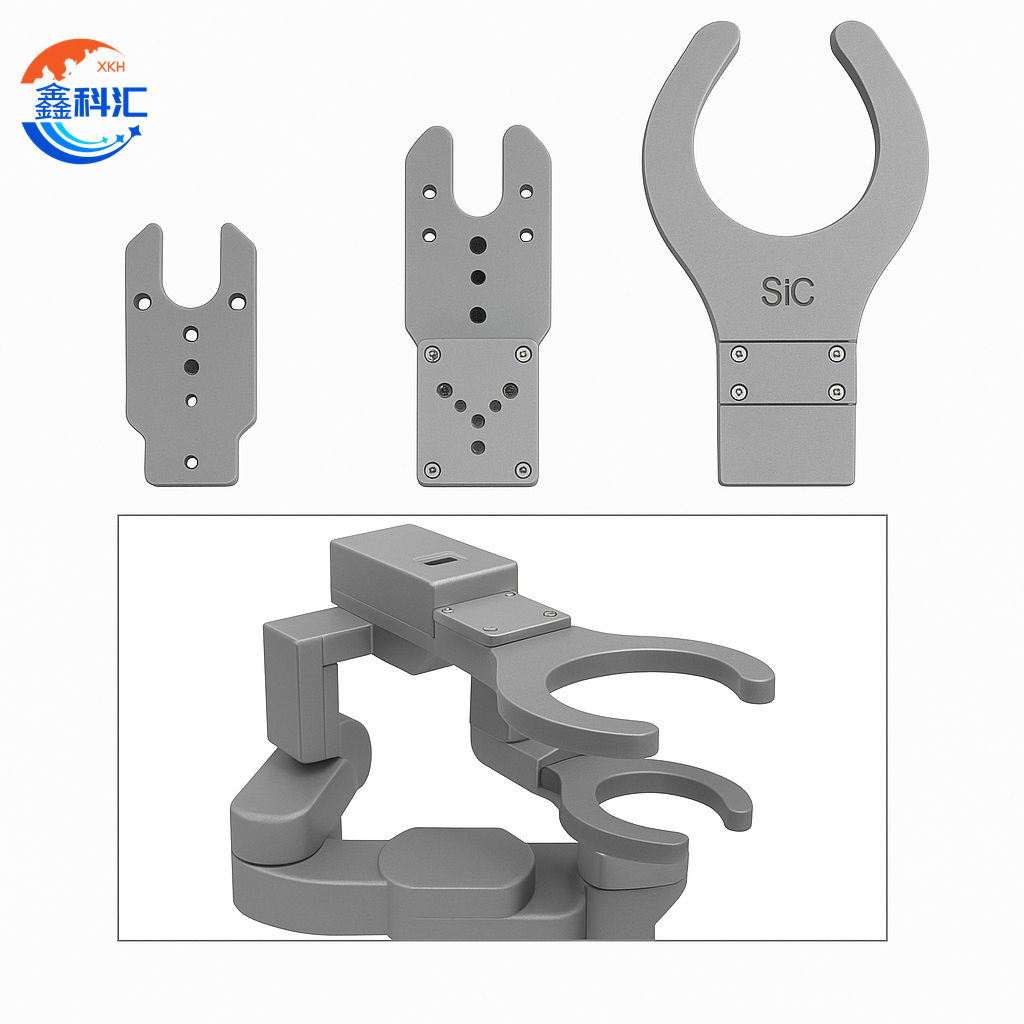

I-SiC ceramic end effector enikezela ingalo yokuphatha iwafer

SiC ceramic end effector Abstract

I-SiC (i-Silicon Carbide) i-ceramic end-effector licandelo elibalulekileyo kwiinkqubo zokuphatha ii-wafer ezichanekileyo ezisetyenziswe kwimveliso ye-semiconductor kunye neendawo eziphambili ze-microfabrication. Yenzelwe ukuhlangabezana neemfuno ezibangwayo zokucoceka okugqithisileyo, ubushushu obuphezulu, kunye neendawo ezizinze kakhulu, esi siphelo sikhethekileyo siqinisekisa uthutho oluthembekileyo nolungenangcoliseko lokuthuthwa kwee-wafers ngexesha lamanyathelo okuvelisa aphambili afana ne-lithography, etching, kunye nokubekwa.

Ukusebenzisa izinto eziphezulu ze-silicon carbide-ezifana nokuhamba okuphezulu kwe-thermal, ukuqina okugqithisileyo, ukungahambi kakuhle kweekhemikhali, kunye nokwandiswa okuncinci kwe-thermal-isiphelo se-ceramic ye-SiC sinikeza ukuqina komatshini kunye nozinzo olungenakulinganiswa naphantsi kwebhayisekile ekhawulezayo yokushisa okanye kumagumbi enkqubo eyonakalisayo. Isizukulwana sayo esisezantsi kunye neempawu zokumelana ne-plasma zenza ukuba ifaneleke ngokukodwa kwi-cleanroom kunye ne-vacuum processing applications, apho ukugcina ingqibelelo yomhlaba we-wafer kunye nokunciphisa ukungcoliseka kwamasuntswana kubaluleke kakhulu.

SiC ceramic end effector Isicelo

1. UkuPhathwa kweWafer yeSemiconductor

Iimpembelelo zokuphela kwe-ceramic ze-SiC zisetyenziswa ngokubanzi kwishishini le-semiconductor yokuphatha ii-silicon wafers ngexesha lemveliso ezenzekelayo. Ezi ziphumo zokugqibela ziqhele ukuxhonywa kwiingalo zerobhothi okanye kwiinkqubo zothumelo lwevacuum kwaye ziyilelwe ukuthwala iiwafers ezinobungakanani obahlukeneyo obufana ne-200mm kunye ne-300mm. Ziyimfuneko kwiinkqubo ezibandakanya i-Chemical Vapor Deposition (CVD), i-Physical Vapor Deposition (PVD), i-etching, kunye ne-diffusion-apho amaqondo okushisa aphezulu, iimeko ze-vacuum, kunye neegesi eziphazamisayo ziqhelekileyo. I-SiC yokumelana ne-thermal ekhethekileyo kunye nokuzinza kweekhemikhali kuyenza ibe yinto efanelekileyo yokumelana neendawo ezingqongileyo ezinzima ngaphandle kokuthotywa.

2. Igumbi lokucoca kunye nokuhambelana kweVacuum

Kwiindawo zokucoca kunye neendawo zokucoca, apho ukungcoliswa kwee-particle kufuneka kuncitshiswe, ii-ceramics ze-SiC zibonelela ngeenzuzo ezibalulekileyo. Indawo exineneyo, egudileyo imelana nokuveliswa kwamasuntswana, inceda ukugcina ingqibelelo ye-wafer ngexesha lothutho. Oku kwenza i-SiC end effectors ifaneleke ngokukodwa kwiinkqubo ezibalulekileyo ezifana ne-Extreme Ultraviolet Lithography (EUV) kunye ne-Atomic Layer Deposition (ALD), apho ucoceko lubalulekile. Ngaphaya koko, ukukhutshwa okuphantsi kwe-SiC kunye nokuchasana okuphezulu kweplasma kuqinisekisa ukusebenza okuthembekileyo kumagumbi okufunxa, ukwandisa ixesha lokuphila kwezixhobo kunye nokunciphisa ukugcinwa rhoqo.

3. IiNkqubo zokuPositioning ezichanekileyo

Ukuchaneka kunye nozinzo zibalulekile kwiinkqubo zokuphatha ii-wafer, ngakumbi kwi-metrology, ukuhlolwa, kunye nezixhobo zokulungelelanisa. I-ceramics ye-SiC ine-coefficient ephantsi kakhulu yokwandiswa kwe-thermal kunye nokuqina okuphezulu, okuvumela ukuba umphumo wokugqibela ugcine ukuchaneka kwesakhiwo naphantsi kwebhayisikili ye-thermal okanye umthwalo womatshini. Oku kuqinisekisa ukuba ama-wafers ahlala ehambelana ngokuchanekileyo ngexesha lokuthutha, ukunciphisa umngcipheko we-micro-scratches, ukungahambi kakuhle, okanye iimpazamo zokulinganisa-izinto ezibaluleke kakhulu kwiinkqubo ze-sub-5nm.

SiC ceramic end effector Properties

1. Amandla aphezulu oomatshini kunye nobunzima

Iiseramics ze-SiC zinamandla akhethekileyo omatshini, anamandla aguqukayo ahlala edlula i-400 MPa kunye nexabiso lobulukhuni beVickers ngaphezulu kwe-2000 HV. Oku kubenza baxhathise kakhulu kuxinzelelo lomatshini, impembelelo, kunye nokunxiba, nasemva kokusetyenziswa kwexesha elide. Ubungqongqo obuphezulu be-SiC bukwanciphisa ukuphambuka ngexesha lokudluliswa kwe-wafer ngesantya esiphezulu, iqinisekisa indawo echanekileyo kunye nokuphindaphindwayo.

2. Ukuzinza kweThermal okugqwesileyo

Enye yezona zinto zixabisekileyo ze-ceramics ze-SiC yikhono labo lokumelana nokushisa okuphezulu kakhulu-ngokuphindaphindiweyo ukuya kwi-1600 ° C kwi-atmospheres inert-ngaphandle kokulahlekelwa ukunyaniseka komatshini. I-coefficient yabo ephantsi yokwandiswa kwe-thermal (~ 4.0 x 10⁻⁶ / K) iqinisekisa ukuzinza kwe-dimensional phantsi kwebhayisikili ye-thermal, okwenza kube lula kwizicelo ezifana ne-CVD, i-PVD, kunye ne-annealing ephezulu yokushisa.

I-SiC ceramic end effector Q&A

Q: Zeziphi izinto ezisetyenziswayo kwi-wafer end effector?

A:I-wafer end effectors iqhele ukwenziwa kwizinto ezibonelela ngamandla aphezulu, uzinzo lwe-thermal, kunye nesizukulwana esiphantsi samasuntswana. Phakathi kwezi, i-Silicon Carbide (SiC) i-ceramic yenye yezona zinto zihamba phambili kwaye zikhethwayo. Iiseramikhi ze-SiC ziqine kakhulu, zizinzile ngokwe-thermal, zingena kwikhemikhali, kwaye ziyaxhathisa ukunxitywa, zizenza zilungele ukuphatha ii-silicone ezithambileyo zafers kwindawo ecocekileyo kunye ne-vacuum. Xa kuthelekiswa ne-quartz okanye i-coated metals, i-SiC inikeza ukuzinza okuphezulu kwe-dimensional phantsi kwamaqondo okushisa aphezulu kwaye ayifuni ukulahla iincinci, ezinceda ukukhusela ukungcola.