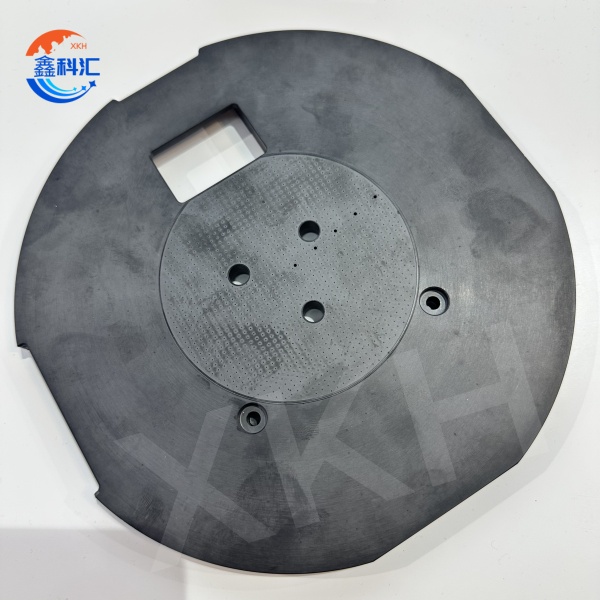

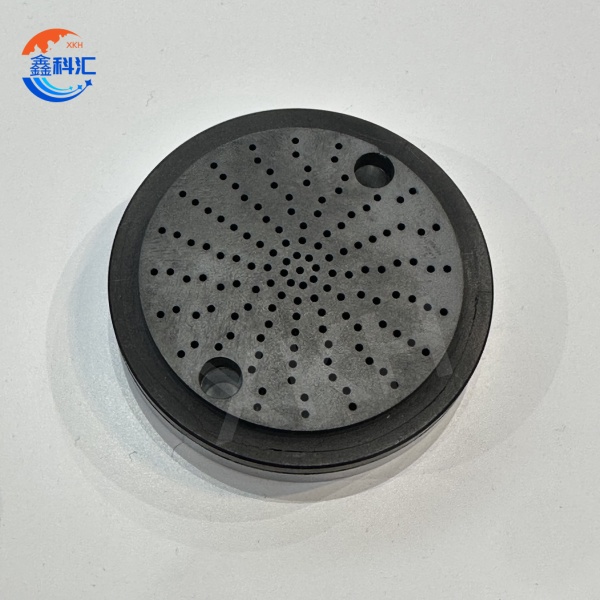

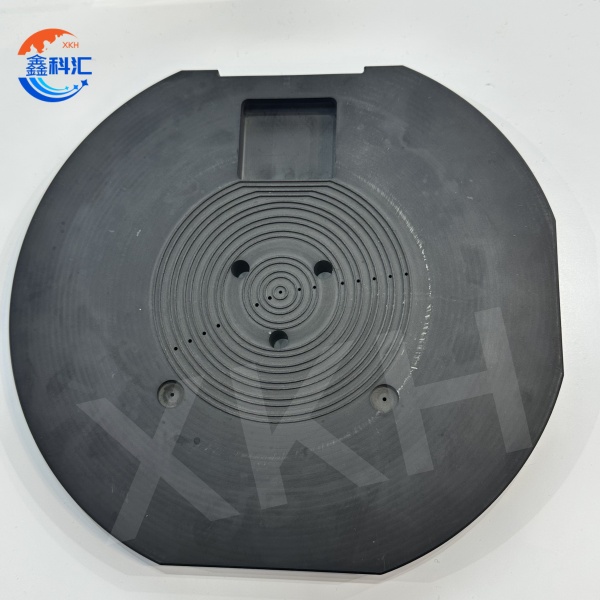

I-SiC ceramic chuck tray Iikomityi zokufunxa zeCeramic ezichanekileyo zokwenziwa ngokwezifiso

Iimpawu zezinto eziphathekayo:

I-1.Ubunzima obuphezulu: ubunzima be-Mohs be-silicon carbide yi-9.2-9.5, okwesibini kuphela kwidayimane, kunye nokuxhatshazwa okunamandla.

2. I-thermal conductivity ephezulu: i-thermal conductivity ye-silicon carbide iphezulu njenge-120-200 W / m · K, ekwazi ukukhupha ukushisa ngokukhawuleza kwaye ifanelekile kwindawo yokushisa ephezulu.

3. I-coefficient yokwandisa i-thermal ephantsi: i-silicon carbide i-coefficient yokwandisa i-thermal iphantsi (4.0-4.5 × 10⁻⁶ / K), isenokugcina ukuzinza kwe-dimensional kwiqondo lokushisa eliphezulu.

4. Ukuzinza kweekhemikhali: i-silicon carbide acid kunye ne-alkali ukumelana nokugqwala, ilungele ukusetyenziswa kwimo engqongileyo yeekhemikhali.

5. Amandla aphezulu omatshini: i-silicon carbide inamandla okugoba aphezulu kunye namandla acinezelayo, kwaye inokumelana noxinzelelo olukhulu lomatshini.

Iimbonakalo:

1.Kwishishini le-semiconductor, ii-wafers ezibhityileyo ngokugqithisileyo kufuneka zibekwe kwikomityi yokufunxa ivacuum, i-vacuum suction isetyenziselwa ukulungisa ii-wafers, kwaye inkqubo yokuwaxisa, ukuncipha, ukuweksa, ukucocwa kunye nokusika kwenziwa kwiiwafers.

I-2.I-Silicon carbide sucker ine-conductivity efanelekileyo ye-thermal, inokunciphisa ngokufanelekileyo ixesha lokuxutywa kunye ne-waxing, ukuphucula ukusebenza kakuhle kwemveliso.

I-3.I-Silicon carbide vacuum sucker nayo ine-asidi elungileyo kunye nokumelana nokubola kwe-alkali.

I-4.Xa kuthelekiswa nepleyiti yendabuko ye-corundum, nciphisa ukulayishwa kunye nokukhulula ukufudumeza kunye nexesha lokupholisa, ukuphucula ukusebenza kakuhle; Ngexesha elifanayo, kunokunciphisa ukunxiba phakathi kwamacwecwe angaphezulu nangaphantsi, kugcinwe ukuchaneka kwendiza elungileyo, kunye nokwandisa ubomi benkonzo malunga nama-40%.

5.Umlinganiselo wezinto eziphathekayo uncinci, ubunzima obulula. Kulula kubaqhubi ukuba baphathe iipallets, ukunciphisa umngcipheko wokungqubuzana komonakalo obangelwa ubunzima bezothutho malunga ne-20%.

6.Ubungakanani: ubukhulu obukhulu be640mm; Ukucaba: 3um okanye ngaphantsi

Indawo yesicelo:

1. Ukwenziwa kweSemiconductor

● Ukwenziwa kweWafer:

Ukulungiswa kwe-wafer kwi-photolithography, i-etching, i-deposition yefilimu encinci kunye nezinye iinkqubo, ukuqinisekisa ukuchaneka okuphezulu kunye nokuhambelana kwenkqubo. Ubushushu bayo obuphezulu kunye nokunganyangeki kwe-corrosion kulungele indawo yokuvelisa i-semiconductor enzima.

● Ukukhula kwe-Epitaxial:

Kwi-SiC okanye i-GaN ukukhula kwe-epitaxial, njengomthwali wokushisa kunye nokulungisa ama-wafers, ukuqinisekisa ukufana kweqondo lokushisa kunye nomgangatho we-crystal kumaqondo aphezulu, ukuphucula ukusebenza kwesixhobo.

2. Izixhobo zombane

● Ukwenziwa kwe-LED:

Isetyenziselwa ukulungisa i-sapphire okanye i-substrate ye-SiC, kwaye njengomthwali wokufudumeza kwinkqubo ye-MOCVD, ukuqinisekisa ukufana kokukhula kwe-epitaxial, ukuphucula ukukhanya kwe-LED kunye nomgangatho.

● Idayidi yeLaser:

Njengomgangatho ophezulu wokuchaneka, ukulungiswa kunye nokufudumeza i-substrate ukuqinisekisa ukuzinza kweqondo lokushisa, ukuphucula amandla okuphuma kunye nokuthembeka kwe-laser diode.

3. Umatshini ochanekileyo

●Ukulungiswa kwelungu lokukhanya:

Isetyenziselwa ukulungisa amacandelo achanekileyo afana neelensi ze-optical kunye nezihlungi zokuqinisekisa ukuchaneka okuphezulu kunye nokungcola okuphantsi ngexesha lokucubungula, kwaye ifanelekile kwi-high-intensity machining.

● Ukwenziwa kweCeramic:

Njengozinzo oluphezulu, lufanelekile ukuchaneka kwe-machining yezinto ze-ceramic ukuqinisekisa ukuchaneka kwe-machining kunye nokuhambelana phantsi kobushushu obuphezulu kunye nokusingqongileyo.

4. Imifuniselo yezenzululwazi

●Uvavanyo lobushushu obuphezulu:

Njengesixhobo sokulungiswa kwesampulu kwiindawo eziphakamileyo zokushisa, ixhasa iimvavanyo ezigqithisileyo zokushisa ngaphezu kwe-1600 ° C ukuqinisekisa ukufana kweqondo lokushisa kunye nokuzinza kwesampuli.

● Uvavanyo lwevacuum:

Njengokulungiswa kwesampulu kunye nokufudumeza umthwali kwindawo ye-vacuum, ukuqinisekisa ukuchaneka kunye nokuphindaphinda kovavanyo, olufanelekileyo kwi-vacuum coating kunye nonyango lobushushu.

Iinkcukacha zobugcisa:

| (Impahla yezinto) | (Iyunithi) | (sic) | |

| (Umxholo weSiC) |

| (Wt)% | >99 |

| (Ubungakanani obuphakathi kweenkozo) |

| micron | 4-10 |

| (Ukuxinana) |

| kg/dm3 | >3.14 |

| (Ibonakala ngathi i-porosity) |

| Vo1% | <0.5 |

| (Vickers ubulukhuni) | HV 0.5 | GPA | 28 |

| *(Amandla e-Flexural) | 20ºC | MPa | 450 |

| (Amandla acinezelayo) | 20ºC | MPa | 3900 |

| (Elastic Modulus) | 20ºC | GPA | 420 |

| (Ukuqina kokwaphuka) |

| MPa/m'% | 3.5 |

| (I-Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Ukuxhathisa) | 20°C | Ohm.cm | 106-108 |

|

| a(RT**...80ºC) | K-1*10-6 | 4.3 |

|

|

| oºC | 1700 |

Ngeminyaka yokuqokelela kobugcisa kunye namava oshishino, i-XKH iyakwazi ukulungisa iiparameters eziphambili ezifana nobukhulu, indlela yokufudumeza kunye noyilo lwe-vacuum adsorption ye-chuck ngokweemfuno ezithile zomthengi, ukuqinisekisa ukuba imveliso ilungelelaniswe ngokugqibeleleyo kwinkqubo yomthengi. I-SiC silicon carbide ceramic chucks ibe zizinto eziyimfuneko ekusetyenzweni kwe-wafer, ukukhula kwe-epitaxial kunye nezinye iinkqubo eziphambili ngenxa ye-thermal conductivity egqwesileyo, uzinzo oluphezulu lobushushu kunye nokuzinza kweekhemikhali. Ngokukodwa ekwenzeni izixhobo ze-semiconductor zesizukulwana sesithathu ezifana ne-SiC kunye ne-GaN, imfuno ye-silicon carbide ceramic chucks iyaqhubeka ikhula. Kwixesha elizayo, ngophuhliso olukhawulezayo lwe-5G, izithuthi zombane, i-intelligence yokufakelwa kunye nobunye ubuchwepheshe, amathuba okusetyenziswa kwe-silicon carbide ceramic chucks kwishishini le-semiconductor liya kuba libanzi.

Idayagram eneenkcukacha