Semiconductor Laser Lift-Off izixhobo

Idayagram eneenkcukacha

Isishwankathelo seMveliso yeLaser Lift-Off Equipment

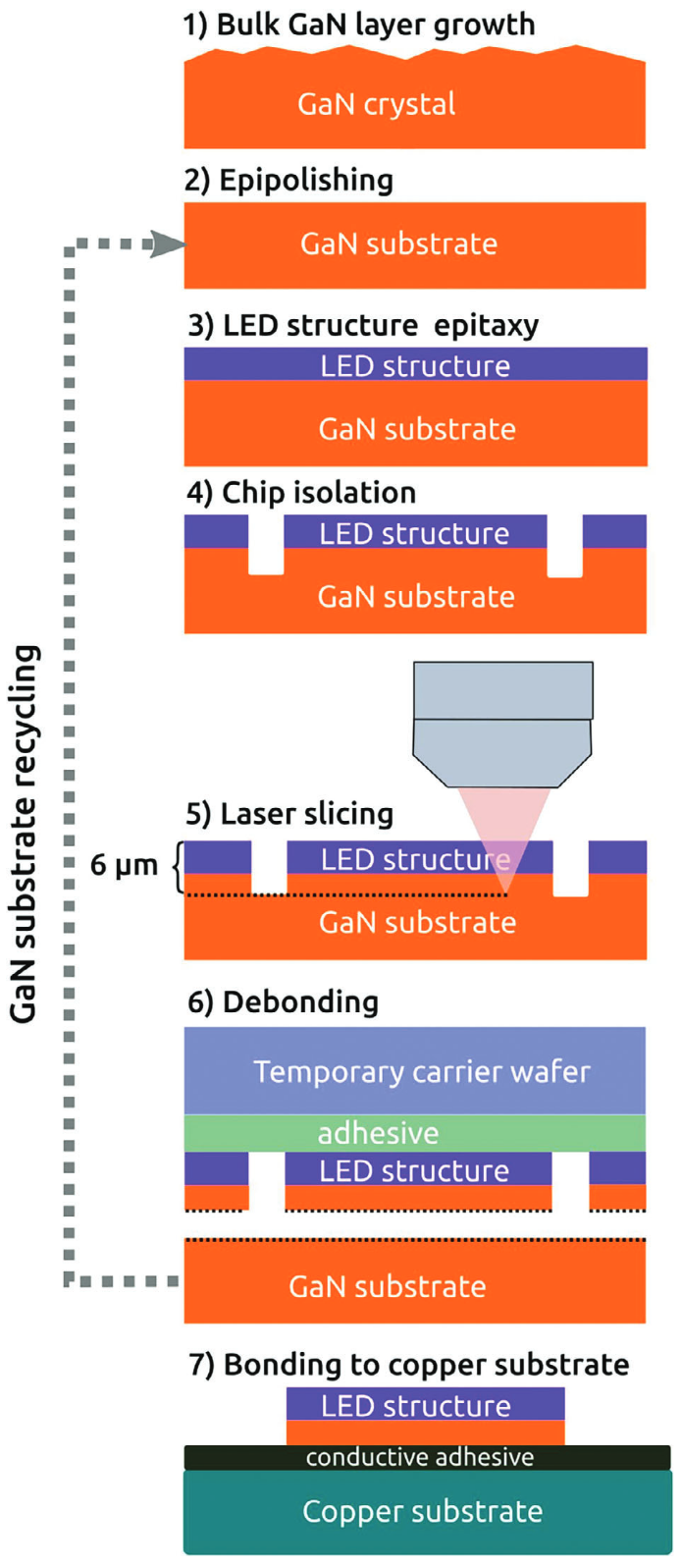

I-Semiconductor Laser Lift-Off Equipment imele isisombululo sesizukulwana esilandelayo se-ingot thinning kwi-semiconductor material processing. Ngokungafaniyo neendlela zakwantu zokuwela ezixhomekeke ekusileni koomatshini, kwisarha yocingo lwedayimani, okanye ukucwangciswa kwekhemikhali, eli qonga lisekelwe kwi-laser libonelela ngonxibelelwano olungafunekiyo, olungonakalisiyo lokususa iileya ezibhityileyo kwi-ingots ezininzi ze-semiconductor.

Ilungiselelwe izinto ezinqabileyo kunye nexabiso eliphezulu ezifana ne-gallium nitride (GaN), i-silicon carbide (SiC), isafire, kunye ne-gallium arsenide (i-GaAs), i-Semiconductor Laser Lift-Off Equipment yenza ukunqunyulwa ngokuchanekileyo kweefilimu ze-wafer-scale ngqo kwi-crystal ingot. Le teknoloji yempumelelo iyayinciphisa ngokubonakalayo inkunkuma yezinto, iphucula i-throughput, kwaye iphucula ingqibelelo ye-substrate - zonke ezo zibaluleke kakhulu kwisizukulwana esilandelayo kwizixhobo ze-electronics zamandla, iinkqubo zeRF, iifotonics, kunye ne-micro-displays.

Ngokugxininiswa kulawulo oluzenzekelayo, ukubunjwa kwe-beam, kunye ne-laser-material interaction analytics, i-Semiconductor Laser Lift-Off Equipment yenzelwe ukudibanisa ngokungenamthungo kwi-workflows ye-semiconductor yokuvelisa ngelixa ixhasa ukuguquguquka kwe-R & D kunye nokunyuka kwemveliso yobuninzi.

Ubuchwephesha kunye noMgaqo wokuSebenza weSixhobo sokuLifta iLaser

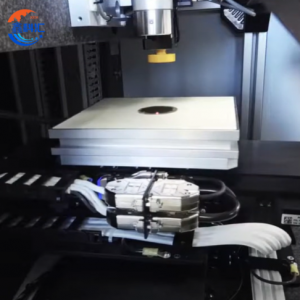

Inkqubo eyenziwa yi-Semiconductor Laser Lift-Off Equipment iqala ngokukhupha i-ingot yomxhasi ukusuka kwelinye icala usebenzisa i-high-energy ultraviolet laser beam. Lo mqadi ugxininise kubunzulu obuthile bangaphakathi, ngokwesiqhelo kunye nojongano lobunjineli, apho ukufunxwa kwamandla kuye kwandiswa ngenxa yokuchasana kokubona, i-thermal, okanye imichiza.

Kulo maleko wokufunxa amandla, ukufudumeza kwendawo kukhokelela kugqabhuko-dubulo olukhawulezileyo lwerhasi, ukwanda kwerhasi, okanye ukubola komgangatho wobuso (umzekelo, ifilimu yoxinzelelo okanye i-oksidi yombingelelo). Oku kuphazamiseka okulawulwa ngokuchanekileyo kubangela ukuba umgangatho ophezulu we-crystalline - kunye nobukhulu beshumi le-micrometers - ukukhupha kwi-ingot yesiseko ngokucocekileyo.

I-Semiconductor Laser Lift-Off Equipment iphakamisa iintloko zokuskena ezinyakazayo, ulawulo lwe-z-axis olucwangcisiweyo, kunye ne-real-time reflectometry ukuqinisekisa ukuba yonke i-pulse ihambisa amandla ngqo kwinqwelo-moya ekujoliswe kuyo. Isixhobo sinokuthi siqwalaselwe ngemowudi yokuqhuma okanye i-pulse-multi-pulse ukunyusa ukugudisa kwe-detachment kunye nokunciphisa uxinzelelo olushiyekileyo. Okubalulekileyo, ngenxa yokuba umqa we-laser awukhe uqhagamshelane nezinto eziphathekayo, umngcipheko wokukrazula, ukugoba, okanye ukutshitshwa komphezulu uyancipha kakhulu.

Oku kwenza indlela yokuthoba i-laser ibe ngumtshintshi-mdlalo, ngakumbi kwizicelo apho iiwafers ezithe tyaba, ezibhityileyo kakhulu zifuneka nge-sub-micron TTV (Ukwahluka koButyenene buphelele).

IParameter yeSemiconductor Laser Lift-Off Equipment

| Ubude bamaza | IR/SHG/THG/FHG |

|---|---|

| Pulse Ububanzi | Nanosecond, Picosecond, Femtosecond |

| Inkqubo yokubona | Inkqubo ye-optical esisigxina okanye inkqubo ye-Galvano-optical |

| Inqanaba leXY | 500 mm × 500 mm |

| Uluhlu lokuqhubekekisa | 160 mm |

| Isantya sokuhamba | Ubuninzi 1,000 mm/sec |

| Ukuphindaphinda | ±1 μm okanye ngaphantsi |

| Ukuchaneka kwesikhundla esipheleleyo: | ±5 μm okanye ngaphantsi |

| Ubungakanani beWafer | 2–6 intshi okanye ngokwezifiso |

| Ulawulo | Windows 10,11 kunye ne-PLC |

| Ubonelelo lwaMandla ombane | I-AC 200 V ±20 V, isigaba esinye, 50/60 kHz |

| Imilinganiselo yangaphandle | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Ubunzima | 1,000 kg |

Usetyenziso lwezoShishino lweZixhobo zokuLifta iLaser

IsiXhobo seSemiconductor Laser Lift-Off sitshintsha ngokukhawuleza indlela izinto ezilungiswa ngayo kuzo zonke iindawo ezininzi zesemiconductor:

- Izixhobo zaMandla zeGaN ezithe nkqo zeLaser Lift-Off Equipment

Ukuphakanyiswa kweefilimu ze-GaN-on-GaN ezibhityileyo kakhulu ukusuka kwiingots ezininzi kuvumela ulwakhiwo oluthe nkqo lwe-architecture kunye nokusetyenziswa kwakhona kwee-substrates ezibizayo.

- I-SiC Wafer Thinning ye-Schottky kunye ne-MOSFET Devices

Yehlisa ubungqingqwa bomaleko wesixhobo ngelixa igcina i-substrate planarity - ilungele ukutshintsha amandla ombane okhawulezayo.

- I-LED esekelwe kwiSapphire kunye neZixhobo zokuBonisa zeLaser Lift-Off Equipment

Inika amandla ukwahlulwa okusebenzayo kweeleya zesixhobo ukusuka kwiibhowule zesafire ukuxhasa imveliso ecekethekileyo, ephuculwe ngokushushu yemicro-LED.

- I-III-V yobuNjineli beMaterial ye-Laser Lift-Off Equipment

Iququzelela i-detachment ye-GaAs, i-InP, kunye ne-AlGaN yeeleyile zokuhlanganiswa kwe-optoelectronic.

- I-Thin-Wafer IC kunye neSensor Fabrication

Ivelisa iileya ezibhityileyo ezisebenzayo zeenzwa zoxinzelelo, i-accelerometers, okanye i-photodiodes, apho isambuku yi-bottleneck yokusebenza.

- Ii-Electronics eziguquguqukayo nezingafihli nto

Ilungisa i-ultra-thin substrates ilungele imiboniso ebhetyebhetye, iisekethe ezinxitywayo, kunye neefestile ezicacileyo.

Kwindawo nganye kwezi, iSemiconductor Laser Lift-Off Equipment idlala indima ebalulekileyo ekwenzeni i-miniaturization, ukusetyenziswa kwakhona kwezinto, kunye nokwenza lula inkqubo.

Imibuzo Ebuzwa Rhoqo (FAQ) yeLaser Lift-Off Equipment

I-Q1: Bubuphi ubungqingqwa obuncinane endinokubufumana ndisebenzisa iSemiconductor Laser Lift-Off Equipment?

A1:Ngokuqhelekileyo phakathi kwe-10-30 microns kuxhomekeke kwizinto eziphathekayo. Inkqubo iyakwazi ukwenza iziphumo ezinqabileyo kunye nokusetha okulungisiweyo.

I-Q2: Ngaba oku kungasetyenziselwa ukucanda ii-wafers ezininzi kwi-ingot enye?

A2:Ewe. Abathengi abaninzi basebenzisa ubuchule bokuphakamisa i-laser ukwenza utsalo olulandelelanayo lweeleya ezininzi ezibhityileyo ukusuka kwingot enye.

I-Q3: Ziziphi iimpawu zokhuseleko ezibandakanyiweyo ekusebenzeni kwe-laser yamandla aphezulu?

A3:Iindawo ezivaliweyo zodidi loku-1, iinkqubo zokudityaniswa, ukukhuselwa kwemiqadi, kunye nezitshixo ezizisebenzelayo ziyimigangatho yonke.

I-Q4: Le nkqubo ithelekisa njani neesarha zocingo lwedayimani ngokwexabiso?

A4:Nangona i-capex yokuqala ingaba phezulu, ukunyuswa kwe-laser kunciphisa kakhulu iindleko ezisetyenziswayo, umonakalo we-substrate, kunye namanyathelo okuthunyelwa emva kokucubungula - ukunciphisa iindleko ezipheleleyo zobunini (TCO) ixesha elide.

Q5: Ingaba inkqubo scalable ukuya 6-intshi okanye 8-intshi ingots?

A5:Ngokuqinisekileyo. Iqonga lixhasa ukuya kuthi ga kwi-12-intshi ye-substrates kunye nokusabalalisa i-beam efanayo kunye nezigaba zokunyakaza kwefomathi enkulu.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.