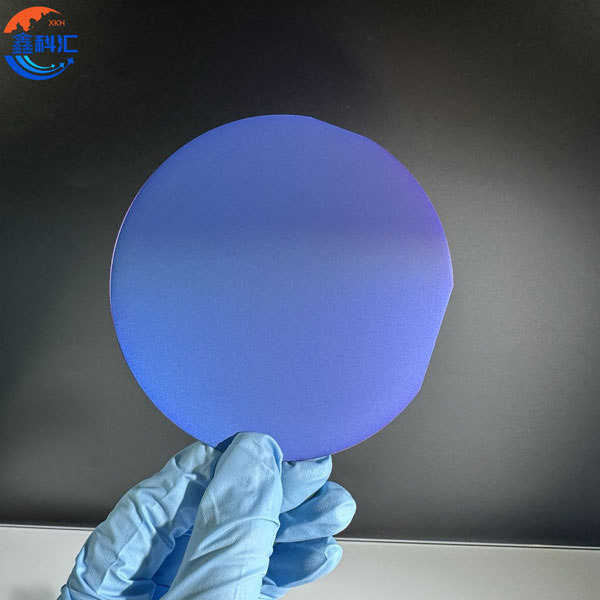

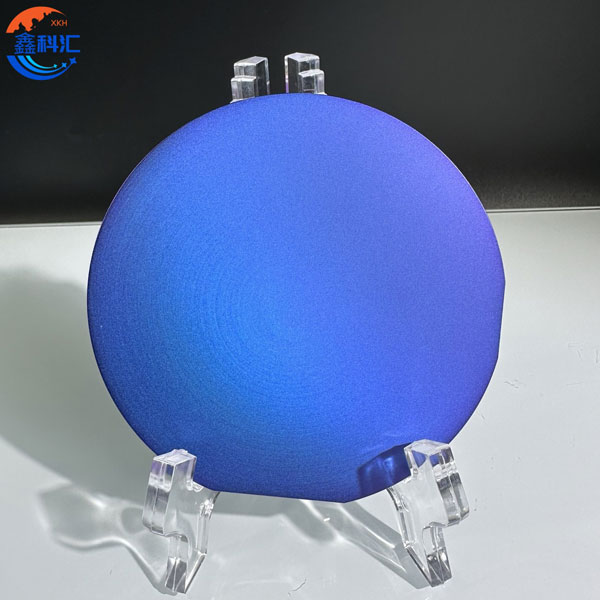

ISemi-Insulating SiC kwiSi Composite Substrates

| Izinto | Inkcazo | Izinto | Inkcazo |

| Ububanzi | 150±0.2mm | Ukuqhelaniswa | <111>/<100>/<110> njalo njalo |

| Polytype | 4H | Uhlobo | P/N |

| Ukuxhathisa | ≥1E8ohm·cm | Ukucaba | Isicaba/Inotshi |

| Ukugqithisela umaleko Ukutyeba | ≥0.1μm | I-Edge Chip, i-Scratch, i-Crack (ukuhlolwa okubonakalayo) | Akukho nanye |

| Ilize | ≤5ea/wafer (2mm>D>0.5mm) | TTV | ≤5μm |

| Uburhabaxa bangaphambili | Ra≤0.2nm (5μm*5μm) | Ukutyeba | 500/625/675±25μm |

Le ndibaniselwano ibonelela ngenani leenzuzo kwimveliso yombane:

Ukuhambelana: Ukusetyenziswa kwe-silicon substrate kwenza ukuba ihambelane neendlela eziqhelekileyo zokusetyenzwa kwe-silicon kwaye ivumela ukudibanisa kunye neenkqubo ezikhoyo zokuvelisa i-semiconductor.

Ukusebenza kobushushu obuphezulu: I-SiC ine-conductivity egqwesileyo ye-thermal kwaye inokusebenza kumaqondo obushushu aphezulu, iyenze ilungele amandla aphezulu kunye nosetyenziso lwe-elektroniki oluhamba rhoqo.

I-Voltage ye-High Breakdown Voltage: Izixhobo ze-SiC zine-voltage ephezulu yokuphuka kwaye inokumelana namasimi aphezulu ombane ngaphandle kokuphuka kombane.

UkuNcitshiswa koLahleko lwaMandla: Ii-substrates ze-SiC zivumela ukuguqulwa kwamandla okusebenzayo kunye nokulahlekelwa kwamandla aphantsi kwizixhobo zombane xa kuthelekiswa nezinto eziqhelekileyo ezisekelwe kwi-silicon.

I-wide bandwidth: I-SiC ine-bandwidth ebanzi, evumela ukuphuhliswa kwezixhobo zombane ezinokusebenza kumaqondo aphezulu kunye nokuxinana kwamandla aphezulu.

Ke i-semi-insulating SiC kwi-Si composite substrates idibanisa ukuhambelana kwe-silicon kunye neempawu eziphezulu zombane kunye ne-thermal ye-SiC, iyenza ilungele ukusetyenziswa kwe-electronics ephezulu yokusebenza.

Ukupakisha kunye nokuhanjiswa

1. Siza kusebenzisa iplastiki ekhuselayo kunye nebhokisi elungiselelwe ukupakisha. (Izinto ezihambelana nokusingqongileyo)

2. Sinokwenza ukupakisha okulungiselelwe ngokobuninzi.

3. I-DHL/Fedex/UPS Express idla ngokuthatha malunga neentsuku ezi-3-7 zokusebenza ukuya kwindawo ekuyiwa kuyo.

Idayagram eneenkcukacha