ISapphire thermocouple ukhuseleko ityhubhu yeemveliso ezisetyenziswa kwi-crystal Single Al2O3

Ukwazisa ngebhokisi ye-wafer

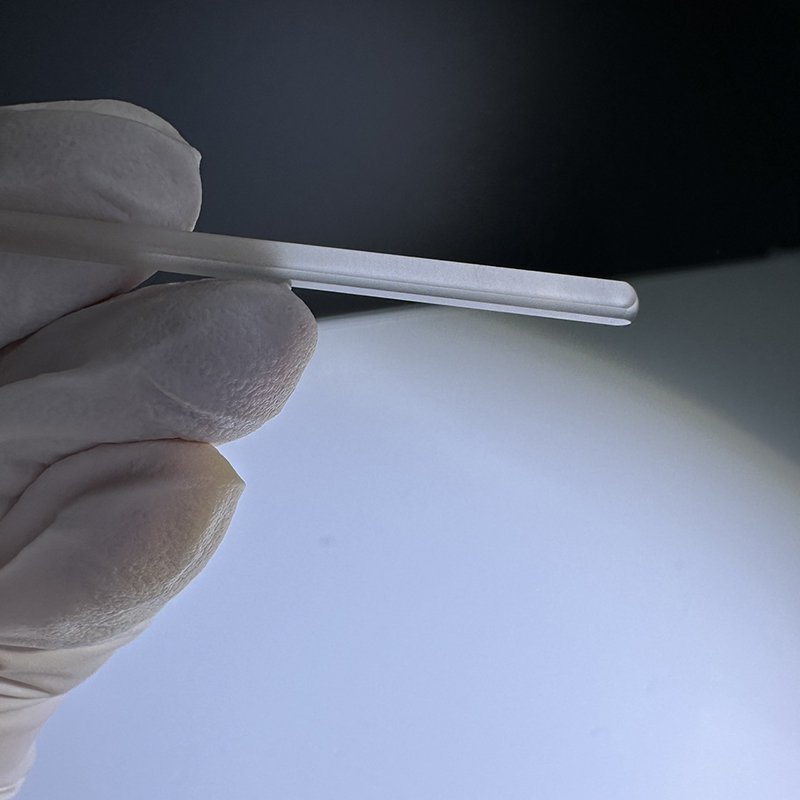

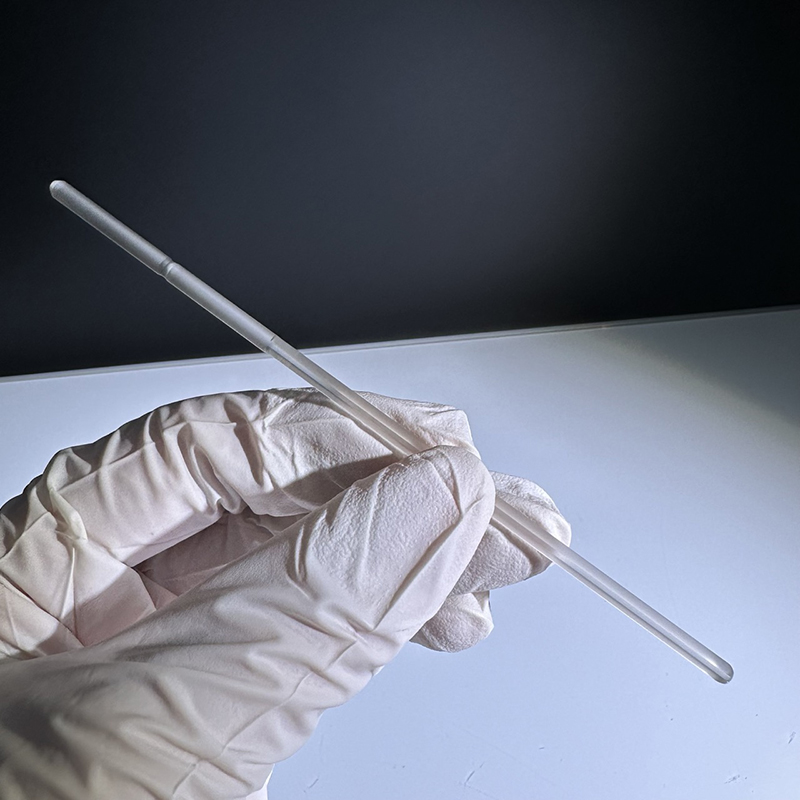

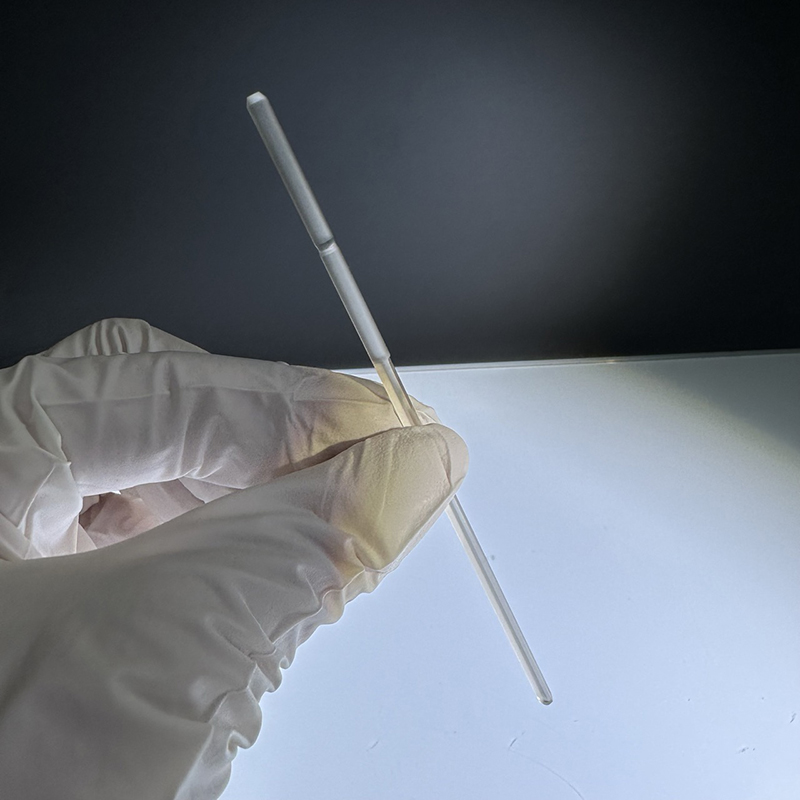

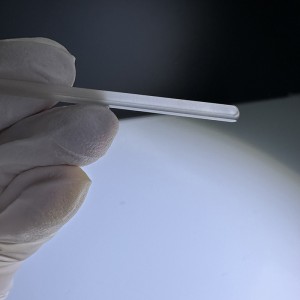

I-Sapphire thermocouple yokukhusela ityhubhu yityhubhu yokukhusela isafire ye-thermocouple kunye nomkhono wokukhusela we-thermocouple, okhuliswe ngokuthe ngqo kwi-sapphire enye yekristale ngexesha elinye, ilungele ukutshintshwa ityhubhu ye-corundum yokukhusela i-thermocouple njenge-sleeve yokukhusela i-thermocouple, ilungele ukukhuselwa kwe-thermocouple kwiqondo lokushisa eliphezulu kunye ne-sleeve yokukhusela i-sleeve, indawo yokukhusela i-corrosion kunye noxinzelelo oluphezulu lwe-corrosion.

Iimpawu zetyhubhu ekhuselayo yesafire

1. Ukushisa okugqwesileyo kunye nokuxhatshazwa koxinzelelo: Iibhubhu zethu ze-KY kunye ne-EFG ze-sapphire ziyakwazi ukumelana nokushisa okuphezulu ukuya kwi-2000 degrees Celsius, nazo zimelana noxinzelelo oluphezulu kunye nokubola kweekhemikhali, kwaye zibe nokumelana nokugqwesa kweekhemikhali kuneetyhubhu zokukhusela i-corundum.

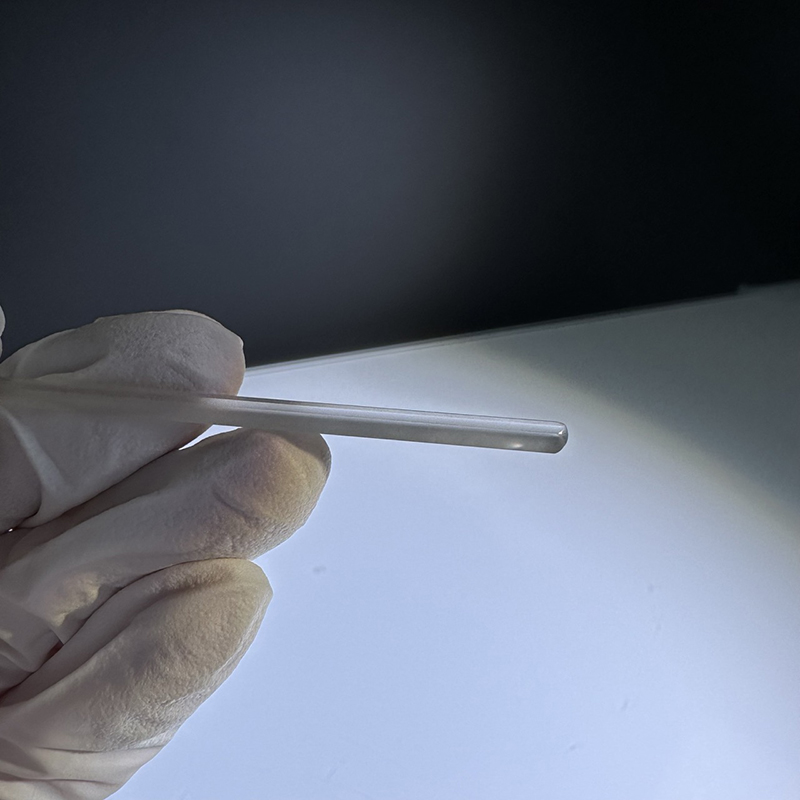

2. I-Ultra-high purity: I-EFG yethu ye-sapphire ityhubhu ithatha iteknoloji yokubumba i-crystal eyodwa yokukhula, ukucoceka ukuya kwi-99.998%, ukucoceka kwe-ultra-high iqinisekisa inzuzo yokusebenza kwesafire.

3. Ubulukhuni obuphezulu kunye nokuqina: Ubunzima betyhubhu yesafire buphezulu njenge-Mohs9, enokumelana okuqinileyo nokufa.

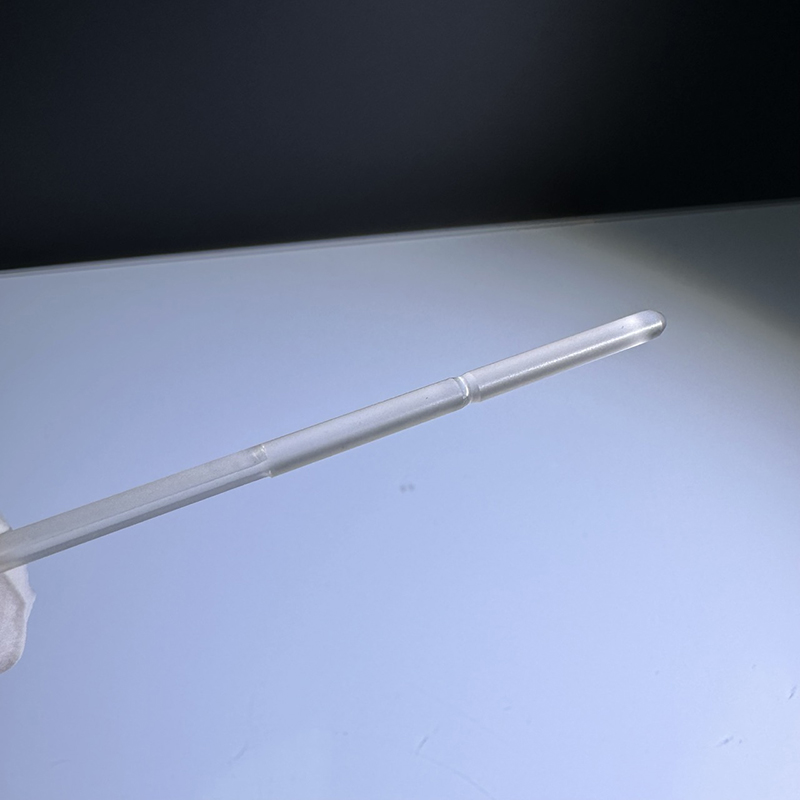

4. Ukuqina komoya okuqinileyo: I-tube yethu yesafire ithatha iteknoloji ye-EFG ukuba yenze kanye, kunye ne-100% yoxinzelelo lomoya, ukuthintela ukungena kwegesi eseleyo kunye nokumelana nokubola kwekhemikhali, ukugqithisa kakhulu ukusebenza kwe-corundum yokukhusela i-thermocouple tube.

Ngenxa yezi mpawu zibalaseleyo zomkhono okhuselayo we-thermocouple, sisixhobo esigqwesileyo sokusetyenziswa kwindawo ezingqongileyo ezinje ngamaqondo obushushu aphezulu (2000 degrees Celsius). I-Thermocouple protective bushing ineenzuzo ezikhethekileyo zesicelo kwishishini lemichiza, ukucocwa kweoyile, ishishini leglasi kunye nebhubhoratri.

I-tube yokukhusela i-sapphire thermocouple ingasetyenziselwa kwiindawo apho ityhubhu ye-emery ceramic ingahlangabezani neemfuno zokuzinza. Ingasetyenziselwa i-oyile enzima yokutshisa i-reactors, imveliso ye-hydrogen, iibhokisi zeglasi, ii-furnaces eziqhumayo, i-inorganic acids (i-mineral acids), kunye nomlinganiselo wobushushu kwiinkqubo ze-metallurgical.

Idayagram eneenkcukacha