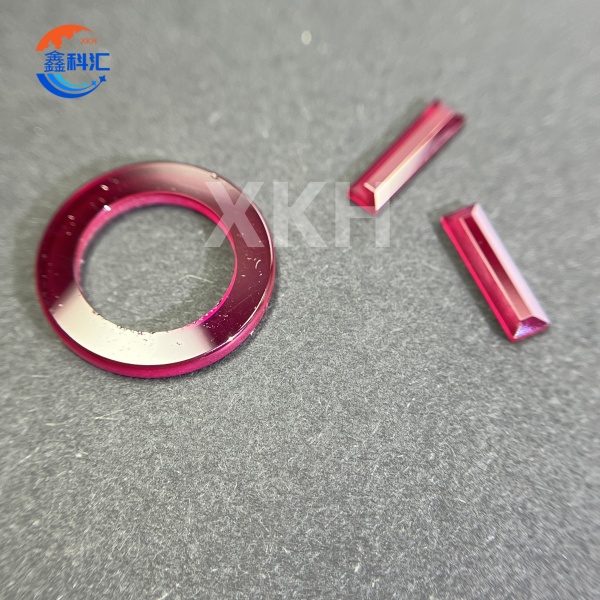

I-Ruby Optical Components Ukuchaneka kwee-Windows Ukuthwala ii-Assemblies zokuchasana nobushushu obuphezulu

ISapphire (α-Al₂O₃) iye yavela njengento ebalulekileyo esebenzayo kushishino lwanamhlanje, ebonisa ixabiso elingenakuphinda libuyiselwe kuzo zonke iinkqubo ezininzi zobugcisa obuphezulu ngenxa yeempawu zayo ezizodwa zephysicochemical. Njengomboneleli okhokelayo wezisombululo zezinto zesafire, i-XKH inegunya elipheleleyo leshishini-ukusuka ekukhuleni kwekristale ukuya kwi-machining echanekileyo-isenza sikwazi ukuhambisa izinto ezenziwe ngokwezifiso zesafire kubandakanya iifestile zamehlo, iibheringi zoomatshini, kunye nezinto zelaser. Ukusebenzisa itekhnoloji ephezulu yokuvelisa kunye neenkqubo ezingqongqo zolawulo lomgangatho, sizibophelele ekuboneleleni abathengi beshishini ngokusebenza okuphezulu, izisombululo ezithembekileyo zemveliso yesafire.

Iinkcukacha zobuchwephesha:

| Uluhlu lweParameter | Inkcazo |

| Iipropati ezisisiseko | |

| Ulwakhiwo lweCrystal | Hexagonal (α-Al₂O₃) |

| Mohs Ubunzima | 9 |

| Ukuxinana | 3.98 g/cm³ |

| Indawo yokunyibilika | 2050°C |

| IiPropathi zokubona | |

| Uluhlu loThutho | 0.15-5.5 μm |

| Refractive Index | 1.76 @ 589nm |

| I-Birefringence | 0.008 |

| Iipropati zoomatshini | |

| Amandla e-Flexural | 400-700 MPa |

| Imodyuli ye-elastic | 345 GPA |

| I-Thermal Expansion Coeff. | 7.5×10⁻⁶/K (25-1000°C) |

| Unyango loMphezulu | |

| Ukugqiba okusemgangathweni | Ra ≤ 0,05 μm |

| Ukuchaneka okuphezulu Gqiba | Ra ≤ 0,01 μm |

| Iinketho zoKwaleka | I-AR / HR / i-Metallic coatings |

Ezona mpawu:

- Ukuguquguquka okuKhethekileyo kokusiNgqongileyo

Amalungu eSapphire abonisa ukusebenza okugqwesileyo kwiindawo ezigqithisileyo, egcina ukusebenza okuzinzile kuluhlu olubanzi lobushushu obuphakathi kwe -200°C ukuya +1000°C. Isakhiwo sabo esiyingqayizivele sekristale sinikezela ukuxhathisa ukothuka kwe-thermal, ukuthintela ukuqhekeka okanye ukuguqulwa kwangaphantsi kokutshintsha kweqondo lokushisa ngokukhawuleza. Kwiimeko ze-vacuum, amacandelo e-sapphire asebenza ngokuthembekileyo kumazinga e-ultra-high vacuum (10⁻⁶ Pa) ngaphandle kokungcola okuphumayo. Ukongeza, isafire ibonisa ukuxhathisa okugqwesileyo kwimitha, igcina imfezeko yesakhiwo kunye nokusebenza kwiidosi zemitha ukuya kuthi ga kwi-10⁶ Gy.

- Ukuqina okungenakuthelekiswa nanto

Ngobulukhuni be-Mohs be-9 (yesibini kuphela kwidayimane), amacandelo esafire anika ukuxhathisa okukhethekileyo kokunxiba. Uvavanyo oluthelekisayo lubonisa amacandelo esafire abonisa amaxabiso okunxiba nje nge-1/10 yezinto zentsimbi zemveli. Ngokomchiza, isafire iyaxhathisa phantse kuzo zonke iiasidi ezomeleleyo (ngaphandle kwe-HF), iialkali, kunye nezinyibilikisi eziphilayo. Ezi zakhiwo zenza amacandelo e-sapphire afezekise ubomi benkonzo ngamaxesha angama-5-8 ubude kunezinto eziqhelekileyo, ukunciphisa kakhulu iindleko zokugcinwa kunye nokunciphisa ixesha.

- Ukusebenza ngoKuchaneka okuPhezulu

Sapphire components provide unique advantages in precision manufacturing. Their ultra-low thermal expansion coefficient (7.5×10⁻⁶/K) ensures dimensional stability, typically achieving ±0.1μm/100mm variation. Through precision machining, we achieve surface flatness of λ/10@632.8nm and angular tolerances of ±15 arc-seconds, meeting the most stringent optical system requirements. These characteristics make sapphire ideal for high-precision measurement and optical applications.

Izinto Eziluncedo Ezingundoqo:

- Ulungelelwaniso lokuSebenza ukuya kwiiNdleko

Amacandelo ethu esafire agcina ngaphezulu kwe-85% yeemetriki zokusebenza eziphambili ngelixa sinikezela ngaphezulu kwe-30% yogcino lweendleko xa kuthelekiswa neemveliso zesafire zemveli. Ngokusebenzisa ukukhula kwekristale kunye neenkqubo zomatshini, sifezekisa ibhalansi efanelekileyo phakathi kokusebenza kunye neendleko. Ulawulo olungqongqo lobulunga luqinisekisa ukuhambelana kwebhetshi-kwibhetshi kunye ≤3% nokutenxa kwipharamitha.

- Izakhono zeNkonzo eziBanzi

Sigcina inkqubo yokuphendula ngokukhawuleza, ukuhambisa izisombululo zobuchwepheshe kwiiyure ze-48. Imodeli yethu yokuvelisa i-flexible ithatha ii-odolo ukusuka kwi-1 ukuya kwiiyunithi ze-10,000. Iprothokholi yokuhlola enamanyathelo angama-36 ibandakanya ukuchaneka komda, umgangatho womphezulu, kunye neempawu zoomatshini ukuqinisekisa imigangatho yobulunga beprimiyamu.

Izicelo eziphambili:

Izicelo zoShishino oluPhezulu

Uveliso lweSemiconductor: Isikhokelo somzila weerobhothi zokuphatha iwafer

I-Precision Metrology: Iiprobe zee-CMM (Lungelelanisa oomatshini bokulinganisa)

IFiber Optics: Ukuzoba imilomo ngokuzinza okuphezulu kwe-thermal

2. IiNkqubo eziPhezulu ze-Optical

Itekhnoloji yeLaser: I-High-LIDT (i-Laser-Induced Damage Threshold) windows kunye ne-Q-switches

Izicelo zoKhuseleko: Iinfrared missile domes

I-Spectroscopy: Iiprism kunye neefestile zezixhobo zokuhlalutya

3. Izicelo zokusiNgqongileyo ezigqithisileyo

I-Aerospace: Iibheringi zokulawula isimo sengqondo kwiziphekepheke

Ukuphononongwa koLwandle oluNzulu: Iindawo zokujonga ezinganyangekiyo kuxinzelelo

Ishishini leNyukliya: Iifestile zokujonga ezikhuselwe kumitha

XKH'sIinkonzo:

I-XKH ibonelela ngezisombululo zecandelo lesafire ekupheleni ukuya ekupheleni:

· Ipotfoliyo yeMveliso: 200+ iimodeli eziqhelekileyo kwisitokhwe; ubukhulu ngokwesiko ukusuka 0.5-300mm

· Iinkonzo zobuGcisa: Ubunjineli besicelo, ukulinganisa kwe-FEA, uhlalutyo lokusilela

· Unyango lwe-Surface: Iingubo ze-DLC, i-AR (i-Anti-Reflective) i-coatings

· Uqinisekiso loMgangatho: Iingxelo zokuhlola eziqinisekisiweyo zeqela lesithathu

· Ulungiselelo: Izindululo zobugcisa zeeyure ezingama-48; Iiveki ezi-2-4 zokuhanjiswa kwesampula

Ukuqukumbela

Amacandelo e-Sapphire anikezela ixabiso elikhethekileyo kwizicelo eziphezulu zemizi-mveliso ngokusebenzisa iipropathi zazo ze-physicochemical ezingahambelaniyo. Le ngxelo inike iinkcukacha ngeempawu zabo ezibalulekileyo, izibonelelo, kunye nokusetyenziswa kwemisebenzi emininzi. Ngokudibanisa iinkqubo zenkonzo ezomeleleyo kunye nolawulo olungqongqo lwekhwalithi, i-XKH ibonelela ngezisombululo ezithembekileyo, ezingabizi kakhulu zesafire. Ukuqhubela phambili, siya kuqhubeka siqhubela phambili ukusebenza kwemathiriyeli kunye nokusetyenzwa kwetekhnoloji ukwandisa usetyenziso lwesafire kwiisemiconductors, optics, aerospace, nangaphaya. Siyakwamkela ukusebenzisana kunye namahlakani kushishino ngokudibeneyo ukuqhuba ukusungula izinto ezintsha kwitekhnoloji yesafire.