I-Microjet Water-Guided Laser Cutting System kwi-Advanced Materials

Izinto eziluncedo eziphezulu

1. UkuGxininisa kuMandla angenakuthelekiswa nanto ngesiKhokelo saManzi

Ngokusebenzisa ijethi yamanzi egxininiswe kakuhle njenge-laser waveguide, inkqubo iphelisa ukuphazamiseka komoya kwaye iqinisekisa ukugxila kwe-laser epheleleyo. Isiphumo si-ultra-namxinwa ububanzi bokusika-ebuncinci njenge-20μm-kunye neengqungquthela ezibukhali, ezicocekileyo.

2. Ubuncinci boNyawo lweThermal

Inkqubo yolawulo lwexesha lokwenyani lwe-thermal iqinisekisa ukuba indawo echaphazeleke bubushushu ayinakudlula i-5μm, ibalulekile ekugcineni ukusebenza kwezinto kunye nokuphepha i-microcracks.

3. Ukuhambelana kwezinto eziBanzi

Imveliso yobude obuphindwe kabini (532nm/1064nm) ibonelela ngokulungiswa kokufunxa okuphuculweyo, okwenza umatshini ulungelelaniswe neentlobo ezahlukeneyo zamaza, ukusuka kwiikristale ezibonakalayo ukuya kwi-opaque ceramics.

4. Isantya esiphezulu, i-High-Precision-Precision Motion Control

Ngeenketho zeenjini ze-linear kunye ne-direct-drive motors, inkqubo isekela iimfuno eziphezulu ngaphandle kokuphazamisa ukuchaneka. Intshukumo ye-axis emihlanu iqhubela phambili ukwenza ipateni entsonkothileyo kunye nokusikwa kwamacala amaninzi.

5. Uyilo lweModyuli kunye neScalable

Abasebenzisi banokulungelelanisa ulungelelwaniso lwenkqubo olusekwe kwiimfuno zesicelo-ukusuka kwiprototyping esekwe kwilebhu ukuya kwimveliso-eyenziwe ifaneleke kuyo yonke iR&D kunye nemimandla yoshishino.

IiNdawo zokuSebenza

IiSemiconductors zesiZukulwana sesithathu:

Ifanelekile kwi-SiC kunye ne-GaN wafers, inkqubo yenza ukudayiva, ukuthunga, kunye nokusika ngokunyaniseka okukhethekileyo.

Idayimani kunye ne-Oxide Semiconductor Machining:

Isetyenziselwa ukusika kunye nokugrumba izinto ezinobunzima obuphezulu njengedayimani enye yekristale kunye ne-Ga₂O₃, ngaphandle kwe-carbonization okanye i-thermal deformation.

Amacandelo e-Aerospace aPhakamileyo:

Ixhasa ukubunjwa kolwakhiwo lwee-composites ze-ceramic ezinobunzima obuphezulu kunye ne-superalloys ye-jet injini kunye nezixhobo zesathelayithi.

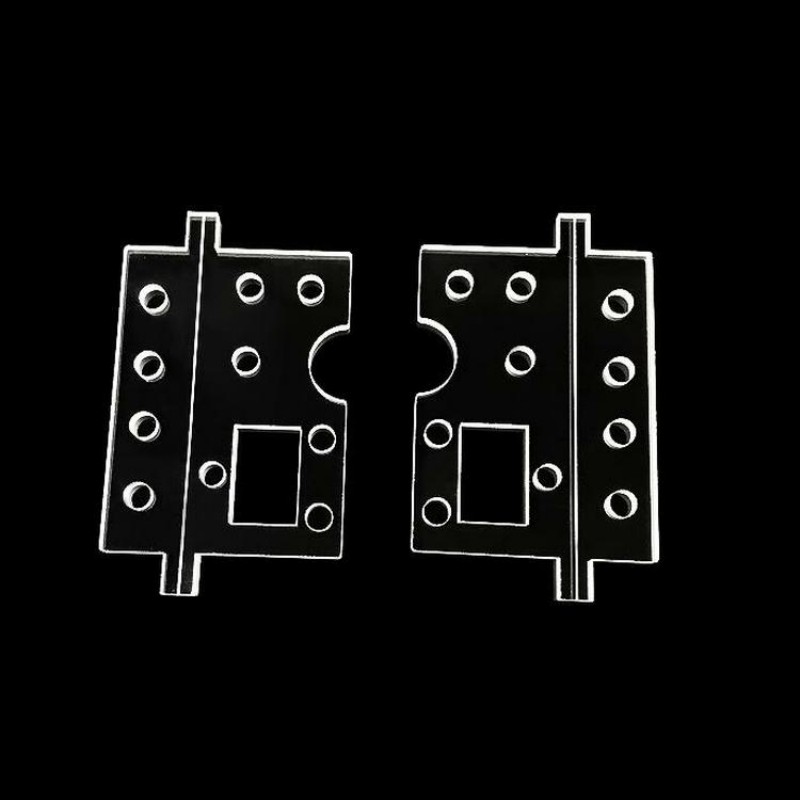

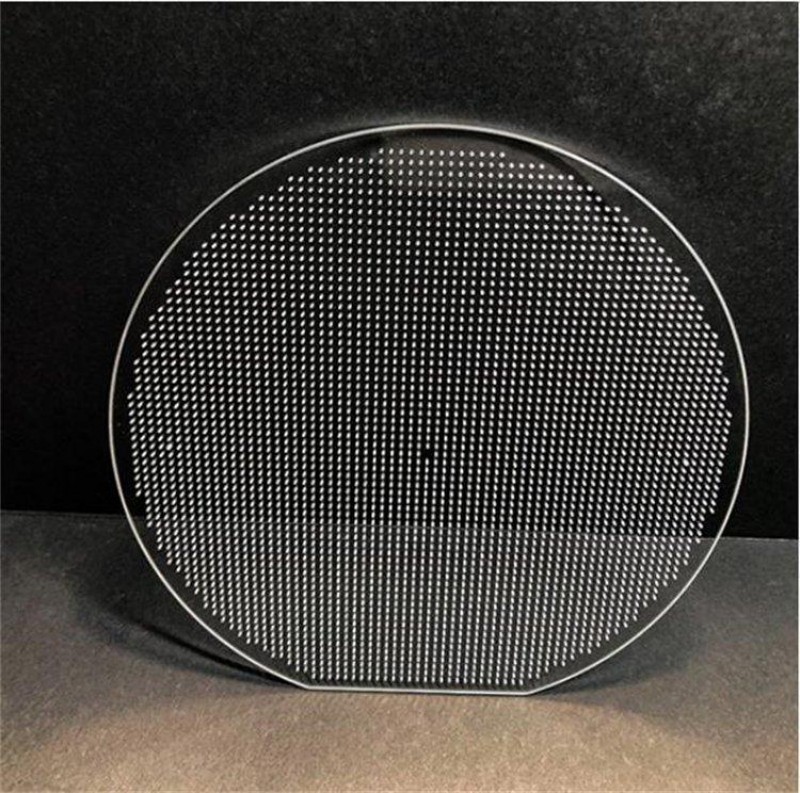

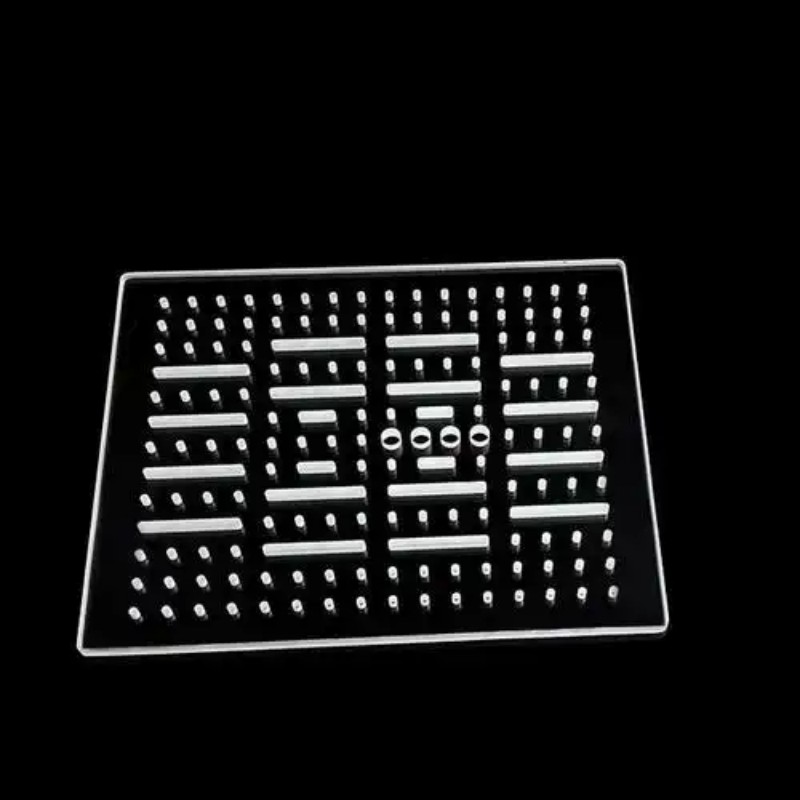

I-Photovoltaic kunye ne-Ceramic Substrates:

Yenza i-burr-free ukusika ii-wafers ezibhityileyo kunye ne-LTCC substrates, kubandakanywa nemingxunya ephumayo kunye ne-slot milling yokudibanisa.

I-scintillators kunye ne-Optical Components:

Igcina ukugudiswa komphezulu kunye nokuhanjiswa kwezinto ezibonakalayo ezibuthathaka njenge-Ce: YAG, LSO, kunye nezinye.

Inkcazo

| Uphawu | Inkcazo |

| Umthombo weLaser | DPSS Nd:YAG |

| Iinketho zeWavelength | 532nm / 1064nm |

| Amanqanaba ombane | 50/100/200 Watts |

| Ukuchaneka | ±5μm |

| Sika Ububanzi | Umxinwa njenge 20μm |

| Indawo eChaphazeleke bubushushu | ≤5μm |

| Uhlobo lweSindululo | Linear / Direct Drive |

| Izixhobo ezixhaswayo | SiC, GaN, Diamond, Ga₂O₃, njl. |

Kutheni Ukhetha Le Sistim?

● Ukuphelisa imiba eqhelekileyo yelaser efana nokuqhekeka kwe-thermal kunye nokuqhekeka komphetho

● Ukuphucula isivuno kunye nokuhambelana kwezinto ezixabisa kakhulu

● Ukulungelelaniswa nokusetyenziswa kolingelo nakwimizi-mveliso

● Iqonga lobungqina bexesha elizayo lenzululwazi yemathiriyeli

Q&A

I-Q1: Ziziphi izinto ezinokuthi le nkqubo yenkqubo?

A: Inkqubo yenzelwe ngokukodwa izinto ezinzima kunye ne-brittle eziphezulu zexabiso. Iyakwazi ukucubungula ngokufanelekileyo i-silicon carbide (SiC), i-gallium nitride (i-GaN), idayimane, i-gallium oxide (i-Ga₂O₃), i-LTCC substrates, i-aerospace composite, i-photovoltaic wafers, kunye neekristale ze-scintillator ezifana ne-Ce: YAG okanye i-LSO.

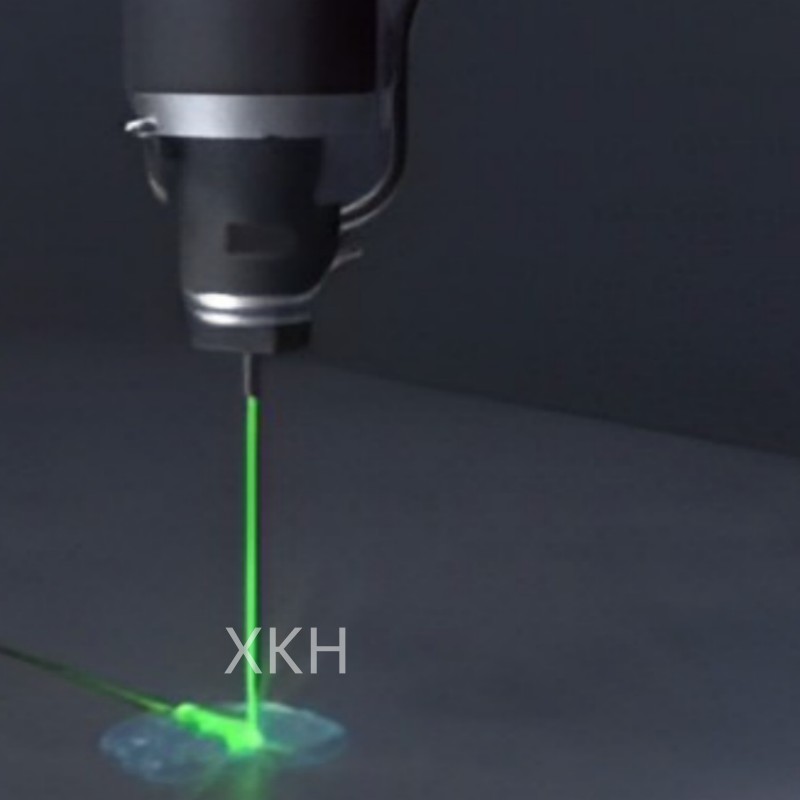

I-Q2: Isebenza njani iteknoloji yelaser ekhokelwa ngamanzi?

A: Isebenzisa i-microjet yoxinzelelo oluphezulu lwamanzi ukukhokela umqadi we-laser ngokubonakaliswa kwangaphakathi okupheleleyo, ukuhambisa ngokufanelekileyo amandla e-laser ngokusasazwa okuncinci. Oku kuqinisekisa ukugxilwa kwe-ultra-fine, umthwalo ophantsi we-thermal, kunye nokunciphisa okuchanekileyo kunye nobubanzi bomgca ukuya kwi-20μm.

I-Q3: Luluphi ulungelelwaniso lwamandla e-laser olukhoyo?

A: Abathengi banokukhetha kwi-50W, i-100W, kunye ne-200W iinketho zamandla e-laser ngokuxhomekeke kwisantya sokusebenza kunye neemfuno zesisombululo. Zonke iinketho zigcina uzinzo oluphezulu lwe-beam kunye nokuphindaphinda.

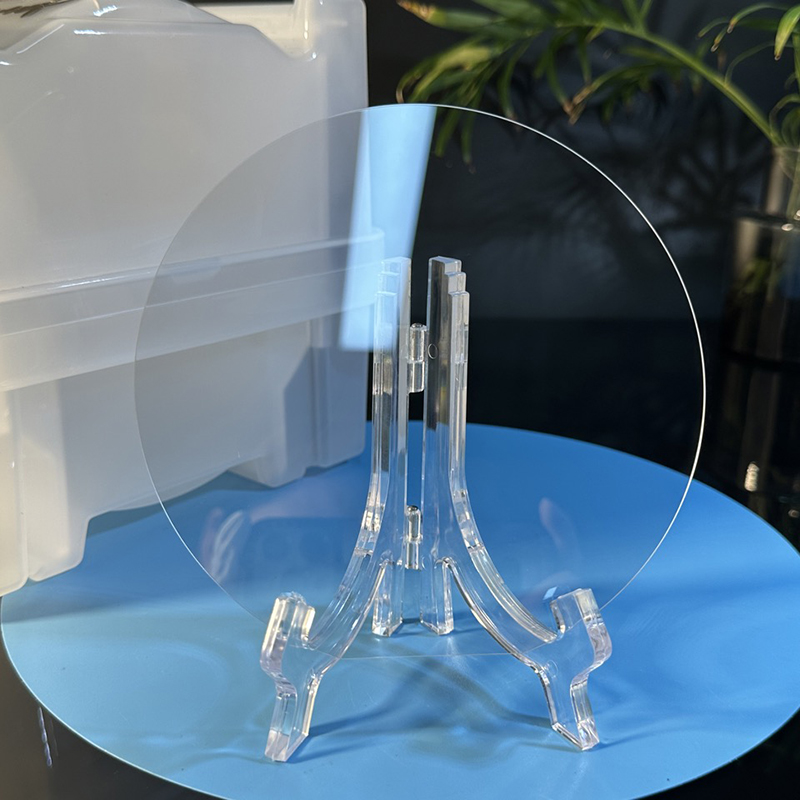

Idayagram eneenkcukacha