Isixhobo sokusika iLaser ye-Infrared Picosecond Dual-Platform yeLaser yeOptical Glass/Quartz/Sapphire Processing

Eyona parameter

| Uhlobo lweLaser | I-Infrared Picosecond |

| Ubungakanani beqonga | 700×1200 (mm) |

| 900×1400 (mm) | |

| Ukusika Ukutyeba | 0.03-80 (mm) |

| Ukusika isantya | 0-1000 (mm/s) |

| Ukuqhekeka komphetho | <0.01 (mm) |

| Qaphela: Ubungakanani beqonga bungenziwa ngokwezifiso. | |

Ezona mpawu

1.Itekhnoloji yeLaser ekhawulezayo:

· Inqanaba lePicosecond-level pulses short (10⁻¹²s) kudityaniswe ne-MOPA tuning technology ifikelela incopho yoxinaniso lwamandla >10¹² W/cm².

· I-infrared wavelength (1064nm) igqobhoza imathiriyeli ecacileyo ngokufunxwa okungahambelaniyo, ukuthintela ukutsalwa komhlaba.

· Inkqubo ye-optical egxininise kakhulu yobunini ivelisa iindawo ezine ezizimeleyo zokusetyenzwa ngaxeshanye.

2.ISitishi esiNxibelelaniso seNkqubo yokuNxibelelana:

· Isiseko seGranite-isiseko senqanaba leenjini ezimbini ezilandelelanayo (ukuchaneka kokubeka: ±1μm).

· Ixesha lokutshintsha isitishi <0.8s, ivumela imisebenzi ehambelanayo "yokulayisha-ukulayisha / ukukhulula".

· Ulawulo oluzimeleyo lobushushu (23±0.5°C) kwisikhululo ngasinye luqinisekisa uzinzo lwexesha elide lomatshini.

3.Ulawulo Lwenkqubo Ekrelekrele:

· Isiseko sedatha ehlanganisiweyo (200+ iiparamitha zeglasi) zokuthelekisa iparamitha ezenzekelayo.

· Ixesha langempela lokujongwa kweplasma kuguqula amandla e-laser (ukulungiswa kokulungiswa: 0.1mJ).

· Ukukhuselwa komkhusane womoya kunciphisa i-edge micro-cracks (<3μm).

Kwimeko yesicelo esiqhelekileyo esibandakanya i-0.5mm-thick sapphire wafer dicing, inkqubo ifezekisa isantya sokusika i-300mm / s kunye nemilinganiselo ye-chipping <10μm, emele i-5x yokuphucula ukusebenza kakuhle kwiindlela zendabuko.

Ukulungiswa kwezinto eziluncedo

I-1.I-Integrated dual-station yokusika kunye nenkqubo yokwahlula ukusebenza okuguquguqukayo;

2.Isantya esiphezulu somatshini wejiyometri entsonkothileyo yongeza inkqubo yoguqulo olusebenzayo;

I-3.I-Taper-free cutting edges kunye ne-chipping encinci (<50μm) kunye nokuphathwa okukhuselekileyo komqhubi;

I-4.Utshintsho olungenamthungo phakathi kweenkcazo zemveliso kunye nokusebenza okubonakalayo;

5.Iindleko zokusebenza eziphantsi, izinga eliphezulu lesivuno, inkqubo engasetyenziswayo kunye nengenangcoliseko;

6.Ukungabikho kokuveliswa kwe-slag, ulwelo olulahlwayo okanye amanzi amdaka anemfezeko eqinisekisiweyo yomphezulu;

Umboniso wesampuli

Usetyenziso oluqhelekileyo

1.Ukwenziwa koMthengi we-Electronics:

· Ukusikwa kwecontour echanekileyo ye-smartphone ye-3D yeglasi yesigqubuthelo (ukuchaneka kwe-R-engile: ± 0.01mm).

· Ukugrumba umngxuma omncinci kwiilensi zesafire (ubuncinci bokungena: Ø0.3mm).

· Ukugqitywa kweezowuni zegilasi yamehlo kwiikhamera ezibonisa ngaphantsi.

2.IMveliso yecandelo leOptical:

· I-Microstructure machining ye-AR/VR lens arrays (ubukhulu besici ≥20μm).

· I-angled cut of quartz prisms ye-laser collimators (ukunyamezela i-angular: ± 15").

· Ukubunjwa kweprofayili yezihluzi ze-infrared (i-taper yokusika <0.5 °).

3.Ukupakishwa kweSemiconductor:

· Ukusetyenzwa kweglasi nge-(TGV) kwinqanaba le-wafer (i-aspect ratio 1:10).

· I-Microchannel etching kwi-substrates yeglasi ye-microfluidic chips (Ra <0.1μm).

· Ukucutshungulwa rhoqo kwe-MEMS quartz resonators.

Ukwenziwa kwefestile ye-LiDAR yemoto ye-Optical window, inkqubo yenza ukuba i-contour isikwe kwiglasi ye-quartz engqindilili ye-2mm ene-perpendicularity ye-89.5 ± 0.3 °, ihlangabezana neemfuno zovavanyo lwe-auto-grade vibration.

Inkqubo yezicelo

Yenzelwe ngokukodwa ukusika izinto ezinqabileyo / ezinzima ezibandakanya:

I-1.Iglasi eqhelekileyo kunye neeglasi ze-optical (BK7, i-silica edibeneyo);

2. Iikristale zequartz & nesafire substrates;

3. Iglasi epholileyo kunye nezihluzo zamehlo

4. I-Mirror substrates

Iyakwazi ukusika i-contour kunye nokuchaneka komngxuma wangaphakathi wokomba (ubuncinci Ø0.3mm)

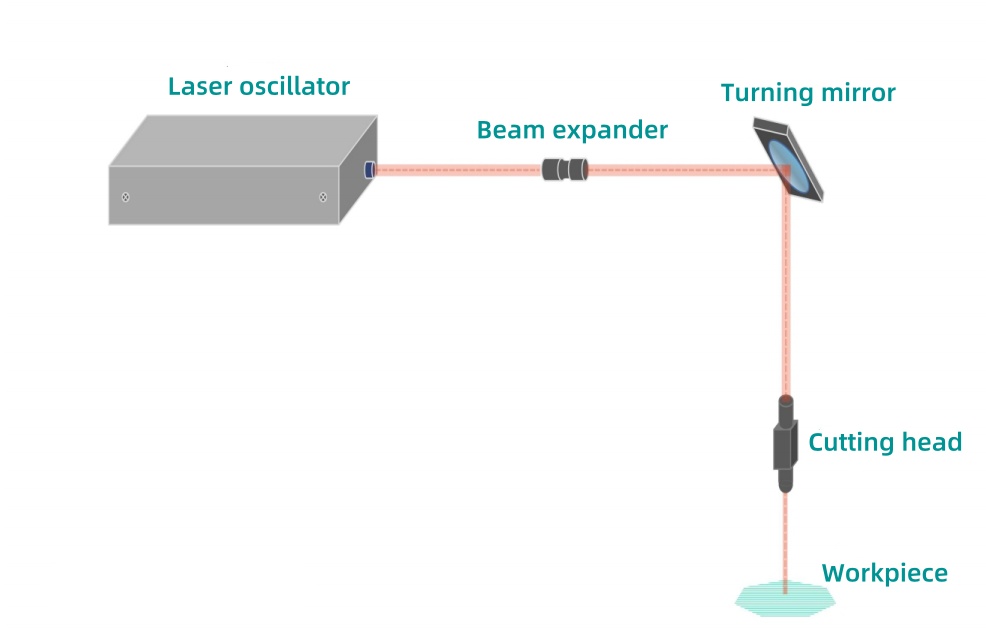

Laser Cutting Principle

I-laser ivelisa i-ultrashort pulses enamandla aphezulu kakhulu asebenzisana ne-workpiece ngaphakathi kwe-femtosecond-to-picosecond timescales. Ngexesha lokusasaza ngezinto eziphathekayo, umqadi uphazamisa isakhiwo sayo soxinzelelo ukwenza imingxuma ye-filamentation micron-scale. Isithuba semingxuma esilungiselelweyo sivelisa iintanda ezincinci ezilawulwayo, ezidibanisa netekhnoloji yokucanda ukufezekisa ukwahlula okuchanekileyo.

Laser Cutting Izinto eziluncedo

I-1.Ukuhlanganiswa okuphezulu okuzenzekelayo (okudibeneyo ukusika / ukucanda ukusebenza) kunye nokusetyenziswa kwamandla aphantsi kunye nokusebenza lula;

I-2.Ukucubungula okungekho qhagamshelwano kwenza ukuba amandla awodwa angafumaneki ngeendlela eziqhelekileyo;

I-3.I-Consumable-free operation inciphisa iindleko zokuqhuba kwaye iphakamisa ukugcinwa kokusingqongileyo;

4.Ukuchaneka okuphezulu kunye ne-zero taper angle kunye nokupheliswa komonakalo we-workpiece yesibini;

I-XKH ibonelela ngeenkonzo ezibanzi zokwenziwa ngokwezifiso kwiinkqubo zethu zokusika i-laser, kubandakanywa ulungelelwaniso lweqonga olulungiselelweyo, uphuhliso lwenkqubo ekhethekileyo yeparamitha, kunye nezisombululo ezithe ngqo kwisicelo ukuhlangabezana neemfuno ezizodwa zemveliso kumashishini ahlukeneyo.