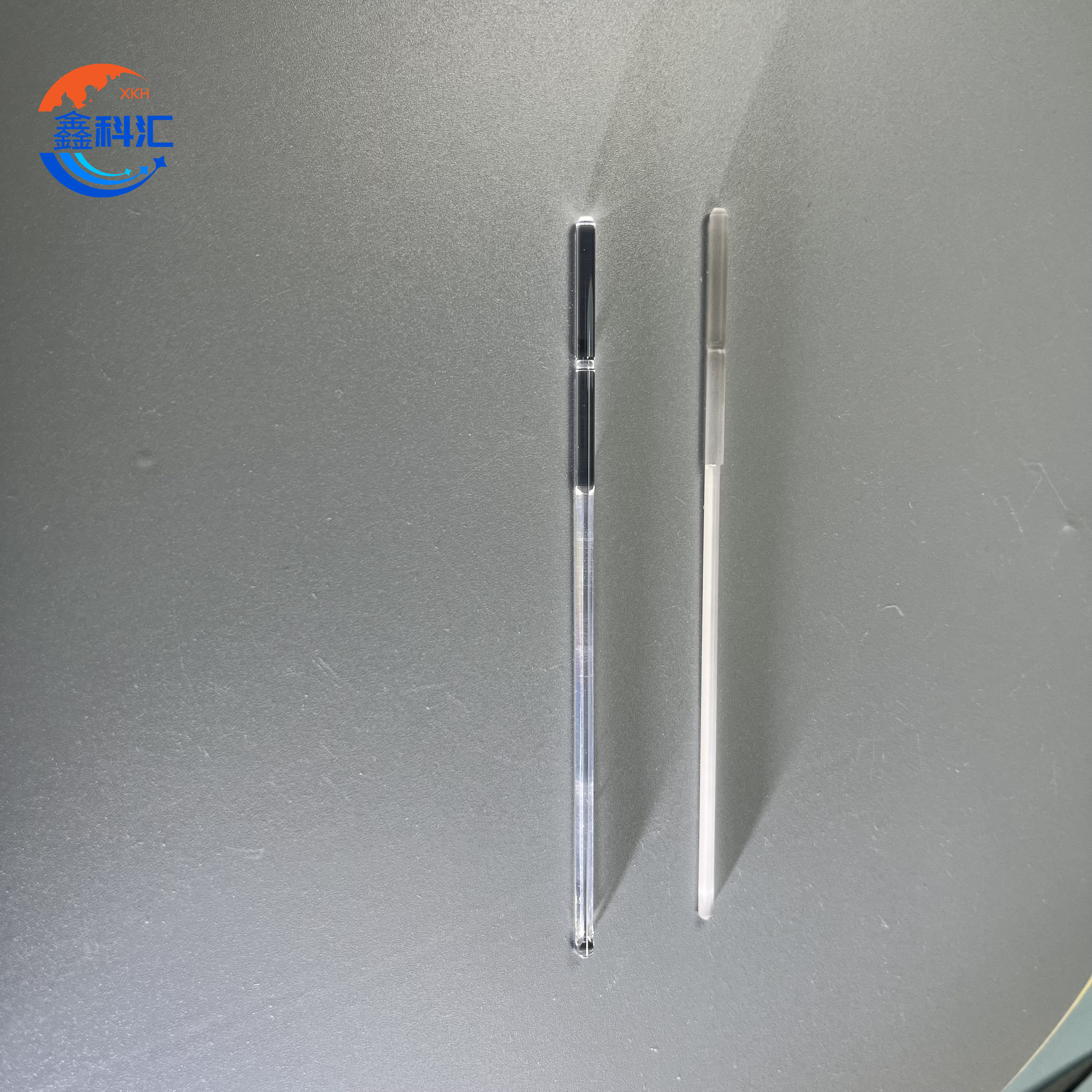

I-Industrial Sapphire Lift Rod kunye nePin, i-High Hardness ye-Al2O3 ye-Sapphire Pin yokuPhathwa kwe-Wafer, i-Radar System kunye ne-Semiconductor Processing - Ububanzi be-1.6mm ukuya kwi-2mm

Abstract

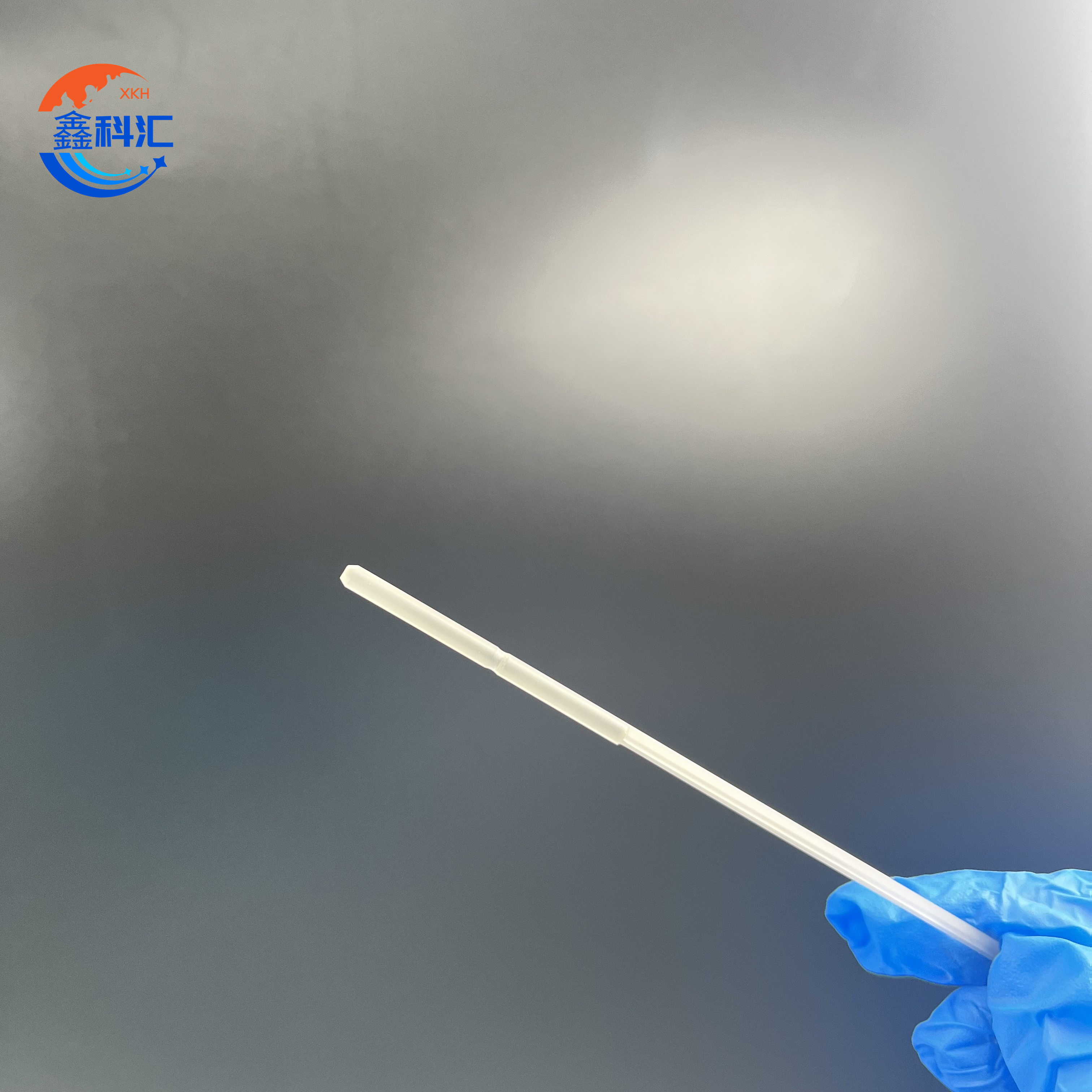

I-Industrial Sapphire Lift Rod kunye nePin ziyilelwe ngokuchaneka kunye nokuqina kwizicelo ezifunwa kakhulu ezifana nokuphathwa kwe-wafer, iinkqubo ze-radar, kunye nokulungiswa kwe-semiconductor. Yenziwe kwi-crystal eyodwa ye-Al2O3 (isafire), ezi zikhonkwane zinika ubunzima obubalaseleyo kunye nokumelana ne-thermal. Ifumaneka kwi-diameters ukusuka kwi-1.6mm ukuya kwi-2mm, ezi ntonga zokunyusa kunye nezikhonkwane ziyakwazi ukulungelelanisa iimfuno ezikhethekileyo zoshishino. Babonelela ngokugqwesa ukuxhathisa ukukrwempa kunye nokunxiba okuphantsi, okubenza babe ngamacandelo abalulekileyo kwiinkqubo zokusebenza eziphezulu.

Iimbonakalo

● Ukuqina okuPhezulu kunye noKuhlala ixesha elide:Ngobunzima be-Mohs be-9, ezi zikhonkwane kunye neentonga zixhathisa ukukrala, ziqinisekisa ukusebenza kwexesha elide kwizicelo eziphezulu zokunxiba.

● Ubungakanani obulungele wena:Ifumaneka kwi-diameters ukusuka kwi-1.6mm ukuya kwi-2mm, kunye nenketho yemilinganiselo yesiko ukuhlangabezana neemfuno ezithile zesicelo.

●Ukumelana neThermal:Iqondo eliphezulu lokunyibilika kweSapphire (2040°C) liqinisekisa ukuba ezi zikhonkwane ziyakwazi ukumelana nobushushu obuphezulu ngaphandle kokuthotywa.

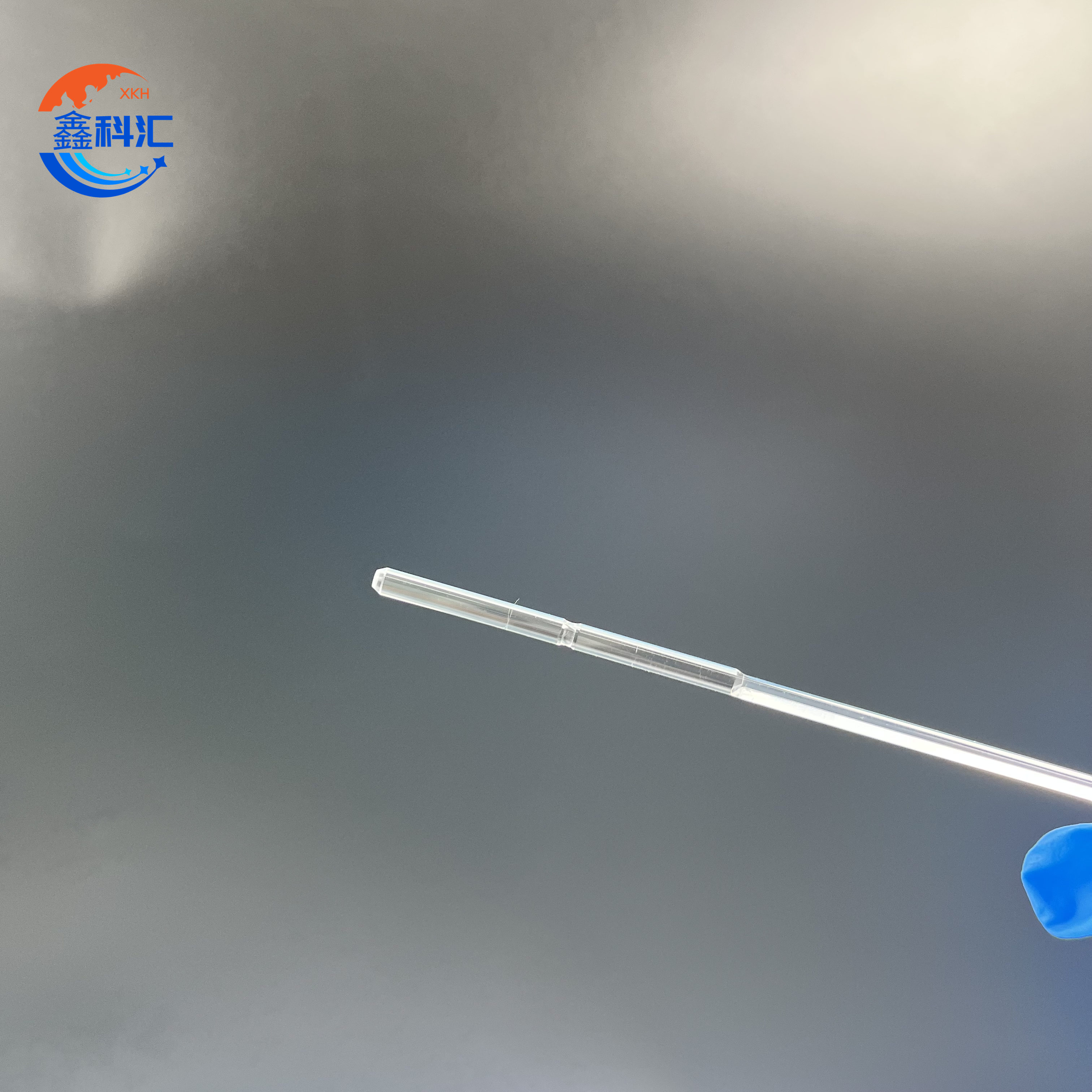

● Iinkcazelo Ngeempawu eziBalaseleyo:Ukucaca okubonakalayo kweSapphire kwenza ezi zikhonkwane zokuphakamisa zilungele ukusetyenziswa kwiinkqubo zamehlo kunye nezixhobo ezichanekileyo.

●I-Low Friction kunye nokunxiba:Umphezulu ogudileyo wesafire unciphisa ukunxiba kuzo zombini izikhonkwane zokuphakamisa kunye nezixhobo, ukunciphisa iindleko zokulondolozwa.

Usetyenziso

●Ukuphatha iWafer:Isetyenziselwa ukusetyenzwa kwe-semiconductor yokuguqulwa kwe-wafer eethe-ethe.

● IiNkqubo zeRada:Izikhonkwane eziphezulu zokusebenza ezisetyenziselwa kwiinkqubo ze-radar zokuqina kwazo kunye nokuchaneka.

●Ukwenziwa kweSemiconductor:Igqibelele ukuphatha ama-wafers kunye namanye amacandelo kwiinkqubo zokwenziwa kwe-semiconductor ephezulu.

● Iinkqubo zoShishino:Ifanelekile kwiinkqubo ezahlukeneyo zemizi-mveliso ezifuna ukuqina okuphezulu kunye nokuchaneka.

IiParameters zeMveliso

| Uphawu | Inkcazo |

| Izinto eziphathekayo | ICrystal enye Al2O3 (Sapphire) |

| Ukuqina | Mohs 9 |

| Uluhlu lweDiameter | 1.6mm ukuya 2mm |

| I-Thermal Conductivity | 27 W·m^-1·K^-1 |

| Indawo yokunyibilika | 2040°C |

| Ukuxinana | 3.97g/cc |

| Usetyenziso | UkuPhathwa kweWafer, iiNkqubo zeRadar, ukuPhathwa kweSemiconductor |

| Ukwenza ngokwezifiso | Ifumaneka ngoBubungakanani beSiko |

Q&A (imibuzo ebuzwa rhoqo)

I-Q1: Kutheni isafire iyimathiriyeli efanelekileyo yezikhonkwane zokuphakamisa ezisetyenziselwa ukuphatha i-wafer?

A1: Isafire kakhuluukumelana nemikrwelokwaye unayo aindawo yokunyibilika ephezulu, iyenza ibe yimathiriyeli egqwesileyo kwimisebenzi ebuthathaka njengeukuphatha i-wafer, apho ukuchaneka kunye nokuqina kubalulekile.

I-Q2: Yintoni inzuzo yokwenza ngokwezifiso ubungakanani bezikhonkwane zokuphakamisa isafire?

A2: Ubungakanani obuqhelekileyo buvumela ezi zikhonkwane zokuphakamisa ukuba zilungelelaniswe ukuze zilungele izicelo ezithile, ziqinisekisa ukusebenza kakuhle kwiinkqubo ezahlukeneyo, kuquka.ukusetyenzwa kwe-semiconductorkwayeiinkqubo zerada.

I-Q3: Ngaba izikhonkwane zokuphakamisa isafire zinokusetyenziswa kwizicelo eziphezulu zokushisa?

A3: Ewe,isafireuneindawo yokunyibilika ephezuluye2040°C, iyenza ilungele ukusetyenziswa kwiindawo ezinobushushu obuphezulu.

Idayagram eneenkcukacha