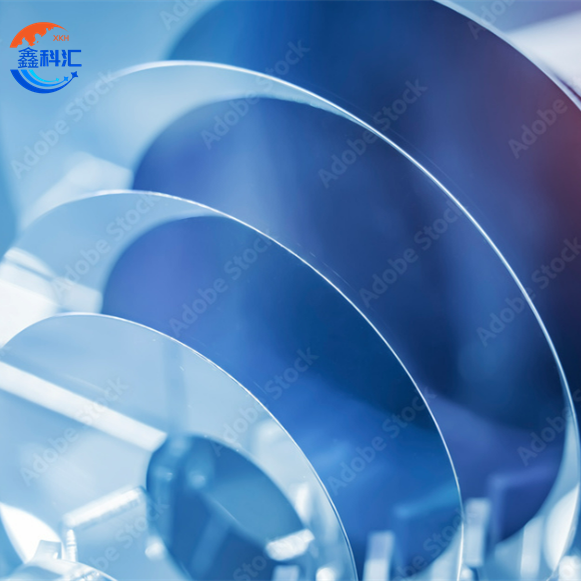

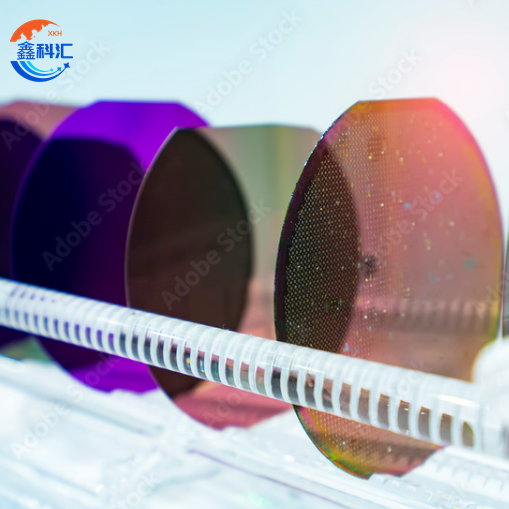

HPSI SiCOI wafer 4 6inch Hydropholic Bonding

I-SiCOI Wafer (iSilicon Carbide-on-Insulator) Isishwankathelo seePropati

I-SiCOI wafers yi-substrate ye-semiconductor yesizukulwana esitsha edibanisa i-Silicon Carbide (i-SiC) kunye ne-insulating layer, ehlala i-SiO₂ okanye isafire, ukuphucula ukusebenza kumandla ombane, i-RF, kunye ne-photonics. Apha ngezantsi kukho inkcazo ebanzi yeepropathi zabo ezahlulwe ngokwamacandelo aphambili:

| Ipropati | Inkcazo |

| Ukuqulunqwa kwezinto | I-Silicon Carbide (SiC) umaleko obotshelelwe kwi-substrate ekhuselayo (ngokuqhelekileyo i-SiO₂ okanye isafire) |

| Ulwakhiwo lweCrystal | Ngokuqhelekileyo i-4H okanye i-6H i-polytypes ye-SiC, eyaziwayo ngomgangatho ophezulu we-crystal kunye nokufana |

| Iipropati zoMbane | Indawo yombane eyophukayo ephezulu (~3 MV/cm), i-bandgap ebanzi (~3.26 eV ye-4H-SiC), ukuvuza okuphantsi kwangoku |

| I-Thermal Conductivity | I-thermal conductivity ephezulu (~ 300 W/m·K), eyenza ukuchithwa kobushushu okusebenzayo |

| Uluhlu lweDielectric | I-Insulating layer (i-SiO₂ okanye isafire) ibonelela ngombane wedwa kwaye inciphisa amandla eparasitic |

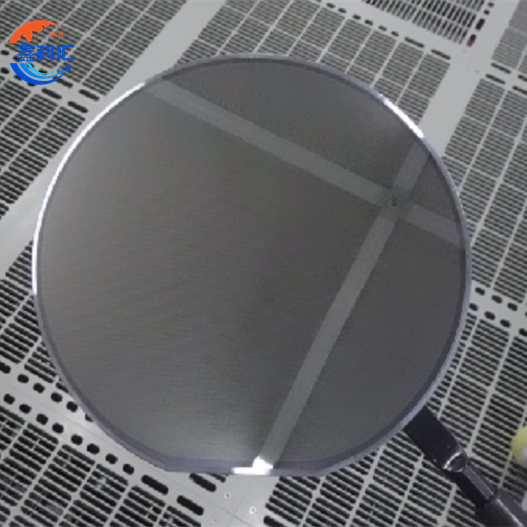

| Iipropati zoomatshini | Ukuqina okuphezulu (~ 9 Mohs isikali), amandla abalaseleyo omatshini, kunye nokuzinza kwe-thermal |

| Umphezulu Gqiba | Ngokuqhelekileyo i-ultra-smooth kunye noxinzelelo oluphantsi lwesiphene, ilungele ukwenziwa kwesixhobo |

| Usetyenziso | Ii-elektroniki zamandla, izixhobo ze-MEMS, izixhobo zeRF, izinzwa ezifuna ubushushu obuphezulu kunye nokunyamezela kwamandla ombane |

Ii-wafers ze-SiCOI (i-Silicon Carbide-on-Insulator) imele ulwakhiwo oluphezulu lwe-semiconductor substrate, olubandakanya umaleko ophakamileyo obhityileyo we-silicon carbide (SiC) edityaniswe kwi-insulating layer, ngokuqhelekileyo isilicon dioxide (SiO₂) okanye isafire. I-Silicon carbide yi-wide-bandgap semiconductor eyaziwa ngokukwazi ukumelana nombane ophezulu kunye namaqondo obushushu aphakamileyo, kunye ne-thermal conductivity egqwesileyo kunye nobunzima obuphezulu bomatshini, iyenza ilungele amandla aphezulu, i-high-frequency, kunye nobushushu obuphezulu bezicelo ze-elektroniki.

Umaleko wokugquma kwii-wafers ze-SiCOI unikezela ukwahlula kombane okusebenzayo, ukunciphisa kakhulu i-parasitic capacitance kunye nokuvuza kwemisinga phakathi kwezixhobo, ngaloo ndlela kuphucula ukusebenza kwesixhobo kunye nokuthembeka. Umphezulu we-wafer ugudiswe ngokuchanekileyo ukuze ufezekiseke kakhulu kwaye uneziphene ezincinci, ukuhlangabezana neemfuno ezingqongqo zokwenziwa kwesixhobo esincinci kunye ne-nano-scale.

Esi sakhiwo sezinto eziphathekayo asiphuculi kuphela iimpawu zombane zezixhobo ze-SiC kodwa ziphucula kakhulu ulawulo lwe-thermal kunye nokuzinza komatshini. Ngenxa yoko, ii-wafers ze-SiCOI zisetyenziswa ngokubanzi kumbane wombane, i-radio frequency (RF) components, i-microelectromechanical systems (MEMS) sensors, kunye nobushushu obuphezulu be-elektroniki. Ngokubanzi, ii-wafers ze-SiCOI zidibanisa iipropathi ezingaqhelekanga ze-silicon carbide kunye neenzuzo zokuhlukaniswa kombane zomaleko we-insulator, ebonelela ngesiseko esifanelekileyo kwisizukulwana esilandelayo sezixhobo zokusebenza eziphezulu ze-semiconductor.

Isicelo seSiCOI wafer

Izixhobo zoMbane zoMbane

Ukutshintsha kwamandla ombane aphezulu kunye namandla aphezulu, ii-MOSFETs, kunye neediode

Zuza kwibhendi ebanzi ye-SiC, amandla ombane aphezulu wokuqhekeka, kunye nokuzinza kwe-thermal

Ukunciphisa ukulahlekelwa kwamandla kunye nokuphucula ukusebenza kakuhle kwiinkqubo zokuguqula amandla

Izixhobo zeRadio Frequency (RF).

Ii-transistors eziphezulu kunye ne-amplifiers

Umthamo we-parasitic ophantsi ngenxa yomaleko wokugquma uphucula ukusebenza kweRF

Ifanelekile kunxibelelwano lwe-5G kunye neenkqubo ze-radar

IiNkqubo zeMicroelectromechanical (MEMS)

Iinzwa kunye nee-actuators ezisebenza kwindawo ezinzima

Ukomelela koomatshini kunye nokungasebenzi kweekhemikhali zandisa ubomi besixhobo

Kubandakanya iinzwa zoxinzelelo, i-accelerometers, kunye ne-gyroscopes

I-Electronics yobushushu obuphezulu

I-elektroniki yezemoto, i-aerospace, kunye nokusetyenziswa kwemizi-mveliso

Sebenza ngokuthembekileyo kumaqondo obushushu aphezulu apho isilicon isilela

Izixhobo zeFotonic

Ukudibanisa kunye namacandelo e-optoelectronic kwii-substrates ze-insulator

Yenza i-on-chip photonics ngolawulo oluphuculweyo lwe-thermal

I-SiCOI wafer's Q&A

Umbuzo:yintoni i-wafer ye-SiCOI

A:I-SiCOI wafer imele iSilicon Carbide-on-Insulator wafer. Luhlobo lwe-substrate ye-semiconductor apho umaleko omncinci we-silicon carbide (SiC) udityaniswe kwi-insulating layer, ngokuqhelekileyo i-silicon dioxide (SiO₂) okanye ngamanye amaxesha isafire. Esi sakhiwo siyafana nengcamango kwii-Silicon-on-Insulator (SOI) eyaziwayo kodwa isebenzisa i-SiC endaweni ye-silicon.

Umfanekiso