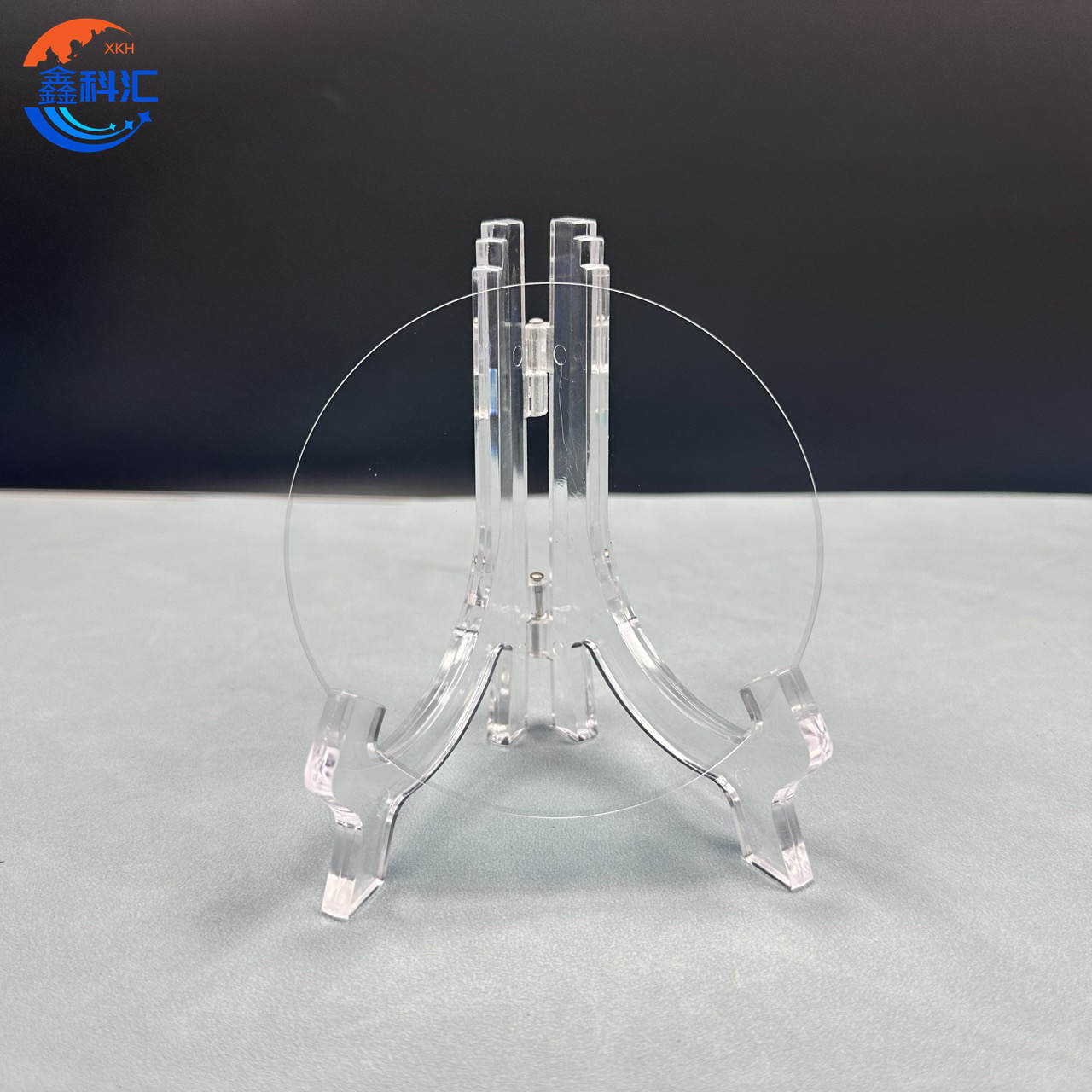

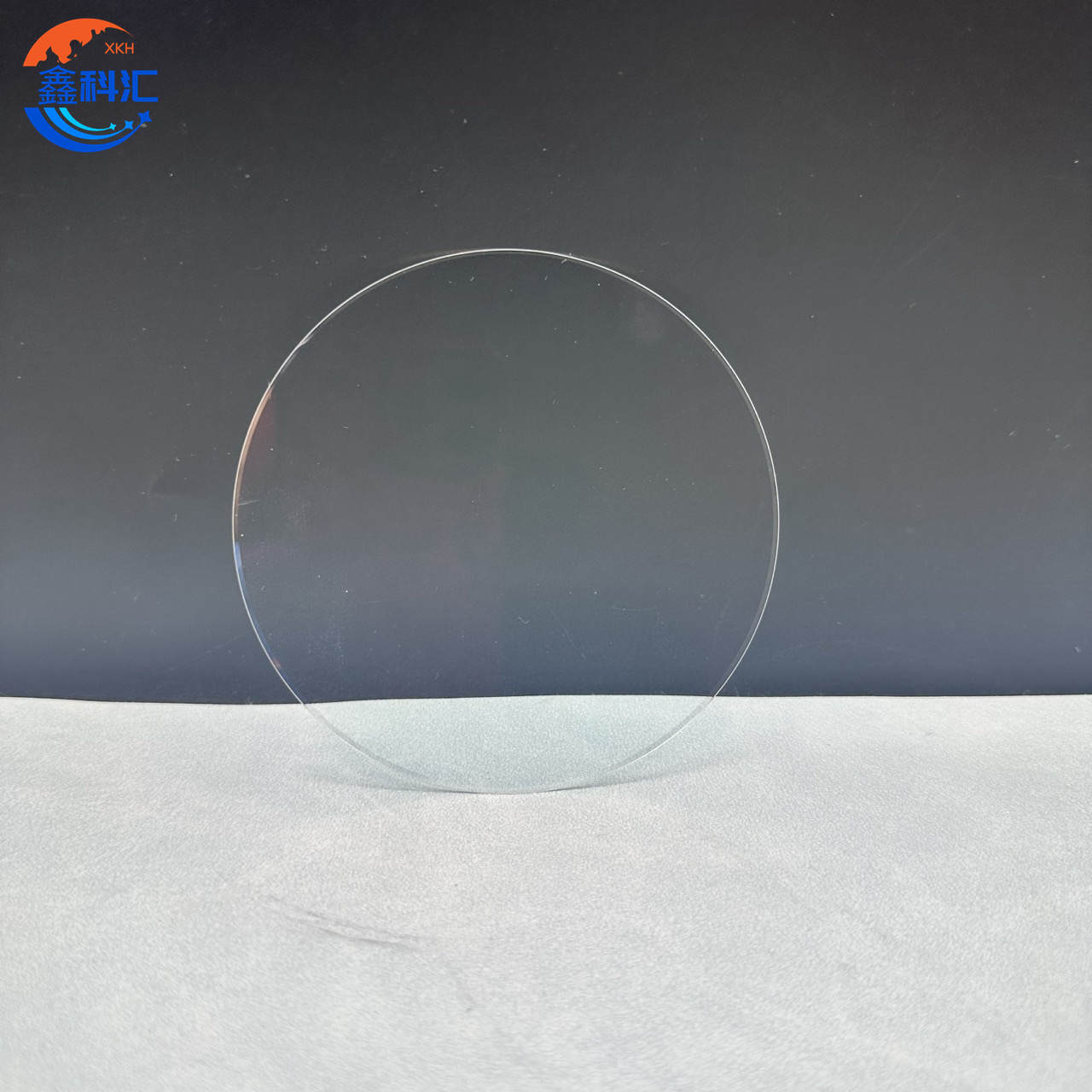

I-HPSI SiC wafer dia:3inch ubukhulu:350um± 25 µm kuMbane woMbane

Isicelo

Ii-wafers ze-HPSI SiC zisetyenziswa kuluhlu olubanzi lwezicelo ze-elektroniki zamandla, kubandakanya:

IiSemiconductors zamandla:Ii-wafers ze-SiC zidla ngokusetyenziswa ekuveliseni ii-diode zamandla, ii-transistors (MOSFETs, IGBTs), kunye ne-thyristors. Ezi semiconductors zisetyenziswa ngokubanzi kwizicelo zoguqulo lwamandla ezifuna ukusebenza kakuhle kunye nokuthembeka, njengokuqhutywa kweemoto zoshishino, izixhobo zombane, kunye nee-inverters zeenkqubo zamandla avuselelekayo.

Izithuthi zoMbane (EVs):Kwiimoto zombane zombane, izixhobo zamandla ezisekelwe kwi-SiC zibonelela ngesantya sokutshintsha ngokukhawuleza, ukusebenza kakuhle kwamandla, kunye nokunciphisa ilahleko yobushushu. Amacandelo e-SiC afanelekile kwizicelo kwiinkqubo zokulawula ibhetri (i-BMS), izibonelelo zokutshaja, kunye neetshaja ezisebhodini (i-OBCs), apho ukunciphisa ubunzima kunye nokwandisa ukuguqulwa kwamandla okusebenza kubalulekile.

IiNkqubo zaMandla aVuselelwayo:Ii-wafers ze-SiC zisetyenziswa kakhulu kwii-inverters zelanga, iijenereyitha ze-injini yomoya, kunye neenkqubo zokugcina amandla, apho ukusebenza okuphezulu kunye nokomelela kubalulekile. Amacandelo asekelwe kwi-SiC anika amandla amandla aphezulu kunye nokusebenza okuphuculweyo kwezi zicelo, ukuphucula ukusebenza kakuhle kokuguqulwa kwamandla.

I-Electronic Power ye-Industrial:Kwizicelo zemizi-mveliso ezisebenza kakhulu, ezinje ngeemoto, iirobhothi, kunye nezixhobo zombane ezinkulu, ukusetyenziswa kwee-wafers ze-SiC kuvumela ukuphuculwa kokusebenza ngokufanelekileyo, ukuthembeka, kunye nolawulo lobushushu. Izixhobo ze-SiC zinokubamba amaza okutshintsha okuphezulu kunye namaqondo obushushu aphezulu, azenze zilungele indawo ezifunayo.

UNxibelelwano ngoNxibelelwano kunye namaZiko eDatha:I-SiC isetyenziselwa ukubonelela ngombane kwizixhobo zonxibelelwano kunye namaziko edatha, apho ukuthembeka okuphezulu kunye nokuguqulwa kwamandla okusebenzayo kubalulekile. Izixhobo zamandla ezisekelwe kwi-SiC zenza ukusebenza okuphezulu kubukhulu obuncinci, obuguqulela ekunciphiseni ukusetyenziswa kwamandla kunye nokusebenza kakuhle kokupholisa kwiziseko ezinkulu.

Umbane ophezulu wokophuka, ukuxhathisa okuphantsi, kunye nokuhanjiswa kwe-thermal kwe-SiC wafers kuzenza zibe yeyona substrate ifanelekileyo kwezi zicelo zihambele phambili, okwenza uphuhliso lwesizukulwana esilandelayo sombane wamandla ombane awonga amandla.

Iipropati

| Ipropati | Ixabiso |

| I-Wafer Diameter | ii-intshi ezi-3 (76.2 mm) |

| Ukutyeba kweWafer | 350 µm ± 25 µm |

| I-Wafer Orientation | <0001> kwi-axis ± 0.5 ° |

| Uxinaniso lweMibhobho (MPD) | ≤ 1 cm⁻² |

| Ukuxhathisa koMbane | ≥ 1E7 Ω·cm |

| I-Dopant | Ingaguqulwanga |

| Ukuqhelaniswa neFlethi okuPhambili | {11-20} ± 5.0° |

| Ubude beFlethi obuPhambili | 32.5 mm ± 3.0 mm |

| Ubude beFlethi yesibini | 18.0 mm ± 2.0 mm |

| Ukuqhelaniswa neFlethi yesibini | Si jonga phezulu: 90° CW ukusuka kwiflethi yokuqala ± 5.0° |

| Ukungabandakanywa kuMda | 3 mm |

| LTV/TTV/Bow/Warp | 3 µm / 10 µm / ±30 µm / 40 µm |

| Uburhabaxa boMphezulu | Ubuso be-C: bukhazimlisiwe, ubuso beSi: CMP |

| Iintanda (zihlolwe ngokukhanya okuphezulu) | Akukho nanye |

| Iipleyiti zeHex (zihlolwe ngokukhanya okuphezulu) | Akukho nanye |

| Iindawo zePolytype (zihlolwe ngokukhanya okuphezulu) | Indawo eyongezelekayo 5% |

| Imikrwelo (ihlolwe sisibane sokukhanya okuphezulu) | ≤ Imikrwelo emi-5, ubude obuninzi ≤ 150 mm |

| Edge Chipping | Akukho kuvunyelweyo ≥ 0.5 mm ububanzi nobunzulu |

| Ungcoliseko loMphezulu (uhlolwe sisibane sobukhulu obuphezulu) | Akukho nanye |

IiNzuzo eziPhambili

I-High Thermal Conductivity:Ii-wafers ze-SiC zaziwa ngobuchule bazo obukhethekileyo bokuchitha ubushushu, obuvumela izixhobo zamandla ukuba zisebenze ngokufanelekileyo kwaye zibambe imisinga ephezulu ngaphandle kokufudumeza. Olu phawu lubalulekile kumandla ombane apho ulawulo lobushushu luyingxaki enkulu.

Ukwahlulwa kwamandla ombane aphezulu:I-bandgap ebanzi ye-SiC yenza ukuba izixhobo zikwazi ukunyamezela amanqanaba ombane aphezulu, zizenza zilungele usetyenziso olunombane ophezulu onje ngeegridi zamandla, izithuthi zombane, kunye noomatshini bemizi-mveliso.

Ukusebenza okuphezulu:Ukudityaniswa kwee-frequencies eziphezulu zokutshintsha kunye ne-low on-resistance iziphumo kwizixhobo ezinokulahlekelwa kwamandla aphantsi, ukuphucula ukusebenza kakuhle kokuguqulwa kwamandla kunye nokunciphisa imfuno yeenkqubo zokupholisa ezinzima.

Ukuthembeka Kwimekobume Eburhabaxa:I-SiC iyakwazi ukusebenza kumaqondo obushushu aphezulu (ukuya kuthi ga kwi-600 ° C), okwenza ukuba ilungele ukusetyenziswa kwiindawo ezinokuthi zonakalise izixhobo zemveli ze-silicon.

Ugcino lwamandla:Izixhobo zamandla ze-SiC ziphucula ukusebenza kakuhle kokuguqulwa kwamandla, okubaluleke kakhulu ekunciphiseni ukusetyenziswa kwamandla, ngakumbi kwiinkqubo ezinkulu ezifana neziguquli zamandla emizi-mveliso, izithuthi zombane, kunye neziseko zombane ezivuselelwayo.

Idayagram eneenkcukacha