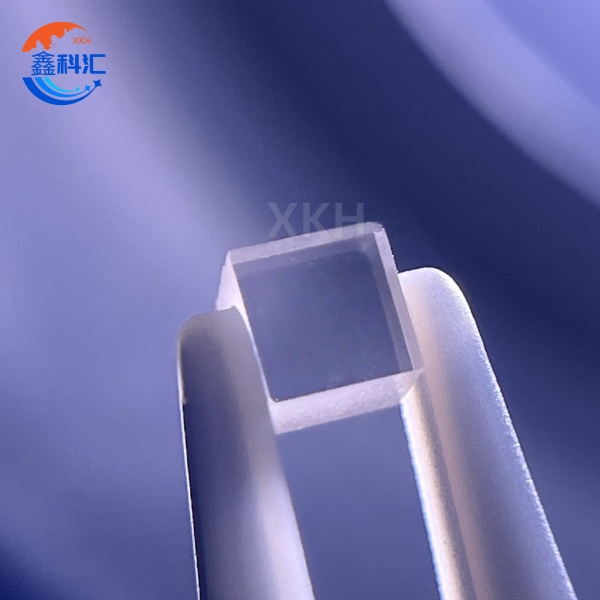

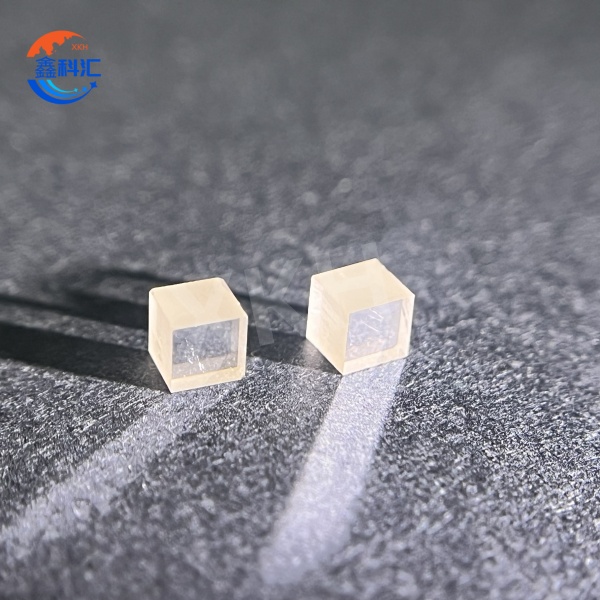

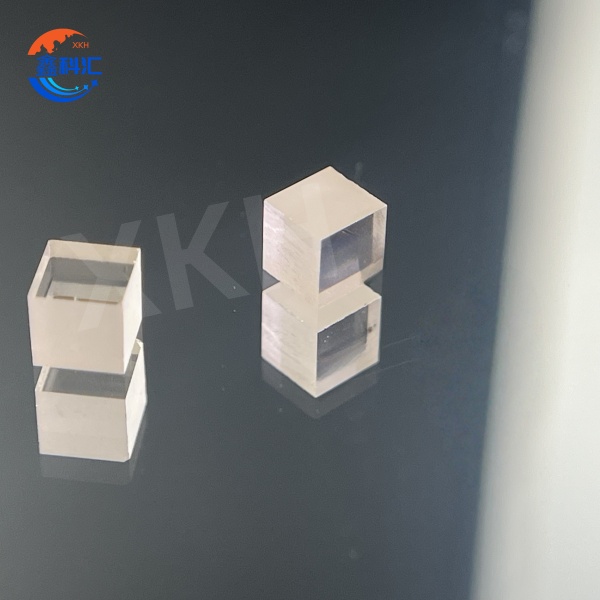

Ukucoceka okuphezulu kwe-SiC ye-Optical Lens Cubic 4H-semi 6SP Ubungakanani obulungiselelweyo

Iimpawu zeSiC Optical Lens

1. Ukubalasela kwezinto eziphathekayo

Ukuguquguquka okugqithisileyo kokusiNgqongileyo: Imelana namaqondo obushushu angaphezulu kwe-1500°C, i-asidi eyomeleleyo/i-alkali corrosion, kunye nemitha ene-eneji ephezulu, ilungele iziphekepheke kunye nezixhobo zenyukliya.

Amandla aKhethekileyo oomatshini: Ukuqina kwedayimane ekufutshane (i-Mohs 9.5), amandla aguquguqukayo> 400 MPa, kunye nokuchasana kwempembelelo kugqithise kakhulu iglasi ebonakalayo yesiqhelo.

Ukuzinza kwe-Thermal: I-Thermal conductivity 100 × ephezulu kune-silica edibeneyo, kunye ne-CTE nje i-1/10 yeglasi eqhelekileyo, iqinisekisa uzinzo phantsi kwebhayisikile ye-thermal ekhawulezayo.

2. Izinto eziluncedo kwiNtsebenzo ye-Optical

Usasazo olubanzi lwe-spectral (0.2-6 μm); Iingubo ezikhethekileyo zinokwandisa ukudluliselwa kwi> 95% kwiibhanti ezithile (umzekelo, 3-5 μm phakathi kwe-IR).

Ilahleko ephantsi yokusabalalisa (<0.5% / cm), ukugqiba umgangatho ukuya kwi-10/5 i-scratch-dig standard, kunye ne-flatness surface λ/10@633 nm.

I-laser-induced threshold damage threshold (LIDT) >15 J/cm² (1064 nm, 10 ns pulses), ilungele iinkqubo zokugxininisa kwi-laser yamandla aphezulu.

3. Precision Machining Izakhono

Ixhasa iindawo ezinzima (i-aspheric, i-freeform) ngokuchaneka kwefom <100 nm PV kunye ne-centration <1 arcmin.

Iyakwazi ukwenza iilensi ze-SiC ezinobukhulu obugqithisileyo (ubukhulu>500 mm) ukwenzela iiteleskopu zeenkwenkwezi kunye ne-space Optics.

Izicelo eziphambili zeSiC Optical Lens

1. I-Space Optics kunye noKhuseleko

Iilensi zesathelayithi zokubona okude kunye nokukhanya kweteleskopu yasemkhathini, ukusebenzisa iipropathi ezikhaphukhaphu zeSiC (uxinano 3.21 g/cm³) kunye nokumelana nemitha.

Iifestile ze-Misile ezijongayo, ezinyamezela ukufudumeza kwe-aerodynamic (>1000 ° C) ngexesha lokubhabha kwe-hypersonic.

2. IiNkqubo zeLaser zaMandla aphezulu

Iilensi zokujolisa kwimizi-mveliso yelaser yokusika/izixhobo zokuwelda, ukugcina ukuvezwa ixesha elide kwii-kW-class lasers eziqhubekayo.

Izinto zokubumba i-Beam kwiinkqubo ze-inertial confinement fusion (ICF), eziqinisekisa ukuhanjiswa kwelaser ene-energy echanekileyo.

3. ISemiconductor & Precision Manufacturing

I-SiC mirror substrates ye-EUV lithography optics, ene-thermal deformation <1 nm ngaphantsi kwe-10 kW/m² ubushushu bobushushu.

Iilensi ze-Electromagnetic zezixhobo zokuhlola ze-e-beam, zisebenzisa i-SiC's conductivity yokulawula ubushushu obusebenzayo.

4. Ukuhlolwa koShishino kunye naMandla

Iilensi ze-Endoscope kwiziko lobushushu obuphezulu (1500 ° C ngokuqhubekayo ukusebenza).

Amacandelo e-infrared optical yezixhobo zokugawulwa kwe-oyile, ukuxhathisa uxinzelelo lwe-downhole (> 100 MPa) kunye nemidiya ephazamisayo.

Iinzuzo ezingundoqo zoKhuphiswano

1. UbuNkokheli boMsebenzi oBanzi

Iilensi ze-SiC zidlula izinto eziqhelekileyo ezibonakalayo (i-silica edibeneyo, i-ZnSe) kwi-thermal / mechanical / stability yekhemikhali, kunye neempawu zabo "ze-conductivity ephezulu + yokwandisa okuphantsi" ekusombululeni imingeni ye-thermal deformation kwi-optics enkulu.

2. Ukuphumelela kweendleko zoBomi

Nangona iindleko zokuqala ziphezulu, iilensi ze-SiC 'inkonzo eyandisiweyo yobomi (i-5-10 × iglasi eqhelekileyo) kunye nokusebenza okungenalo ukugcinwa kunciphisa kakhulu iindleko ezipheleleyo zobunini (TCO).

3. Inkululeko yoyilo

Iinkqubo ze-Reaction-bonded okanye ze-CVD zenza i-SiC lightweight optical structures (i-honeycomb cores), ifezekise ukuqina okungenakulinganiswa kobunzima.

Ubunakho beNkonzo ye-XKH

1. Iinkonzo zokuVelisa ngokweSiko

Izisombululo zokugqibela ukusuka kuyilo lwe-optical (Zemax / Code V ukulinganisa) ukuya kunikezelo lokugqibela, ukuxhasa i-aspheric / off-axis parabolic freeform surfaces.

Iingubo ezikhethekileyo: i-anti-reflection (AR), i-carbon-like diamond (LIDT> 50 J / cm²), i-ITO eqhubayo, njl.

2. IiNkqubo zoQinisekiso loMgangatho

Izixhobo ze-Metrology ezibandakanya i-interferometers ye-4D kunye neeprofayili zokukhanya ezimhlophe ziqinisekisa i-λ / 20 ukuchaneka kwendawo.

Inqanaba leMaterial QC: XRD crystallographic orientation analysis for every SiC blank.

3. Iinkonzo ezongeziweyo kwiXabiso

Uhlalutyo lwe-Thermo-structural coupling (ukulinganisa kwe-ANSYS) ukuqikelela ukusebenza.

Uyilo oludityanisiweyo lwe-SiC lens yokuxhoma ukulungelelaniswa kolwakhiwo.

Ukuqukumbela

Iilensi ze-SiC zichaza kwakhona imida yokusebenza yeenkqubo ezichanekileyo eziphezulu ze-optical ngokusebenzisa izinto zazo ezingenakulinganiswa. Amandla ethu adityanisiweyo ngokuthe nkqo kwi-SiC imathiriyeli yokudibanisa, ukuchaneka komatshini, kunye novavanyo luzisa izisombululo eziguquguqukayo ze-aerospace kunye necandelo lemveliso eliphambili. Ngenkqubela phambili ekukhuleni kwekristale ye-SiC, uphuhliso lwexesha elizayo luya kujolisa kwimingxuma emikhulu (> 1m) kunye neejometri ezintsonkothileyo zomphezulu (uluhlu olukhululekileyo).

Njengomvelisi ohamba phambili wamacandelo optical aphambili, i-XKH igxile kwizinto eziphezulu zokusebenza ezibandakanya isafire, i-silicon carbide (i-SiC), kunye ne-silicon wafers, enikezela izisombululo zokuphela-to-ekupheleni ukusuka ekuqhutyweni kwezinto eziluhlaza ukuya ekugqityweni ngokuchanekileyo. Ubungcali bethu buhamba:

1. Ukwenziwa ngokweSiko: Ukuchaneka komatshini wejiyometri entsonkothileyo (i-aspheric, i-freeform) enokunyamezela ukuya kwi-±0.001mm

2. I-Versatility yeMathiriyeli: Ukucubungula isafire (iifestile ze-UV-IR), i-SiC (i-high-power optics), kunye ne-silicon (IR/micro-optics)

3. Iinkonzo ezongeziweyo kwiXabiso:

Izinto zokugquma ezichasayo/ezihlala ixesha elide (UV-FIR)

I-Metrology-backed quality assurance (λ/20 flatness)

Indibano yegumbi lokucoca ukwenzela izicelo ezingevani kungcoliseko

Ukukhonza i-aerospace, i-semiconductor, kunye nemizi-mveliso ye-laser, sidibanisa ubuchule besayensi yezinto eziphathekayo kunye nemveliso ephucukileyo ukuhambisa izinto zamehlo ezimelana neemeko ezingqongileyo ezigqithisileyo ngelixa siphucula ukusebenza kwamehlo.