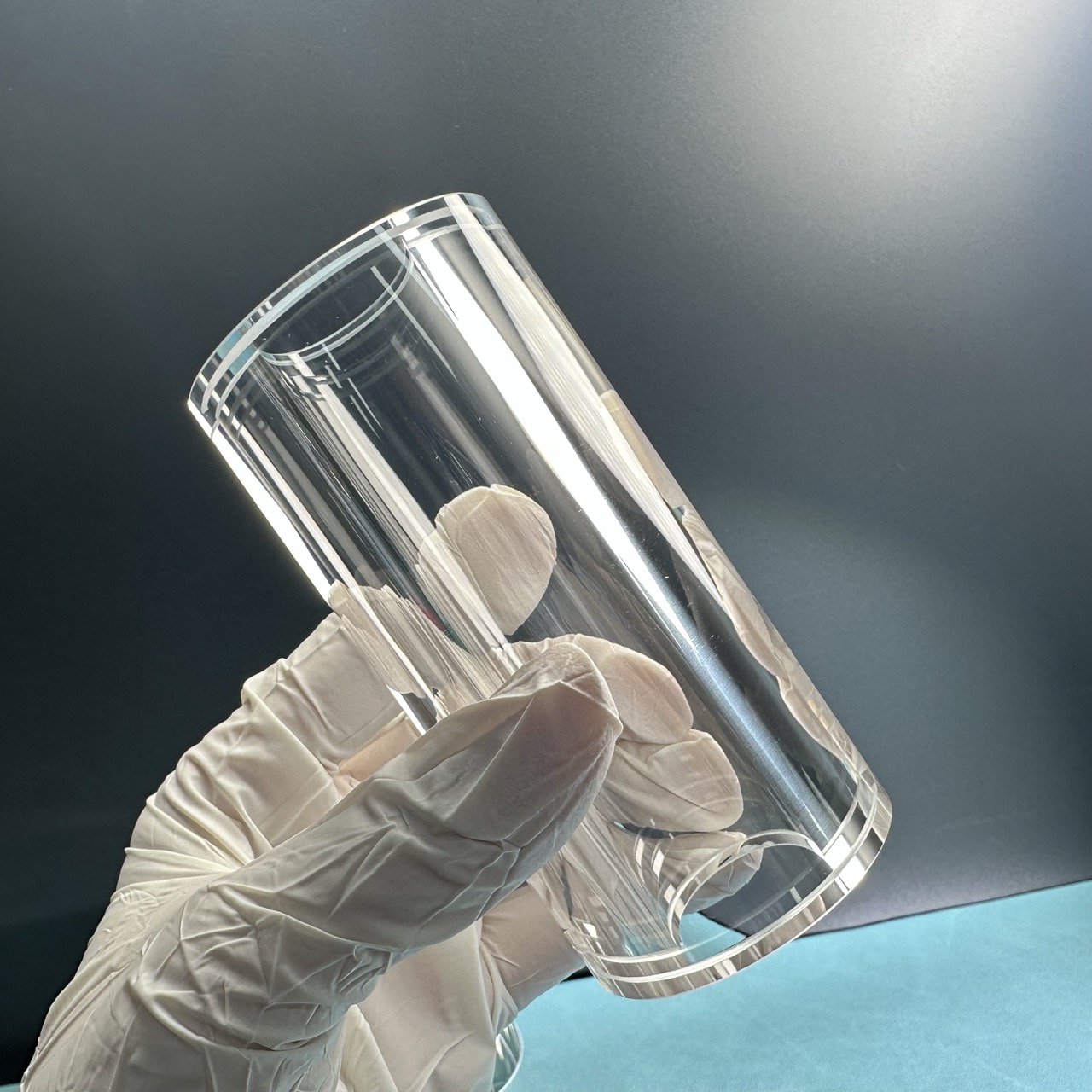

IiWafers zeQuartz eziDityanisiweyo eziPhezulu zeSemiconductor, iiFotonikhi zokuSebenza okuLawulayo 2″4″6″8″12″

Idayagram eneenkcukacha

Isishwankathelo seglasi yeQuartz

Ii-wafers ze-quartz zenza umqolo wezixhobo zanamhlanje ezingenakubalwa eziqhuba ihlabathi lanamhlanje ledijithali. Ukusuka kukhangelo kwi-smartphone yakho ukuya kumqolo wezikhululo ezisisiseko ze-5G, i-quartz ihambisa ngokuzolileyo uzinzo, ukucoceka, kunye nokuchaneka okufunekayo kwi-elektroniki yokusebenza okuphezulu kunye neefotonics. Nokuba ixhasa ukujikeleza okuguquguqukayo, ukwenza abenzi boluvo be-MEMS, okanye ukwenza isiseko se-quantum computing, iimpawu ezizodwa ze-quartz ziyenza ibe yimfuneko kuwo wonke amashishini.

"I-Silica eFused" okanye "i-Quartz eFused" eyisigaba se-amorphous se-quartz (SiO2). Xa kuthelekiswa neglasi ye-borosilicate, i-silica edibeneyo ayinazo izongezo; kungoko ikhona kwimo yayo ecocekileyo, iSiO2. I-silica edibeneyo inokudluliselwa okuphezulu kwi-infrared kunye ne-ultraviolet spectrum xa kuthelekiswa neglasi eqhelekileyo. I-silica edibeneyo iveliswa ngokunyibilika kunye nokuqinisa kwakhona i-ultrapure SiO2. Isilica edityanisiweyo yokwenziwa kwelinye icala yenziwe kwi-silicon-rich rich precursors iikhemikhali ezifana ne-SiCl4 efakwe igesi yaze yafakwa i-oxidized kwi-atmosfera ye-H2 + O2. Uthuli lwe-SiO2 olwenziwe kule meko luxutywe kwi-silica kwi-substrate. Iibhloko ze-silica ezidityanisiweyo zisikwa zibe ziwafers emva koko iiwafers ekugqibeleni zikhazimlisiwe.

Iimpawu eziphambili kunye neeNzuzo zeQuartz Glass Wafer

-

Ucoceko oluPhezulu kakhulu (≥99.99% SiO2)

Ilungele i-ultra-clean semiconductor kunye ne-photonics iinkqubo apho ukungcoliseka kwezinto kufuneka kuncitshiswe. -

Uluhlu olubanzi lokuSebenza kweThermal

Igcina ingqibelelo yesakhiwo ukusuka kumaqondo obushushu e-cryogenic ukuya kuthi ga kwi-1100 ° C ngaphandle kokulwa okanye ukuthotywa. -

Ukusasazwa kwe-UV kunye ne-IR ebalaseleyo

Ihambisa ukucaca okugqwesileyo kwamehlo ukusuka kwi-ultraviolet enzulu (DUV) nge-infrared ekufutshane (NIR), exhasa usetyenziso oluchanekileyo lokukhanya. -

I-Coefficient yoKwandiswa kweThermal ephantsi

Ukwandisa ukuzinza kwe-dimensional phantsi kokutshintsha kweqondo lokushisa, ukunciphisa uxinzelelo kunye nokuphucula ukuthembeka kwenkqubo. -

Ukumelana neMichiza ePhezulu

I-inert kwi-acids ezininzi, i-alkalis, kunye ne-solvents-iyenza ifaneleke kakuhle kwiindawo ezinobundlongo bekhemikhali. -

Umphezulu Ukugqiba Ukuguquguquka

Ifumaneka nge-ultra-smooth, i-single-side okanye i-double-side-side polished finishes, ehambelana neefotoni kunye neemfuno ze-MEMS.

Inkqubo yokuVeliswa kweQuartz Glass Wafer

Iiwafers zequartz ezidityanisiweyo ziveliswa ngothotho lwamanyathelo alawulwayo nachanekileyo:

-

UKhetho lweMathiriyeli ekrwada

Ukukhethwa komgangatho ophezulu we-quartz yendalo okanye imithombo ye-synthetic SiO₂. -

Ukunyibilika kunye neFusion

I-quartz inyibilika kwi ~ 2000 ° C kwiziko lombane phantsi kwe-atmospheric elawulwayo ukuphelisa ukubandakanywa kunye namaqamu. -

Ukuqulunqa iBloko

I-silica etyhidiweyo ipholiswa ibe ziibhloko eziqinileyo okanye iingots. -

I-Wafer Slicing

Idayimani echanekileyo okanye iisarha zocingo zisetyenziselwa ukusika ii-ingots zibe yi-wafer blanks. -

Ukuqhawula kunye nokuhombisa

Yomibini imiphezulu yenziwe mcaba kwaye ipolishiwe ukuhlangabezana ngqo neenkcukacha zokukhanya, ukutyeba, kunye noburhabaxa. -

Ukucoca & Ukuhlola

IiWafers zicocwa kumagumbi acocekileyo e-ISO 100/1000 kwaye aphantsi kohlolo olungqongqo lweziphene kunye nokuhambelana komda.

Iipropati ze-Quartz Glass wafer

| spec | iyunithi | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|

| Ubukhulu / ubungakanani (okanye isikwere) | mm | 100 | 150 | 200 | 250 | 300 |

| Unyamezelo (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Ukutyeba | mm | 0.10 okanye ngaphezulu | 0.30 okanye ngaphezulu | 0.40 okanye ngaphezulu | 0.50 okanye ngaphezulu | 0.50 okanye ngaphezulu |

| Iflethi yereferensi yokuqala | mm | 32.5 | 57.5 | Isiqingatha-notshi | Isiqingatha-notshi | Isiqingatha-notshi |

| I-LTV (5mm×5mm) | μm | < 0.5 | < 0.5 | < 0.5 | < 0.5 | < 0.5 |

| TTV | μm | < 2 | <3 | <3 | < 5 | < 5 |

| Ukuqubuda | μm | ±20 | ±30 | ±40 | ±40 | ±40 |

| I-Wap | μm | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 50 | ≤ 50 |

| PLTV (5mm×5mm) <0.4μm | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Ukujikeleza komda | mm | Iyahambelana ne-SEMI M1.2 Standard / bhekisa kwi-IEC62276 | ||||

| Uhlobo lomphezulu | Icala elinye likhazimlisiwe / Amacala amabini akhazimlisiwe | |||||

| Icala elikhazimlisiweyo uRa | nm | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Iikhrayitheriya ezisecaleni ngasemva | μm | jikelele 0.2-0.7 okanye ngokwezifiso | ||||

I-Quartz vs. Ezinye izinto eziNgaphandle

| Ipropati | Iglasi yeQuartz | Iglasi yeBorosilicate | Isafire | Iglasi eqhelekileyo |

|---|---|---|---|---|

| Ubukhulu beTempile yokuSebenza | ~1100°C | ~500°C | ~2000°C | ~200°C |

| Usasazo lweUV | Kugqwesileyo (JGS1) | Ubuhlwempu | Kulungile | Ihlwempu kakhulu |

| Ukumelana nemichiza | Egqwesileyo | Phakathi | Egqwesileyo | Ubuhlwempu |

| Ubunyulu | Iphezulu kakhulu | Phantsi ukuya phakathi | Phezulu | Phantsi |

| Ukwandiswa kweThermal | Isezantsi kakhulu | Phakathi | Phantsi | Phezulu |

| Iindleko | Phakathi ukuya phezulu | Phantsi | Phezulu | Isezantsi kakhulu |

FAQ yeQuartz Glass Wafer

I-Q1: Uthini umahluko phakathi kwe-quartz edibeneyo kunye ne-silica edibeneyo?

Ngelixa zombini iifom ze-amorphous ze-SiO₂, i-quartz edibeneyo isuka kwimithombo yendalo ye-quartz, ngelixa i-silica edibeneyo iveliswa ngokwenziwa. Ngokusebenzayo, banikezela ngokusebenza okufanayo, kodwa i-silica edibeneyo inokuba nobunyulu obuphezulu kunye ne-homogeneity.

I-Q2: Ngaba ii-wafers ze-quartz ezidityanisiweyo zingasetyenziswa kwiindawo ezine-vacuum ephezulu?

Ewe. Ngenxa yeepropathi zabo eziphantsi zokukhupha umoya kunye nokuxhathisa okuphezulu kwe-thermal, ii-wafers ze-quartz ezidityanisiweyo zigqwesile kwiinkqubo ze-vacuum kunye nezicelo ze-aerospace.

I-Q3: Ngaba ezi ziqwenga zifanelekile kwizicelo ze-laser ezinzulu ze-UV?

Ngokuqinisekileyo. I-quartz edityanisiweyo inokuhanjiswa okuphezulu ukuya kuthi ga kwi- ~ 185 nm, iyenza ilungele i-DUV optics, imaski ye-lithography, kunye neenkqubo ze-laser ye-excimer.

I-Q4: Ngaba uyakuxhasa ukwenziwa kwe-wafer yesiko?

Ewe. Sinikezela ngolungelelwaniso olupheleleyo kubandakanya ububanzi, ubukhulu, umgangatho womphezulu, iiflethi / iinotshi, kunye nepateni yelaser, ngokusekwe kwiimfuno zakho zesicelo.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.