IziXhobo zokuhombisa ezikwicala elinye elichanekileyo

Ividiyo yesiXhobo sokuhombisa esikwicala elinye

Ukwaziswa kweSixhobo sokuNgcwelisa kwicala elinye

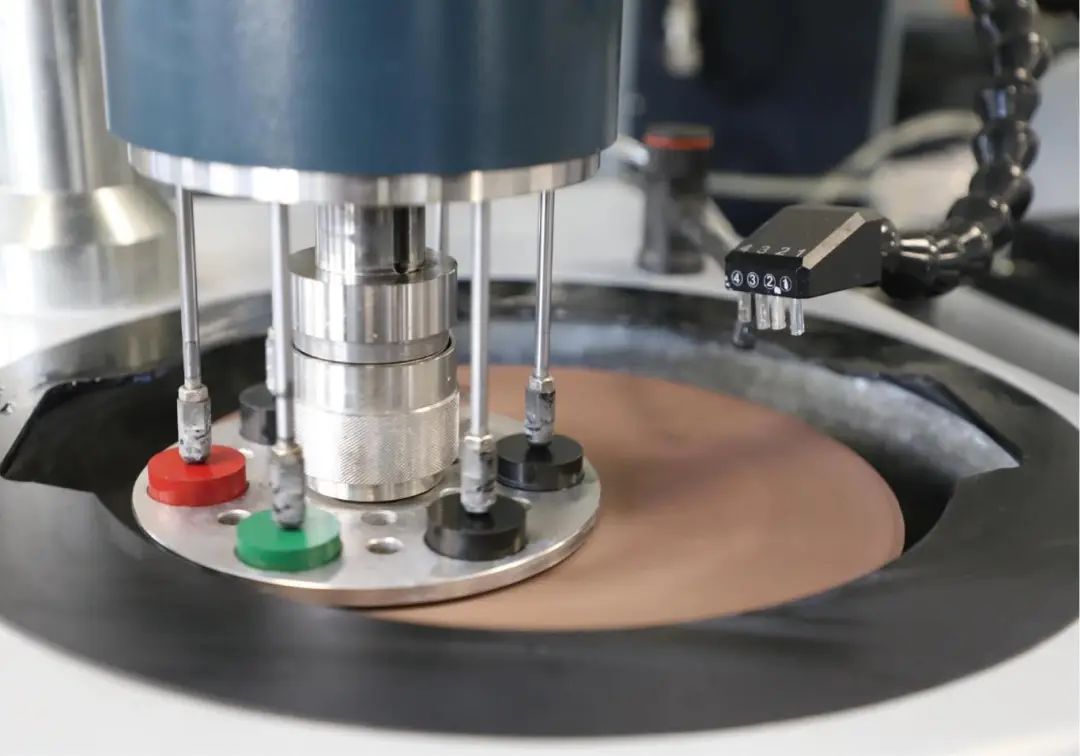

Umatshini wecala elinye lokupholisha licandelo elikhethekileyo lesixhobo esenzelwe ukugqitywa ngokuchanekileyo kwezinto ezinzima kunye nezinqabileyo. Ngophuhliso olukhawulezayo lweshishini le-semiconductor, i-optoelectronics, i-optical components, kunye nosetyenziso lwemathiriyeli ephucukileyo, imfuno yokuchaneka okuphezulu kunye nezixhobo zokupolisha ezisebenza ngokufanelekileyo ziye zangxamiseka ngakumbi. Umatshini wecala elinye wokupolisha usebenzisa intshukumo ehambelanayo phakathi kwediski yokupolisha kunye neepleyiti zeceramic ukuvelisa uxinzelelo olufanayo kumphezulu womsebenzi, okwenza kube lula ukucwangcisa kunye nokugqiba okufana nesipili.

Ngokungafaniyo noomatshini bokugudisa becala eliphindwe kabini, umatshini wokupolisha kwicala elinye unika ukuguquguquka okukhulu ekuphatheni ubungakanani obahlukeneyo kunye nobukhulu beewafers okanye substrates. Oku kuyenza ilunge ngakumbi kwizinto zokucubungula ezifana ne-silicon wafers, i-silicon carbide, isafire, i-gallium arsenide, i-germanium flakes, i-lithium niobate, i-lithium tantalate, kunye neglasi yokukhanya. Ukuchaneka okuphunyeziweyo ngolu hlobo lwezixhobo kuqinisekisa ukuba amacandelo acutshungulwayo ahlangabezana neemfuno ezingqongqo ze-microelectronics, i-substrates ye-LED, kunye ne-high-performance optics.

I-Advanteji yeSixhobo sokuNgcwelisa kwicala elinye

Ifilosofi yoyilo lomatshini wokupholisa kwicala elinye igxininisa uzinzo, ukuchaneka, kunye nokusebenza kakuhle. Umzimba oyintloko womatshini udla ngokwenziwa ngentsimbi kunye nentsimbi ekhandiweyo, enika ukuzinza okuqinileyo komatshini kunye nokunciphisa ukungcangcazela ngexesha lokusebenza. Amacandelo akumgangatho ophezulu wamazwe ngamazwe amkelwe kwiinkqubo ezibalulekileyo ezifana ne-rotation drive, ukuhanjiswa kwamandla, kunye nenkqubo yokulawula, ukuqinisekisa ukusebenza okuthembekileyo kunye nobomi obude benkonzo.

Olunye uncedo oluphambili lukwi-interface yokusebenza komntu. Oomatshini banamhlanje becala elinye baxhotyiswe ngeepaneli zokulawula ezikrelekrele, ezivumela abaqhubi ukuba bahlengahlengise ngokukhawuleza iiparamitha zenkqubo ezifana nesantya sokupholisha, uxinzelelo, kunye nesantya sokujikeleza. Oku kwenza iimeko zokusetyenzwa kwakhona zikwazi ukuveliswa kwakhona, okuyimfuneko kumashishini apho ukuhambelana kubaluleke kakhulu.

Ukusuka kumbono wenkqubo eguquguqukayo, izixhobo zinokuthatha uluhlu olubanzi lobungakanani bomatshini, ngokuqhelekileyo ukusuka kwi-50mm ukuya kwi-200mm okanye enkulu, kuxhomekeke kwimodeli. Umyinge wokujikeleza kwediski yokupholisha ngokuqhelekileyo iwela phakathi kwe-50 ukuya kwi-80 rpm, ngelixa umlinganiselo wamandla uhluka ukusuka kwi-11kW ukuya kwi-45kW. Ngolungelelwaniso olubanzi olunjalo, abasebenzisi banokukhetha imodeli ehambelana neemfuno zabo zemveliso, nokuba yeyelebhu zophando okanye imveliso yemizi-mveliso emikhulu.

Ngaphaya koko, iimodeli eziphucukileyo zineentloko zokupholisha ezininzi, ezidityaniswa ziinkqubo zolawulo lwe-servo zombane. Oku kuqinisekisa ukuba zonke iintloko zokupholisha zigcina isantya esihambelanayo ngexesha lokusebenza, ngaloo ndlela ziphucula zombini umgangatho wokucubungula kunye nesivuno. Ukongezelela, iinkqubo zokupholisa kunye nokulawula ubushushu ezidibeneyo kumatshini ziqinisekisa ukuzinza kwe-thermal, eyona nto ibalulekileyo xa ujongene nezinto ezithintekayo ukushisa.

Umatshini wokupholisa kwicala elinye ubonisa into ebalulekileyo yezixhobo zokuvelisa kwixesha langoku lobuchwepheshe obuphezulu. Ukudityaniswa kwayo koyilo lomatshini olomeleleyo, ulawulo olukrelekrele, ukuhambelana kwezinto ezininzi, kunye nokusebenza okuphezulu kokugqiba umphezulu kwenza kube sisixhobo esiyimfuneko kwiinkampani kunye namaziko ophando afuna ukulungiswa okuphezulu kokuchaneka kwezinto eziphambili.

Iimpawu zeeMveliso zeSixhobo sokuNgcwelisa kwicala elinye

-

Ukuzinza okuphezulu: Umzimba womatshini uphoswe kwaye udityanisiwe ukuze kuqinisekiswe ukuqina kwesakhiwo kunye nokuzinza okugqwesileyo kokusebenza.

-

Amacandelo achanekileyo: Iibheringi zodidi lwamazwe ngamazwe, iinjini, kunye neeyunithi zolawulo lwe-elektroniki ziqinisekisa ubomi obude benkonzo kunye nokusebenza okuthembekileyo.

-

Iimodeli eziguquguqukayo: Ifumaneka kwiichungechunge ezininzi (305, 36D, 50D, 59D, kunye ne-X62 S59D-S) ukuhlangabezana neemfuno ezahlukeneyo zemveliso.

-

IsiNxulumanisi esiBantu: Iphaneli yokusebenza ekulula ukuyisebenzisa enesethingi yedijithali yeeparamitha zokupholisha, eyenza uhlengahlengiso olukhawulezayo lweresiphi.

-

Ukupholisa okuSebenzayo: Iinkqubo ezidibeneyo zokupholisa amanzi kunye nezinzwa ezichanekileyo zeqondo lokushisa ukuze kugcinwe iimeko ezizinzileyo zokupholisha.

-

Ungqamaniso lweentloko ezininzi: Ulawulo lwe-elektroniki lwe-Servo luqinisekisa isantya esilungelelanisiweyo seentloko ezininzi zokupholisha kwiziphumo ezihambelanayo.

IiNkcazelo zobuGcisa beSixhobo sokuNgcwelisa kwicala elinye

| Udidi | Into | 305 Series | 36D Series | 50D Series | 59D Series |

|---|---|---|---|---|---|

| Icwecwe leDiskhi | Ububanzi | 820 mm | 914 mm | 1282 mm | 1504 mm |

| Amacwecwe eCeramic | Ububanzi | 305 mm | 360 mm | 485 mm | 576 mm |

| Elona Machining | Ubungakanani bomsebenzi | 50-100 mm | 50-150 mm | 150-200 mm | 200 mm |

| Amandla | IMotor engundoqo | 11kW | 11kW | 18.5 kW | 30 kW |

| Ireyithi yokujikeleza | Icwecwe leDiskhi | 80 rpm | 65 rpm | 65 rpm | 50 rpm |

| Imilinganiselo (L×W×H) | - | 1920×1125×1680 mm | 1360×1330×2799 mm | 2334×1780×2759 mm | 1900×1900×2700 mm |

| Ubunzima bomatshini | - | 2000 kg | 3500 kg | 7500 kg | 11826 kg |

| Into | Ipharamitha | Izinto eziphathekayo |

|---|---|---|

| Ububanzi beDiskhi yokuNgcwelisa | Φ1504 × 40 mm | SUS410 |

| Idayamitha yeDiskhi yokupholisha (iNtloko) | Φ576 × 20 mm | SUS316 |

| Isantya esiphezulu seDiskhi yokuNgcwelisa | 60 rpm | - |

| Isantya esiphezulu seNtloko yokuphosa ePhezulu | 60 rpm | - |

| Inani leentloko ezigudileyo | 4 | - |

| Imilinganiselo (L×W×H) | 2350 × 2250 × 3050 mm | - |

| Ubunzima beZixhobo | 12 t | - |

| Uluhlu loxinzelelo oluphezulu | 50–500 ± kg | - |

| Amandla Aphelele oMatshini wonke | 45 kW | - |

| Umthamo wokulayisha (ngentloko nganye) | 8 h/φ 150 mm (6”) okanye 5 h/φ 200 mm (8”) | - |

Uluhlu lweSicelo seSixhobo sokuGolisha esikwicala elinye

Umatshini wenzelweUkugulisa icala elinyeyeentlobo ngeentlobo zemathiriyeli elukhuni kunye ne-brittle, kuquka:

-

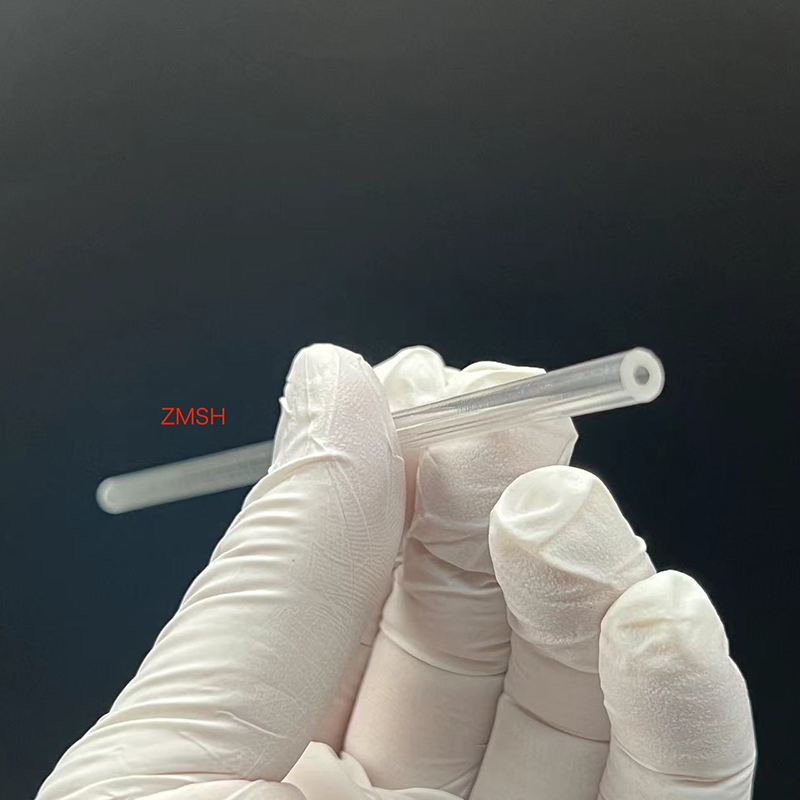

Ii-Silicon wafers zezixhobo ze-semiconductor

-

I-silicon carbide yombane wamandla kunye ne-LED substrates

-

Amaqhekeza eSapphire e-optoelectronics kunye neekristale zewotshi

-

I-Gallium arsenide yezicelo ze-elektroniki ze-high-frequency

-

Iiflakes ze-Germanium ze-infrared optics

-

I-Lithium niobate kunye ne-lithium tantalate yamacandelo e-piezoelectric

-

Iisubstrates zeglasi zokuchaneka kwamehlo kunye nezixhobo zonxibelelwano

Imibuzo Ebuzwa Rhoqo (FAQ) yeSixhobo sokuNgcwelisa esikwicala elinye

I-Q1: Ziziphi izinto ezinokuthi inkqubo yomatshini wokupolisha kwicala elinye?

Lo matshini ulungele ii-silicon wafers, isafire, isilicon carbide, i-gallium arsenide, iglasi, kunye nezinye izinto ezinqabileyo.(Amagama angundoqo: umatshini wokupolisha, imathiriyeli enqabileyo)

I-Q2: Zeziphi iisayizi zediski zokupholisha eziqhelekileyo ezikhoyo?

Ngokuxhomekeke kuluhlu, iidiski zokupholisa zivela kwi-820 mm ukuya kwi-1504 mm ububanzi.(Amagama angundoqo: icwecwe lokupholisha, ubukhulu bomatshini)

I-Q3: Yintoni isantya sokujikeleza kwediski yokupholisa?

Izinga lokujikeleza lihluka ukusuka kwi-50 ukuya kwi-80 rpm, kuxhomekeke kwimodeli.(Amagama angundoqo: izinga lokujikeleza, isantya sokupholisha)

I-Q4: Inkqubo yokulawula iphucula njani umgangatho wokupolisha?

Umatshini usebenzisa i-servo yolawulo lwe-elektroniki yokujikeleza kwentloko ehambelanayo, ukuqinisekisa uxinzelelo olufanayo kunye neziphumo ezizinzileyo.(Amagama angundoqo: inkqubo yolawulo, intloko yokupholisha)

I-Q5: Yintoni ubunzima kunye neenyawo zomatshini?

Ubunzima bomatshini buvela kwiitoni ezi-2 ukuya kwiitoni ezili-12, kunye neenyawo phakathi kwe-1360 × 1330 × 2799 mm kunye ne-2350 × 2250 × 3050 mm.(Amagama angundoqo: ubunzima bomatshini, imilinganiselo)

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.