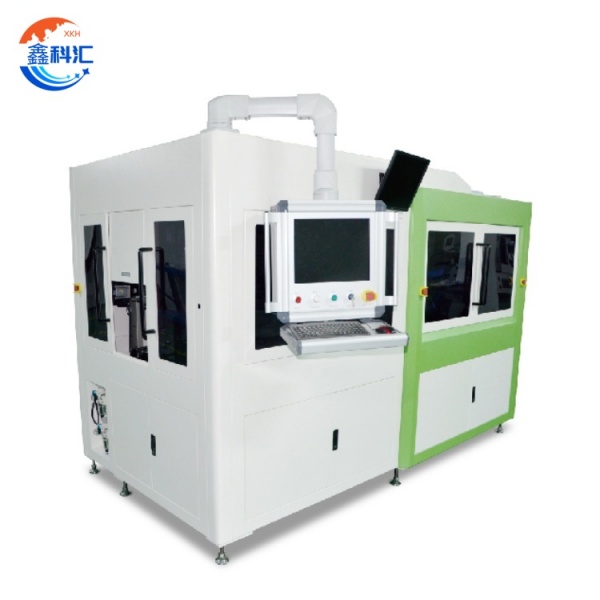

Ukuchaneka okuphezulu umatshini wokomba welaser wesafire ye-ceramic imathiriyeli enqabileyo ethwele umbhobho wokugrumba

Intshayelelo yeMveliso

Izinto ezisebenzayo: Ifanelekile kwintsimbi yendalo, i-polycrystalline steel, i-ruby, isafire, ithusi, i-ceramics, i-rhenium, insimbi engenasici, i-carbon steel, i-alloy steel kunye nezinye izinto ezinzima kakhulu, izinto ezichasene nobushushu obuphezulu kwiimilo ezahlukeneyo, ububanzi, ubunzulu kunye nokugaya i-taper.

Iimeko zokusebenza

1. Ilungele ukusebenza phantsi kobushushu be-ambient ye-18℃-28℃ kunye nokufuma okuhambelana ne-30% -60%.

2. Ifanelekile unikezelo lwamandla amabini /220V/50HZ/10A.

3. Qwalasela iiplagi ezihlangabezana neemfuno zemigangatho efanelekileyo yaseTshayina. Ukuba akukho plagi enjalo, kufuneka kunikwe iadaptha efanelekileyo.

4. Isetyenziswa kakhulu kumzobo wedayimani wocingo lokufa, ukucotha kocingo lokufa, umngxuma we-muffler, umngxuma yenaliti, ukuthwala igugu, umbhobho kunye namanye amashishini okugqobhoza.

Iiparamitha zobugcisa

| Igama | Idatha | Umsebenzi |

| Ubude bemaza obubonayo | 354.7nm okanye 355nm | Imisela ukuhanjiswa kwamandla kunye nomthamo wokungena we-laser beam, kwaye ichaphazela izinga lokufunxa izinto kunye nesiphumo sokucubungula. |

| Amandla emveliso aphakathi | 10.0 / 12.0/15.0 w@40khz | Ukuchaphazela ukusebenza kakuhle kunye nesantya sokubetha, amandla aphezulu, ngokukhawuleza isantya sokucubungula. |

| Ububanzi be-Pulse | Ngaphantsi kwe-20ns@40KHz | Ububanzi be-pulse obufutshane bunciphisa indawo echaphazelekayo yobushushu, buphucula ukuchaneka kwe-machining, kunye nokuphepha umonakalo we-thermal wezinto eziphathekayo. |

| Isantya sokuphindaphinda i-Pulse | 10-200KHz | Ukumisela ukuhanjiswa kwamaza kunye nokusebenza kakuhle kwe-laser beam, kokukhona i-frequency ephezulu, isantya sokubetha ngokukhawuleza. |

| umgangatho we-optical beam | M²<1.2 | Imiqadi ekumgangatho ophezulu iqinisekisa ukuchaneka kokomba kunye nomgangatho womphetho, ukunciphisa ukulahleka kwamandla. |

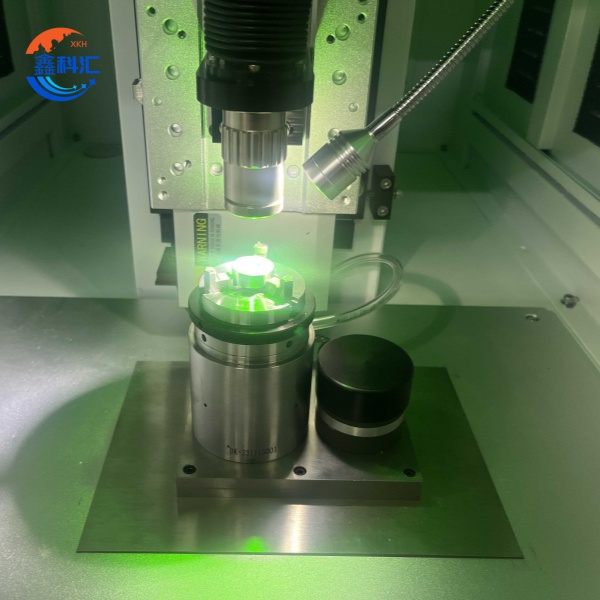

| Idayamitha yendawo | 0.8±0.1mm | Qinisekisa ubuncinci bokuvula kunye nokuchaneka kwe-machining, i-spot encinci, encinci i-aperture, iphakamileyo yokuchaneka. |

| umqadi-ukwahlukana engile | Ngaphezulu kwe-90% | Ikhono lokugxila kunye nobunzulu bokubetha kwe-laser beam kuyachaphazeleka. Incinci i-Angle yokuhlukana, inamandla amandla okugxila. |

| Ibeam ellipticity | Ngaphantsi kwe-3% ye-RMS | Ubuncinci be-ellipticity, ngokusondeleyo ukumila komngxuma kwisangqa, kuphezulu ukuchaneka komatshini. |

Ukusetyenzwa kwamandla

Oomatshini bokugrumba be-laser abachanekileyo banamandla okusebenza kwaye banokubhoboza imingxuma ukusuka kwi-microns ezimbalwa ukuya kwiimilimitha ezimbalwa ububanzi, kwaye imilo, ubukhulu, indawo kunye ne-Angle yemingxuma inokulawulwa ngokuchanekileyo. Ngelo xesha, izixhobo zixhasa i-360-degree-round-round drilling, enokuthi ihlangabezane neemfuno zokugaya iintlobo ezahlukeneyo zemilo kunye nezakhiwo. Ukongeza, umatshini wokuchaneka we-laser ochaneke kakhulu unomgangatho obalaseleyo wecala kunye nokugqitywa komphezulu, imingxuma esetyenziweyo ayinayo i-burr, akukho mphetho wokunyibilika, kwaye umngxuma womngxuma ugudile kwaye uthe tyaba.

Ukusetyenziswa komatshini wokubetha welaser ochanekileyo:

1. Umzi mveliso wombane:

Ibhodi yesekethe eprintiweyo (PCB) : isetyenziselwa ukusetyenzwa kwe-microhole ukuhlangabezana neemfuno ze-high-density interconnection.

Ukupakishwa kweSemiconductor: Punch imingxuma kwii-wafers kunye nempahla yokupakisha ukuphucula ukuxinana kwephakheji kunye nokusebenza.

2. I-Aerospace:

Imingxuma yokupholisa iblade ye-injini: Imingxunya emincinci yokupholisa yenziwe ngoomatshini kwiincakuba ze-superalloy ukuphucula ukusebenza kwe-injini.

Ukusetyenzwa kwe-Composite: Ukwembiwa okuphezulu kokuchaneka kwee-carbon fiber composites ukuqinisekisa ukomelela kwesakhiwo.

3. Izixhobo zonyango:

Izixhobo zotyando ezincinci: Ukutshiza i-microholes kwizixhobo zotyando ukuphucula ukuchaneka kunye nokhuseleko.

Inkqubo yokuhanjiswa kweziyobisi: Gxobhoza imingxuma kwisixhobo sokuhanjiswa kweziyobisi ukulawula izinga lokukhutshwa kwechiza.

4. Ukwenziwa kweMoto:

Inkqubo yokutofa ngamafutha: Ukwenza imingxunya emincinci kumbhobho wenaliti yamafutha ukuze kuphuculwe isiphumo se-atomization yamafutha.

Ukwenziwa kwenzwa: Ukugrumba imingxuma kwi-sensor element ukuphucula ubuntununtunu kunye nesantya sokuphendula.

5. Izixhobo zamehlo:

I-Optical fiber connector: Ukucoca i-microholes kwi-fiber optical connector ukuqinisekisa umgangatho wokuhanjiswa kwesignali.

Isihluzi se-Optical: Gcoba imingxunya kwisihluzi samehlo ukufezekisa ukhetho oluthile lwamaza obude.

6. Oomatshini abachanekileyo:

Ukubumba okuchanekileyo: Ukucoca i-microholes kwi-mold ukuphucula ukusebenza kunye nobomi benkonzo ye-mold.

Amalungu amancinci: Gcoba imingxuma kwiindawo ezincinci ukuhlangabezana neemfuno zendibano ephezulu echanekileyo.

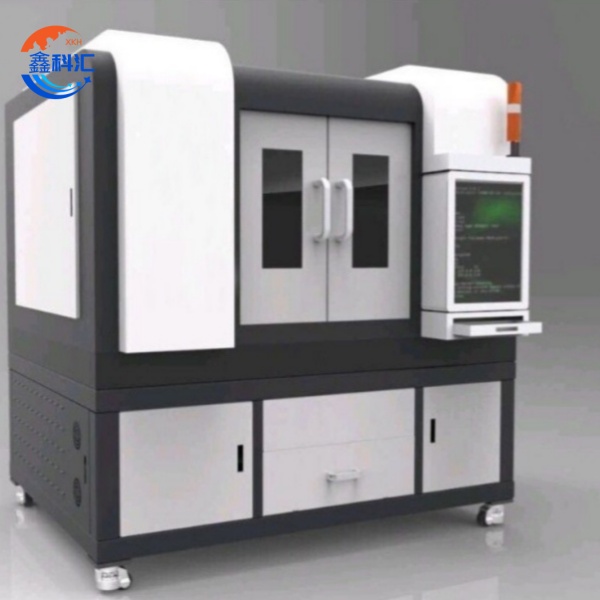

I-XKH inikezela ngoluhlu olupheleleyo lweenkonzo zoomatshini bokugrumba i-laser ephezulu, kubandakanywa ukuthengiswa kwezixhobo, inkxaso yobugcisa, izisombululo ezilungiselelwe, ukufakwa kunye nokugunyaziswa, uqeqesho lokusebenza kunye nokugcinwa kokuthengiswa emva kokuthengisa, njl., Ukuqinisekisa ukuba abathengi ekusebenziseni inkxaso yobuchwephesha, esebenzayo kunye neyongezelelweyo.

Idayagram eneenkcukacha